- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PW60-3 Wheel Excavator Shop Manual SEBM020B0303

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM020B0303

- Format: PDF

- Size: 39.0MB

- Number of Pages: 355

Category: Komatsu Shop Manual PDF

-

Model List:

- PW60-3 Wheel Excavator

- 1. COVER

- 2. CONTENTS

- 3. ENGINE

- 3.1. STRUCTURE AND FUNCTION

- 3.1.1. ENGINE CONTROL

- 3.1.2. AUTODECELERATION SYSTEM

- 3.2. TESTING AND ADJUSTING

- 3.2.1. TESTING AND ADJUSTING DATA

- 3.2.2. TESTING AND ADJUSTING TOOL LIST

- 3.2.3. ADJUSTING VALVE CLEARANCE

- 3.2.4. ADJUSTING FUEL INJECTION TIMING

- 3.2.5. MEASURING COMPRESSION PRESSURE

- 3.2.6. MEASURING EXHAUST GAS COLOR

- 3.2.7. MEASURING BLOWBY PRESSURE

- 3.2.8. TESTING AND ADJUSTING FAN BELT TENSION

- 3.3. DISASSEMBLY AND ASSEMBLY

- 3.3.1. ENGINE OIL COOLER

- 3.3.2. FAN AND FAN PULLEY

- 3.3.3. FUEL INJECTION PUMP

- 3.3.4. RADIATOR AND HYDRAULIC OIL COOLER

- 3.3.4.1. REMOVAL

- 3.3.4.2. INSTALLATION

- 3.3.5. ENGINE AND HYDRAULIC PUMP

- 3.4. STRUCTURE AND FUNCTION

- 3.4.1. POWER TRAIN

- 3.4.2. TRAVEL SYSTEM

- 3.4.3. SCHEMATIC OF POWER TRAIN

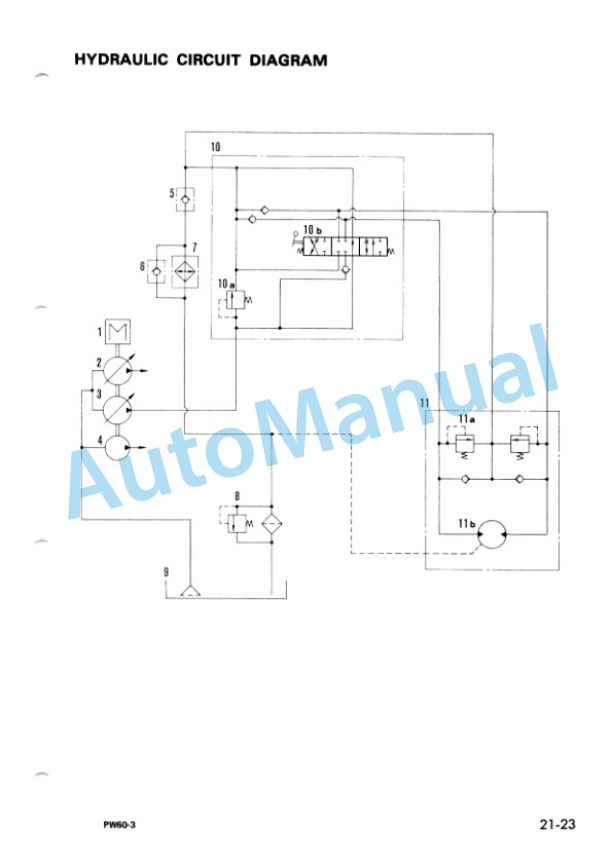

- 3.4.4. HYDRAULIC CIRCUIT DIAGRAM

- 3.4.5. TRAVEL MOTOR

- 3.4.6. CENTER SWIVEL JOINT

- 3.4.7. TRANSMISSION

- 3.4.8. SOLENOID VALVE FOR FORWARDREVERSE SELECTION

- 3.4.9. FORWARDREVERSE SELECTOR LEVER

- 3.4.10. TRAVEL PPC VALVE

- 3.4.11. HIGHLOW SPEED SELECTION CONTROL

- 3.4.12. SWING SYSTEM

- 3.4.13. SCHEMATIC OF SWING SYSTEM

- 3.4.14. HYDRAULIC CIRCUIT DIAGRAM

- 3.4.15. SWING MOTOR AND BRAKE VALVE ASSEMBLY

- 3.4.16. SWING MECHANICAL BRAKE

- 3.4.17. SWING MACHINERY

- 3.4.18. SWING CIRCLE

- 3.5. TESTING AND ADJUSTING

- 3.5.1. ADJUSTING TRAVEL SPEED SELECTOR LEVER

- 3.6. DISASSEMBLY AND ASSEMBLY

- 3.6.1. CENTER SWIVEL JOINT

- 3.6.2. SWING MACHINERY

- 3.7. MAINTENANCE STANDARD

- 3.7.1. TRAVEL BRAKE VALVE

- 3.7.2. TRAVEL SUCTION VALVE

- 3.7.3. TRANSMISSION

- 3.7.4. SWING MACHINERY

- 3.7.5. SWING CIRCLE

- 3.7.6. SWING MOTOR

- 4. STEERING AND BRAKE SYSTEM

- 4.1. STRUCTURE AND FUNCTION

- 4.1.1. STEERING SYSTEM

- 4.1.2. STEERING PUMP

- 4.1.3. SCHEMATIC OF STEERING SYSTEM

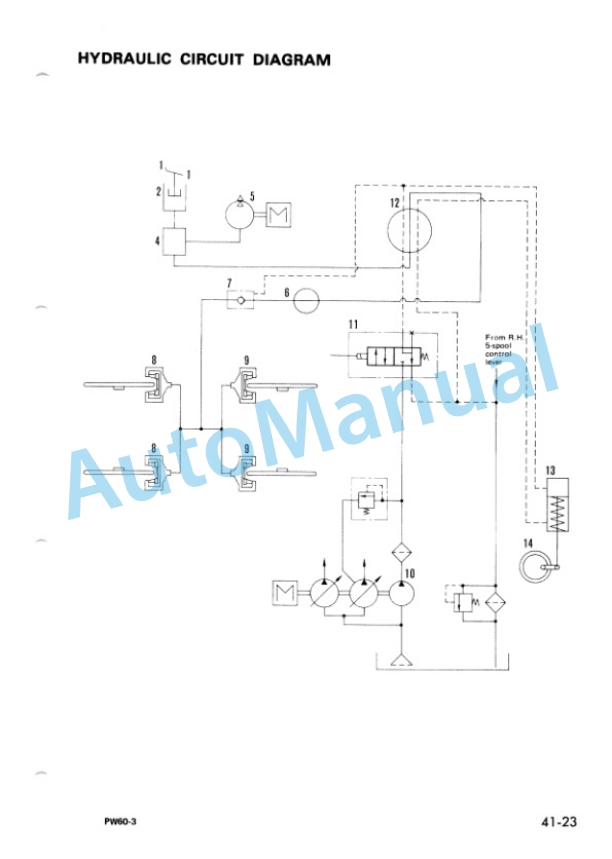

- 4.1.4. HYDRAULIC CIRCUIT DIAGRAM

- 4.1.5. STEERING VALVE AND MAIN RELIEF VALVE

- 4.1.6. STEERING MAIN RELIEF VALVE

- 4.1.7. STEERING VALVE

- 4.1.8. STEERING CYLINDER

- 4.1.9. AXLE

- 4.1.10. DIFFERENTIAL GEAR

- 4.1.11. FINAL DRIVE

- 4.1.12. DRIVE SHAFT

- 4.1.13. WHEEL

- 4.1.14. BRAKE SYSTEM

- 4.1.15. SCHEMATIC OF BRAKE SYSTEM

- 4.1.16. HYDRAULIC CIRCUIT DIAGRAM

- 4.1.17. BRAKE MASTER CYLINDER

- 4.1.18. HYDROMASTER

- 4.1.19. BRAKE SWIVEL JOINT

- 4.1.20. BRAKE LOCK VALVE

- 4.1.21. PARKING BRAKE SELECTOR SOLENOID VALVE

- 4.1.22. WHEEL BRAKE

- 4.1.23. PARKING BRAKE

- 4.1.24. PARKING BRAKE CYLINDER

- 4.1.25. SUSPENSION SYSTEM

- 4.1.26. SCHEMATIC OF SUSPENSION SYSTEM

- 4.1.27. HYDRAULIC CIRCUIT DIAGRAM

- 4.1.28. SUSPENSION LOCK VALVE

- 4.1.29. SUSPENSION LOCK CYLINDER

- 4.2. TESTING AND ADJUSTING

- 4.2.1. TESTING AND ADJUSTING TOEIN

- 4.2.2. ADJUSTING MAXIMUM STEERING ANGLE FOR FRONT AXLE

- 4.2.3. ADJUSTING PARKING BRAKE

- 4.2.4. ADJUSTING PARKING BRAKE ROD

- 4.2.5. BLEEDING AIR FROM BRAKE CIRCUIT

- 4.3. DISASSEMBLY AND ASSEMBLY

- 4.3.1. STEERING PUMP

- 4.3.1.1. REMOVAL

- 4.3.1.2. INSTALLATION

- 4.3.2. STEERING CYLINDER

- 4.3.2.1. REMOVAL

- 4.3.2.2. INSTALLATION

- 4.3.3. FRONT FINAL DRIVE AND HUB

- 4.3.4. SUSPENSION LOCK VALVE

- 4.3.5. SUSPENSION LOCK CYLINDER

- 4.3.5.1. REMOVAL

- 4.3.5.2. INSTALLATION

- 4.3.5.3. DISASSEMBLY

- 4.3.5.4. ASSEMBLY

- 4.4. MAINTENANCE STANDARD

- 4.4.1. STEERING PUMP

- 4.4.2. STEERING CYLINDER

- 4.4.3. DIFFERENTIAL

- 4.4.4. FINAL DRIVE

- 4.4.5. KING PIN AND KNUCKLE AND TIEROD

- 4.4.6. WHEEL BRAKE

- 4.4.7. PARKING BRAKE

- 4.4.8. SUSPENSION LOCK CYLINDER

- 5. HYDRAULIC SYSTEM

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. HYDRAULIC SYSTEM

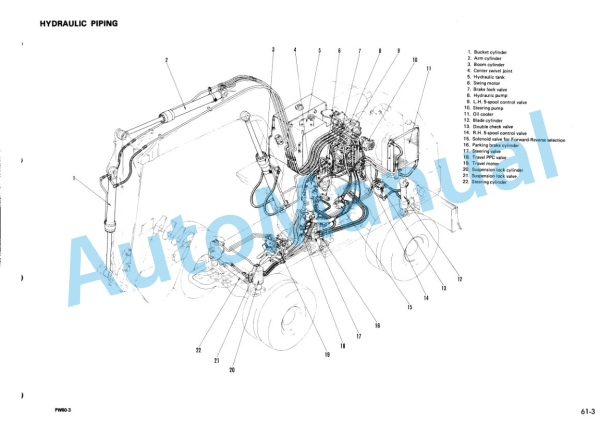

- 5.1.2. HYDRAULIC PIPING

- 5.1.3. SCHEMATIC OF HYDRAULIC SYSTEM

- 5.1.4. HYDRAULIC CIRCUIT DIAGRAM

- 5.1.5. HYDRAULIC TANK AND FUEL TANK

- 5.1.6. HYDRAULIC PUMP

- 5.1.7. PC CONTROL SYSTEM

- 5.1.8. OLSS SYSTEM(IF EQUIPPED)

- 5.1.9. SPOOL CONTROL VALVE

- 5.1.10. SPOOL CONTROL VALVE

- 5.1.11. MAIN RELIEF VALVE

- 5.1.12. WORK EQUIPMENT CONTROL

- 5.1.13. BOOM CONTROL

- 5.1.14. ARM CONTROL

- 5.1.15. BUCKET CONTROL

- 5.1.16. HYDRAULIC CYLINDER

- 5.2. TESTING AND ADJUSTING

- 5.2.1. TABLE OF JUDGEMENT STANDARD VALUE

- 5.2.2. TESTING AND ADJUSTING TOOL LIST

- 5.2.3. TESTING AND ADJUSTING MAIN RELIEF VALVE

- 5.2.4. TESTING AND ADJUSTING CHARGING CIRCUIT PRESSURE

- 5.2.5. MEASURING DELIVERY OF PISTON PUMP

- 5.2.6. MEASURING OIL LEAKAGE FROM SWING AND TRAVEL MOTORS

- 5.2.7. TROUBLESHOOTING

- 5.2.7.1. POSITION OF CONNECTOR FOR TROUBLESHOOTING

- 5.2.7.2. CONNECTION TABLE FOR CONNECTOR PINS

- 5.2.7.3. TROUBLESHOOTING PROCEDURE

- 5.2.7.4. CHECKS BEFORE TROUBLESHOOTING

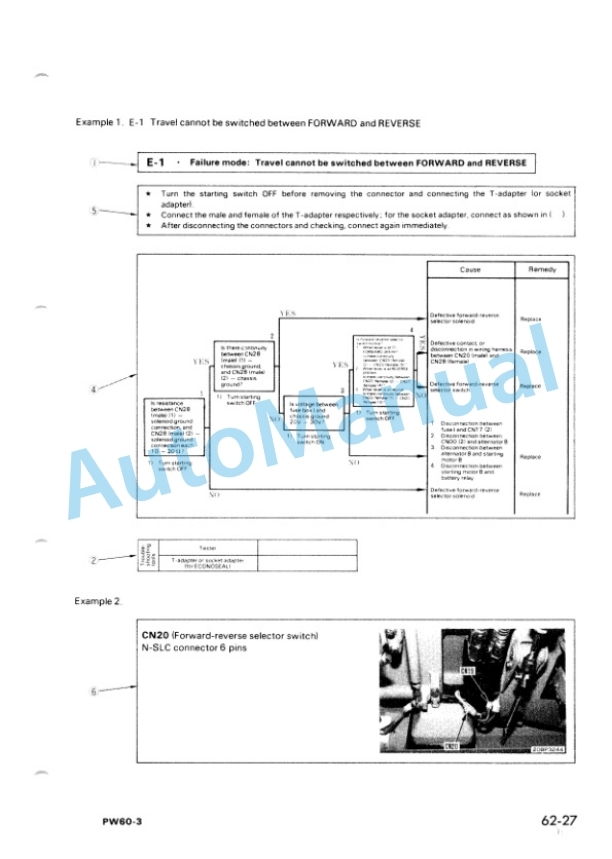

- 5.2.7.5. TROUBLESHOOTING

- 5.3. DISASSEMBLY AND ASSEMBLY

- 5.3.1. HYDRAULIC PUMP INPUT SHAFT OIL SEAL

- 5.3.1.1. REMOVAL

- 5.3.1.2. INSTALLATION

- 5.3.2. SPOOL CONTROL VALVE

- 5.3.2.1. REMOVAL

- 5.3.2.2. INSTALLATION

- 5.3.3. SPOOL CONTROL VALVE

- 5.3.4. BUCKET CYLINDER

- 5.3.5. HYDRAULIC CYLINDER

- 5.3.5.1. DISASSEMBLY

- 5.3.5.2. ASSEMBLY

- 5.4. MAINTENANCE STANDARD

- 5.4.1. SPOOL CONTROL VALVE

- 5.4.2. SPOOL CONTROL VALVE

- 5.4.3. HYDRAULIC CYLINDER

- 5.4.4. CHARGING PUMP

- 6. WORK EQUIPMENT

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. WORK EQUIPMENT

- 6.2. DISASSEMBLY AND ASSEMBLY

- 6.3. MAINTENANCE STANDARD

- 6.3.1. WORK EQUIPMENT

- 7. ELECTRIC AND ELECTRONIC SYSTEM

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. ELECTRICAL SYSTEM

- 7.1.2. ELECTRIC CIRCUIT DIAGRAM

- 7.2. TESTING AND ADJUSTING

- 7.2.1. ELECTRICAL CIRCUIT DIAGRAM

- 7.2.2. TROUBLESHOOTING

- 7.2.2.1. M1 FUEL GAUGE GIVES NO DISPLAY OR GIVES ABNORMAL DISPLAY

- 7.2.2.1.1. DOES NOT DISPLAY

- 7.2.2.1.2. GIVES ABNORMAL DISPLAY

- 7.2.2.2. M2 WATER TEMPERATURE DISPLAY GIVES NO DISPLAY OR GIVES ABNORMAL DISPLAY

- 7.2.2.2.1. DOES NOT DISPLAY

- 7.2.2.2.2. GIVES ABNORMAL DISPLAY

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF