- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PC800-8, PC800LC-8, PC800SE-8, PC850-8, PC850SE-8 Hydraulic Excavator Shop Manual SEN00373-18

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN00373-18

- Format: PDF

- Size: 57.1MB

- Number of Pages: 1138

Category: Komatsu Shop Manual PDF

-

Model List:

- PC800-8 Hydraulic Excavator

- PC800LC-8 Hydraulic Excavator

- PC800SE-8 Hydraulic Excavator

- PC850-8 Hydraulic Excavator

- PC850SE-8 Hydraulic Excavator

- 1. Cover

- 2. Index and foreword

- 2.1. Index

- 2.1.1. Composition of shop manual

- 2.1.2. Table of contents

- 2.2. Foreword and general information

- 2.2.1. Safety notice

- 2.2.2. How to read the shop manual

- 2.2.3. Explanation of terms for maintenance standard

- 2.2.4. Handling of electric equipment and hydraulic component

- 2.2.5. Handling of connectors newly used for engines

- 2.2.6. How to read electric wire code

- 2.2.7. Precautions when carrying out operation

- 2.2.8. Method of disassembling and connecting pushpull type coupler

- 2.2.9. Standard tightening torque table

- 2.2.10. Conversion table

- 3. Specification

- 3.1. Specification and technical data

- 3.1.1. Specification and technical data

- 4. Structure, function and maintenance standard

- 4.1. Engine and cooling system

- 4.1.1. Engine and cooling system

- 4.2. Power train

- 4.2.1. Power train

- 4.3. Undercarriage and frame

- 4.3.1. Undercarriage and frame

- 4.4. Hydraulic system, Part 1

- 4.4.1. Hydraulic system, Part 1

- 4.5. Hydraulic system, Part 2

- 4.5.1. Hydraulic system, Part 2

- 4.6. Work equipment

- 4.6.1. Work equipment

- 4.7. Cab and its attachments

- 4.7.1. Cab and its attachments

- 4.8. Electrical system

- 4.8.1. Engine control

- 4.8.2. Electric control system

- 4.8.3. Monitor system

- 4.8.4. Sensors

- 4.8.5. KOMTRAX system

- 5. Standard value table

- 5.1. Standard service value table

- 5.1.1. Standard service value table

- 6. Testing and adjusting

- 6.1. Testing and adjusting, Part 1

- 6.1.1. Testing and adjusting, Part 1

- 6.2. Testing and adjusting, Part 2

- 6.2.1. Testing and adjusting, Part 2

- 6.3. Testing and adjusting, Part 3

- 6.3.1. Testing and adjusting, Part 3

- 6.4. Testing and adjusting, Part 4

- 6.4.1. Testing and adjusting, Part 4

- 6.5. Testing and adjusting, Part 5

- 6.5.1. Testing and adjusting, Part 5

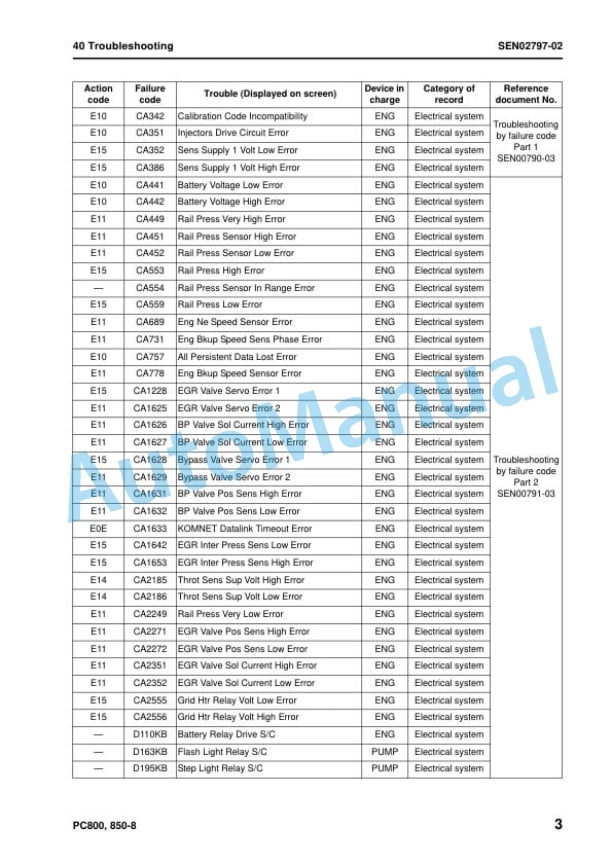

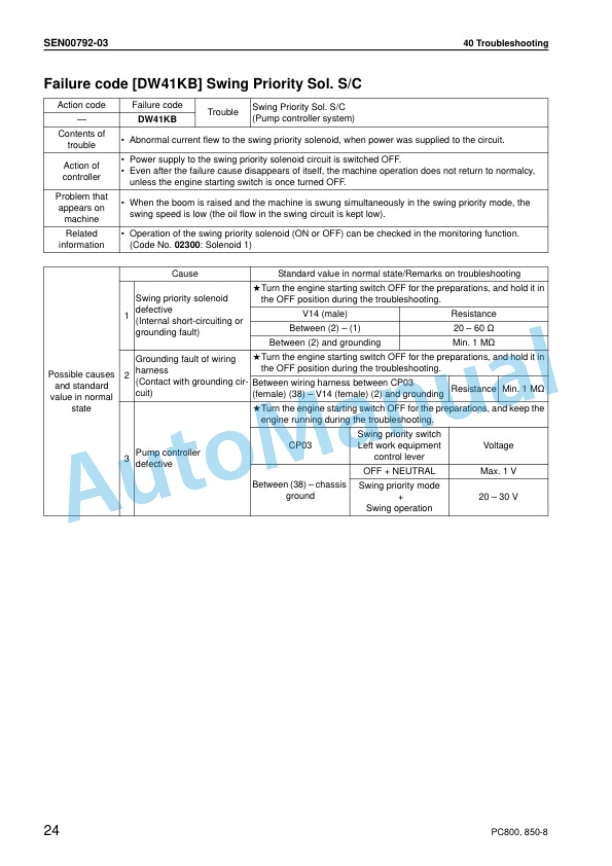

- 7. Troubleshooting

- 7.1. Failure code table and fuse locations

- 7.1.1. Failure code table and fuse locations

- 7.2. General information on troubleshooting

- 7.2.1. General information on troubleshooting

- 7.3. Troubleshooting by failure code (Display of code), Part 1

- 7.3.1. Troubleshooting by failure code (Display of code), Part 1

- 7.4. Troubleshooting by failure code (Display of code), Part 2

- 7.4.1. Troubleshooting by failure code (Display of code), Part 2

- 7.5. Troubleshooting by failure code (Display of code), Part 3

- 7.5.1. Troubleshooting by failure code (Display of code), Part 3

- 7.6. Troubleshooting of electrical system (Emode)

- 7.6.1. Troubleshooting of electrical system (Emode)

- 7.7. Troubleshooting of hydraulic and mechanical system (Hmode)

- 7.7.1. Troubleshooting of hydraulic and mechanical system (Hmode)

- 7.8. Troubleshooting of engine (Smode)

- 7.8.1. Troubleshooting of engine (Smode)

- 8. Disassembly and assembly

- 8.1. General information on disassembly and assembly

- 8.1.1. How to read this manual

- 8.1.2. Coating materials list

- 8.1.3. Special tools list

- 8.1.4. Sketches of special tools

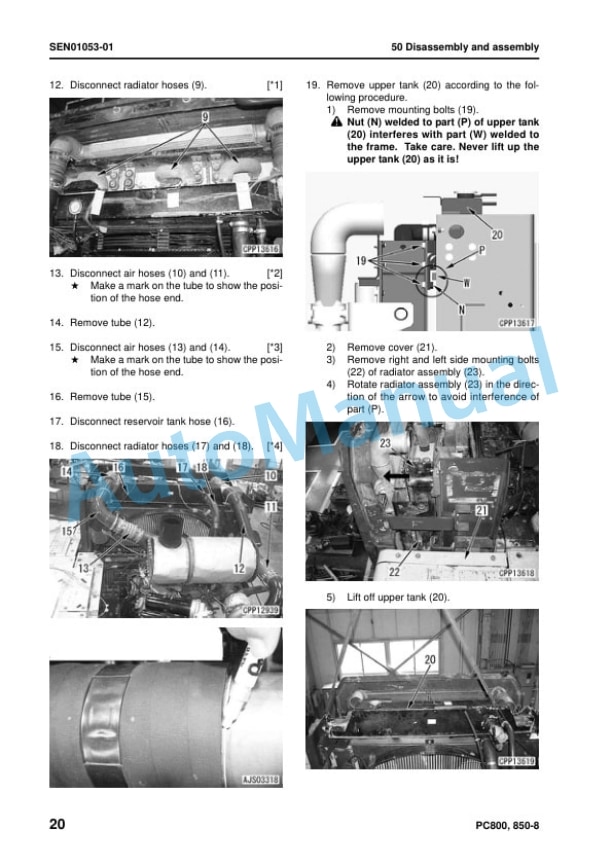

- 8.2. Engine and cooling system (SAA6D140E5)

- 8.2.1. Engine and cooling system

- 8.3. Engine (SAA6D140E5)

- 8.3.1. Engine (SAA6D140E5)

- 8.4. Power train

- 8.4.1. Power train

- 8.5. Undercarriage and frame

- 8.5.1. Undercarriage and frame

- 8.6. Hydraulic system

- 8.6.1. Removal and installation ofhydraulic tank assembly

- 8.6.2. Removal and installation of mainpump assembly

- 8.6.3. Removal and installation of mainpump input shaft oil seal

- 8.6.4. Removal and installation ofcooling fan pump assembly

- 8.6.5. Removal and installation ofcontrol valve assembly

- 8.6.6. Assembly of control valveassembly

- 8.6.7. Removal and installation of swingmotor assembly

- 8.6.8. Removal and installation of centerswivel joint assembly

- 8.6.9. Disassembly and assembly ofcenter swivel joint assembly

- 8.6.10. Removal and installation of travelmotor assembly

- 8.6.11. Removal and installation of solenoidvalve assembly

- 8.6.12. Removal and installation of boomdamping valve assembly

- 8.6.13. Disassembly and assembly ofwork equipment PPC valveassembly

- 8.6.14. Disassembly and assembly oftravel PPC valve assembly

- 8.6.15. Disassembly and assembly ofhydraulic cylinder assembly

- 8.6.16. Disassembly and assembly ofgrease gun assembly

- 8.7. Work equipment

- 8.7.1. Work equipment

- 8.8. Cab and its attachments

- 8.8.1. Cab and its attachments

- 8.9. Electrical system

- 8.9.1. Electrical system

- 9. Diagrams and drawings

- 9.1. Hydraulic diagrams and drawings

- 9.1.1. Hydraulic circuit diagram

- 9.2. Electrical diagrams and drawings

- 9.2.1. Electrical circuit diagram (1/5)

- 9.2.2. Electrical circuit diagram (2/5)

- 9.2.3. Electrical circuit diagram (3/5)

- 9.2.4. Electrical circuit diagram (4/5)

- 9.2.5. Electrical circuit diagram (5/5)

- 9.2.6. Connector list and sterogram

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF