- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PC95-R2 Hydraulic Excavator Shop Manual WEBM001702

$40.00

- Type Of Manual: Shop Manual

- Manual ID: WEBM001702

- Format: PDF

- Size: 9.1MB

- Number of Pages: 366

Category: Komatsu Shop Manual PDF

-

Model List:

- PC95-R2 Hydraulic Excavator

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. STANDARD TIGHTENING TORQUE

- 0.4. COATING MATERIALS

- 0.5. ELECTRIC WIRE CODE

- 0.6. WEIGHT TABLE

- 0.7. TABLE OF OIL AND COOLANT QUANTITIES

- 0.8. CONVERSION TABLE

- 0.9. STRUCTURE AND FUNCTION

- 0.9.2. POWER TRAIN

- 0.9.3. TRACK FRAME

- 0.9.4. IDLER AND RECOIL SPRING

- 0.9.5. CARRIER ROLLER TRACK ROLLER

- 0.9.6. TRACK SHOE

- 0.9.7. SWING CIRCLE

- 0.9.8. SWING MACHINERY

- 0.9.9. FINAL DRIVE

- 0.9.10. HYDRAULIC DIAGRAM STANDARD

- 0.9.11. HYDRAULIC DIAGRAM WITH 2PIECE BOOM

- 0.9.12. HYDRAULIC PUMP

- 0.9.13. SPOOL CONTROL VALVE (STANDARD)

- 0.9.14. SPOOL CONTROL VALVE (STANDARD 2PIECE BOOM)

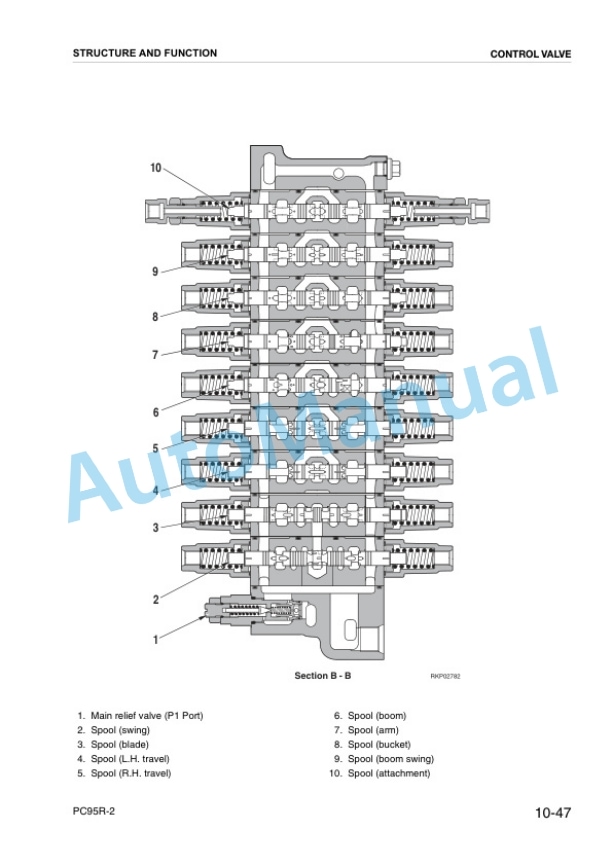

- 0.9.15. CONTROL VALVE

- 0.9.16. BLADE VALVE

- 0.9.17. AND R.H. TRAVEL VALVE BOOM VALVE

- 0.9.18. ARM VALVE BUCKET VALVE

- 0.9.19. BOOM SWING VALVE (2PIECE BOOM VALVE) ATTACHMENT VALVE

- 0.9.20. SERVOCONTROL FEED UNIT

- 0.9.21. ACCUMULATOR

- 0.9.22. SHUTTLE VALVE

- 0.9.23. PPC VALVE

- 0.9.24. BOOM AND ARM SAFETY VALVE

- 0.9.25. BLADE SAFETY VALVE

- 0.9.26. PIECE BOOM SAFETY VALVE

- 0.9.27. OVERLOAD SENSOR SWITCH

- 0.9.28. SOLENOID VALVES

- 0.9.29. AIRCONDITIONING UNIT

- 0.9.30. ELECTRICAL DIAGRAM (1/5)

- 0.9.31. ELECTRICAL DIAGRAM (2/5)

- 0.9.32. ELECTRICAL DIAGRAM (3/5)

- 0.9.33. ELECTRICAL DIAGRAM (4/5)

- 0.9.34. ELECTRICAL DIAGRAM (5/5)

- 0.10. TESTING AND ADJUSTMENTS

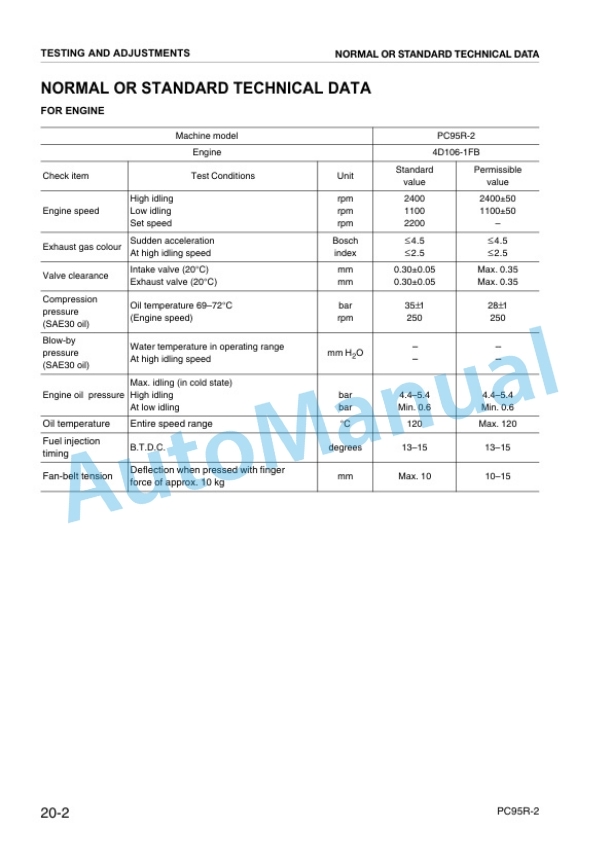

- 0.10.1. NORMAL OR STANDARD TECHNICAL DATA

- 0.10.2. SPECIAL TOOLS

- 0.10.3. MEASURING THE ENGINE SPEED

- 0.10.4. ADJUSTING VALVE CLEARANCE

- 0.10.5. MEASURING COMPRESSION PRESSURE

- 0.10.6. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 0.10.7. TESTING AND ADJUSTING FAN BELT TENSION

- 0.10.8. CHECKING AND TIGHTENING THE COMPRESSOR FANBELT

- 0.10.9. ADJUSTING THE STROKE OF THE ACCELERATOR LEVER

- 0.10.10. ADJUSTING THE SAFETY MICROSWITCH

- 0.10.11. MEASURING THE SWING CIRCLE AXIAL CLEARANCE

- 0.10.12. TESTING AND ADJUSTING TRACKSHOE TENSION

- 0.10.13. AIR BLEEDING FROM HYDRAULIC CIRCUITS

- 0.10.14. RELEASING RESIDUAL PRESSURE FROM THE CIRCUITS

- 0.10.15. CHECKING AND REGULATING PRESSURE IN THE HYDRAULIC CIRCUITS

- 0.10.16. TESTING AND SETTING OF MAIN VALVES

- 0.10.17. ADJUSTING PC VALVE

- 0.10.18. MEASURING LS DIFFERENTIAL PRESSURE AND ADJUSTING LS VALVE

- 0.10.19. CHECKING AND ADJUSTING PRESSURES IN THE SERVOCONTROL FEED UNIT

- 0.10.20. MEASURING PUMPS DELIVERY AND FLOW CONTROL STARTING POINT PUMP P1

- 0.10.21. MEASURING TRAVEL DEVIATION

- 0.10.22. ADJUSTING THE MAXIMUM SPEED OF THE TRAVEL MOTORS

- 0.10.23. MEASURING INNER OIL LEAKAGE OF TRAVEL MOTOR

- 0.10.24. ADJUSTING BOOM AND ARM SAFETY VALVES

- 0.10.25. ADJUSTING 2nd BOOM SAFETY VALVES

- 0.10.26. MEASURING AND SETTING OF PRESSURE SWITCH SIGNAL OVERLOAD OPERATION

- 0.10.27. MEASUREMENT OF INTERNAL OIL LEAKAGES IN THE SWING MOTOR

- 0.10.28. CHECKING FOR LEAKAGES INSIDE THE SWIVEL JOINT

- 0.10.29. ANALYSIS OF THE CAUSES OF HYDRAULIC DRIFTS

- 0.10.30. TESTING THE AIRCONDITIONING UNIT

- 0.10.31. EMPTYING THE AIRCONDITIONING UNIT

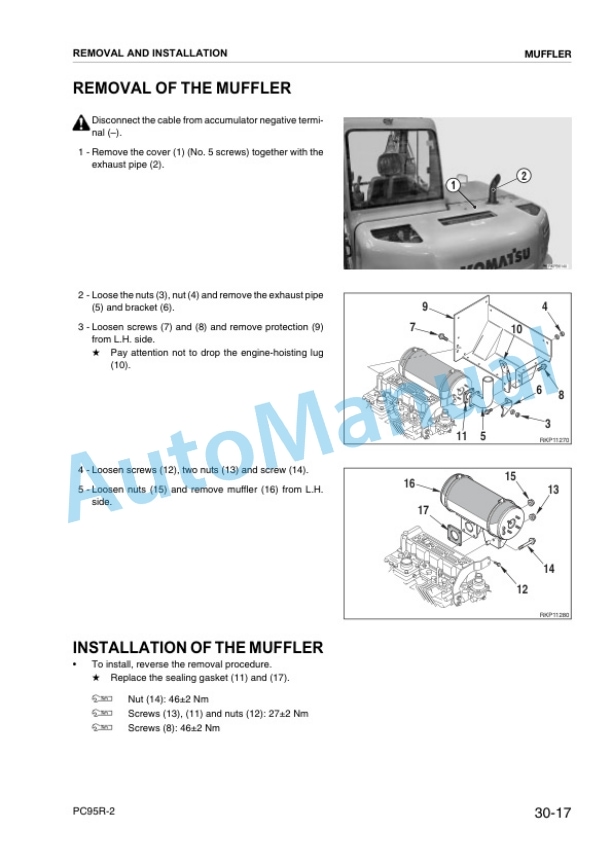

- 0.11. REMOVAL AND INSTALLATION

- 0.11.1. HOW TO READ THE MANUAL

- 0.11.2. PRECAUTIONS TO BE TAKEN WHEN WORKING

- 0.11.3. SPECIAL TOOLS

- 0.11.4. STARTER MOTOR

- 0.11.5. ALTERNATOR

- 0.11.6. AIRCONDITIONING UNIT COMPRESSOR

- 0.11.7. INJECTION PUMP

- 0.11.8. INJECTION NOZZLE

- 0.11.9. HEATING FAN UNIT

- 0.11.10. AIR CONIDTIONING FAN UNIT

- 0.11.11. RADIATOR

- 0.11.12. FUEL TANK

- 0.11.13. HYDRAULIC OIL TANK

- 0.11.14. ENGINEPUMP GROUP

- 0.11.15. PUMP GROUP

- 0.11.16. ENGINEPUMP COUPLING JOINT

- 0.11.17. GEARPUMP

- 0.11.18. SWIVEL JOINT

- 0.11.19. SWING MOTOR

- 0.11.20. SWING MACHINERY

- 0.11.21. CONTROL VALVE

- 0.11.22. REVOLVING FRAME

- 0.11.23. COUNTERWEIGHT

- 0.11.24. SWING CIRCLE

- 0.11.25. TRACK SHOES

- 0.11.26. SPROCKET ASSEMBLY

- 0.11.27. FINAL DRIVE

- 0.11.28. IDLER AND RECOIL SPRING ASSEMBLY

- 0.11.29. IDLER

- 0.11.30. RECOIL SPRING GROUP AND CYLINDER

- 0.11.31. TRACK ROLLER

- 0.11.32. CARRIER ROLLER

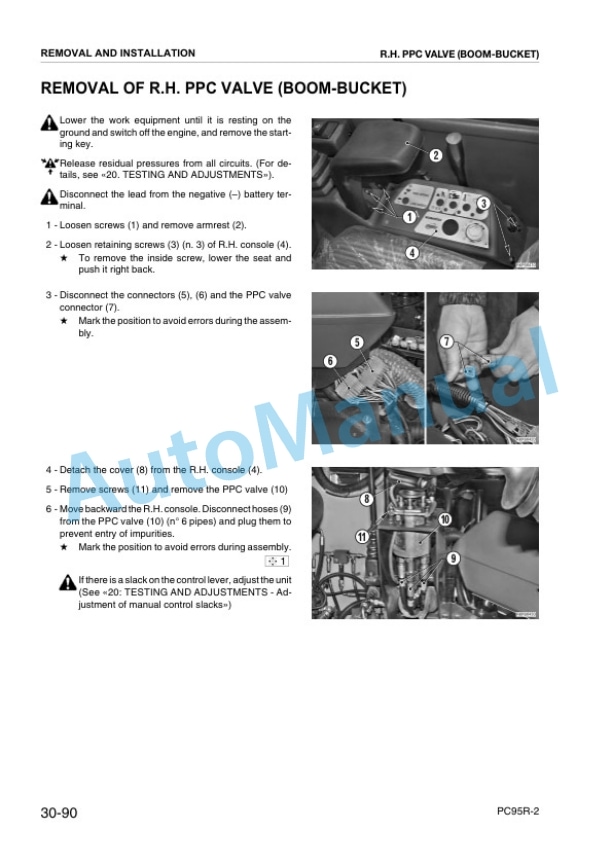

- 0.11.33. PPC VALVE (BOOMBUCKET)

- 0.11.34. PPC VALVE (ARMSWING)

- 0.11.35. BLADE PPC VALVE

- 0.11.36. TRAVEL PEDAL CONTROL

- 0.11.37. BOOM SWING PEDAL CONTROL

- 0.11.38. t BOOM PEDAL CONTROL

- 0.11.39. BOOM CYLINDER (For 1piece boom)

- 0.11.40. BOOM CYLINDER (For 2piece boom)

- 0.11.41. d BOOM CYLINDERS

- 0.11.42. ARM CYLINDER

- 0.11.43. BUCKET CYLINDER

- 0.11.44. BOOM SWING CYLINDER

- 0.11.45. BLADE CYLINDER

- 0.11.46. WORK EQUIPMENT CYLINDERS

- 0.11.47. WORK EQUIPMENT (For 1piece boom)

- 0.11.48. WORK EQUIPMENT (For 2piece boom)

- 0.11.49. BUCKET

- 0.11.51. d BOOM

- 0.11.52. BOOM (For 1piece boom)

- 0.11.53. BOOM (For 2piece boom)

- 0.11.54. SWING SUPPORT

- 0.11.55. BLADE

- 0.12. STANDARD MAINTENANCE

- 0.12.1. SWING MACHINERY

- 0.12.2. SERVOCONTROL FEED UNIT

- 0.12.3. PPC VALVES

- 0.12.4. SAFETY VALVE

- 0.12.5. CYLINDERS

- 0.12.6. WORK EQUIPMENT

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF