- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PW150-1 Wheeled Excavator Shop Manual SEBM020E0104

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM020E0104

- Format: PDF

- Size: 49.0MB

- Number of Pages: 516

Category: Komatsu Shop Manual PDF

-

Model List:

- PW150-1 Wheeled Excavator

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL VIEW

- 3.2. GENERAL ASSEMBLY DRAWING

- 3.3. SPECIFICATIONS

- 3.4. ENGINE ASSEMBLY DRAWING

- 3.5. ENGINE SPECIFICATIONS

- 3.6. WEIGHT TABLE

- 3.7. TABLE OF OIL AND COOLANT CAPACITIES

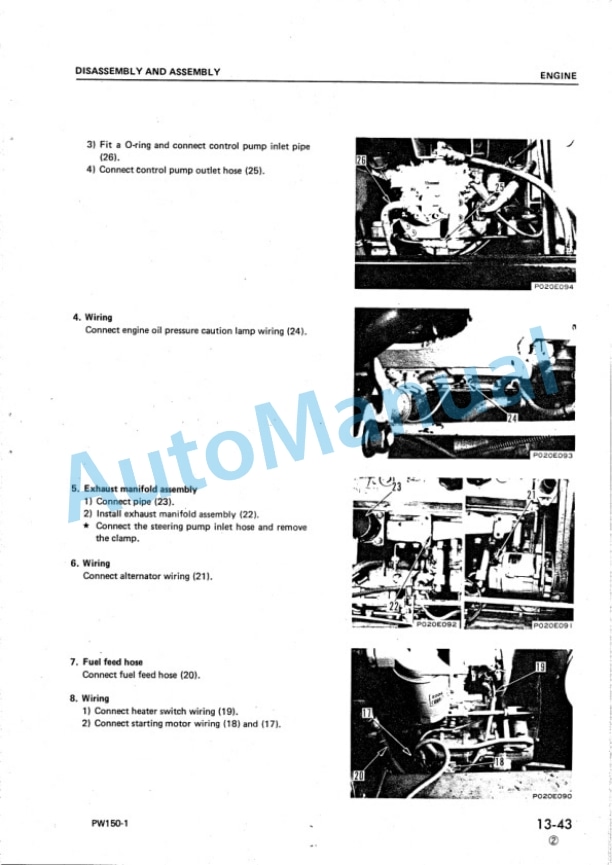

- 4. ENGINE

- 4.1. STRUCTURE AND FUNCTION

- 4.1.1. ENGINE MOUNT

- 4.1.2. RADIATOR AND HYDRAULIC OIL COOLER

- 4.1.3. PTO (POWER TAKEOFF)

- 4.1.4. FUEL TANK AND PIPING

- 4.1.5. ENGINE CONTROL

- 4.2. TESTING AND ADJUSTING

- 4.2.1. STANDARDS FOR TESTING AND ADJUSTING

- 4.2.2. TOOLS FOR TESTING AND ADJUSTING

- 4.2.3. ADJUSTING VALVE CLEARANCE

- 4.2.4. TESTING AND ADJUSTING FAN BELT TENSION

- 4.2.5. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 4.2.6. MEASURING BLOWBY

- 4.2.7. MEASURING COMPRESSION PRESSURE

- 4.2.8. LUBRICATION SYSTEM

- 4.2.9. MEASURING EXHAUST GAS COLOR

- 4.2.10. MEASURING COOLANT TEMPERATURE

- 4.3. DISASSEMBLY AND ASSEMBLY

- 4.3.1. ENGINE OIL COOLER

- 4.3.2. FUEL INJECTION PUMP

- 4.3.3. RADIATOR AND HYDRAULIC OIL COOLER

- 4.4. STRUCTURE AND FUNCTION

- 4.4.1. POWER TRAIN

- 4.4.1.1. OUTLINE

- 4.4.1.2. SCHEMATIC OF POWER TRAIN

- 4.4.1.3. HYDRAULIC CIRCUIT DIAGRAM

- 4.4.2. TRAVEL SYSTEM

- 4.4.2.1. OUTLINE

- 4.4.2.2. SCHEMATIC OF TRAVEL SYSTEM

- 4.4.2.3. HYDRAULIC CIRCUIT DIAGRAM

- 4.4.2.4. CENTER SWIVEL JOINT

- 4.4.2.5. TRAVEL MOTOR AND BRAKE VALVE

- 4.4.2.6. TRAVEL SHUTTLE VALVE

- 4.4.2.7. TRAVEL SUCTION VALVE

- 4.4.2.8. TRANSMISSION

- 4.4.2.9. TRAVEL CONTROL SYSTEM

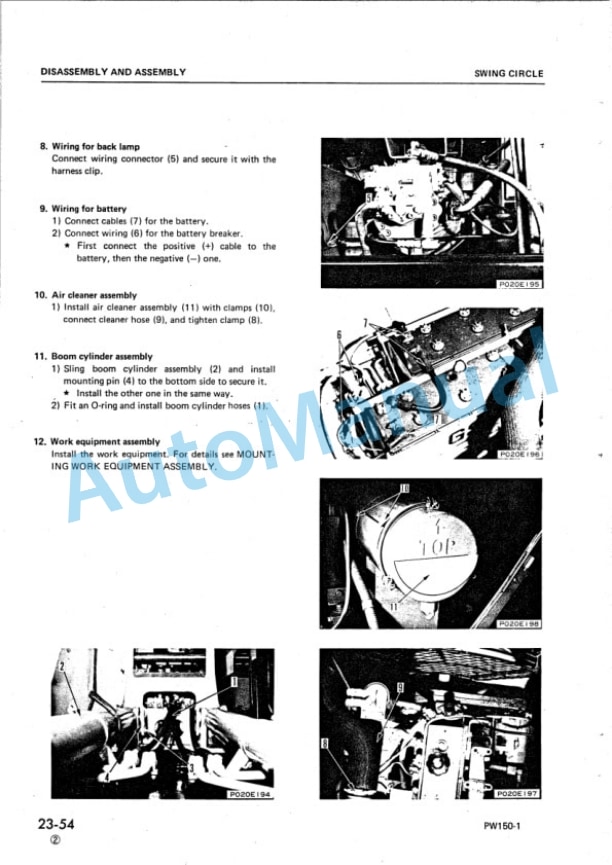

- 4.4.3. SWING SYSTEM

- 4.4.3.1. OUTLINE

- 4.4.3.2. SCHEMATIC OF SWING SYSTEM

- 4.4.3.3. HYDRAULIC CIRCUIT DIAGRAM

- 4.4.3.4. SWING MOTOR AND BRAKE VALVE

- 4.4.3.5. SWING MACHINERY

- 4.4.3.6. SWING CIRCLE

- 4.5. DISASSEMBLY AND ASSEMBLY

- 4.5.1. CENTER SWIVEL JOINT

- 4.5.2. TRAVEL BRAKE VALVE

- 4.5.3. SWING MOTOR AND BRAKE VALVE

- 4.5.3.1. DISMOUNTING

- 4.5.3.2. MOUNTING

- 4.5.4. SWING MACHINERY

- 4.6. MAINTENANCE STANDARD

- 4.6.1. CENTER SWIVEL JOINT

- 4.6.2. TRAVEL BRAKE VALVE

- 4.6.3. TRAVEL SHUTTLE VALVE

- 4.6.4. TRAVEL SUCTION VALVE

- 4.6.5. TRANSMISSION

- 4.6.6. SWING MACHINERY

- 4.6.7. SWING CIRCLE

- 5. STEERING SYSTEM

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. STEERING SYSTEM

- 5.1.1.1. OUTLINE

- 5.1.1.2. SCHEMATIC OF STEERING SYSTEM

- 5.1.1.3. HYDRAULIC CIRCUIT DIAGRAM

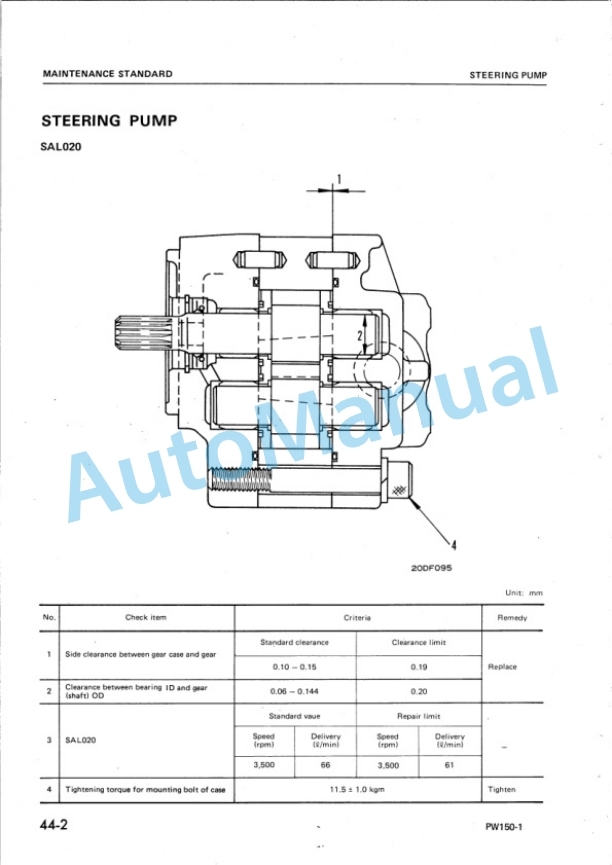

- 5.1.1.4. STEERING PUMP

- 5.1.1.5. STEERING MAIN RELIEF VALVE

- 5.1.1.6. STEERING VALVE

- 5.1.1.7. STEERING CYLINDER

- 5.1.1.8. SCHEMATIC OF BRAKE SYSTEM

- 5.1.1.9. PNEUMATIC CIRCUIT DIAGRAM

- 5.1.1.10. BRAKE VALVE

- 5.1.1.11. SHUTTLE VALVE (DOUBLE CHECK VALVE)

- 5.1.1.12. AIR MASTER

- 5.1.1.13. WHEEL BRAKE

- 5.1.1.14. PARKING BRAKE

- 5.1.1.15. PARKING BRAKE CHAMBER

- 5.1.1.16. WAY CONTROL VALVE

- 5.1.1.17. QUICKRELEASE VALVE

- 5.1.2. SUSPENSION SYSTEM

- 5.1.2.1. OUTLINE

- 5.1.2.2. SCHEMATIC OF SUSPENSION SYSTEM

- 5.1.2.3. HYDRAULIC AND PNEUMATIC CIRCUIT DIAGRAM

- 5.1.2.4. SUSPENSION LOCK VALVE

- 5.1.2.5. SUSPENSION LOCK CYLINDER

- 5.2. TESTING AND ADJUSTING

- 5.2.1. TESTING AND ADJUSTING TOEIN

- 5.2.2. ADJUSTING MAXIMUM TURNING ANGLE OF FRONT WHEELS

- 5.2.3. ADJUSTING PARKING BRAKE

- 5.2.4. ADJUSTING PARKING BRAKE ROD

- 5.2.5. BLEEDING AIR FROM BRAKE CIRCUIT

- 5.3. DISASSEMBLY AND ASSEMBLY

- 5.3.1. STEERING PUMP

- 5.3.1.1. DISMOUNTING

- 5.3.1.2. MOUNTING

- 5.3.2. STEERING MAIN RELIEF VALVE

- 5.3.2.1. DISASSEMBLY

- 5.3.2.2. ASSEMBLY

- 5.3.3. STEERING CYLINDER

- 5.3.4. DIFFERENTIAL (FRONT)

- 5.3.4.1. DISMOUNTING

- 5.3.4.2. MOUNTING

- 5.3.5. DIFFERENTIAL (REAR)

- 5.3.5.1. DISMOUNTING

- 5.3.5.2. MOUNTING

- 5.3.5.3. DISASSEMBLY

- 5.3.5.4. ASSEMBLY

- 5.3.6. AIR MASTER ASSEMBLY

- 5.3.6.1. DISMOUNTING

- 5.3.6.2. MOUNTING

- 5.3.7. DISC PLATE (REAR)

- 5.3.8. SUSPENSION LOCK VALVE

- 5.3.8.1. DISMOUNTING

- 5.3.8.2. MOUNTING

- 5.3.9. SUSPENSION LOCK CYLINDER

- 5.3.9.1. DISMOUNTING

- 5.3.9.2. MOUNTING

- 5.3.9.3. DISASSEMBLY

- 5.3.9.4. ASSEMBLY

- 5.4. MAINTENANCE STANDARD

- 5.4.1. STEERING PUMP

- 5.4.2. STEERING CYLINDER

- 5.4.3. FINAL DRIVE AND DIFFERENTIAL

- 5.4.4. KING PIN AND KNUCKLE AND TIEROD

- 5.4.5. WHEEL BRAKE

- 5.4.6. PARKING BRAKE

- 5.4.7. SUSPENSION LOCK CYLINDER

- 6. AIR SYSTEM

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. AIR SYSTEM

- 6.1.1.1. OUTLINE

- 6.1.1.2. SCHEMATIC OF AIR SYSTEM

- 6.1.1.3. PNEUMATIC CIRCUIT DIAGRAM

- 6.1.1.4. AIR GOVERNOR

- 6.1.1.5. PARKING LAMP SWITCH

- 6.1.1.6. LOW PRESSURE INDICATOR SWITCH

- 6.1.1.7. PRESSURE REGULATOR VALVE

- 6.1.1.8. STOP LAMP SWITCH

- 7. HYDRAULIC SYSTEM

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. HYDRAULIC SYSTEM

- 7.1.1.1. OUTLINE

- 7.1.1.2. SCHEMATIC OF HYDRAULIC SYSTEM

- 7.1.1.3. HYDRAULIC CIRCUIT DIAGRAM

- 7.1.1.4. HYDRAULIC TANK AND FUEL TANK

- 7.1.1.5. HYDRAULIC PUMP

- 7.1.1.6. CONTROL VALVE

- 7.1.2. WORK EQUIPMENT HYDRAULIC SYSTEM

- 7.1.2.1. BOOM, ARM AND BUCKET

- 7.1.2.2. OUTRIGGER

- 7.1.2.3. LEFT AND RIGHT INDEPENDENT OUTRIGGERS

- 7.1.2.4. FRONT OUTRIGGER AND REAR EQUIPMENT

- 7.1.2.5. DOZER BLADE (IF EQUIPPED)

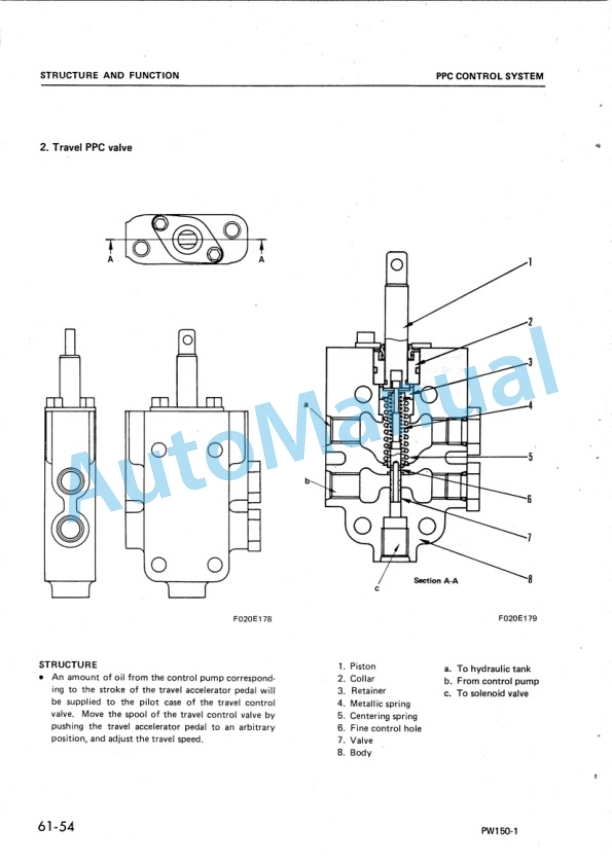

- 7.1.3. PPC CONTROL SYSTEM

- 7.1.3.1. OUTLINE

- 7.1.3.2. SCHEMATIC OF PPC CONTROL SYSTEM

- 7.1.3.3. PPC VALVE

- 7.1.3.4. PPC SHUTTLE VALVE

- 7.1.3.5. SOLENOID VALVE

- 7.2. TESTING AND ADJUSTING

- 7.2.1. STANDARD FOR TESTING AND ADJUSTING

- 7.2.2. TESTING TRAVEL OF CONTROL LEVERS

- 7.2.3. TESTING OPERATING FORCE OF CONTROL LEVERS

- 7.2.4. MEASURING OIL TEMPERATURE

- 7.2.5. MEASURING LEAKAGE OF SWING AND TRAVEL MOTOR

- 7.2.6. MEASURING HYDRAULIC DRIFT OF WORK EQUIPMENT

- 7.2.7. BLEEDING AIR

- 7.2.8. MEASURING PLACE OF OIL PRESSURE

- 7.2.9. ADJUSTING PLACE OF HYDRAULIC PRESSURE

- 7.2.10. TESTING AND ADJUSTING MAIN RELIEF VALVE

- 7.2.11. CHECKING HYDRAULIC ASSIST SYSTEM

- 7.2.12. TROUBLESHOOTING

- 7.2.12.1. FORWARDREVERSE SELECTOR IS INOPERATED

- 7.2.12.2. WORK EQUIPMENT SPEED IS SLOW, OR THERE IS NO POWER

- 7.2.12.3. MACHINE SPEED IS SLOW

- 7.2.12.4. SWING SPEED IS SLOW

- 7.2.12.5. ENGINE STALLS OR SPEED DROPS EXCESSIVELY DURING OPERATIONS

- 7.2.12.6. UPPER STRUCTURE DOES NOT SWING

- 7.3. DISASSEMBLY AND ASSEMBLY

- 7.3.1. L .H . 7SPOOL CONTROL VALVE

- 7.3.1.1. DISMOUNTING

- 7.3.1.2. MOUNTING

- 7.3.1.3. DISASSEMBLY

- 7.3.1.4. ASSEMBLY

- 7.3.2. R .H . 5SPOOL CONTROL VALVE

- 7.3.2.1. DISMOUNTING

- 7.3.2.2. MOUNTING

- 7.3.3. SAFETY VALVE AND SUCTION VALVE

- 7.3.3.1. DISASSEMBLY

- 7.3.3.2. ASSEMBLY

- 7.3.4. MAIN RELIEF VALVE

- 7.3.4.1. DISASSEMBLY

- 7.3.4.2. ASSEMBLY

- 7.3.5. SLOW RETURN VALVE

- 7.3.6. BUCKET CYLINDER

- 7.3.6.1. DISMOUNTING

- 7.3.6.2. MOUNTING

- 7.3.7. OUTRIGGER CYLINDER

- 7.3.7.1. DISMOUNTING

- 7.3.7.2. MOUNTING

- 7.3.8. HYDRAULIC CYLINDER

- 7.3.8.1. DISASSEMBLY

- 7.3.8.2. ASSEMBLY

- 7.3.9. HYDRAULIC CYLINDER PISTON RING AND WEAR RING

- 7.3.9.1. DISMOUNTING

- 7.3.9.2. MOUNTING

- 7.4. MAINTENANCE STANDARD

- 7.4.1. L .H . 7SPOOL CONTROL VALVE

- 7.4.2. R .H . 5SPOOL CONTROL VALVE

- 7.4.3. CONTROL PUMP

- 7.4.4. SLOW RETURN VALVE

- 7.4.5. HYDRAULIC CYLINDER

- 8. WORK EQUIPMENT

- 8.1. STRUCTURE AND FUNCTION

- 8.1.1. WORK EQUIPMENT

- 8.1.1.1. BOOM, ARM AND BUCKET

- 8.1.1.2. REAR OUTRIGGER

- 8.1.1.3. FRONT OUTRIGGER (IF EQUIPPED)

- 8.1.1.4. DOZER BLADE IF (IF EQUIPPED)

- 8.2. DISASSEMBLY AND ASSEMBLY

- 8.3. MAINTENANCE STANDARD

- 8.3.1. WORK EQUIPMENT

- 9. ELECTRIC AND ELECTRONIC SYSTEM

- 9.1. STRUCTURE AND FUNCTION

- 9.1.1. ELECTRIC AND ELECTRONIC SYSTEM

- 9.1.1.1. OUTLINE

- 9.1.1.2. ELECTRIC CIRCUIT DIAGRAM

- 10. OTHERS

- 10.1. OTHERS

- 10.1.1. OPERATORS CAB HEATER

- 10.1.2. OVERLOAD WARNING DEVICE (IF EQUIPPED)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF