- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA250-5L Wheel Loader Operation and Maintenance Manual CEAM011301

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM011301

- Format: PDF

- Size: 3.0MB

- Number of Pages: 227

-

Model List:

- WA250-5L Wheel Loader

- 1. MAIN MENU

- 2. COVER

- 3. INTRODUCTION

- 3.1. FOREWORD

- 3.2. SAFETY INFORMATION

- 3.3. INTRODUCTION

- 3.3.1. DIRECTIONS OF MACHINE

- 3.4. NECESSARY INFORMATION

- 3.4.1. MACHINE SERIAL NO. PLATE

- 3.4.2. ENGINE SERIAL NO. PLATE AND POSITION

- 3.4.3. SERVICE METER POSITION

- 3.4.4. ENTER SERIAL NO. AND DISTRIBUTOR

- 4. TABLE OF CONTENTS

- 5. SAFETY

- 5.1. SAFETY LABELS

- 5.1.1. LOCATION OF SAFETY LABELS

- 5.2. GENERAL PRECAUTIONS

- 5.2.1. SAFETY RULES

- 5.2.2. IF ABNORMALITIES ARE FOUND

- 5.2.3. CLOTHING AND PERSONAL PROTECTIVE ITEMS

- 5.2.4. FIRE EXTINGUISHER AND FIRST AID KIT

- 5.2.5. SAFETY FEATURES

- 5.2.6. KEEP THE MACHINE CLEAN

- 5.2.7. INSIDE OPERATORS COMPARTMENT

- 5.2.8. ALWAYS APPLY LOCK WHEN LEAVING OPERATORS SEAT

- 5.2.9. HANDRAILS AND STEPS

- 5.2.10. MOUNTING AND DISMOUNTING

- 5.2.11. NO PEOPLE ON ATTACHMENTS

- 5.2.12. DO NOT GET CAUGHT IN ARTICULATED PORTION

- 5.2.13. BURN PREVENTION

- 5.2.14. FIRE PREVENTION

- 5.2.15. ACTION IF FIRE OCCURS

- 5.2.16. WINDOW WASHER LIQUID

- 5.2.17. PRECAUTIONS WHEN USING ROPS

- 5.2.18. PRECAUTIONS FOR ATTACHMENTS

- 5.2.19. UNAUTHORIZED MODIFICATION

- 5.2.20. SAFETY AT WORK SITE

- 5.2.21. WORKING ON LOOSE GROUND

- 5.2.22. DO NOT GO CLOSE TO HIGHVOLTAGE CABLES

- 5.2.23. ENSURE GOOD VISIBILITY

- 5.2.24. BE CAREFUL ABOUT EXHAUST FUMES

- 5.2.25. CHECKING SIGNALMANS SIGNALS AND SIGNS

- 5.2.26. EMERGENCY EXIT FROM OPERATORS CAB

- 5.2.27. ASBESTOS DUST HAZARD

- 5.2.28. PRECAUTIONS WHEN STARTING

- 5.2.29. PRECAUTIONS IN COLD AREAS

- 5.3. PRECAUTIONS FOR OPERATION

- 5.3.1. BEFORE STARTING ENGINE

- 5.3.2. CHECKS BEFORE OPERATION

- 5.3.3. PRECAUTIONS BEFORE MOVING FORWARD OR BACK

- 5.3.4. PRECAUTIONS WHEN TRAVELING

- 5.3.5. TRAVELING ON SLOPES

- 5.3.6. PROHIBITED OPERATIONS

- 5.3.7. PRECAUTIONS WHEN OPERATING

- 5.3.8. PARKING MACHINE

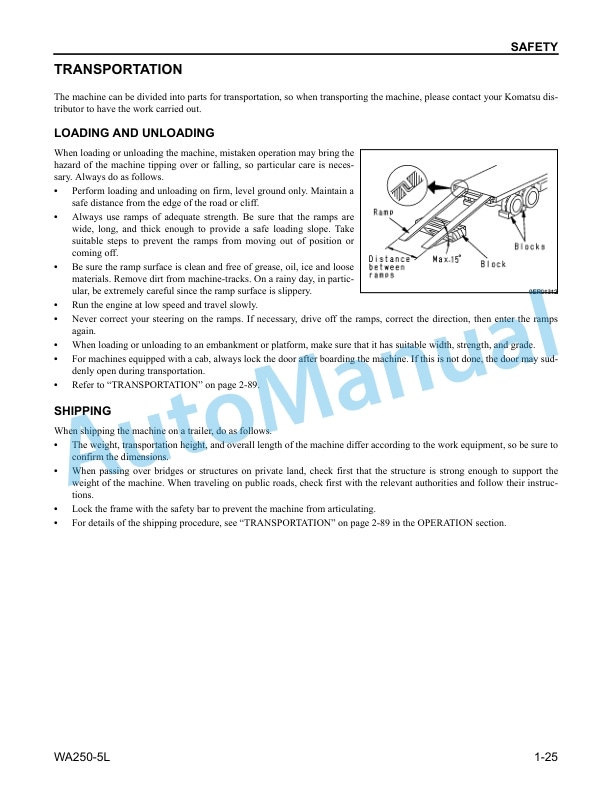

- 5.3.9. TRANSPORTATION

- 5.3.10. BATTERY

- 5.3.11. STARTING WITH BOOSTER CABLES

- 5.3.12. TOWING

- 5.3.13. PRECAUTIONS FOR MAINTENANCE

- 5.3.14. MAINTENANCE WITH ENGINE RUNNING

- 5.3.15. TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING

- 5.3.16. INSPECTION AND MAINTENANCE AFTER TURNING E.C.S.S. SWITCH OFF

- 5.3.17. PROPER TOOLS

- 5.3.18. ACCUMULATOR

- 5.3.19. PERSONNEL

- 5.3.20. ATTACHMENTS

- 5.3.21. WORK UNDER THE MACHINE

- 5.3.22. NOISE

- 5.3.23. PRECAUTIONS WHEN USING HAMMER

- 5.3.24. REPAIR WELDING

- 5.3.25. REMOVING BATTERY TERMINAL

- 5.3.26. PRECAUTIONS WITH HIGHPRESSURE OIL

- 5.3.27. HANDLING HIGHPRESSURE HOSES

- 5.3.28. WASTE MATERIALS

- 5.3.29. MAINTENANCE OF AIR CONDITIONER

- 5.3.30. COMPRESSED AIR

- 5.3.31. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 5.4. PRECAUTIONS WITH TIRES

- 5.4.1. HANDLING TIRES

- 5.4.2. PRECAUTIONS WHEN STORING TIRES

- 6. OPERATION

- 6.1. GENERAL VIEW

- 6.1.1. WA2505L

- 6.1.2. CONTROLS AND GAUGES

- 6.1.3. MACHINE MONITOR

- 6.2. EXPLANATION OF COMPONENTS

- 6.2.1. MACHINE MONITOR

- 6.2.2. MONITOR SYSTEM

- 6.2.3. CHARACTER DISPLAY PORTION

- 6.3. EMERGENCY STOP ITEM

- 6.3.1. BRAKE OIL PRESSURE CAUTION LAMP

- 6.3.2. ENGINE OIL PRESSURE CAUTION LAMP

- 6.3.3. BATTERY CHARGE CIRCUIT CAUTION LAMP

- 6.3.4. STEERING OIL PRESSURE CAUTION LAMP RED

- 6.3.5. CAUTION ITEMS

- 6.3.6. AXLE OIL TEMPERATURE CAUTION LAMP

- 6.3.7. PARKING BRAKE REMINDER CAUTION LAMP

- 6.3.8. HST OIL TEMPERATURE CAUTION LAMP

- 6.3.9. ENGINE COOLING WATER TEMPERATURE CAUTION LAMP

- 6.3.10. FUEL LEVEL CAUTION LAMP

- 6.3.11. WARNING/LIMIT FUNCTIONS FOR TRAVEL SPEED

- 6.3.12. TRAVEL SPEED LIMIT FUNCTION

- 6.3.13. INSPECTION AND MAINTENANCE ITEM

- 6.3.14. RADIATOR COOLANT LEVEL CAUTION LAMP

- 6.3.15. MAINTENANCE CAUTION LAMP

- 6.3.16. HST OIL FILTER CLOG CAUTION LAMP

- 6.3.17. PILOT DISPLAY PORTION

- 6.3.18. PARKING BRAKE PILOT LAMP

- 6.3.19. PREHEATING PILOT LAMP

- 6.3.20. EMERGENCY STEERING PILOT LAMP GREEN

- 6.3.21. DIRECTIONAL LEVER POSITION PILOT LAMP

- 6.3.22. PILOT LAMP FOR SPEED RANGE SELECTOR SWITCH POSITION

- 6.3.23. TURN SIGNAL PILOT LAMP

- 6.3.24. HEAD LAMP HIGH BEAM PILOT LAMP

- 6.3.25. METER DISPLAY PORTION

- 6.3.26. HST OIL TEMPERATURE GAUGE

- 6.3.27. ENGINE COOLANT TEMPERATURE GAUGE

- 6.3.28. FUEL GAUGE

- 6.3.29. SPEEDOMETER

- 6.3.30. METER DISPLAY PILOT LAMP

- 6.3.31. OTHER FUNCTIONS OF MACHINE MONITOR

- 6.3.32. RESET METHOD FOR FILTER, OIL REPLACEMENT TIME

- 6.3.33. SWITCHES

- 6.3.34. CONTROL LEVERS, PEDALS

- 6.3.35. AIR CONDITIONER

- 6.3.36. PRECAUTIONS WHEN USING

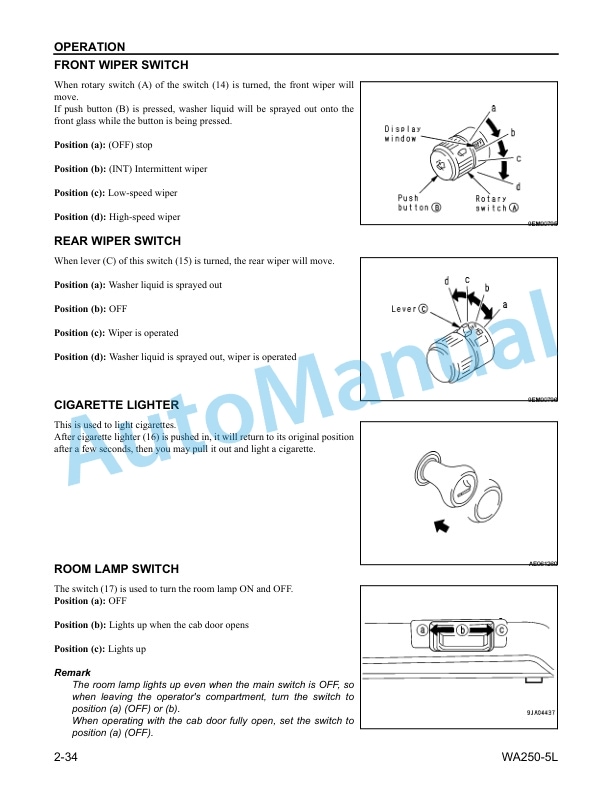

- 6.3.37. HANDLING CAB WIPER

- 6.4. OPERATION

- 6.4.1. CHECK BEFORE STARTING ENGINE, ADJUST

- 6.4.2. CHECK BEFORE STARTING

- 6.4.3. ADJUSTMENT

- 6.4.4. OPERATIONS AND CHECKS BEFORE STARTING ENGINE

- 6.4.5. STOPPING ENGINE

- 6.4.6. MOVING THE MACHINE (DIRECTIONAL, SPEED), STOPPING THE MACHINE

- 6.4.7. OPERATION OF WORK EQUIPMENT

- 6.4.8. WORK POSSIBLE USING WHEEL LOADER

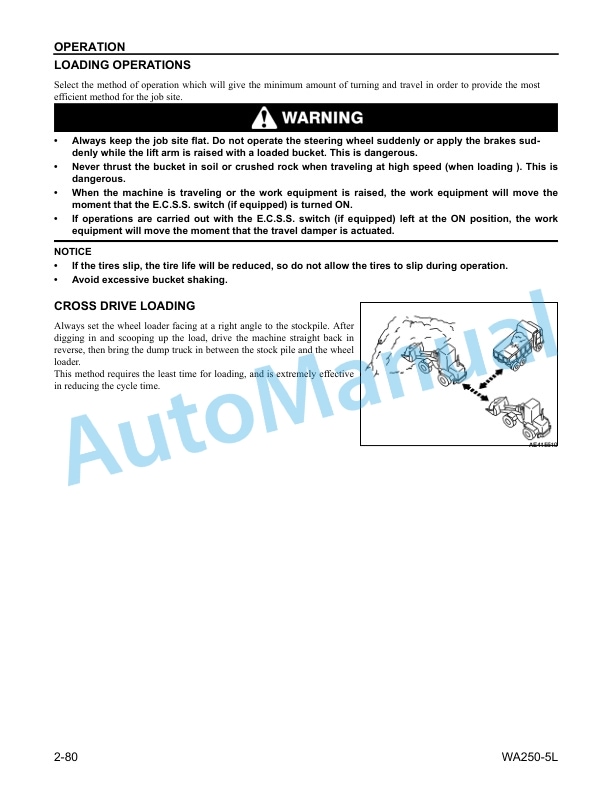

- 6.4.9. PRECAUTIONS FOR OPERATION

- 6.4.10. PRECAUTIONS WHEN DRIVING UP OR DOWN SLOPES

- 6.4.11. HANDLING THE TIRES

- 6.4.12. TRANSPORTATION

- 6.4.13. COLD WEATHER OPERATION

- 6.4.14. LONG TERM STORAGE

- 6.5. TROUBLESHOOTING

- 6.5.1. WHEN MACHINE RUNS OUT OF FUEL

- 6.5.2. TOWING THE MACHINE

- 6.5.3. OTHER TROUBLE

- 7. MAINTENANCE

- 7.1. GUIDES TO MAINTENANCE

- 7.1.1. CHECK SERVICE METER

- 7.1.2. KOMATSU GENUINE REPLACEMENT PARTS

- 7.1.3. KOMATSU GENUINE OILS

- 7.1.4. ALWAYS USE CLEAN WASHER FLUID

- 7.1.5. ALWAYS USE CLEAN OIL AND GREASE

- 7.1.6. CHECKING FOR FOREIGN MATERIALS IN DRAINED OIL AND ON FILTERS

- 7.1.7. FUEL STRAINER

- 7.1.8. WELDING INSTRUCTIONS

- 7.1.9. DO NOT DROP THINGS INSIDE MACHINE

- 7.1.10. DUSTY WORK SITES

- 7.1.11. AVOID MIXING OIL

- 7.1.12. LOCKING INSPECTION COVERS

- 7.1.13. BLEEDING AIR FROM HYDRAULIC CIRCUIT

- 7.1.14. PRECAUTIONS WHEN INSTALLING HYDRAULIC HOSES

- 7.1.15. CHECKS AFTER INSPECTION AND MAINTENANCE

- 7.2. OUTLINES OF SERVICE

- 7.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 7.3. WEAR PARTS

- 7.3.1. WEAR PARTS LIST

- 7.4. FLUID USE ACCORDING TO AMBIENT TEMPERATURE

- 7.4.1. PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS

- 7.4.2. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 7.5. MAINTENANCE SCHEDULE CHART

- 7.5.1. MAINTENANCE SCHEDULE CHART

- 7.6. SERVICE PROCEDURE

- 7.6.1. INITIAL 250 HOURS SERVICE

- 7.6.2. WHEN REQUIRED

- 7.6.3. CHECK BEFORE STARTING

- 7.6.4. EVERY 50 HOURS SERVICE

- 7.6.5. EVERY 100 HOURS SERVICE

- 7.6.6. EVERY 250 HOURS SERVICE

- 7.6.7. EVERY 500 HOURS SERVICE

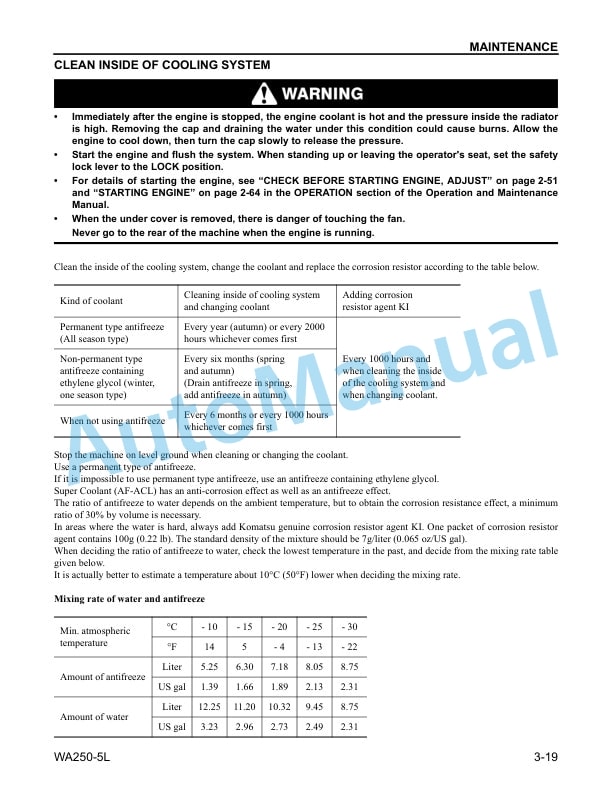

- 7.6.8. EVERY 1000 HOURS SERVICE

- 7.6.9. EVERY 2000 HOURS SERVICE

- 7.6.10. EVERY 4000 HOURS SERVICE

- 8. SPECIFICATIONS

- 8.1. SPECIFICATIONS

- 8.1.1. WA2505L WITH BOLTON CUTTING EDGE

- 9. OPTIONS, ATTACHMENTS

- 9.1. BUCKETS AND TIRES SELECTION

- 9.2. AM/FM RADIOCASSETTE STEREO

- 9.2.1. COMPONENTS

- 9.2.2. METHOD OF OPERATION

- 9.2.3. PRECAUTIONS FOR USE

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF