- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu SA12V140Z-1, SAA12V140ZE-2 Series Diesel Engine Shop Manual CEBM002603

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM002603

- Format: PDF

- Size: 6.0MB

- Number of Pages: 286

Category: Komatsu Shop Manual PDF

-

Model List:

- SA12V140Z-1 Series Diesel Engine

- SAA12V140ZE-2 Series Diesel Engine

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATIONS

- 3.2. GENERAL ASSEMBLY DRAWING

- 3.2.1. VIEW FROM LEFT SIDE

- 3.2.2. VIEW FROM RIGHT SIDE

- 3.2.3. VIEW FROM FRONT

- 3.2.4. VIEW FROM REAR

- 3.2.5. VIEW FROM LEFT SIDE (CUSTOM CONNECTIONS)

- 3.2.6. VIEW FROM TOP

- 3.3. ENGINE PERFORMANCE CURVE

- 3.3.1. WA8002LC

- 3.3.2. WA9001LC

- 4. STRUCTURE AND FUNCTION

- 4.1. GENERAL STRUCTURE

- 4.2. INTAKE AND EXHAUST SYSTEM

- 4.2.0.1. ROCKER ARM HOUSING COVER

- 4.2.0.2. FUEL INJECTION NOZZLE

- 4.2.1. MAIN REVOLVING SYSTEM

- 4.2.2. FLYWHEEL AND FLYWHEEL HOUSING

- 4.2.2.1. REAR SEAL

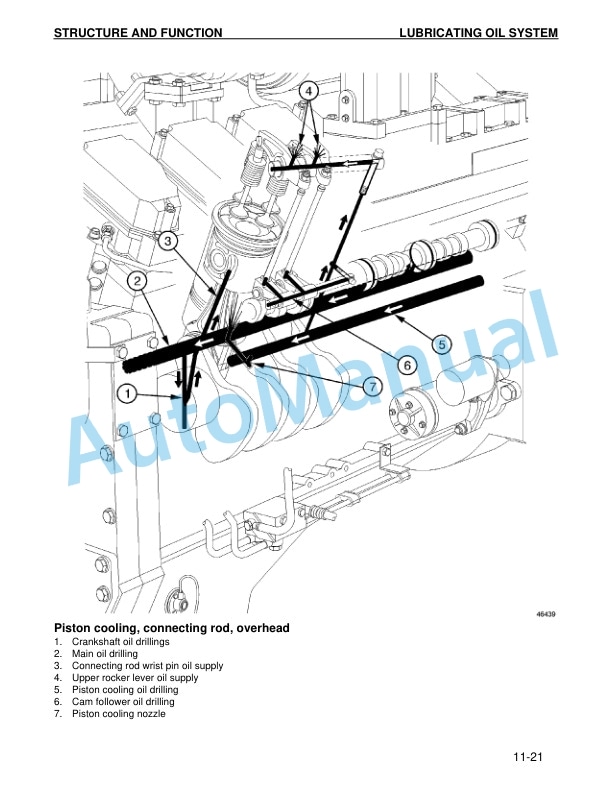

- 4.3. LUBRICATING OIL SYSTEM

- 4.3.1. PISTON COOLING, CONNECTING ROD, OVERHEAD

- 4.3.2. FRONT GEAR TRAIN

- 4.3.3. TURBOCHARGER

- 4.3.4. FULL FLOW LUBRICATING OIL FILTERS

- 4.3.5. LUBRICATING OIL PUMP

- 4.3.5.1. SPECIFICATIONS

- 4.3.6. MAIN RELIEF VALVE

- 4.3.6.1. SPECIFICATIONS

- 4.3.7. OIL COOLER BYPASS VALVE

- 4.3.7.1. SPECIFICATIONS

- 4.3.7.2. REGULATOR VALVE

- 4.3.8. LUBRICATING OIL FILTER

- 4.3.8.1. SPECIFICATIONS

- 4.3.8.2. SAFETY VALVE

- 4.3.9. LUBRICATING OIL BYPASS FILTER

- 4.3.9.1. SPECIFICATIONS

- 4.3.10. LUBRICATING OIL COOLER

- 4.3.10.1. SPECIFICATIONS

- 4.4. FUEL SYSTEM

- 4.4.1. FLOW DIAGRAM

- 4.4.2. FUEL INJECTION PUMP

- 4.4.2.1. SPECIFICATIONS

- 4.4.3. RIGHT BANK PIPING

- 4.4.4. LEFT BANK PIPING

- 4.4.5. FUEL INJECTION NOZZLE

- 4.4.5.1. SPECIFICATIONS

- 4.4.6. FUEL FILTER

- 4.4.6.1. SPECIFICATIONS

- 4.5. COOLING SYSTEM

- 4.5.1. THERMOSTAT HOUSING FLOW

- 4.5.2. COOLING FAN BELT

- 4.5.3. WATER PUMP

- 4.5.3.1. SPECIFICATIONS

- 4.5.4. COOLING FAN

- 4.5.5. CORROSION RESISTOR

- 4.6. ELECTRICAL SYSTEM

- 4.6.1. ALTERNATOR MOUNTING

- 4.6.2. ALTERNATOR WITH REGULATOR

- 4.6.3. STARTING MOTOR

- 4.6.4. ELECTRICAL INTAKE AIR HEATER

- 4.6.4.1. SPECIFICATIONS

- 5. TESTING, ADJUSTING AND TROUBLESHOOTING

- 5.1. ADJUSTING VALVE CLEARANCE

- 5.2. MEASURING COMPRESSION PRESSURE

- 5.3. FUEL SYSTEM

- 5.3.1. FUEL PUMP REMOVAL

- 5.3.2. FUEL PUMP INSTALLATION AND TIMING

- 5.4. CHECKING INJECTION TIMING

- 5.4.1. USING PROXIMITY SENSOR

- 5.4.2. USING FUEL PUMP LOCK PIN

- 5.5. SENSOR INSTALLATION

- 5.5.1. SPEED SENSOR

- 5.5.2. TIMING SENSOR (WITH FLYWHEEL TIMING HOLES)

- 5.5.3. D DESIGN (FLYWHEEL TIMING LUGS)

- 5.6. FUEL OVERFLOW VALVE PRESSURE

- 5.7. ADJUSTING FUEL INJECTION PRESSURE

- 5.8. PERFORMANCE TEST

- 5.8.1. ENGINE TESTING

- 5.8.1.1. IN SERVICE RUN

- 5.8.1.2. ENGINE DYNAMOMETER RUNIN

- 5.8.1.3. PORTABLE DYNAMOMETER OR LOAD BANK RUNIN

- 5.8.1.4. INSITE SERVICE TOOL

- 5.8.2. FUEL FLOW MEASUREMEnT

- 5.8.2.1. INSTALLATION

- 5.8.2.2. MEASUREMENT OF FUEL CONSUMPTION RATIO

- 5.8.2.3. SPECIFICATIONS

- 5.8.3. DYNAMOMETER WORKSHEET

- 5.9. ENGINE DYNAMOMETER TESTING

- 5.9.1. SETUP

- 5.9.2. COOLANT PLUMBING

- 5.9.3. GENERAL ENGINE TEST PROCEDURES

- 5.9.4. ENGINE THROTTLE CONTROL

- 5.9.5. TESTING PROCEDURE

- 5.9.5.1. ENGINE SPEED (RPM) WITH A VERIFIED TACHOMETER

- 5.9.5.2. FUEL INLET RESTRICTION

- 5.9.5.3. FUEL DRAIN LINE RESTRICTION

- 5.9.5.4. INTAKE MANIFOLD PRESSURE

- 5.9.5.5. INTAKE AIR RESTRICTION

- 5.9.5.6. EXHAUST RESTRICTION

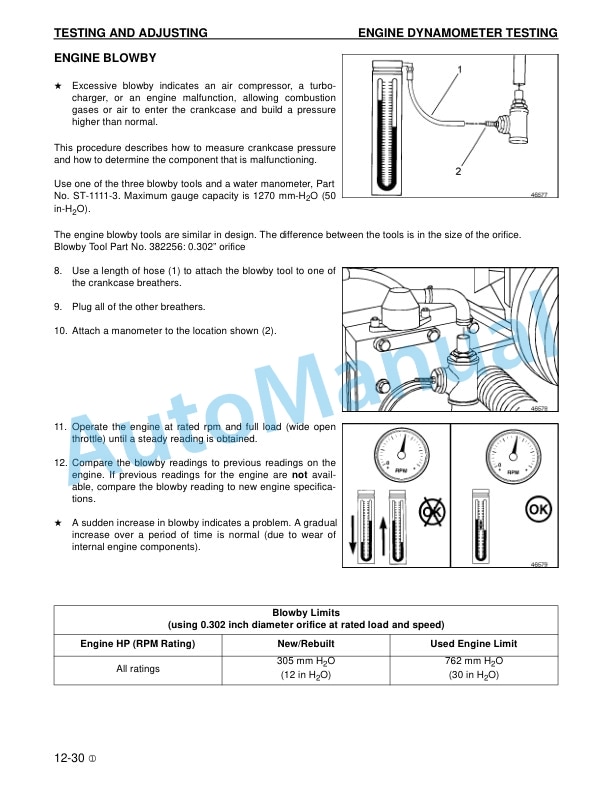

- 5.9.5.7. ENGINE BLOWBY

- 5.9.5.8. LUBRICATING OIL PRESSURE

- 5.9.5.9. COOLANT PRESSURE

- 5.9.5.10. LUBRICATING OIL TEMPERATURE

- 5.9.5.11. AIR COMPRESSOR

- 5.9.5.12. STARTING MOTOR

- 5.9.6. ENGINE RUNIN INSTRUCTIONS

- 5.9.6.1. TEST LOAD

- 5.10. TESTING AND ADJUSTING TOOL LIST

- 5.11. COOLING SYSTEM

- 5.11.1. CHECKING FAN BELT TENSION

- 5.11.1.2. WA800/WA900

- 5.12. ALTERNATOR BELT

- 5.12.1. CHECKING BELT TENSION

- 5.12.2. ADJUSTING BELT TENSION

- 5.12.3. DRIVE BELT TENSION

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. DISASSEMBLY

- 6.1.1. SPECIAL TOOLS

- 6.1.2. WASHING

- 6.1.3. SETTING ENGINE STAND

- 6.1.4. GENERAL DISASSEMBLY

- 6.1.4.1. ENGINE COOLING WATER AND ENGINE OIL

- 6.1.4.2. MUFFLES ASSEMBLY

- 6.1.4.4. AIR COMPRESSOR ASSEMBLY

- 6.1.4.5. FUEL PUMP DRIVE ASSEMBLY

- 6.1.4.6. WATER PUMP ASSEMBLY

- 6.1.4.7. BREATHER

- 6.1.4.8. OIL COOLER ASSEMBLY

- 6.1.4.9. ROCKER LEVER COVER

- 6.1.4.10. ROCKER LEVER

- 6.1.4.11. CYLINDER HEAD ASSEMBLY

- 6.1.4.12. CAM FOLLOWER ASSEMBLY

- 6.1.4.13. THERMOSTAT HOUSING

- 6.1.4.14. ACCESSORY DRIVE ASSEMBLY

- 6.1.4.15. DAMPER, CRANKSHAFT PULLEY ASSEMBLY

- 6.1.4.16. OIL PAN

- 6.1.4.17. MAIN RELIEF VALVE, SUCTION TUBE

- 6.1.5. WASHING CYLINDER BLOCK

- 6.1.6. WASHING CRANKSHAFT

- 6.1.7. WASHING CONNECTING ROD

- 6.2. MEASURING PARTS

- 6.2.1. MEASURING CURVATURE OF CRANKSHAFT

- 6.2.2. MEASURING OUTSIDE DIAMETER OF JOURNAL

- 6.2.3. MEASURING OUTOFROUNDNESS OF JOURNAL

- 6.2.4. MEASURING SURFACE ROUGHNESS OF OUTSIDE DIAMETER OF JOURNAL

- 6.2.5. DIAMETER OF JOURNAL

- 6.2.6. MEASURING DEPTH OF CYLINDER LINER COUNTERBORE

- 6.2.7. MEASURING MAIN BEARING BORE

- 6.2.8. MEASURING CURVATURE OF CAMSHAFT

- 6.2.9. MEASURING OUTSIDE DIAMETER OF JOURNAL

- 6.2.10. MEASURING HEIGHT OF CAM

- 6.2.11. MEASURING PISTON RING GROOVE

- 6.2.11.1. SPECIAL TOOLS

- 6.2.12. MEASURING PISTON RING END GAP

- 6.2.13. MEASURING OUTSIDE DIAMETER OF PISTON

- 6.2.14. MEASURING LENGHT OF CONNECTING ROD

- 6.2.15. MEASURING INSIDE DIAMTER AT SMALL END OF CONNECTING ROD

- 6.2.16. MEASURING INSIDE DIAMETER AT BIG END OF CONNECTING ROD

- 6.2.17. MEASURING CURVATURE, TWISTING OF CONNECTING ROD

- 6.2.18. STANDARD PRESSURE FOR PARTS PRESSURE TESTING

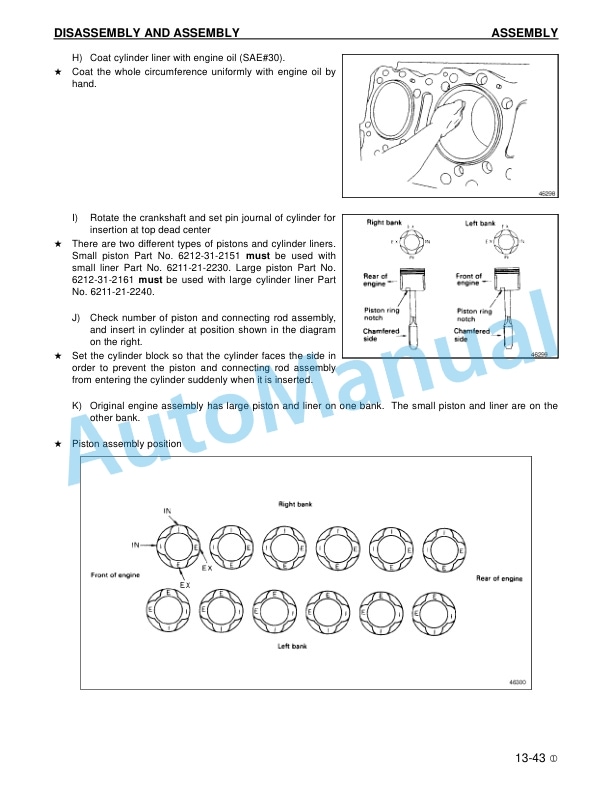

- 6.3. ASSEMBLY

- 6.3.1. TIGHTENING BOLTS BY PLASTIC RANGE TURNING ANGLE METHOD

- 6.3.2. SPECIAL TOOLS

- 6.3.3. PREPARATORY WORK

- 6.3.4. GENERAL ASSEMBLY

- 6.3.4.1. MAIN RELIEF VALVE, SUCTION PIPE

- 6.3.4.2. OIL PAN

- 6.3.4.3. DAMPER, CRANKSHAFT PULLEY ASSEMBLY

- 6.3.4.4. ACCESSORY DRIVE ASSEMBLY

- 6.3.4.5. THERMOSTAT HOUSING

- 6.3.4.6. CAM FOLLOWER ASSEMBLY

- 6.3.4.7. CYLINDER HEAD ASSEMBLY

- 6.3.4.8. ROCKER LEVER

- 6.3.4.9. ROCKER LEVER COVER

- 6.3.4.10. OIL COOLER ASSEMBLY

- 6.3.4.11. BREATHER

- 6.3.4.12. WATER PUMP ASSEMBLY

- 6.3.4.13. FUEL PUMP DRIVE

- 6.3.4.14. AIR COMPRESSOR ASSEMBLY

- 6.3.4.15. FUEL INJECTION PUMP

- 6.3.4.16. EXHAUST MANIFOLD ASSEMBLY

- 6.3.4.17. INTAKE MANIFOLD, AFTERCOOLER ASSEMBLY

- 6.3.4.18. TURBOCHARGER ASSEMBLY

- 6.3.4.19. INTAKE CONNECTOR

- 6.3.4.21. GENERAL ASSEMBLY

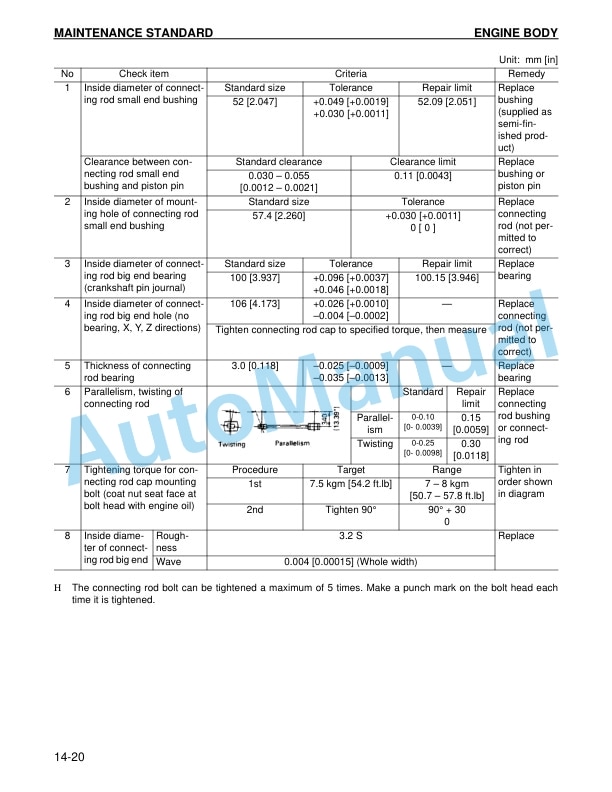

- 7. MAINTENANCE STANDARD

- 7.1. INTAKE AND EXHAUST SYSTEM

- 7.1.1. TURBOCHARGER

- 7.2. ENGINE BODY

- 7.2.1. CYLINDER HEAD

- 7.2.2. VALVE, VALVE SPRING AND VALVE GUIDE

- 7.2.3. ROCKER ARM AND SHAFT

- 7.2.4. CROSSHEAD AND GUIDE

- 7.2.5. CYLINDER BLOCK

- 7.2.6. CYLINDER LINER

- 7.2.7. CRANKSHAFT

- 7.2.8. CAMSHAFT

- 7.2.9. CAM FOLLOWER AND PUSH ROD

- 7.2.10. TIMING GEAR

- 7.2.11. PISTON, PISTON RING AND PISTON PIN

- 7.2.12. CONNECTING ROD

- 7.2.13. FLYWHEEL AND FLYWHEEL HOUSING

- 7.3. LUBRICATION SYSTEM

- 7.3.1. OIL PUMP

- 7.3.2. MAIN RELIEF VALVE

- 7.3.3. OIL COOLER BYPASS VALVE, REGULATOR VALVE

- 7.4. COOLING SYSTEM

- 7.4.1. WATER PUMP

- 7.4.2. THERMOSTAT

- 8. REPAIR AND REPLACEMENT OF PARTS

- 8.1. TABLE OF SPECIAL TOOLS

- 8.2. CYLINDER HEAD

- 8.2.1. CYLINDER AND MOUNTING FACE

- 8.2.2. REPLACING VALVE SEAT

- 8.2.3. PRESSURE TEST OF CYLINDER HEAD

- 8.2.4. REPLACING VALVE GUIDE

- 8.2.5. REPLACING CROSSHEAD GUIDE

- 8.2.6. GRINDING VALVE

- 8.3. CYLINDER BLOCK

- 8.3.1. METHOD OF CHECKING INSIDE DIAMETER OF MAIN BEARING MOUNTING HOLE USING ALIGNMENT BAR

- 8.3.2. CORRECTING CYLINDER BLOCK TOP SURFACE, COUNTERBORE

- 8.3.3. REPLACING MAIN BEARING CAP

- 8.3.4. REPLACING CAM BUSHING

- 8.4. CRANKSHAFT

- 8.4.1. CORRECTING SURFACE ROUGHNESS OF CRANKSHAFT JOURNAL PORTION

- 8.4.2. GRINDING CRANKSHAFT

- 8.4.3. CORRECTING FRONT SEAL CONTACT SURFACE

- 8.4.4. CORRECTING REAR SEAL CONTACT SURFACE

- 8.5. CONNECTING ROD

- 8.5.1. REPLACING CONNECTING ROD SMALL END BUSHING

- 8.5.2. REPLACING CRANKSHAFT GEAR

- 8.5.3. REPLACING CAMSHAFT GEAR

- 8.5.4. REPLACING FLYWHEEL RING GEAR

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF