- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA250-3 Parallel Tool Carrier Shop Manual CEBM001801

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM001801

- Format: PDF

- Size: 13.1MB

- Number of Pages: 716

Category: Komatsu Shop Manual PDF

-

Model List:

- WA250-3 Parallel Tool Carrier

- 1. MAIN MENU

- 2. COVER

- 3. CONTENTS

- 4. GENERAL

- 4.1. SPECIFICATION DRAWINGS

- 4.2. SPECIFICATIONS

- 4.3. WEIGHT TABLE

- 4.4. FUEL, COOLANT AND LUBRICANTS

- 4.5. ENGINE OIL SPECIFICATIONS

- 4.6. DIESEL FUEL SPECIFICATIONS

- 4.7. COOLANT SPECIFICATIONS

- 5. STRUCTURE AND FUNCTION

- 5.1. POWER TRAIN

- 5.2. PATH OF POWER TRANSMISSION

- 5.3. TORQUE CONVERTER, TRANSMISSION PIPING

- 5.4. TORQUE CONVERTER, TRANSMISSION HYDRUALIC SYSTEM DIAGRAM

- 5.5. TORQUE CONVERTER, TRANSMISSION HYDRAULIC CIRCUIT DIAGRAM

- 5.6. TORQUE CONVERTER

- 5.7. TORQUE CONVERTER OIL FILTER

- 5.8. TRANSMISSION

- 5.9. TRANSMISSION CONTROL VALVE

- 5.10. DRIVE SHAFT

- 5.11. AXLE

- 5.12. FINAL DRIVE

- 5.13. AXLE MOUNT

- 5.14. CENTER HINGE PIN

- 5.15. STEERING PIPING

- 5.16. STEERING COLUMN

- 5.17. PRIORITY VALVE

- 5.18. STEERING VALVE (ORBITROLL)

- 5.19. STEERING VALVE

- 5.20. WAY RESTRICTOR VALVE

- 5.21. BRAKE PIPING

- 5.22. POWER MASTER CYLINDER

- 5.23. BRAKE

- 5.24. PARKING BRAKE CONTROL

- 5.25. HYDRAULIC PIPING

- 5.26. STEERING, HYDRAULIC PUMP HYDRAULIC SYSTEM DIAGRAM

- 5.27. STEERING, HYDRAULIC PUMP HYDRAULIC CIRCUIT DIAGRAM

- 5.28. WORK EQUIPMENT LEVER LINKAGE

- 5.29. HYDRAULIC TANK

- 5.30. MAIN CONTROL VALVE

- 5.31. WORK EQUIPMENT LINKAGE

- 5.32. BUCKET

- 5.33. BUCKET POSITIONER AND BOOM KICKOUT

- 5.34. ROPS CAB

- 5.35. AIR CONDITIONER/HEATER PIPING

- 5.36. AIR CONDITIONER/HEATER WIRING DIAGRAM (EAGLE)

- 5.37. MACHINE MONITOR SYSTEM

- 5.38. MAIN MONITOR

- 5.39. MAINTENANCE MONITOR DISPLAY FUNCTION

- 5.40. SENSORS AND SWITCHES

- 5.41. ELECTRIC WIRING DIAGRAM (1/4)

- 5.42. ELECTRIC WIRING DIAGRAM (2/4)

- 5.43. ELECTRIC WIRING DIAGRAM (3/4)

- 5.44. ELECTRIC WIRING DIAGRAM (4/4)

- 5.45. ENGINE STARTING CIRCUIT

- 5.46. ENGINE STOP CIRCUIT

- 5.47. AUTOMATIC PREHEATING CIRCUIT (Q.H.S. CIRCUIT)

- 5.48. ELECTRICAL TRANSMISSION CONTROL

- 5.49. COMBINATION SWITCH

- 5.50. TRANSMISSION CUTOFF FUNCTION

- 5.51. PARKING BRAKE NEUTRALIZER RELAY FUNCTION

- 5.52. KICK DOWN SWITCH

- 5.53. KICK DOWN ELECTRIC CIRCUIT DIAGRAM

- 5.54. DUMP SPEED SWITCH

- 5.55. QUICK COUPLER SWITCH

- 6. TESTING AND ADJUSTING

- 6.1. STANDARD VALUE TABLE FOR ENGINE

- 6.2. STANDARD VALUE TABLE FOR CHASSIS

- 6.3. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 6.4. SERVICE TOOLS FOR TESTING, ADJUSTING TROUBLESHOOTING

- 6.5. MEASURING ENGINE SPEED

- 6.6. MEASURING ENGINE LUBRICATING OIL PRESSURE

- 6.7. MEASURING FUEL FILTER INLET RESTRICTION

- 6.8. MEASURING BLOWBY PRESSURE

- 6.9. MEASURING COMPRESSION PRESSURE

- 6.10. MEASURING EXHAUST COLOR

- 6.11. MEASURING COOLANT TEMPERATURE

- 6.12. MEASURING AND ADJUSTING VALVE CLEARANCE

- 6.13. MEASURING ACCELERATOR PEDAL

- 6.14. MEASURING SHIFT LEVER

- 6.15. MEASURING STALL SPEEDS

- 6.16. MEASURING TORQUE CONVERTER, TRANSMISSION OIL PRESSURE

- 6.17. METHOD OF OPERATING EMERGENCY MANUAL SPOOL

- 6.18. TESTING AND ADJUSTING STEERING WHEEL

- 6.19. MEASURING STEERING OIL PRESSURE

- 6.20. MEASURING BRAKE PEDAL

- 6.21. TESTING AND ADJUSTING BRAKE PEDAL LINKAGE

- 6.22. MEASURING BRAKE PERFORMANCE

- 6.23. MEASURING BRAKE OIL PRESSURE

- 6.24. MEASURING WEAR OF BRAKE DISC

- 6.25. BLEEDING AIR FROM BRAKE SYSTEM

- 6.26. MEASURING PARKING BRAKE PERFORMANCE

- 6.27. TESTING AND ADJUSTING PARKING BRAKE LINKAGE

- 6.28. TESTING PARKING BRAKE PISTON STROKE

- 6.29. MEASURING WEAR OF PARKING BRAKE DISC

- 6.30. MEASURING AND ADJUSTING WORK EQUIPMENT CONTROL LEVER

- 6.31. MEASURING STROKE OF WORK EQUIPMENT VALVE SPOOL

- 6.32. MEASURING WORK EQUIPMENT HYDRAULIC PRESSURE

- 6.33. MEASURING WORK EQUIPMENT

- 6.34. TESTING AND ADJUSTING BOOM KICKOUT (IF EQUIPPED)

- 6.35. TESTING AND ADJUSTING BUCKET/FORK POSITIONER

- 6.36. ADJUSTING MAIN MONITOR (SPEEDOMETER MODULE)

- 6.37. CHECKING FOR ABNORMALITY IN FUEL LEVEL SENSOR

- 6.38. TROUBLESHOOTING TABLE OF CONTENTS

- 6.38.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 6.38.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

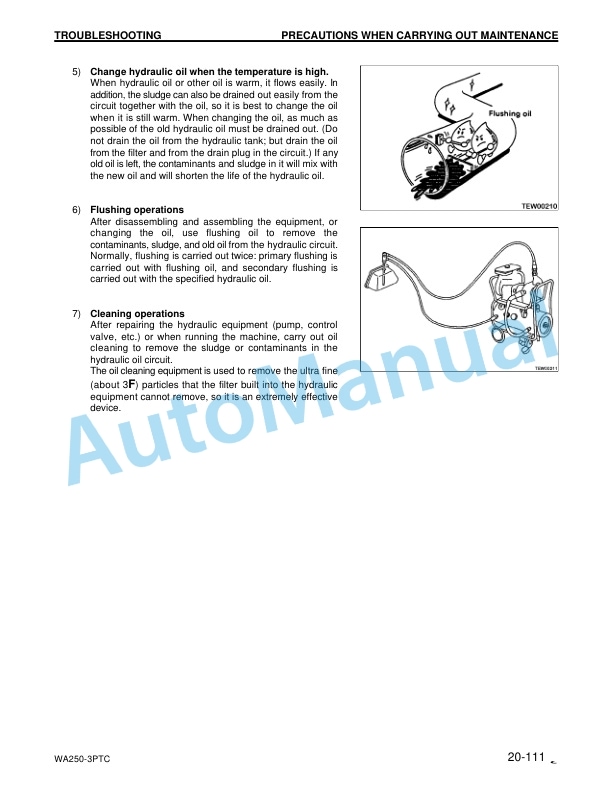

- 6.38.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 6.38.4. CHECKS BEFORE TROUBLESHOOTING

- 6.38.5. JUDGEMENT OF POWER TRAIN

- 6.38.6. PRECAUTIONS WHEN TROUBLESHOOTING

- 6.38.7. PREVENTING RECURRANCE OF TROUBLE

- 6.38.8. METHODS OF USING TORUBLESHOOTING CHARTS

- 6.38.9. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 6.38.10. CONNECTOR PIN ARRANGEMENT DIAGRAM (1/3)

- 6.38.11. CONNECTOR PIN ARRANGEMENT DIAGRAM (2/3)

- 6.38.12. CONNECTOR PIN ARRANGEMENT DIAGRAM (3/3)

- 6.38.13. CONNECTOR TYPE AND PIN IDENTIFICATIONS

- 6.38.14. ELECTRICAL CIRCUIT DIAGRAM

- 6.38.15. PREHEATING SYSTEM

- 6.38.16. TRANSMISSION CONTROL, PARKING BRAKE SYSTEM

- 6.38.17. MACHINE MONITOR SYSTEM

- 6.38.18. ELECTRICAL CIRCUIT DIAGRAM FOR WORK EQUIPMENT

- 6.38.19. TROUBLESHOOTING OF ENGINE SYSTEM (SMODE)

- 6.38.20. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (CHASSIS RELATED) (TMODE)

- 6.38.21. TROUBLESHOOTING OF ELECTRICAL SYSTEM FOR ENGINE TRANSMISSION AND WORK EQUIPMENT (EMODE)

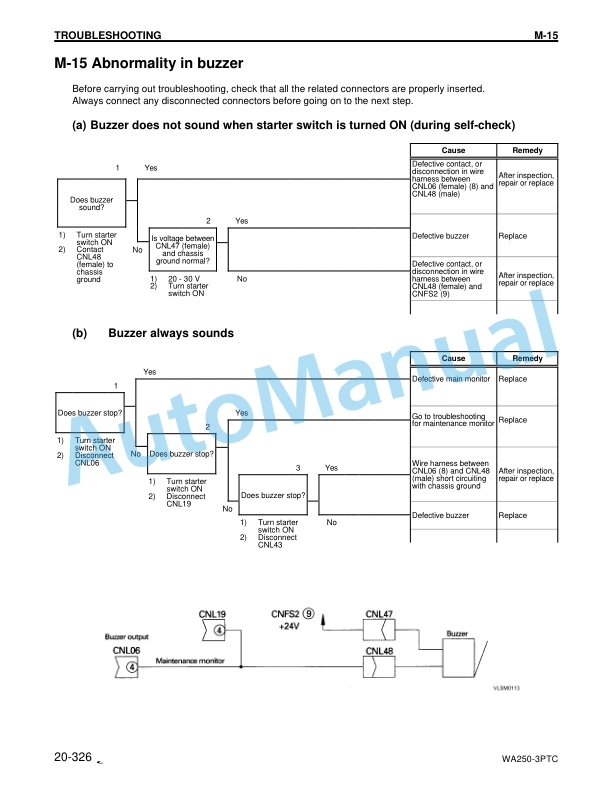

- 6.38.22. TROUBLESHOOTING OF MAIN MONITOR SYSTEM (MMODE)

- 6.38.23. TROUBLESHOOTING OF MAINTENANCE MONITOR SYSTEM (KMODE)

- 6.38.24. TROUBLESHOOTINGEAGLE AIR CONDITIONER

- 7. DISASSEMBLY AND ASSEMBLY

- 7.1. METHOD OF USING MANUAL

- 7.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 7.2.1. PRECAUTIONS WHEN CARRYING OUT REMOVAL WORK

- 7.2.2. PRECAUTIONS WHEN CARRYING OUT INSTALLATION WORK

- 7.2.3. PRECAUTIONS WHEN COMPLETING THE OPERATIONS

- 7.3. SPECIAL TOOL LIST

- 7.4. FUEL INJECTION PUMP

- 7.4.1. REMOVAL

- 7.4.2. INSTALLLATION

- 7.5. ENGINE OIL COOLER

- 7.6. MUFFLER AND AIR CLEANER

- 7.6.1. REMOVAL

- 7.6.2. INSTALLATION

- 7.7. TORQUE CONVERTER CHARGING PUMP

- 7.7.1. REMOVAL

- 7.7.2. INSTALLATION

- 7.8. TORQUE CONVERTER, TRANSMISSION

- 7.8.1. REMOVAL

- 7.8.2. INSTALLATION

- 7.9. TORQUE CONVERTER

- 7.10. TRANSMISSION CLUTCH PACK

- 7.10.1. DISASSEMBLY

- 7.10.2. ASSEMBLY

- 7.11. PARKING BRAKE ASSEMBLY

- 7.11.1. DISASSEMBLY

- 7.11.2. ASSEMBLY

- 7.12. TRANSMISSION CONTROL VALVE

- 7.12.1. REMOVAL

- 7.12.2. INSTALLATION

- 7.12.3. DISASSEMBLY

- 7.12.4. ASSEMBLY

- 7.13. TRANSMISSION SOLENOID VALVE

- 7.13.1. DISASSEMBLY

- 7.13.2. ASSEMBLY

- 7.14. ACCUMULATOR VALVE

- 7.15. CENTER HINGE PIN

- 7.16. MAIN CONTROL VALVE

- 7.16.1. REMOVAL

- 7.16.2. INSTALLATION

- 7.16.3. DISASSEMBLY

- 7.16.4. ASSEMBLY

- 7.17. STEERING CYLINDER

- 7.17.1. REMOVAL

- 7.17.2. INSTALLATION

- 7.18. POWER MASTER CYLINDER

- 7.18.1. REMOVAL

- 7.18.2. INSTALLATION

- 7.18.3. DISASSEMBLY

- 7.18.4. ASSEMBLY

- 7.19. PARKING BRAKE DISC

- 7.20. HYDRAULIC FILTER

- 7.20.1. REMOVAL

- 7.20.2. INSTALLATION

- 7.21. WORK EQUIPMENT, STEERING PUMP

- 7.22. HYDRAULIC CYLINDER

- 7.22.1. DISASSEMBLY

- 7.22.2. ASSEMBLY

- 7.23. BOOM AND PARALLEL TOOL LINKAGE

- 7.24. MAINTENANCE MONITOR ASSEMBLY

- 7.24.1. REMOVAL

- 7.24.2. INSTALLATION

- 8. MAINTENANCE STANDARD

- 8.1. ENGINE MOUNT, TRANSMISSION MOUNT

- 8.2. TORQUE CONVERTER, CHARGING PUMP

- 8.3. TORQUE CONVERTER

- 8.4. TRANSMISSION

- 8.5. TRANSMISSION CONTROL VALVE

- 8.6. ACCUMULATOR VALVE

- 8.7. DRIVE SHAFT

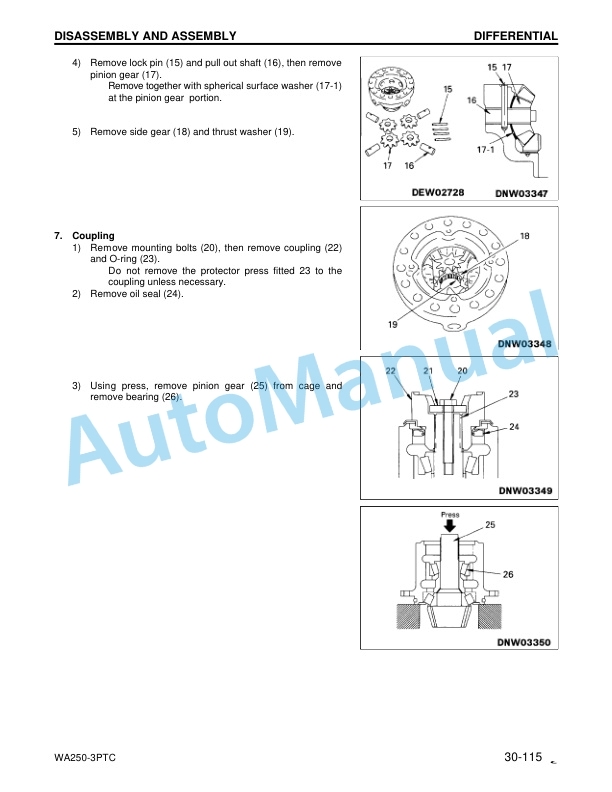

- 8.8. DIFFERENTIAL

- 8.9. FINAL DRIVE

- 8.10. AXLE MOUNT

- 8.11. CENTER HINGE PIN

- 8.12. STEERING COLUMN

- 8.13. PRIORITY VALVE

- 8.14. MASTER CYLINDER

- 8.15. BRAKE

- 8.16. PARKING BRAKE

- 8.17. HYDRAULIC PUMP

- 8.18. MAIN CONTROL VALVE

- 8.19. HYDRAULIC CYLINDER

- 8.20. STEERING CYLINDER MOUNT

- 8.21. WORK EQUIPMENT LINKAGE

- 8.22. BUCKET POSTIONER AND BOOM KICKOUT

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF