- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PW170ES-6K Hydraulic Excavator Shop Manual UEBM000801

$40.00

- Type Of Manual: Shop Manual

- Manual ID: UEBM000801

- Format: PDF

- Size: 21.1MB

- Number of Pages: 707

Category: Komatsu Shop Manual PDF

-

Model List:

- PW170ES-6K Hydraulic Excavator

- 1. PW170ES 6K

- 2. K32001 and up K34001 and up

- 3. CONTENTS

- 4. GENERAL…………………………………………………HelveticaBold

- 5. STRUCTURE AND FUNCTION

- 6. TESTING AND ADJUSTING

- 7. DISASSEMBLY AND ASSEMBLY

- 8. MAINTENANCE STANDARD…………………………………………..

- 9. SAFETY

- 10. FOREWORD

- 11. HOW TO READ THE SHOP MANUAL

- 12. HOISTING INSTRUCTIONS

- 13. COATING MATERIALS

- 14. STANDARD TIGHTENING TORQUE

- 15. ELECTRIC WIRE CODE

- 16. CONVERSION TABLE

- 17. ENGINE RELATED PARTS

- 18. RADIATOR OIL COOLER

- 19. SWING CIRCLE

- 20. SWING MACHINERY UNDERCARRIAGE

- 21. CLUTCH CONTROL CIRCUIT

- 22. AXLE

- 23. SUSPENSION LOCK CYLINDER

- 24. BRAKING TRAIN

- 25. BRAKE PEDAL

- 26. BRAKE PEDAL INCORPORATING BRAKE VALVE

- 27. ACCUMULATOR FOR BRAKE SYSTEM

- 28. STEERING TRAIN

- 29. ITEM

- 30. STEERING COLUMN

- 31. HYDRAULIC CIRCUIT DIAGRAM

- 32. HYDRAULIC CIRCUIT DIAGRAM

- 33. HYDRAULIC TANK

- 34. HYDRAULIC TANK

- 35. HYDRAULIC PUMP

- 36. PPC PUMPLESS SYSTEM

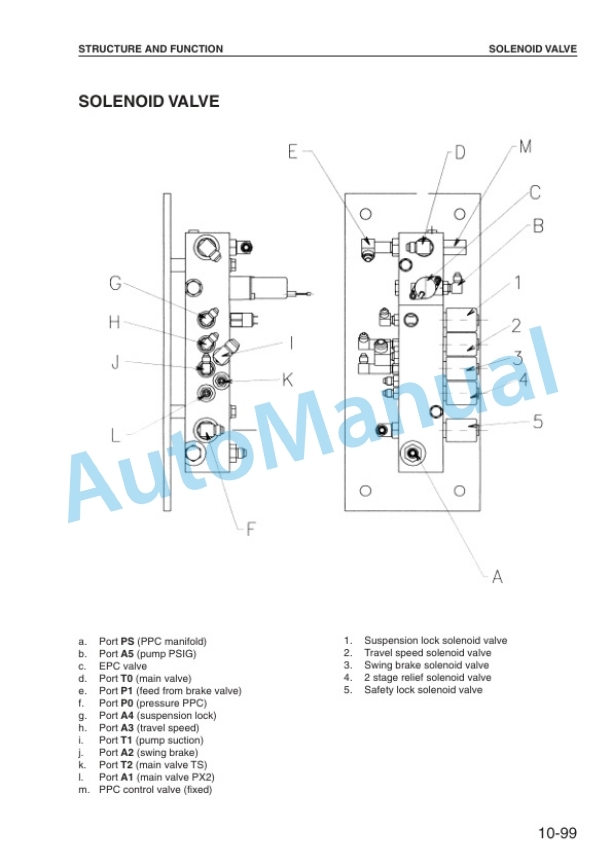

- 37. CONTROL VALVE

- 38. CLSS

- 39. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 40. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 41. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 42. CHECKS BEFORE TROUBLESHOOTING

- 43. CONNECTOR TYPES

- 44. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 45. EXPLANATION OF CONTROL MACHANISM FOR ELECTRICAL SYSTEM

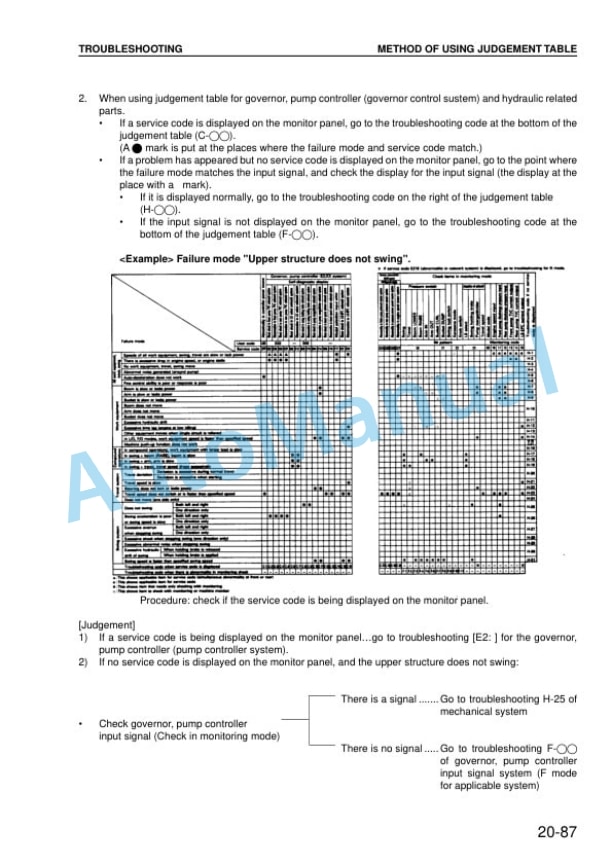

- 46. METHOD OF USING JUDGEMENT TABLE

- 47. METHOD OF USING TROUBLESHOOTING CHARTS

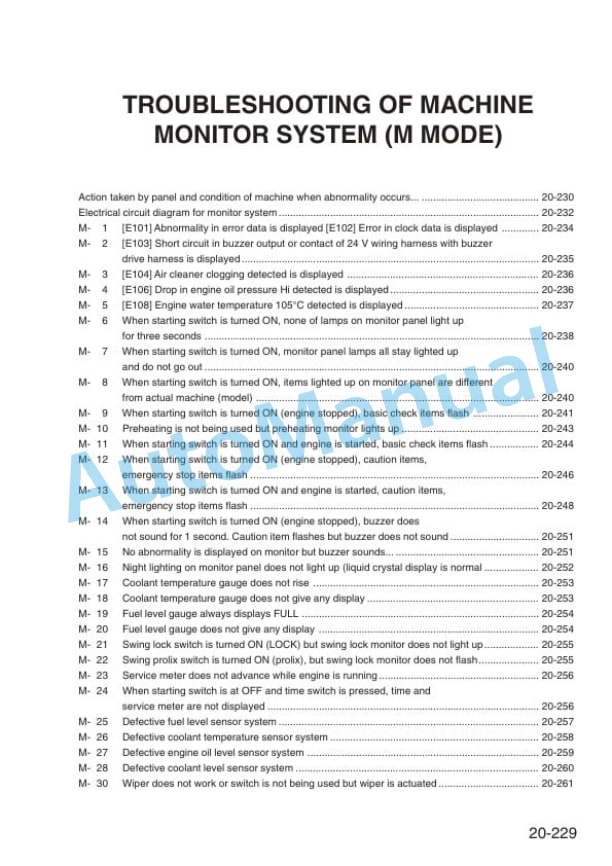

- 48. DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE

- 49. SERVICE CODE TABLE

- 50. POINTS TO REMEMBER WHEN CARRYING OUT TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER SYSTEM

- 51. ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE

- 52. JUDGEMENT TABLE FOR GOVERNOR, PUMP GOVERNOR ( GOVERNOR CONTROL SYSTEM) AND ENGINE RELATED PARTS

- 53. ELECTRICAL CIRCUIT DIAGRAM FOR E MODE 1/ 2

- 54. ELECTRICAL CIRCUIT DIAGRAM FOR E MODE 2/ 2

- 55. E 1 Abnormality in governor, pump controller power source ( controller LED is OFF)

- 56. E 2 E308 Abnormality in fuel control dial input value is displayed

- 57. E 3 E317 Abnormality ( disconnection) in motor drive system is displayed

- 58. E 4 E318 Abnormality ( short circuit) in motor drive system is displayed

- 59. E 5 E306 Abnormality in feedback potentiometer system is displayed

- 60. E 6 E315 Abnormality ( short circuit) in battery relay output system is displayed

- 61. E 7 E316 Abnormality ( step out) in motor is displayed

- 62. E 8 Engine does not start

- 63. METHOD OF USING TROUBLESHOOTING CHARTS

- 64. S 1 Starting performance is poor ( starting always takes time)

- 65. S 2 Engine does not start

- 66. S 3 Engine does not pick up smoothly ( follow up is poor)

- 67. S 4 Engine stops during operations

- 68. S 5 Engine does not rotate smoothly ( hunting)

- 69. S 6 Engine lacks output ( no power)

- 70. S 7 Exhaust smoke is black ( incomplete combustion)

- 71. S 8 Oil consumption is excessive ( or exhaust smoke is blue)

- 72. S 9 Oil becomes contaminated quickly

- 73. S 10 Fuel consumption is excessive

- 74. S 11 Oil is in cooling water, or water spurts back, or water level goes down

- 75. S 12 Oil pressure caution lamp lights up ( drop in oil pressure)

- 76. S 13 Oil level rises ( water, fuel in oil)

- 77. S 14 Water temperature becomes too high ( overheating)

- 78. S 15 Abnormal noise is made

- 79. S 16 Vibration is excessive

- 80. ELECTRICAL CIRCUIT DIAGRAM FOR C MODE 1/ 2 ELECTRICAL CIRCUIT DIAGRAM FOR C MODE 2/ 2 ELECTRICAL CIRCUIT DIAGRAM FOR F MODE 1/ 2 ELECTRICAL CIRCUIT DIAGRAM FOR F MODE 2/ 2

- 81. PW170ES 6K Serial number K32001 and up PW170ES 6K Serial number K32001 and up INSTALLATION OF OPERATORS CAB ASSEMBLY

- 82. REMOVAL OF COUNTERWEIGHT ASSEMBLY

- 83. INSTALLATION OF COUNTERWEIGHT ASSEMBLY

- 84. PW170ES 6K

- 85. K32001 and up K34001 and up

- 86. CONTENTS

- 87. GENERAL…………………………………………………HelveticaBold

- 88. STRUCTURE AND FUNCTION

- 89. TESTING AND ADJUSTING

- 90. DISASSEMBLY AND ASSEMBLY

- 91. MAINTENANCE STANDARD…………………………………………..

- 92. SAFETY

- 93. FOREWORD

- 94. HOW TO READ THE SHOP MANUAL

- 95. HOISTING INSTRUCTIONS

- 96. COATING MATERIALS

- 97. STANDARD TIGHTENING TORQUE

- 98. ELECTRIC WIRE CODE

- 99. CONVERSION TABLE

- 100. ENGINE RELATED PARTS

- 101. RADIATOR OIL COOLER

- 102. SWING CIRCLE

- 103. SWING MACHINERY UNDERCARRIAGE

- 104. CLUTCH CONTROL CIRCUIT

- 105. AXLE

- 106. SUSPENSION LOCK CYLINDER

- 107. BRAKING TRAIN

- 108. BRAKE PEDAL

- 109. BRAKE PEDAL INCORPORATING BRAKE VALVE

- 110. ACCUMULATOR FOR BRAKE SYSTEM

- 111. STEERING TRAIN

- 112. ITEM

- 113. STEERING COLUMN

- 114. HYDRAULIC CIRCUIT DIAGRAM

- 115. HYDRAULIC CIRCUIT DIAGRAM

- 116. HYDRAULIC TANK

- 117. HYDRAULIC TANK

- 118. HYDRAULIC PUMP

- 119. PPC PUMPLESS SYSTEM

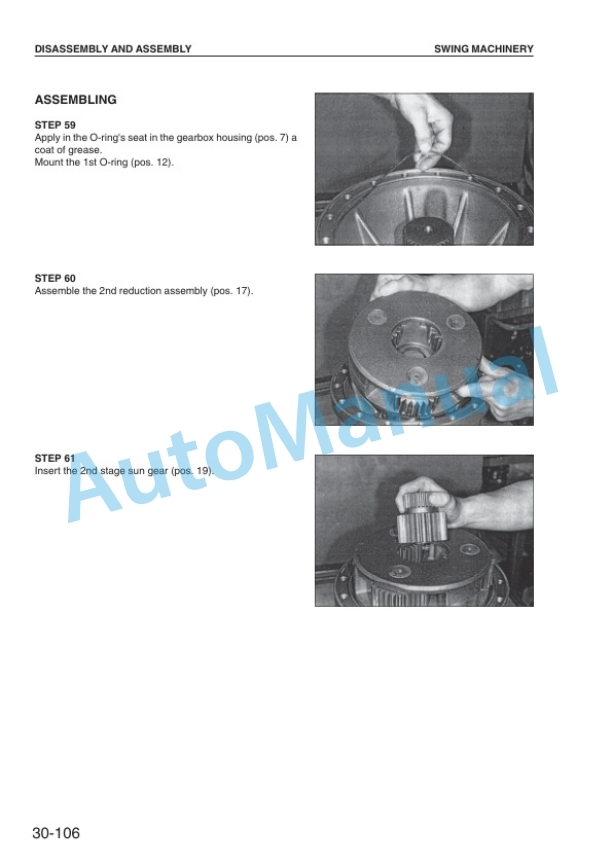

- 120. CONTROL VALVE

- 121. CLSS

- 122. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 123. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 124. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 125. CHECKS BEFORE TROUBLESHOOTING

- 126. CONNECTOR TYPES

- 127. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 128. EXPLANATION OF CONTROL MACHANISM FOR ELECTRICAL SYSTEM

- 129. METHOD OF USING JUDGEMENT TABLE

- 130. METHOD OF USING TROUBLESHOOTING CHARTS

- 131. DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE

- 132. SERVICE CODE TABLE

- 133. POINTS TO REMEMBER WHEN CARRYING OUT TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER SYSTEM

- 134. ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE

- 135. JUDGEMENT TABLE FOR GOVERNOR, PUMP GOVERNOR ( GOVERNOR CONTROL SYSTEM) AND ENGINE RELATED PARTS

- 136. ELECTRICAL CIRCUIT DIAGRAM FOR E MODE 1/ 2

- 137. ELECTRICAL CIRCUIT DIAGRAM FOR E MODE 2/ 2

- 138. E 1 Abnormality in governor, pump controller power source ( controller LED is OFF)

- 139. E 2 E308 Abnormality in fuel control dial input value is displayed

- 140. E 3 E317 Abnormality ( disconnection) in motor drive system is displayed

- 141. E 4 E318 Abnormality ( short circuit) in motor drive system is displayed

- 142. E 5 E306 Abnormality in feedback potentiometer system is displayed

- 143. E 6 E315 Abnormality ( short circuit) in battery relay output system is displayed

- 144. E 7 E316 Abnormality ( step out) in motor is displayed

- 145. E 8 Engine does not start

- 146. METHOD OF USING TROUBLESHOOTING CHARTS

- 147. S 1 Starting performance is poor ( starting always takes time)

- 148. S 2 Engine does not start

- 149. S 3 Engine does not pick up smoothly ( follow up is poor)

- 150. S 4 Engine stops during operations

- 151. S 5 Engine does not rotate smoothly ( hunting)

- 152. S 6 Engine lacks output ( no power)

- 153. S 7 Exhaust smoke is black ( incomplete combustion)

- 154. S 8 Oil consumption is excessive ( or exhaust smoke is blue)

- 155. S 9 Oil becomes contaminated quickly

- 156. S 10 Fuel consumption is excessive

- 157. S 11 Oil is in cooling water, or water spurts back, or water level goes down

- 158. S 12 Oil pressure caution lamp lights up ( drop in oil pressure)

- 159. S 13 Oil level rises ( water, fuel in oil)

- 160. S 14 Water temperature becomes too high ( overheating)

- 161. S 15 Abnormal noise is made

- 162. S 16 Vibration is excessive

- 163. ELECTRICAL CIRCUIT DIAGRAM FOR C MODE 1/ 2 ELECTRICAL CIRCUIT DIAGRAM FOR C MODE 2/ 2 ELECTRICAL CIRCUIT DIAGRAM FOR F MODE 1/ 2 ELECTRICAL CIRCUIT DIAGRAM FOR F MODE 2/ 2

- 164. PW170ES 6K Serial number K32001 and up PW170ES 6K Serial number K32001 and up INSTALLATION OF OPERATORS CAB ASSEMBLY

- 165. REMOVAL OF COUNTERWEIGHT ASSEMBLY

- 166. INSTALLATION OF COUNTERWEIGHT ASSEMBLY

- 167. REMOVAL OF GOVERNOR PUMP CONTROLLER ASSEMBLY

- 168. INSTALLATION OF GOVERNOR, PUMP CONTROLLER ASSEMBLY

- 169. REMOVAL OF MONITOR PANEL ASSEMBLY

- 170. INSTALLATION OF MONITOR PANEL ASSEMBLY

- 171. DISASSEMBLY OF SWING MACHINERY ASSEMBLY ( SPECIAL TOOLS FOR SWING MACHINERY) ( SPECIAL TOOLS FOR SWING MACHINERY) TRANSMISSION

- 172. FRONT AXLE

- 173. REAR AXLE

- 174. ADAPTER WELDING INSTRUCTION ELECTRODE WELDING

- 175. OUTRIGGER CYLINDER

- 176. BLADE CYLINDER

- 177. MAINTENANCE STANDARD

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF