- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PW160-11 Wheeled Excavator Shop Manual VENBM69001

$40.00

- Type Of Manual: Shop Manual

- Manual ID: VENBM69001

- Format: PDF

- Size: 100.8MB

- Number of Pages: 1090

Category: Komatsu Shop Manual PDF

-

Model List:

- PW160-11 Wheeled Excavator

- 1. VENBM69001 PW16011

- 2. FOREWORD

- 2.1. Safety

- 2.2. General

- 2.3. How to read the shop manual

- 2.4. Hoisting instructions

- 2.5. Coating materials

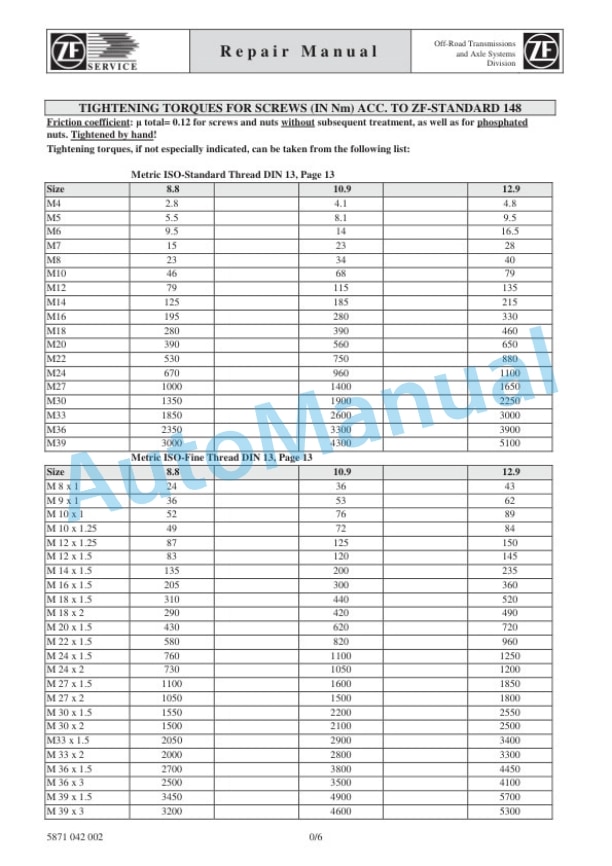

- 2.6. Standard tightening torque

- 2.7. Electric wire code

- 2.8. Conversion tables

- 2.9. Units

- 3. GENERAL

- 3.1. Specification dimension drawings

- 3.2. Working ranges

- 3.3. Weight table

- 3.4. Fuel, coolant and lubricants

- 4. STRUCTURE AND FUNCTION

- 4.1. Abbreviation list

- 4.2. UREA SCR system

- 4.3. BOOTUP system

- 4.4. Engine system

- 4.5. Cooling system

- 4.6. Power train

- 4.7. Swing machinery motor

- 4.8. d Auxiliary circuit in the undercarriage

- 4.9. Hydraulic quick coupler

- 4.10. Full hydraulic quick coupler

- 4.11. Travel motor

- 4.12. Clutch control circuit

- 4.13. Axle

- 4.14. Suspension lock cylinder

- 4.15. Braking system

- 4.16. Power brake valve

- 4.17. Accumulator for brake valve

- 4.18. Steering system

- 4.19. Joystick steering system

- 4.20. Steering column STD

- 4.21. Steering column JSS

- 4.22. Orbitrol valve STD

- 4.23. Orbitrol valve JSS

- 4.24. Hydraulic equipment layout drawings

- 4.25. Hydraulic circuit diagram

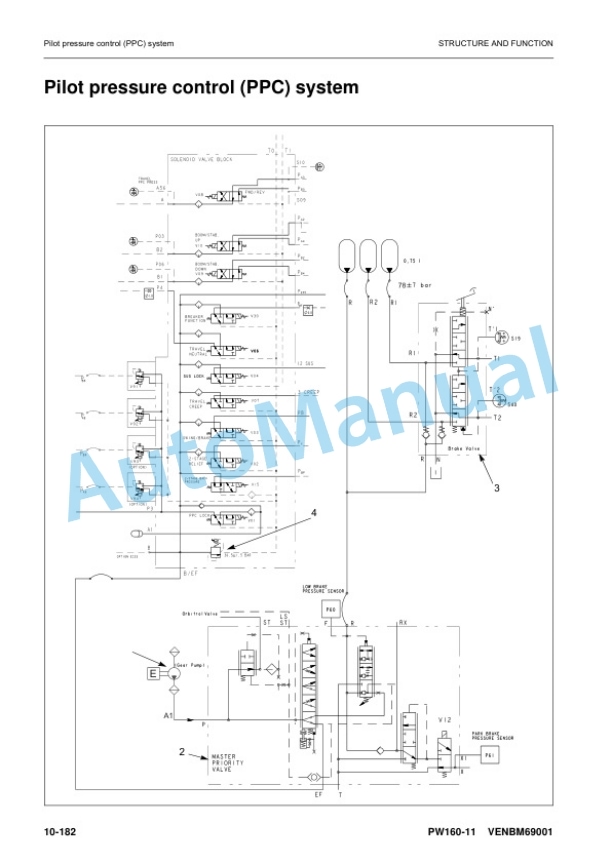

- 4.26. Pilot pressure control (PPC) system

- 4.27. Control main valve

- 4.28. CLSS

- 4.29. Centre swivel joint

- 4.30. Travel PPC pedal

- 4.31. Work equipment Swing PPC valve

- 4.32. Solenoid valve block with integrated ATT EPC

- 4.33. Bucket to 1ATT

- 4.34. Boom safety valve

- 4.35. Boom floating

- 4.36. Hydraulic cylinder

- 4.37. Work equipment

- 4.38. Tool control

- 4.39. ECSS

- 4.40. Breaker return valve

- 4.41. Air conditioner

- 4.42. Electrical wiring diagram

- 4.43. Electrical system

- 4.44. Engine controller

- 4.45. Pump controller

- 4.46. Machine control system diagram

- 4.47. Machine monitor system

- 4.48. KOMTRAX system

- 4.49. KomVision system

- 4.50. KomVision controller

- 4.51. Overload warning device

- 4.52. Sensor

- 4.53. PPC levers

- 4.54. t attachment circuit hydraulic performance (main valve bypassed)

- 4.55. Travel system

- 4.56. Lubrication diagrams

- 4.57. Standard value table for engine related parts

- 4.58. Standard value table for chassis related parts

- 4.59. PM clinic service

- 5. STANDARD VALUE TABLE

- 5.1. Engine and cooling system

- 5.2. Replacing the fan belt

- 5.3. Measurement of clearance in swing circle bearing

- 5.4. Inspection and adjustment of hydraulic oil pressure in hydraulic circuit for work equipment, swing and travel

- 5.5. Inspection and adjustment of control circuit oil pressure

- 5.6. Inspection and adjustment of pump PC (valve inlet) control oil pressure

- 5.7. Inspection and adjustment of pump LS differential pressure

- 5.8. Measurement of solenoid valve output pressure

- 5.9. Adjustment of work equipment and swing PPC valve

- 5.10. Measuring and adjusting quick coupler control valve output pressure

- 5.11. Testing travel motor relief pressure

- 5.12. Testing propshaft speed

- 5.13. Testing transmission clutch control circuit

- 5.14. Inspection of locations of hydraulic drift of work equipment

- 5.15. Release of remaining pressure in hydraulic circuit

- 5.16. Measurement of oil leakage

- 5.17. Air bleeding of various parts

- 5.18. Inspection procedures for diode

- 5.19. Electrical system

- 5.20. Inspection and adjustment of ECSS (ACCU pressure)

- 5.21. Inspection and adjustment of Tool control

- 5.22. Changing the lubrication interval times

- 5.23. Adjust rearview camera angle

- 5.24. Adjust KomVision camera angle

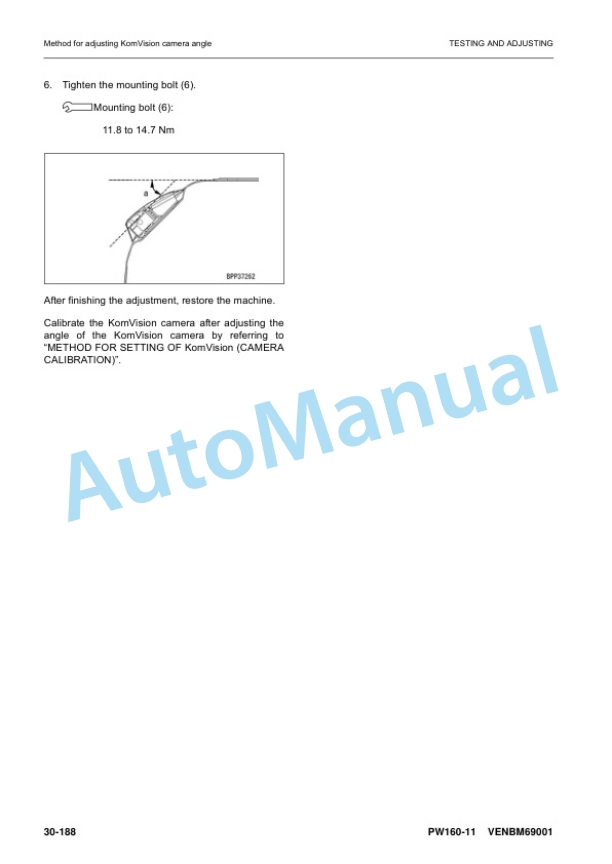

- 5.25. Method for adjusting KomVision camera angle

- 5.26. Adjust KomVision related items

- 6. TESTING AND ADJUSTING

- 7. TROUBLESHOOTING

- 7.1. Troubleshooting

- 7.2. Troubleshooting by failure code (Display of code)

- 7.3. Failure code DB30KR Joystick steering controller malfunction

- 7.4. Failure code DA22KK Pump solenoid power low error

- 7.5. Failure code DCS2KK Machine controller solenoid power voltage low error

- 7.6. Failure code DWB5KY Hot short circuit in 4th outrigger solenoid

- 7.7. General information on troubleshooting

- 7.8. Connector location chart and circuit diagram by system

- 7.9. Connection table for connector pin numbers

- 8. DISASSEMBLY AND ASSEMBLY (preliminary version)

- 8.1. FRONT AXLE

- 8.2. REAR AXLE

- 8.3. TRANSMISSION

- 9. OTHER

- 9.1. Hydraulic circuit diagram (1/3)

- 9.2. Hydraulic circuit diagram (2/3)

- 9.3. Hydraulic circuit diagram (3/3)

- 9.4. Contents

- 9.5. Contents

- 9.6. Power Supply

- 9.7. Grounding

- 9.8. Model Select

- 9.9. Engine PW180

- 9.10. Engine PW180

- 9.11. Engine PW148, PW160

- 9.12. Engine PW148, PW160

- 9.13. Engine Power Supply, Air Intake

- 9.14. Engine Start

- 9.15. d ENGINE STOP, OPERATING LAMP

- 9.16. ADBLUE/DEF DATALINK

- 9.17. ADDBLUE/DPF POWER

- 9.18. REFUELING SYSTEM, FUEL DIAL

- 9.19. BRAKE

- 9.21. CRUISE CONTROL

- 9.22. TRAVEL

- 9.23. SUSLOCK, SPEEDSNR, JOYSTICK POTI

- 9.24. SENSORS ENGINE OIL

- 9.25. QUICK COUPLER, PRESSURE SENSOR

- 9.26. PPC REDUCTION, FLOATING ,PRESSURE SENSOR

- 9.27. SWING LOCK, PRESSURE SENSOR, JOYSTICK SW

- 9.28. BUCKET/2ATT SWITCHING

- 9.29. LOWER ATTACHMENTS

- 9.30. ROTOTILT

- 9.31. BOOM/STABILISER, AUXILARY CIRCUIT, BREAKER

- 9.32. ROAD LIGHT

- 9.33. INDICATOR, SIDE LIGHT, STOP LIGHT

- 9.34. ARM MARKER LIGHT QC SIGNAL BOOM

- 9.35. BEACON, TRAILER (OPT)

- 9.36. WORKLAMP

- 9.37. WORKLAMP

- 9.38. CAMERA SW, SERVICECON., KOMTRAX, KOMNET

- 9.39. KOMVISION

- 9.40. AIR CONDITION, HEATED MIRROR

- 9.41. RADIO, 12V, CIGAR LIGHTER, ROOM LAMP

- 9.42. PPCLOCK, STARTER CUT, SEAT

- 9.43. IDKEY

- 9.44. HORN, TRAVEL ALARM

- 9.45. WIPER

- 9.47. JOYSTICK STEERING

- 9.48. FAN CLUTCH, TOOL CONTROL

- 9.49. ECSS

- 9.50. Harness Summary

- 9.51. Harness Summary

- 9.52. Pin Location List

- 9.53. Pin Location List

- 9.54. Pin Location List

- 9.55. Pin Location List

- 9.56. Pin Location List

- 9.57. Pin Location List

- 9.58. Pin Location List

- 9.59. Pin Location List

- 9.60. Pin Location List

- 9.61. Pin Location List

- 9.62. Pin Location List

- 9.63. Pin Location List

- 9.64. Pin Location List

- 9.65. Pin Location List

- 9.66. Pin Location List

- 9.67. Pin Location List

- 9.68. Pin Location List

- 9.69. Pin Location List

- 9.70. Pin Location List

- 9.71. Pin Location List

- 9.72. Pin Location List

- 9.73. Pin Location List

- 9.74. Pin Location List

- 9.75. Pin Location List

- 9.76. Pin Location List

- 9.77. Pin Location List

- 9.78. Pin Location List

- 9.79. Pin Location List

- 9.80. Pin Location List

- 9.81. Pin Location List

- 9.82. Pin Location List

- 9.83. Pin Location List

- 9.84. Pin Location List

- 9.85. Pin Location List

- 9.86. Pin Location List

- 9.87. Pin Location List

- 9.88. Pin Location List

- 9.89. Pin Location List

- 9.90. Pin Location List

- 9.91. Pin Location List

- 9.92. Pin Location List

- 9.93. Connector diagram 1/10

- 9.94. Connector diagram 2/10

- 9.95. Connector diagram 3/10

- 9.96. Connector diagram 4/10

- 9.97. Connector diagram (5/10)

- 9.98. Connector diagram (6/10)

- 9.99. Connector diagram (7/10)

- 9.100. Connector diagram (8/10)

- 9.101. Connector diagram (9/10)

- 9.102. Connector diagram (10/10)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF