- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PW400MH-6 Material Handler Shop Manual CEBD005600

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBD005600

- Format: PDF

- Size: 15.4MB

- Number of Pages: 662

Category: Komatsu Shop Manual PDF

-

Model List:

- PW400MH-6 Material Handler

- 1. FOREWORD

- 1.1. GENERAL

- 1.2. HOW TO READ THE SHOP MANUAL

- 1.3. HOISTING INSTRUCTIONS

- 1.4. COATING MATERIALS

- 1.5. STANDARD TIGHTENING TORQUE

- 1.6. ELECTRIC WIRE CODE

- 1.7. CONVERSION TABLES

- 2. GENERAL

- 2.1. SPECIFICATIONS AND DRAWING

- 2.2. LIFTING PERFORMANCE

- 2.3. LIFTING CAPACITY

- 2.4. TRANSPORTATION

- 2.5. FUEL COOLANT AND LUBRICANTS

- 2.6. ENGINE OIL SPECIFICATIONS

- 3. STRUCTURE AND FUNCTION

- 3.1. ENGINE COMPONENTS

- 3.2. SWING CIRCLE

- 3.3. SWING MACHINERY

- 3.4. HYDRAULIC PIPING DRAWING

- 3.5. HYDRULIC PIPING SCHEMATIC

- 3.6. HYDRAULIC TANK AND FILTER

- 3.7. HYDRULIC PUMP

- 3.8. CONTROL VALVE

- 3.9. SELF REDUCING PRESSURE VALVE

- 3.10. SUCTION SAFETY VALVE

- 3.11. CLSS

- 3.12. SWING SYSTEM

- 3.13. VALVE CONTROL

- 3.14. PPC VALVE

- 3.15. PPC ACCUMULATOR

- 3.16. PPC SHUTTLE VALVE VIEW

- 3.17. LSEPC VALVE

- 3.18. SOLENOID VALVE

- 3.19. AIR CONDITIONER

- 3.20. ACTUAL ELECTRICAL WIRING DIAGRAM

- 3.21. ACTUAL ELECTRICAL WIRING DIAGRAM (2/2)

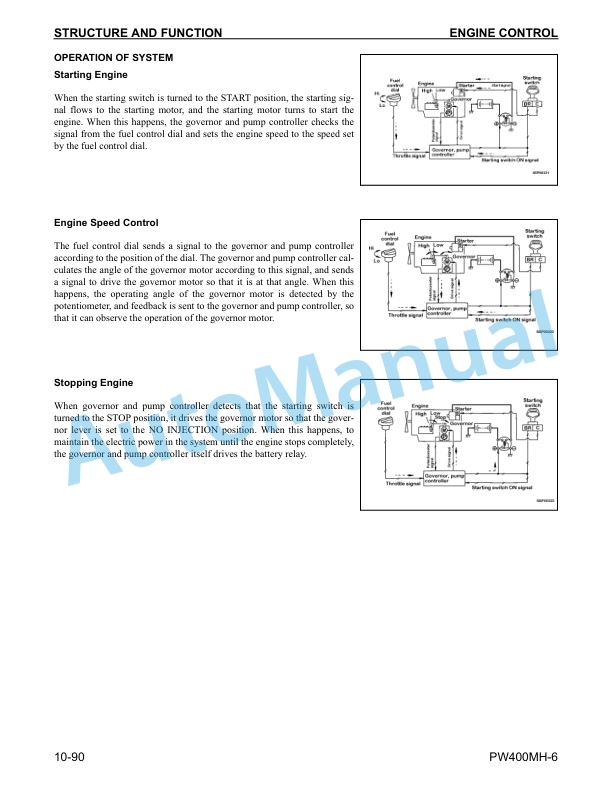

- 3.22. ENGINE CONTROL

- 3.23. ELECTRONIC CONTROL SYSTEM

- 3.24. MACHINE MONITOR SYSTEM

- 3.25. SENSORS

- 4. TESTING, ADJUSTING AND TROUBLESHOOTING

- 4.1. STANDARD VALUE TABLE FOR ENGINE

- 4.2. STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS

- 4.3. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 4.4. SERVICE TOOLS TABLE

- 4.5. ENGINE COMPONENTS

- 4.6. GOVERNOR MOTOR LEVER STROKE

- 4.7. WORK AND SWING EQUIPMENT

- 4.8. TVC VALVE OUTPUT PRESSURE

- 4.9. LS VALVE OUTPUT AND DIFFERENTIAL PRESSURE

- 4.10. CONTROL CIRCUIT OIL PRESSURE

- 4.11. SOLENOID VALVE OUTPUT PRESSURE

- 4.12. PPC VALVE OUTPUT PRESSURE AND SHUTTLE VALVE

- 4.13. WORK EQUIPMENT, SWING PPC VALVE

- 4.14. TRAVEL DEVIATION

- 4.15. LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

- 4.16. MEASURING OIL LEAKAGE

- 4.17. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 4.18. TESTING CLEARANCE OF SWING CIRCLE BEARING

- 4.19. BLEEDING AIR

- 4.20. TROUBLESHOOTING GENERAL

- 4.21. TROUBLESHOOTING ELECTRICAL CONNECTORS

- 4.22. TROUBLESHOOTING COMMUNICATION SYSTEM (NMODE)

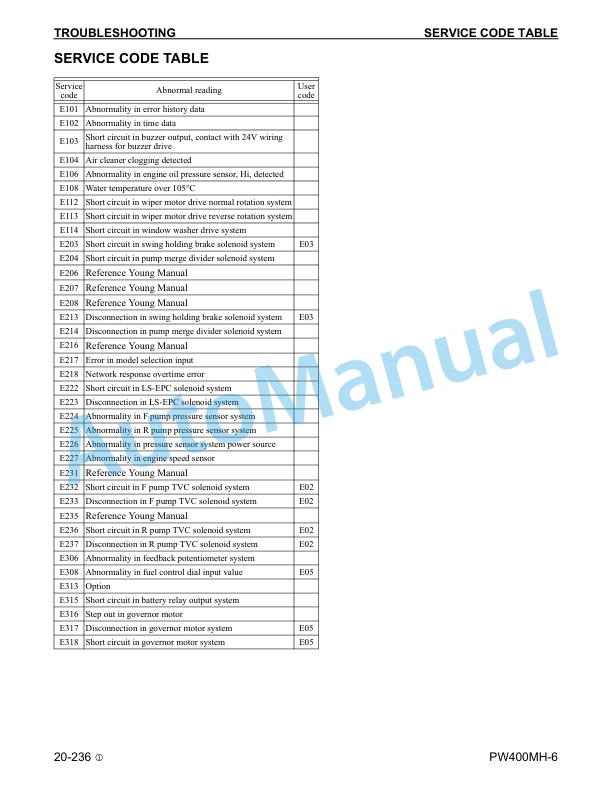

- 4.23. TROUBLESHOTING GOVERNOR PUMP CONTROLLER AND SYSTEM (EMODE)

- 4.24. TROUBLESHOOTING ENGINE SYSTEM (SMODE)

- 4.25. TROUBLESHOOTING GOVERNOR PUMP AND CONTROL SYSTEM (CMODE)

- 4.26. TROUBLESHOOTING GOVERNOR PUMP CONTROLLER INPUT SIGNAL (FMODE)

- 4.27. TROUBLESHOOTING MACHINE MECHANICAL SYSTEM (HMODE)

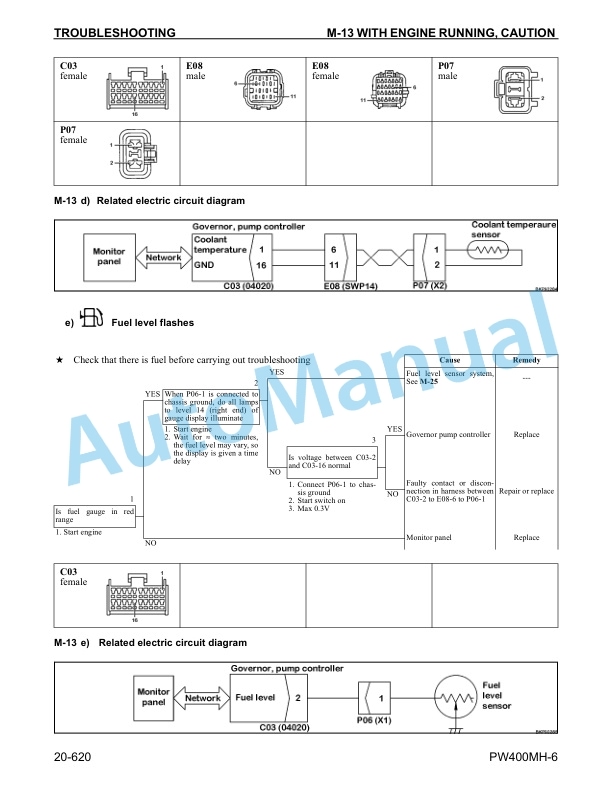

- 4.28. TROUBLESHOOTING MACHINE MONITOR SYSTEM (MMODE)

- 5. DISASSEMBLY AND ASSEMBLY

- 5.1. SPECIAL TOOL LIST

- 5.2. SKETCHES OF SPECIAL TOOLS

- 5.3. ENGINE COMPONENTS

- 5.4. OIL COOLER

- 5.5. RADIATOR, OIL COOLER AND AC CONDENSER

- 5.6. ENGINE WITH MAIN PUMP

- 5.7. CENTER SWIVEL JOINT

- 5.8. SWING MACHINERY

- 5.9. REVOLVING FRAME

- 5.10. SWING CIRCLE

- 5.11. TRAVEL AND CARRIER SYSTEM

- 5.12. WORK SYSTEM

- 5.13. MAIN PUMP

- 5.14. DISASSEMBLY

- 5.15. ASSEMBLY

- 5.16. MAIN PUMP OIL SEAL

- 5.17. PUMP MERGE DIVIDER VALVE

- 5.18. PRESSURE COMPENSATION VALVE

- 5.19. FRONT PUMP SERVO VALVE

- 5.20. REAR PUMP SERVO VALVE

- 5.21. LSEPC SOLENOID VALVE

- 5.22. SOLENOID VALVE

- 5.23. WORK EQUIPMENT PPC VALVE

- 5.24. PPC SHUTTLE VALVE

- 5.25. AIR CONDITIONER UNIT

- 5.26. GOVERNOR, PUMP CONTROLLER

- 5.27. MONITOR PANEL

- 5.28. CONTROL STAND CASE

- 6. MAINTENANCE STANDARD

- 6.1. ENGINE MOUNTS

- 6.2. RADIATOR AND OIL COOLER MOUNTINGS (1/2)

- 6.3. RADIATOR AND OIL COOLER MOUNTINGS (2/2)

- 6.4. SWING MACHINERY

- 6.5. SWING CIRCLE

- 6.6. HYDRAULIC PUMP

- 6.7. CONTROL VALVE

- 6.8. SELF REDUCING PRESSURE VALVE

- 6.9. SUCTION SAFETY VALVE

- 6.10. SWING MOTOR

- 6.11. WORK EQUIPMENT SWING PPC VALVE

- 6.12. LSEPC VALVE

- 6.13. SOLENOID VALVE

- 6.14. CENTER SWIVEL JOINT

- 7. OTHERS

- 7.1. HYDRAULIC PIPING DRAWING

- 7.2. HYDRAULIC PIPING SCHEMATIC

- 7.3. DETAILS OF TROUBLESHOOTING, AND TROUBLESHOOTING PROCEDURE

- 7.4. ACTIONS TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS ON MACHINE (PART I)

- 7.5. ACTIONS TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS ON MACHINE (PART II)

- 7.6. JUDGEMENT TABLE FOR GOVERNOR, PUMP CONTROLLER AND ENGINE RELATED PARTS

- 7.7. ELECTRICAL CIRCUIT DIAGRAM FOR (E) MODE

- 7.8. (A) IDLE SPEED IS IRREGULAR

- 7.9. (B) ENGINE SPEED IS HUNTING

- 7.10. ACTIONS TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS ON MACHINE (PART I)

- 7.11. ACTIONS TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS ON MACHINE (PART II)

- 7.12. ACTIONS TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS ON MACHINE (PART III)

- 7.13. ACTIONS TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS ON MACHINE ( PART IV)

- 7.14. JUDGEMENT TABLE FOR GOVERNOR, PUMP CONTROLLER (PUMP CONTROL SYSTEM) AND HYDRAULIC RELATED PARTS

- 7.15. ELECTRIC CIRCUIT DIAGRAM FOR (C) MODE

- 7.16. ELECTRIC CIRCUIT DIAGRAM FOR (F) MODE

- 7.17. TABLE OF FAILURE MODES AND CAUSES (1/2)

- 7.18. TABLE OF FAILURE MODES AND CAUSES (2/2)

- 7.19. ACTIONS TAKEN BY MONITOR WHEN ABNORMALITY OCCURS ON MACHINE

- 7.20. ELECTRICAL CIRCUIT DIAGRAM FOR (M) MODE

- 7.21. RADIATOR AND OIL COOLER MOUNTINGS (1/2)

- 7.22. RADIATOR AND OIL COOLER MOUNTINGS (2/2)

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF