- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA200-7 Wheel Loader Operation and Maintenance Manual VENAM29502

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: VENAM29502

- Format: PDF

- Size: 16.6MB

- Number of Pages: 362

-

Model List:

- WA200-7 Wheel Loader

- 1. FOREWORD

- 1.1. BEFORE READING THIS MANUAL

- 1.1.1. EU DIRECTIVES

- 1.2. SAFETY INFORMATION

- 1.2.1. SAFETY LABELS

- 1.3. INTRODUCTION

- 1.3.1. USE OF MACHINE

- 1.3.2. DIRECTIONS OF MACHINE

- 1.3.3. VISIBILITY FOR OPERATOR

- 1.4. PRODUCT INFORMATION

- 1.4.1. PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

- 1.4.2. EPA REGULATIONS, ENGINE NUMBER PLATE

- 1.4.3. ROPS/FOPSCAB SERIAL NO. PLATE

- 1.4.4. AXEL SERIAL NO. PLATE

- 1.4.5. TRANSMISSION SERIAL NO. PLATE

- 1.4.6. SEAT OPERATOR SERIAL NO. PLATE

- 1.4.7. SERVICE METER LOCATION

- 1.4.8. DECLARATION OF CONFORMITY

- 1.4.9. RETROFITTING BY THIRDPARTY SUPPLIERS

- 1.4.10. YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR

- 1.4.11. EXPLANATION OF ACRONYMS

- 1.5. CONTENTS

- 2. SAFETY

- 2.1. SAFETY LABELS

- 2.1.1. LOCATION OF SAFETY LABELS

- 2.1.2. SAFETY LABELS

- 2.2. GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

- 2.2.1. PRECAUTIONS BEFORE STARTING OPERATION

- 2.2.2. PREPARATIONS FOR SAFE OPERATION

- 2.2.3. FIRE PREVENTION

- 2.2.4. PRECAUTIONS WHEN GETTING ON OR OFF MACHINE

- 2.2.5. DO NOT GET CAUGHT IN ARTICULATING PARTS

- 2.2.6. PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES

- 2.2.7. UNAUTHORIZED MODIFICATION

- 2.2.8. PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS

- 2.2.9. PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING

- 2.3. PRECAUTIONS FOR OPERATION

- 2.3.1. PRECAUTIONS FOR JOBSITE

- 2.3.2. STARTING ENGINE

- 2.3.3. OPERATION

- 2.3.4. TRANSPORTATION

- 2.3.5. TOWING

- 2.4. PRECAUTIONS FOR MAINTENANCE

- 2.4.1. PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE

- 2.4.2. PRECAUTIONS FOR INSPECTION AND MAINTENANCE

- 2.4.3. GENERAL VIEW OF MACHINE

- 2.4.4. GENERAL VIEW OF CONTROLS AND GAUGES

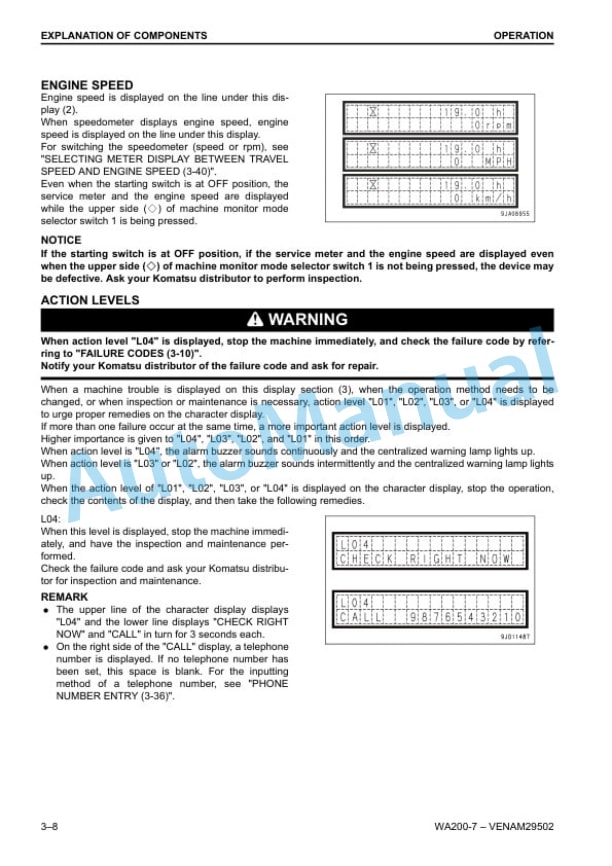

- 2.4.5. MACHINE MONITOR

- 2.5. EXPLANATION OF COMPONENTS

- 2.5.1. MACHINE MONITOR

- 2.5.2. SWITCHES

- 2.5.3. CONTROL LEVERS AND PEDALS

- 2.5.4. CAPS AND COVERS WITH LOCK

- 2.5.5. ASHTRAY

- 2.5.6. FRAME LOCK BAR

- 2.5.7. TOWING PIN

- 2.5.8. GREASE PUMP HOLDER

- 2.5.9. BATTERY DISCONNECT SWITCH

- 2.5.10. SYSTEM OPERATING LAMP

- 2.5.11. BACKUP ALARM

- 2.5.12. OPEN AND CLOSE CAB DOOR

- 2.5.13. OPEN AND CLOSE ENGINE SIDE COVER

- 2.5.14. FUSE

- 2.5.15. SLOW BLOW FUSE

- 2.5.16. AUXILIARY ELECTRIC POWER

- 2.5.17. TOOL BOX

- 2.5.18. HANDLING RADIO

- 2.5.19. HANDLING AIR CONDITIONER

- 2.5.20. HANDLING FRONT WIPER

- 2.5.21. FIRE EXTINGUISHER

- 2.5.22. HANDLING Komatsu Closed Crankcase Ventilation (KCCV)

- 2.5.23. HANDLING MACHINES EQUIPPED WITH KOMTRAX

- 2.5.24. AUTOGREASING SYSTEM

- 2.6. MACHINE OPERATIONS AND CONTROLS

- 2.6.1. CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE

- 2.6.2. STARTING ENGINE

- 2.6.3. CHECKS AFTER STARTING ENGINE

- 2.6.4. STOPPING ENGINE

- 2.6.5. MACHINE OPERATION

- 2.6.6. STEERING MACHINE

- 2.6.7. WORK EQUIPMENT CONTROLS AND OPERATIONS

- 2.6.8. HANDLING HYDRAULIC TYPE QUICK COUPLER

- 2.6.9. RECOMMENDED APPLICATIONS

- 2.6.10. RULES FOR OPERATION

- 2.6.11. ADJUST WORK EQUIPMENT POSTURE

- 2.6.12. BUCKET LEVEL INDICATOR

- 2.6.13. PARKING MACHINE

- 2.6.14. CHECK AFTER FINISHING WORK

- 2.6.15. LOCKING

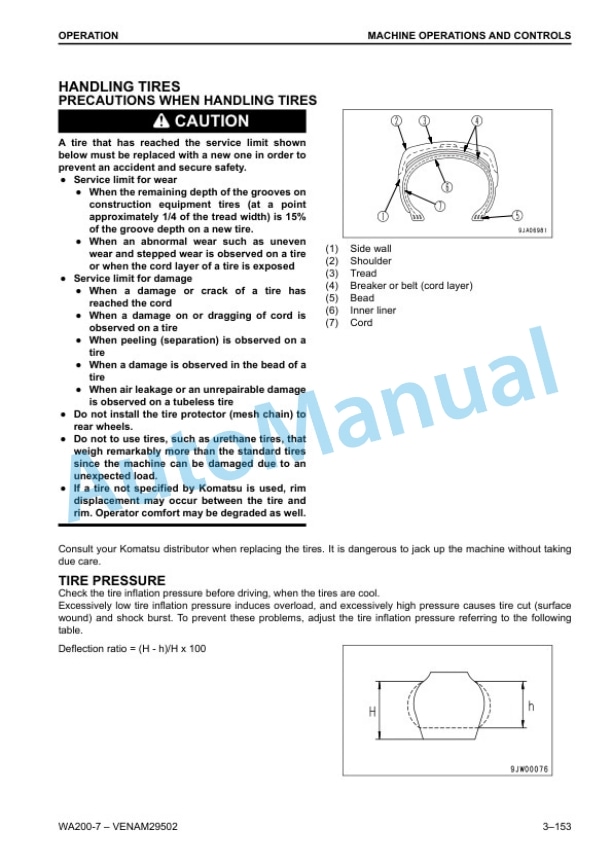

- 2.6.16. HANDLING TIRES

- 2.7. TRANSPORTATION

- 2.7.1. TRANSPORTATION PROCEDURE

- 2.7.2. LOADING AND UNLOADING WITH TRAILER

- 2.7.3. LIFTING MACHINE

- 2.8. COLD WEATHER OPERATION

- 2.8.1. COLD WEATHER OPERATION INFORMATION

- 2.8.2. AFTER DAILY WORK COMPLETION

- 2.8.3. IN COLD AREAS

- 2.8.4. AFTER COLD WEATHER SEASON

- 2.9. LONGTERM STORAGE

- 2.9.1. BEFORE STORAGE

- 2.9.2. DURING STORAGE

- 2.9.3. AFTER STORAGE

- 2.9.4. STARTING MACHINE AFTER LONGTERM STORAGE

- 2.10. TROUBLES AND ACTIONS

- 2.10.1. RUNNING OUT OF FUEL

- 2.10.2. TOWING MACHINE

- 2.10.3. DISCHARGED BATTERY

- 2.10.4. OTHER TROUBLE

- 3. MAINTENANCE

- 3.1. RULES FOR MAINTENANCE

- 3.1.1. SERVICE METER READING

- 3.1.2. KOMATSU GENUINE REPLACEMENT PARTS

- 3.1.3. KOMATSU GENUINE LUBRICANTS

- 3.1.4. ALWAYS USE CLEAN WASHER FLUID

- 3.1.5. FRESH AND CLEAN LUBRICANTS

- 3.1.6. CHECK DRAINED OIL AND USED FILTER

- 3.1.7. CAUTION FOR REFILLING OIL OR FUEL

- 3.1.8. WELDING INSTRUCTIONS

- 3.1.9. DO NOT DROP THINGS INSIDE MACHINE

- 3.1.10. DUSTY JOBSITES

- 3.1.11. AVOID MIXING OIL

- 3.1.12. LOCKING INSPECTION COVERS

- 3.1.13. BLEED AIR FROM HYDRAULIC CIRCUIT

- 3.1.14. PRECAUTIONS WHEN INSTALLING HYDRAULIC HOSES

- 3.1.15. CHECKS AFTER INSPECTION AND MAINTENANCE

- 3.1.16. FUEL AND LUBRICANTS TO MATCH THE AMBIENT TEMPERATURE

- 3.1.17. CLOSE ENGINE SIDE COVER SECURELY

- 3.2. OUTLINE OF MAINTENANCE

- 3.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 3.2.2. HANDLING ELECTRICAL COMPONENTS

- 3.3. STANDARD TIGHTENING TORQUE FOR BOLTS AND NUTS

- 3.3.1. TIGHTENING TORQUE LIST

- 3.4. MAINTENANCE SCHEDULE

- 3.4.1. MAINTENANCE SCHEDULE TABLE

- 3.5. MAINTENANCE PROCEDURE

- 3.5.1. EVERY 10 HOURS MAINTENANCE (ONLY FOR THE FIRST 100 HOURS)

- 3.5.2. INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)

- 3.5.3. WHEN REQUIRED

- 3.5.4. CHECKS BEFORE STARTING

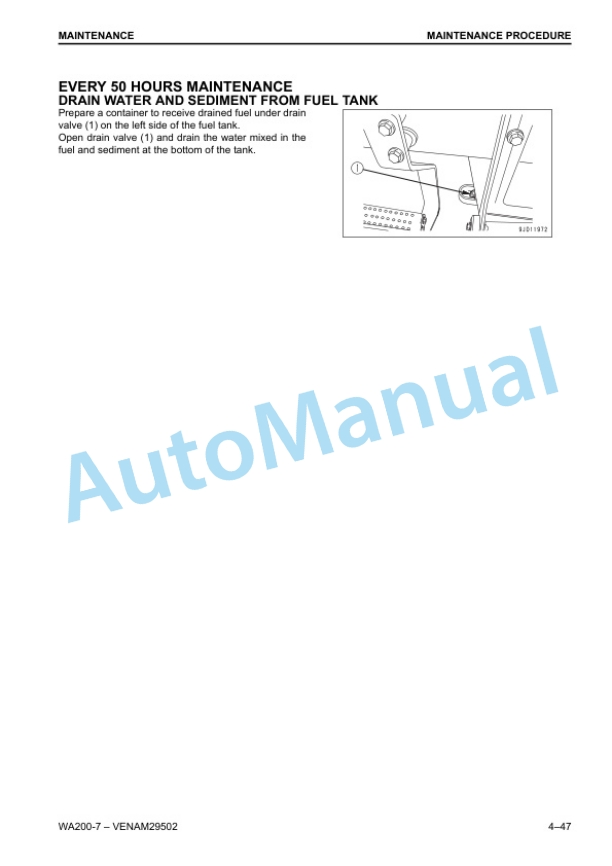

- 3.5.5. EVERY 50 HOURS MAINTENANCE

- 3.5.6. EVERY 100 HOURS MAINTENANCE

- 3.5.7. EVERY 250 HOURS MAINTENANCE

- 3.5.8. EVERY 500 HOURS MAINTENANCE

- 3.5.9. EVERY 1000 HOURS MAINTENANCE

- 3.5.10. EVERY 2000 HOURS MAINTENANCE

- 3.5.11. EVERY 4000 HOURS MAINTENANCE

- 3.5.12. EVERY 8000 HOURS MAINTENANCE

- 4. SPECIFICATIONS

- 4.1. SPECIFICATIONS

- 4.2. NOISE EMISSION LEVELS

- 4.3. VIBRATION LEVEL

- 5. ATTACHMENTS AND OPTIONS

- 5.1. TIRE AND BUCKET SELECTION

- 5.2. HANDLING FORK

- 5.2.1. EXPLANATION OF COMPONENTS

- 5.2.2. MACHINE OPERATIONS AND CONTROLS

- 5.3. PCS (Proportional Control Switch)

- 5.3.1. DISPLAY OF LIQUID CRYSTAL UNIT

- 5.3.2. SETTING METHOD OF PCS

- 5.4. Rear view camera

- 5.4.1. Safety information

- 5.4.2. Operation of monitor

- 5.4.3. Monitor

- 5.5. Cold area kit

- 5.6. Connecting dimensions and maximum permissible load torque

- 5.6.1. Loader link 41793H1320

- 6. REPLACEMENT PARTS

- 6.1. SAFETY CRITICAL PARTS

- 6.1.1. SAFETY CRITICAL PARTS LIST

- 6.2. CONSUMABLE PARTS

- 6.2.1. CONSUMABLE PARTS LIST

- 6.3. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 6.3.1. LUBRICATION CHART

- 6.3.2. LUBRICANTS TO MATCH THE AMBIENT TEMPERATURE AND RECOMMENDED GENUINE LUBRICANTS

- 6.3.3. RECOMMENDED BRANDS AND QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL

- 7. INDEX

- 7.1. Index

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF