- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA250PZ-5 Wheel Loader Operation and Maintenance Manual VEAM945100

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: VEAM945100

- Format: PDF

- Size: 8.7MB

- Number of Pages: 261

-

Model List:

- WA250PZ-5 Wheel Loader

- 1. FOREWORD

- 1.1. Foreword

- 1.2. Safety information

- 1.3. Introduction

- 1.3.1. Intended use

- 1.3.2. Directions of machine

- 1.4. Necessary information

- 1.4.1. Machine serial No. plate and position

- 1.4.2. Engine serial No. plate and position

- 1.4.3. ROPS/FOPSCab serial no. plate

- 1.4.4. Axle serial no. plate

- 1.4.5. Transmission serial no. plate

- 1.4.6. Seat operator serial no. plate

- 1.4.7. Position of service meter

- 1.4.8. Table to enter serial No. and distributor

- 1.5. Contents

- 1.6. Dimensions, weights and operating data

- 1.6.1. WA250PZ5 Dimensions, weights and operating data

- 1.7. CEconforming equipment

- 1.7.1. CEconforming equipment (pin on version)

- 1.7.2. CEconforming equipment (quick coupler version)

- 1.7.3. Manufacturersupplied CEconforming equipment, according to document 42193H1900

- 2. SAFETY

- 2.1. Safety labels

- 2.1.1. Location of safety labels

- 2.1.2. Presentation of safety labels

- 2.2. General precautions

- 2.2.1. Safety rules

- 2.3. Precautions for operation

- 2.3.1. Starting engine

- 2.3.2. Operation

- 2.3.3. Transportation

- 2.3.4. Battery

- 2.3.5. Towing

- 2.4. Precautions for maintenance

- 2.4.1. Safety instructions

- 2.5. Precautions with tires

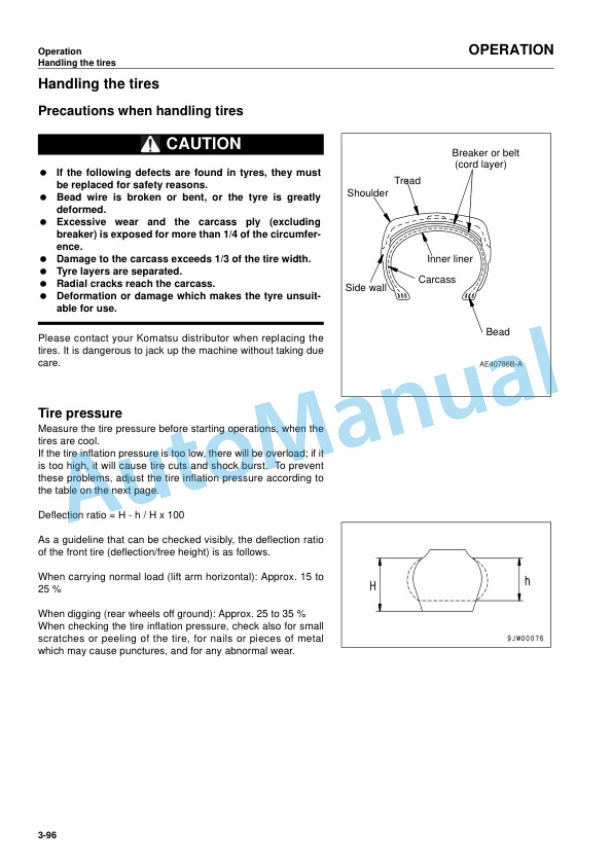

- 2.5.1. Handling tires

- 2.5.2. Precautions when storing tires

- 3. OPERATION

- 3.1. General view

- 3.1.1. General view of machine

- 3.1.2. General view of controls and gauges

- 3.2. Explanation of components

- 3.2.1. Machine monitor

- 3.2.2. Switches

- 3.2.3. Control levers, pedals

- 3.2.4. Steering tilt lock lever

- 3.2.5. Cap and cover with lock

- 3.2.6. Safety bar

- 3.2.7. Towing pin

- 3.2.8. Grease pump

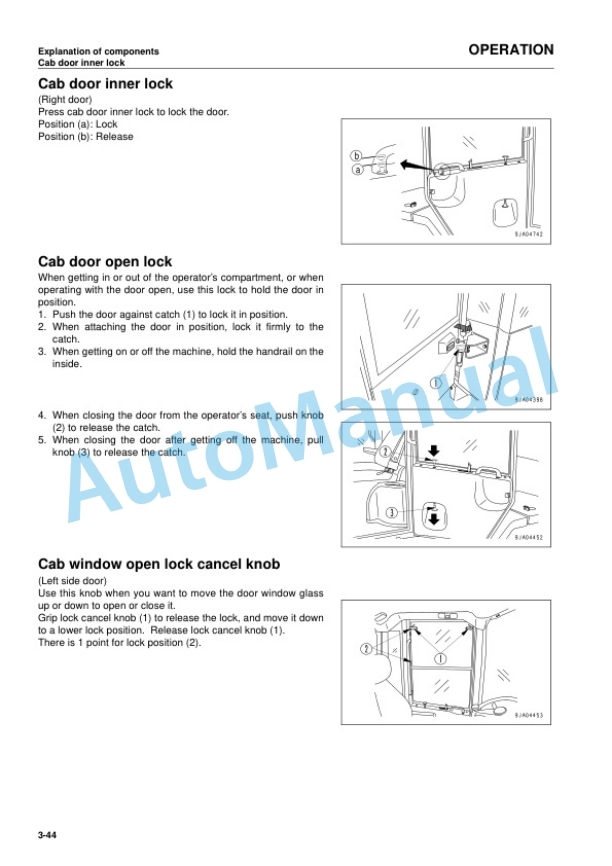

- 3.2.9. Cab door inner lock

- 3.2.10. Cab door open lock

- 3.2.11. Cab window open lock cancel knob

- 3.2.12. Fuse

- 3.2.13. Slow blow fuse

- 3.2.14. Power outlet

- 3.2.15. Air conditioner

- 3.2.16. Handling cab wiper

- 3.3. Operation

- 3.3.1. Check before starting engine, adjust

- 3.3.2. Starting engine

- 3.3.3. Operations and checks after starting engine

- 3.3.4. Stopping engine

- 3.3.5. Moving the machine (Directional, speed), stopping the machine

- 3.3.6. Turning

- 3.3.7. Operation of work equipment

- 3.3.8. Handling hydraulic quick coupler (option)

- 3.3.9. Work possible using wheel loader

- 3.3.10. Precautions for operation

- 3.3.11. Adjusting work equipment posture

- 3.3.12. Parking machine

- 3.3.13. Check after stopping engine

- 3.3.14. Checks after completion of operation

- 3.3.15. Locking

- 3.3.16. Handling the tires

- 3.4. Transportation

- 3.4.1. Transportation procedure

- 3.4.2. Loading, unloading work with trailers

- 3.4.3. Lifting machine

- 3.5. Cold weather operation

- 3.5.1. Precautions for low temperature

- 3.5.2. Precautions after completion of work

- 3.5.3. After cold weather

- 3.5.4. Warmingup operation for steering hydraulic circuit in cold weather

- 3.6. Longterm storage

- 3.6.1. Before storage

- 3.6.2. During storage

- 3.6.3. After storage

- 3.7. Troubleshooting

- 3.7.1. When machine runs out of fuel

- 3.7.2. Towing the machine

- 3.7.3. If battery is discharged

- 3.7.4. Other trouble

- 4. MAINTENANCE

- 4.1. Guides to maintenance

- 4.2. Outlines of service

- 4.2.1. Handling oil, fuel, coolant, grease and performing oil clinic

- 4.2.2. Outline of electric system

- 4.3. Wear parts

- 4.3.1. Wear parts list

- 4.4. Fuel, coolant and lubricants

- 4.4.1. Lubrication chart

- 4.4.2. Proper selection of fuel, coolant and lubricants

- 4.5. Standard tightening torques for bolts and nuts

- 4.5.1. Torque list

- 4.6. Periodic replacement of safety critical parts

- 4.6.1. Safety critical parts

- 4.7. Maintenance schedule chart

- 4.7.1. Service schedule

- 4.8. Service procedure

- 4.8.1. Initial 50 hours service (only after the first 50 hours)

- 4.8.2. Initial 250 hours service (only after the first 250 hours)

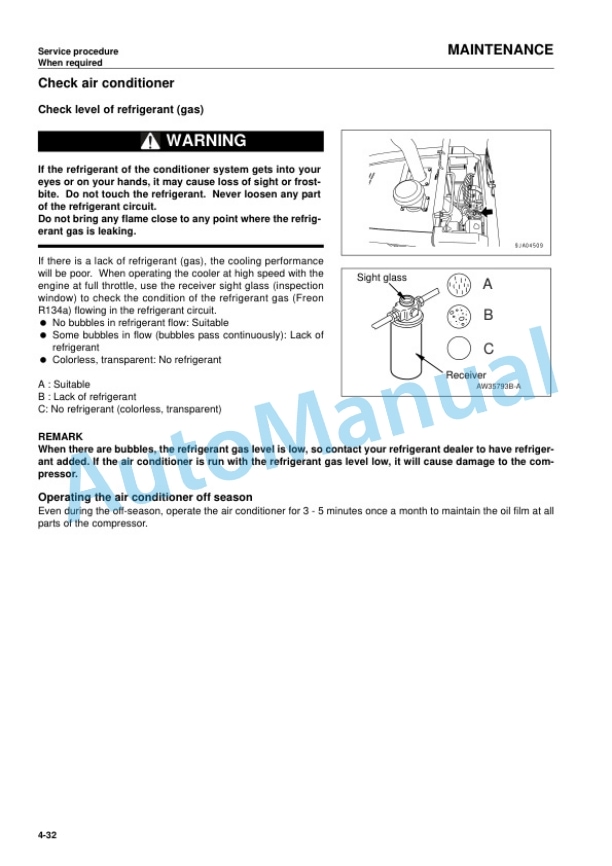

- 4.8.3. When required

- 4.8.4. Check before starting

- 4.8.5. Every 50 hours service

- 4.8.6. Every 100 hours service

- 4.8.7. Every 250 hours service

- 4.8.8. Every 500 hours service

- 4.8.9. Every 1000 hours service

- 4.8.10. Every 2000 hours service

- 4.8.11. Every 4000 hours service

- 5. TECHNICAL DATA

- 5.1. Technical data

- 5.2. Noise emission levels

- 5.3. Vibration levels

- 5.3.1. Operating condition

- 5.3.2. Guide to Reduce Vibration Levels on Machine

- 6. ATTACHMENTS, OPTIONS

- 6.1. Selecting bucket and tires

- 6.2. Handling fork tool

- 6.2.1. Explanation of components

- 6.2.2. Operation

- 6.3. Method of using 3 levers

- 6.3.1. Explanation of components

- 6.3.2. Operation

- 6.4. Central lubrication system

- 6.4.1. Operating the central lubrication system

- 6.4.2. Display and control unit

- 6.4.3. Changing the lubrication interval times

- 7. INDEX

- 7.1. Index

- 8. NOTES

- 8.1. NOTES

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF