- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu SK815-5N, SK815-5NA Skid Steer Loader Shop Manual CEBM015901

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM015901

- Format: PDF

- Size: 30.1MB

- Number of Pages: 288

Category: Komatsu Shop Manual PDF

-

Model List:

- SK815-5N Skid Steer Loader

- SK815-5NA Skid Steer Loader

- 0.1. GENERAL

- 0.2. HOW TO READ THE SHOP MANUAL

- 0.2.1. VOLUMES

- 0.2.2. DISTRIBUTION AND UPDATING

- 0.2.3. FILING METHOD

- 0.2.4. REVISED EDITION MARK

- 0.2.5. REVISIONS

- 0.2.6. SYMBOLS

- 0.3. HOISTING INSTRUCTIONS

- 0.3.1. HOISTING

- 0.3.2. WIRE ROPES

- 0.4. PUSH PULL COUPLER

- 0.5. COATING MATERIALS

- 0.6. SPECIFIC DRIVING TORQUE

- 0.7. STANDARD TIGHTENING TORQUE

- 0.7.1. STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS

- 0.7.2. TIGHTENING TORQUE OF HOSE NUTS

- 0.7.3. TIGHTENING TORQUE OF SPLIT FLANGE BOLTS

- 0.7.4. TIGHTENING TORQUE FOR FLARED NUTS

- 0.7.5. TABLE OF TIGHTENING TORQUES FOR ORING BOSS PIPING JOINTS

- 0.7.6. TABLE OF TIGHTENING TORQUES FOR ORING BOSS PLUGS

- 0.7.7. TIGHTENING TORQUE TABLE FOR HOSES (TAPER SEAL TYPE AND FACE SEAL TYPE)

- 0.8. ELECTRIC WIRE CODE

- 0.8.1. CLASSIFICATION BY THICKNESS

- 0.8.2. CLASSIFICATION BY COLOR AND CODE

- 0.9. CONVERSION TABLES

- 0.9.1. METHOD OF USING THE CONVERSION TABLE

- 1. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 1.1.1. Maintenance Standard

- 1.2. POWER TRAIN

- 1.2.1. Maintenance Standard

- 1.3. FINAL DRIVE

- 1.3.1. Maintenance Standard

- 1.3.2. Description

- 1.3.3. Hydraulic Motor

- 1.3.4. Flushing Relief Valve

- 1.3.5. Reduction Gearing

- 1.4. HYDRAULIC PUMP

- 1.4.1. HST Pump LPV40 40 (Standard Flow)

- 1.4.2. HST Pump LPV40 40 (High Flow)

- 1.4.3. HST Pump LPV40 40 (Standard Flow and High Flow)

- 1.4.4. Operation

- 1.4.5. Maintenance Standards

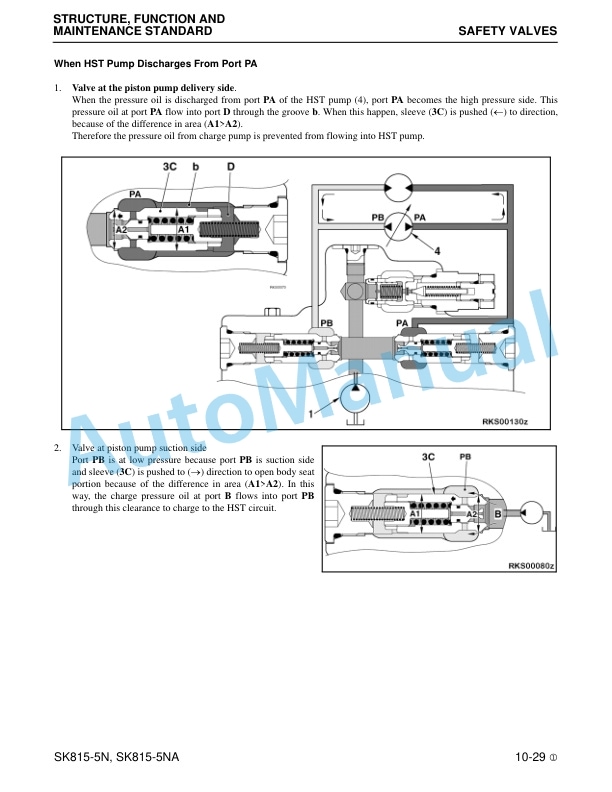

- 1.5. SAFETY VALVES

- 1.5.1. Suction Safety Valve Action

- 1.5.2. Charge Safety Valve Action

- 1.5.3. Charge Pump

- 1.6. ANTI ENGINESTALL VALVE (AS VALVE)

- 1.6.1. Maintenance Standards

- 1.7. CONTROL VALVES

- 1.7.1. Standard 3Spool Valve Port Location

- 1.7.2. Valve Sectional Views

- 1.7.3. Super HighFlow 4Spool Valve Port Location

- 1.7.4. Valve Sectional Views

- 1.7.5. Maintenance Standards

- 1.8. CLSS (CLOSED CENTER LOAD SENSING SYSTEM)

- 1.8.1. Pressure Compensation Control

- 1.8.2. System Series Circuit Operation

- 1.8.3. Self Leveling Function

- 1.8.4. System In SeriesParallel Circuit Operation

- 1.8.5. Pressure Compensation Valve

- 1.8.6. Dividing Function

- 1.9. SOLENOID VALVE

- 1.9.1. Valve Group ST1

- 1.9.2. Valve Group ST2

- 1.10. ACCUMULATOR

- 1.11. PATTERN CHANGE VALVE (OPTIONAL)

- 1.11.1. Operation

- 1.11.2. Maintenance Standards

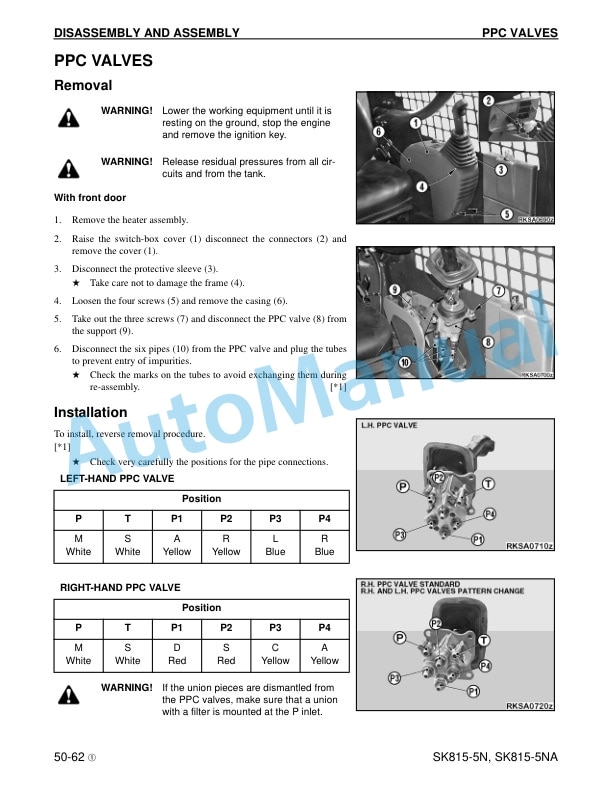

- 1.12. PPC VALVE (STANDARD)

- 1.12.1. Equipment Control

- 1.12.2. Maintenance Standards

- 1.13. PPC VALVE (PATTERN CHANGE) (OPTIONAL)

- 1.13.1. Equipment and Travel Control

- 1.14. PPC VALVE (STANDARD)

- 1.14.1. Travel Control

- 1.14.2. Maintenance Standards

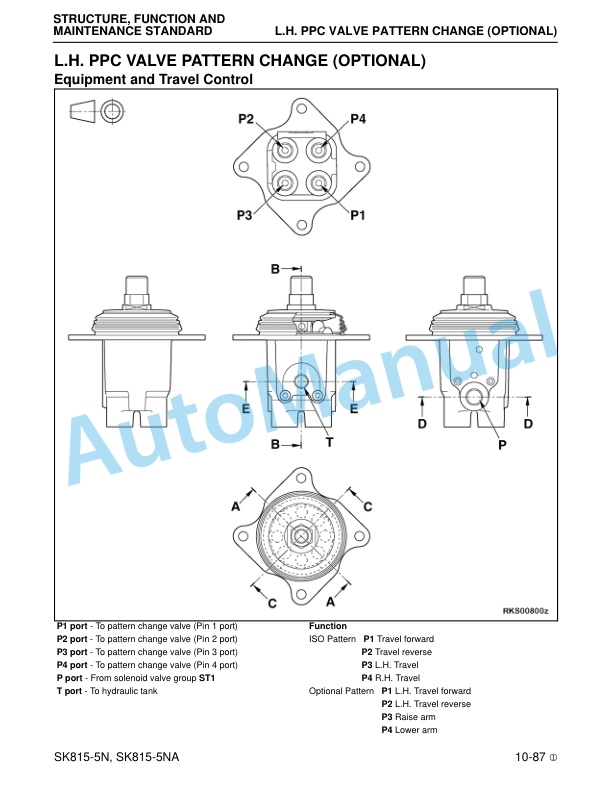

- 1.15. PPC VALVE PATTERN CHANGE (OPTIONAL)

- 1.15.1. Equipment and Travel Control

- 1.15.2. Maintenance Standards

- 1.16. PATTERN CHANGE VALVE (OPTIONAL)

- 1.16.1. Maintenance Standard

- 1.17. CYLINDERS

- 1.17.1. Boom

- 1.17.2. Bucket

- 1.17.3. Maintenance Standards

- 1.18. WORKING EQUIPMENT

- 2. STANDARD VALUE TABLES

- 2.1. STANDARD SERVICE VALUE TABLE

- 2.1.1. Standard Value Table

- 3. TESTING AND ADJUSTING

- 3.1. SPECIAL TOOLS

- 3.2. TADAPTER PROCEDURES AND KITS

- 3.3. ENGINE COMPONENTS

- 3.3.1. Measuring Exhaust Smoke

- 3.3.2. Measuring Exhaust Temperature

- 3.3.3. Measuring Crankcase Pressure

- 3.3.4. Measuring Boost Pressure

- 3.3.5. Measuring Fuel Pressure

- 3.3.6. Bleeding Air From Fuel System

- 3.3.7. Adjusting Engine Stop Solenoid

- 3.3.8. Checking The Engine Speed

- 3.3.9. Adjusting Valve Clearance (SK8155NA)

- 3.3.10. Adjusting Valve Clearance (SK8155N)

- 3.3.11. Measuring Compression Pressure (SK8155NA)

- 3.3.12. Measuring Compression Pressure (SK8155N)

- 3.3.13. Control and Adjustment of Fan Belt Tension

- 3.3.14. Control and Adjustment of the Injection Timing

- 3.3.15. Checking Engine Oil Pressure

- 3.3.16. Adjusting the Stroke of Accelerator Cables

- 3.4. ADJUSTING PPC VALVE DRIVE PRESSURES

- 3.4.1. Disassembly and Regulation

- 3.4.2. Adjustment of the PPC Valve Clearances

- 3.5. ADJUSTING SERVOCONTROL SAFETY SENSOR

- 3.6. GEAR CHAIN TENSION

- 3.6.1. Test

- 3.6.2. Adjustment

- 3.7. HYDRAULIC CIRCUITS

- 3.8. HYDRAULIC PUMP

- 3.9. VALVE CALIBRATION

- 3.9.1. HST Valve Calibration

- 3.9.2. AS Valve Calibration

- 3.9.3. Travel Deviation Check

- 3.10. CONTROL VALVE

- 3.11. SERVOCONTROL POWER SUPPLY

- 3.12. RELIEVING HYDRAULIC PRESSURE

- 3.12.1. Elimination of Pressures From the Hydraulic Circuits.

- 3.12.2. Elimination of Pressure in the Tank

- 3.12.3. Pressurizing the Tank

- 3.13. BLEEDING HYDRAULIC CIRCUITS

- 3.13.1. Sequence for Bleeding the Air

- 4. DISASSEMBLY AND ASSEMBLY

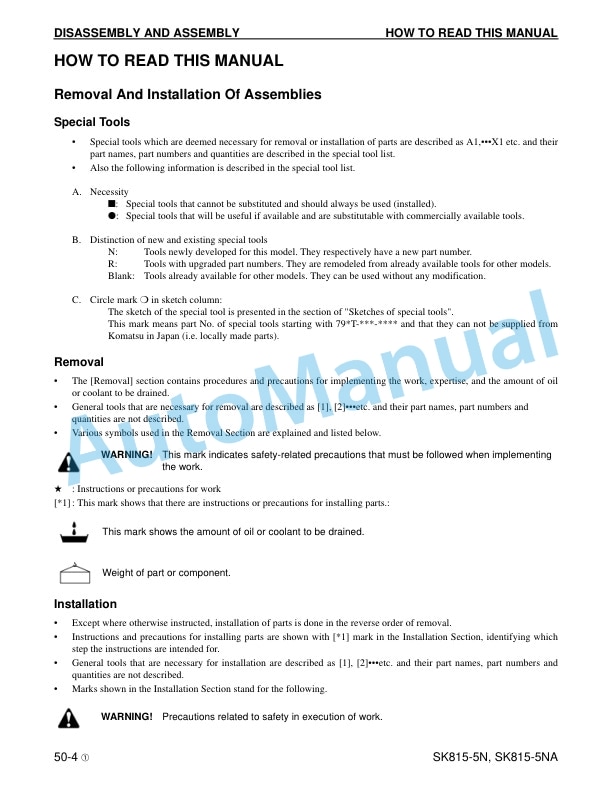

- 4.1. HOW TO READ THIS MANUAL

- 4.1.1. Removal And Installation Of Assemblies

- 4.1.2. Disassembly and Assembly of Assemblies

- 4.2. PRECAUTIONS DURING OPERATION

- 4.2.1. Precautions for Disassembly Operation

- 4.2.2. Precautions for Assembly Operation

- 4.2.3. Precautions for Completing Disassembly and Assembly Operations

- 4.2.4. Other Precautions

- 4.3. CONNECTOR REPAIR PROCEDURES

- 4.3.1. Stripping Insulation

- 4.3.2. Wire Inspection

- 4.3.3. Contact Terminal Removal (HD30 Type)

- 4.3.4. Crimping Contact Terminal (HD30 Type)

- 4.3.5. Insertion Of Contact Terminal (HD30 Type)

- 4.3.6. Contact Terminal Removal (DT Type)

- 4.3.7. Striping Insulation

- 4.3.8. Crimping Contact Terminal (DT Type)

- 4.3.9. Insertion Of Contact Terminal (DT Type)

- 4.4. ENGINE HOOD ASSEMBLY

- 4.4.1. Removal

- 4.4.2. Installation

- 4.5. ENGINE ASSEMBLY

- 4.5.1. Removal

- 4.5.2. Installation

- 4.5.3. Valve Cover (SK8155NA)

- 4.5.4. Valve Cover (SK8155N turbo)

- 4.5.5. Nozzle (SK8155NA)

- 4.5.6. Nozzle (SK8155N turbo)

- 4.5.7. Injector Pump

- 4.5.8. Cylinder Head (SK8155NA)

- 4.5.9. Cylinder Head (SK8155N turbo)

- 4.5.10. Tilting The Cab

- 4.5.11. Lowering The Cab

- 4.5.12. Removing the Cab

- 4.5.13. Installing the Cab

- 4.6. BATTERY

- 4.6.1. Removal

- 4.6.2. Installation

- 4.7. AIR CLEANER ASSEMBLY

- 4.7.1. Removal

- 4.7.2. Installation

- 4.8. MUFFLER (SK8155NA)

- 4.8.1. Removal

- 4.8.2. Installation

- 4.9. MUFFLER (SK8155N turbo)

- 4.9.1. Removal

- 4.9.2. Installation

- 4.10. RADIATOR ASSEMBLY

- 4.11. ENGINE PUMP COUPLING

- 4.12. FINAL DRIVE ASSEMBLY

- 4.12.1. Removal

- 4.12.2. Installation

- 4.13. CYLINDER ASSEMBLIES

- 4.13.1. Lift Cylinder Assembly

- 4.13.2. Bucket Cylinder Assembly

- 4.13.3. Disassembly of Cylinders

- 4.13.4. Assembly of the Cylinders

- 4.14. WORK EQUIPMENT SYSTEM

- 4.14.1. Removal

- 4.14.2. Installation

- 4.15. WORKING EQUIPMENT SUPPORT FRAME

- 4.15.1. Removal

- 4.15.2. Installation

- 5. DIAGRAMS AND SCHEMATICS

- 5.1. ELECTRICAL DIAGRAMS

- 5.1.1. Engine Line (1/2)

- 5.1.2. Engine Line (2/2)

- 5.1.3. Frame Line Standard (1/2)

- 5.1.4. Frame Line Standard (2/2)

- 5.1.5. Frame Line Optional (1/2)

- 5.1.6. Frame Line Optional (2/2)

- 5.1.7. Cabin Line Standard (1/4)

- 5.1.8. Cabin Line Standard (2/4)

- 5.1.9. Cabin Line Standard (3/4)

- 5.1.10. Cabin Line Standard (4/4)

- 5.1.11. Cabin Line Optional (1/6)

- 5.1.12. Cabin Line Optional (2/6)

- 5.1.13. Cabin Line Optional (3/6)

- 5.1.14. Cabin Line Optional (4/6)

- 5.1.15. Cabin Line Optional (5/6)

- 5.1.16. Cabin Line Optional (6/6)

- 5.1.17. TopCabin Light Line Standard (1/2)

- 5.1.18. TopCabin Light Line Standard (2/2)

- 5.1.19. TopCabin Light Line Homologation (1/2)

- 5.1.20. TopCabin Light Line Homologation (2/2)

- 5.2. HYDRAULIC DIAGRAMS

- 5.2.1. Standard

- 5.2.2. HighFlow

- 5.2.3. Road Homologation

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF