Komatsu PC75UU-2 Hydraulic Excavator Shop Manual SEBM001302

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM001302

- Format: PDF

- Size: 26.2MB

- Number of Pages: 391

Category: Komatsu Shop Manual PDF

-

Model List:

- PC75UU-2 Hydraulic Excavator

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL ASSEMBLY DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. LIST OF LUBRICANT AND WATER

- 4. STRUCTURE AND FUNCTION

- 4.1. HYDRAULIC PIPING DIAGRAM

- 4.2. HYDRULIC CIRCUIT DIAGRAM

- 4.3. ELECTRIC WIRING DIAGRAM

- 4.4. ELECTRIC CIRCUIT DIAGRAM

- 5. TESTING AND ADJUSTING

- 5.1. TABLE OF JUDGEMENT STANDARD VALUE

- 5.2. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 5.3. TOOLS FOR TESTING ,ADJUSTING,AND TROUBLESHOOTING

- 5.4. MEASURING ENGINE SPEED

- 5.5. MEASURING ENGINE OIL PRESSURE

- 5.6. MEASURING COMPRESSION PRESSURE

- 5.7. MEASURING BLOWBY

- 5.8. ADJUSTING VALVE CLEARANCE

- 5.9. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.10. TESTING AND ADJUSTING ALTERNATOR FAN BELT TENSION

- 5.11. ADJUSTING FUEL CONTROL LEVER

- 5.12. TESTING AND ADJUSTING TRACK SHOE TENSION

- 5.13. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT

- 5.14. TESTING CONTROL CIRCUIT PRESSURE

- 5.15. MEASURING OUTPUT PRESSURE OF PPC VALVE

- 5.16. ADJUSTING PPC VALVE

- 5.17. MEASURING OUTLET PORT PRESSURE OF SOLENOID VALVE,EPC VALVE

- 5.18. MEASURING OIL LEAKAGE INSIDE CYLINDER

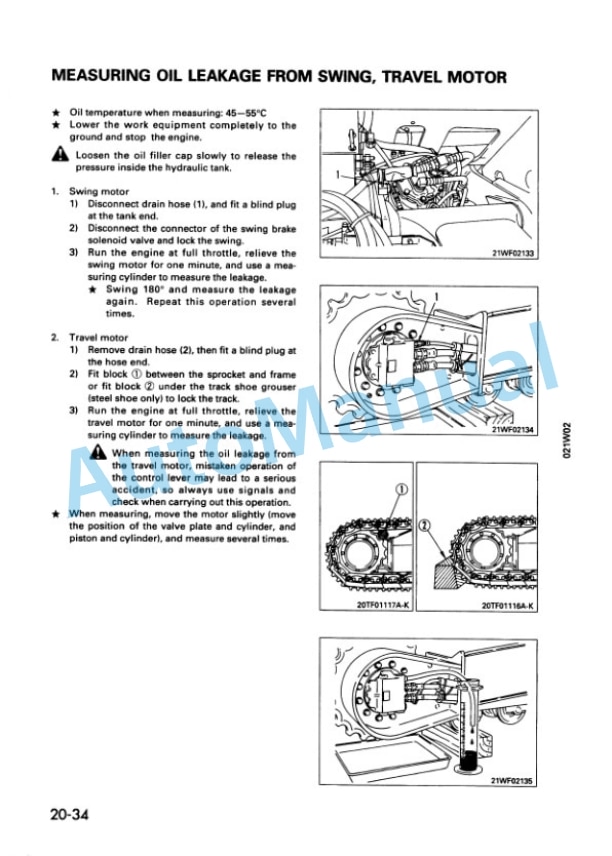

- 5.19. MEASURING OIL LEAKAGE FROM SWING,TRAVEL MOTOR

- 5.20. BLEEDING AIR FROM HYDRAULIC CIRCUIT

- 5.21. RELEASING REMAINING FROM HYDRAULIC CIRCUIT

- 5.22. ADJUSTING BLADE CONTROL LEVER

- 5.23. ADJUSTING TRAVEL CONTROL LEVER

- 5.24. PROCEDURE FOR RESETTING ELECTRICAL SYSTEM INPUT/OUTPUT SIGNALS AND CHECKING OPERATION

- 5.25. PROCEDURE FOR REPLACING POTENTIOMETER

- 5.26. PROCDURE FOR CHECKING DIODE

- 5.27. TROUBLESHOOTING

- 5.27.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.27.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.27.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 5.27.4. CHECKS BEFORE TROUBLESHOOTING

- 5.27.5. ELECTRICAL CIRCUIT DIAGRAMS FOR EACH SYSTEM

- 5.27.6. CONNECTOR ARRANGEMENT DRAWING

- 5.27.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.27.8. HANDING CONNECTORS

- 5.27.9. EXPLANATIONS OF CONTROL MECHANISM OF ELECTRICAL SYSTEM

- 5.27.10. DISPLAY METHOD FOR MONITOR PANEL,CONTROLLER

- 5.27.11. ACTION TAKEN BY SELF DIAGNOSTIC FUNCTION AND PROBLEMS ON MACHINE

- 5.27.12. METHOD OF USING JUDGEMENT TABLE

- 5.27.13. METHOD OF USING TROUBLESHOOTING CHARTS

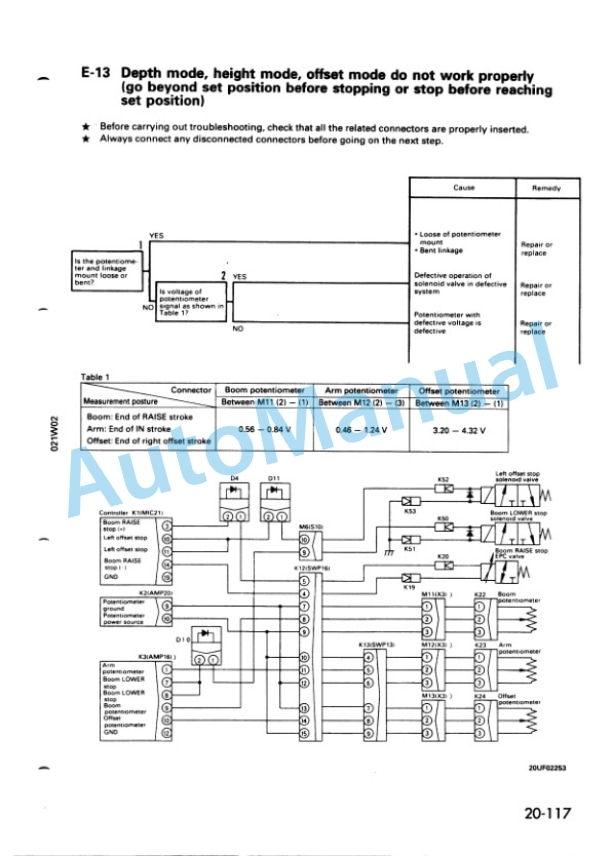

- 5.27.14. TROUBLESHOOTING OF CONTROLLER,ELECTRICAL SYSTEM (E MODE)

- 5.27.15. TROUBLESHOOTING OF HYDRAULIC,MECHANICAL SYSTEM (H MODE)

- 5.27.16. TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOLS LIST

- 6.4. SCHEMATIC DRAWING OF SPECIAL TOOL

- 6.5. STARTING MOTOR

- 6.5.1. REMOVAL AND INSTALLATION

- 6.6. ALTERNATOR

- 6.6.1. REMOVAL AND INSTALLATION

- 6.7. FUEL INJECTION PUMP

- 6.7.1. REMOVAL AND INSTALLATION

- 6.8. WATER PUMP

- 6.8.1. REMOVAL

- 6.8.2. INSTALLATION

- 6.9. NOZZLE HOLDER

- 6.9.1. REMOVAL AND INSTALLTION

- 6.10. THERMOSTAT

- 6.10.1. REMOVAL AND INSTALLATION

- 6.11. ENGINE FRONT SEAL

- 6.11.1. REMOVAL AND INSTALLATION

- 6.12. ENGINE REAR SEAL

- 6.12.1. REMOVAL AND INSTALLATION

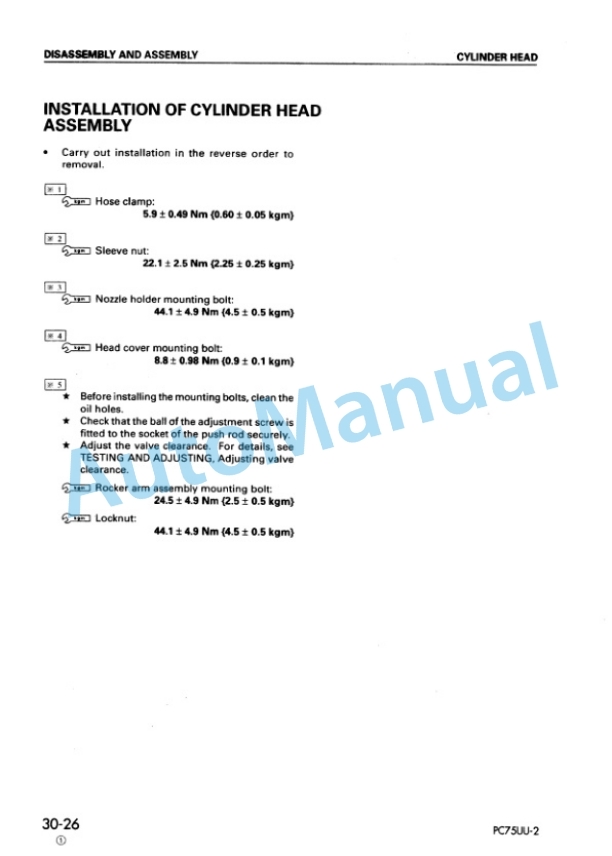

- 6.13. CYLINDER HEAD

- 6.13.1. REMOVAL

- 6.13.2. INSTALLATION

- 6.14. HYDRAULIC OIL COOLER

- 6.14.1. REMOVAL AND INSTALLATION

- 6.15. RADIATOR

- 6.15.1. REMOVAL AND INSTALLATION

- 6.16. ENGINE AND MAIN PUMP

- 6.16.1. REMOVAL

- 6.16.2. INSTALLATION

- 6.17. DAMPER

- 6.17.1. REMOVAL AND INSTALLATION

- 6.18. CENTER SWIVEL JOINT

- 6.18.1. REMOVAL AND INSTALLATION

- 6.18.2. DISASSEMBLY AND ASSEMBLY

- 6.19. TRAVEL MOTOR

- 6.19.1. REMOVAL AND INSTALLATION

- 6.20. SPROCKET

- 6.20.1. REMOVAL AND INSTALLATION

- 6.21. SWING MOTOR AND SWING MACHINERY

- 6.21.1. REMOVAL AND INSTALLATION

- 6.22. SWING MOTOR

- 6.22.1. DISASSEMBLY

- 6.22.2. ASSEMBLY

- 6.23. SWING MACHINERY

- 6.23.1. DISASSEMBLY

- 6.23.2. ASSEMBLY

- 6.24. REVOLVING FRAME

- 6.24.1. REMOVAL

- 6.24.2. INSTALLATION

- 6.25. SWING CIRCLE

- 6.25.1. REMOVAL AND INSTALLATION

- 6.26. IDLER AND RECOIL SPRING

- 6.26.1. REMOVAL AND INSTALLATION

- 6.26.2. REMOVAL AND INSTALLATION

- 6.26.3. DISASSEMBLY

- 6.26.4. ASSEMBLY

- 6.27. RUBBER SHOE

- 6.27.1. REMOVAL AND INSTALLATION

- 6.28. STEEL SHOE AND ROAD LINER

- 6.28.1. EXPANSION AND INSTALLATION

- 6.29. PPC PUMP

- 6.29.1. REMOVAL AND INSTALLATION

- 6.30. MAIN PUMP

- 6.30.1. REMOVAL AND INSTALLATION

- 6.30.2. DISASSEMBLY

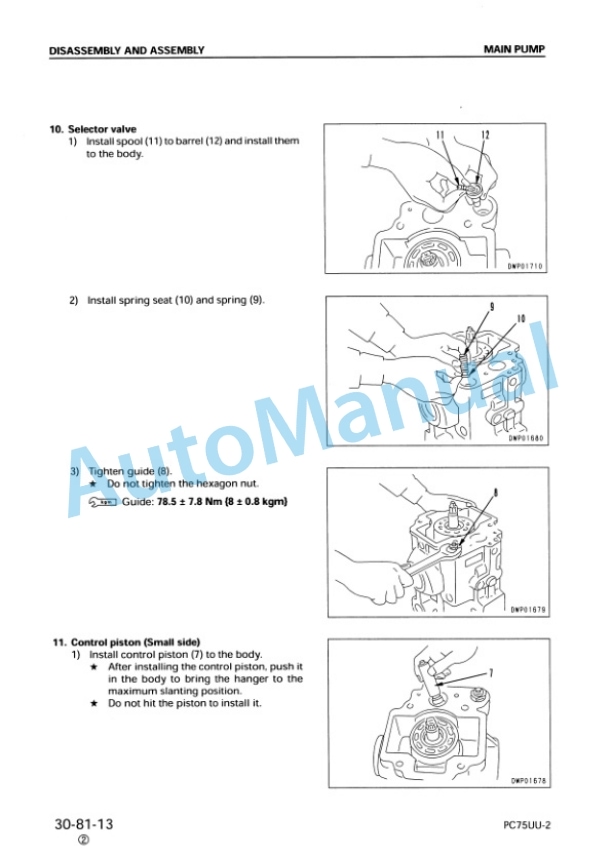

- 6.30.3. ASSEMBLY

- 6.31. SPOOL CONTROL VALVE

- 6.31.1. REMOVAL

- 6.31.2. INSTALLATION

- 6.31.3. DISASSEMBLY

- 6.31.4. ASSEMBLY

- 6.32. SPOOL CONTROL VALVE

- 6.32.1. REMOVAL

- 6.32.2. INSTALLATION

- 6.33. MAIN RELIEF VALVE

- 6.33.1. REMOVAL AND INSTALLATION

- 6.33.2. DISASSEMBLY AND ASSEMBLY

- 6.34. PPC VALVE ASSEMBLY ON LEFT SIDE OF WORK EQUIPMENT

- 6.34.1. REMOVAL AND INSTALLATION

- 6.35. PPC VALVE ON RIGHT SIDE OF WORK EQUIPMENT

- 6.35.1. REMOVAL AND INSTALLATION

- 6.36. WORK EQUIPMENT PPC VALVE

- 6.36.1. DISASSEMBLY

- 6.36.2. ASSEMBLY

- 6.37. PPC VALVE FOR OFFSET OPERATION

- 6.37.1. REMOVAL AND INSTALLATION

- 6.38. ARM CYLINDER

- 6.38.1. REMOVAL

- 6.38.2. INSTALLATION

- 6.39. BUCKERT CYLINDER

- 6.40. OFFSET CYLINDER

- 6.41. HYDRAULIC CYLINDER

- 6.41.1. REMOVAL AND INSTALLATION

- 6.41.2. REMOVAL AND INSTALLATION

- 6.42. OPERATORS CAB

- 6.42.1. REMOVAL AND INSTALLATION

- 6.43. FLOOR FRAME

- 6.43.1. REMOVAL

- 6.43.2. INSTALLATION

- 6.44. FUEL TANK

- 6.44.1. REMOVAL AND INSTALLATION

- 6.45. CONTROLLER

- 6.45.1. REMOVAL AND INSTALLATION

- 6.46. MONITOR

- 6.46.1. REMOVAL AND INSTALLATION

- 6.47. COUNTERWEIGHT

- 6.47.1. REMOVAL AND INSTALLATION

- 7. MAINTENANCE STANDARD

- 7.1. SWING MACHINERY

- 7.2. SWING CIRCLE

- 7.3. TRACK FRAME,RECOIL SPRING

- 7.4. SPOOL CONTROL VALVE(FOR FRONT PUMP)

- 7.5. SPOOL CONTROL VALVE(FOR CENTER PUMP)

- 7.6. SPOOL CONTROL VALVE

- 7.7. SWING MOTOR

- 7.8. CENTER SWIVEL JOINT

- 7.9. PPC VALVE

- 7.10. HYDRAULIC CYLINDER

- 7.11. WORK EQUIPMENT

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00