- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA320-5 Wheel Loader Shop Manual SEBM0346-10

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM0346-10

- Format: PDF

- Size: 87.0MB

- Number of Pages: 860

Category: Komatsu Shop Manual PDF

-

Model List:

- WA320-5 Wheel Loader

- 1. COVER

- 2. CONTENTS

- 3. LIST OF REVISED PAGES

- 4. GENERAL

- 4.1. GENERAL ASSEMBLY DRAWINGS

- 4.2. SPECIFICATIONS

- 4.3. WEIGHT TABLE

- 4.4. LIST OF LUBRICANT AND COOLANT

- 5. STRUCTURE, FUNCTION ANDMAINTENANCE STANDARD

- 5.1. ENGINE MOUNT AND TRANSFER MOUNT

- 5.2. DAMPER

- 5.3. COOLING SYSTEM

- 5.4. POWER TRAIN

- 5.5. POWER TRAIN SYSTEM DIAGRAM

- 5.6. DRIVE SHAFT (PROPELLER SHAFT)

- 5.7. HST HYDRAULIC PIPING DIAGRAM

- 5.8. HST PUMP

- 5.9. HIGHPRESSURE RELIEF VALVE

- 5.10. LOWPRESSURE RELIEF VALVE

- 5.11. HST CHARGE PUMP

- 5.12. SPEEDRELATED VALVE (DA VALVE)

- 5.13. HIGHPRESSURE CUTOFF VALVE

- 5.14. HST MOTOR

- 5.15. EP SERVO VALVE

- 5.16. HA SERVO VALVE

- 5.17. FORWARDREVERSE SHUTTLE VALVE

- 5.18. TRANSFER

- 5.19. CLUTCH SOLENOID VALVE

- 5.20. AXLE

- 5.21. DIFFERENTIAL

- 5.22. LIMITEDSLIP DIFFERENTIAL

- 5.23. FINAL DRIVE

- 5.24. AXLE MOUNTING AND CENTER HINGE PIN

- 5.25. STEERING PIPING

- 5.26. STEERING COLUMN

- 5.27. PRIORITY VALVE

- 5.28. ORBITROLL VALVE

- 5.29. CUSHION VALVE

- 5.30. STEERING CYLINDER

- 5.31. EMERGENCY STEERING PIPING

- 5.32. EMERGENCY STEERING VALVE

- 5.33. BRAKE PIPING

- 5.34. BRAKE VALVE

- 5.35. INCHING VALVE

- 5.36. CHARGE VALVE

- 5.37. ACCUMULATOR (FOR BRAKE)

- 5.38. SLACK ADJUSTER

- 5.39. BRAKE

- 5.40. PARKING BRAKE CONTROL

- 5.41. PARKING BRAKE

- 5.42. HYDRAULIC PIPING

- 5.43. WORK EQUIPMENT LEVER LINKAGE

- 5.44. HYDRAULIC TANK

- 5.45. GEAR PUMP UNIT

- 5.46. ACCUMULATOR (FOR PPC CIRCUIT)

- 5.47. LOCK VALVE

- 5.48. VALVE

- 5.49. ACCUMULATOR (FOR E.C.S.S.)

- 5.50. HYDRAULIC PIPING OF COOLING SYSTEM

- 5.51. COOLING FAN MOTOR

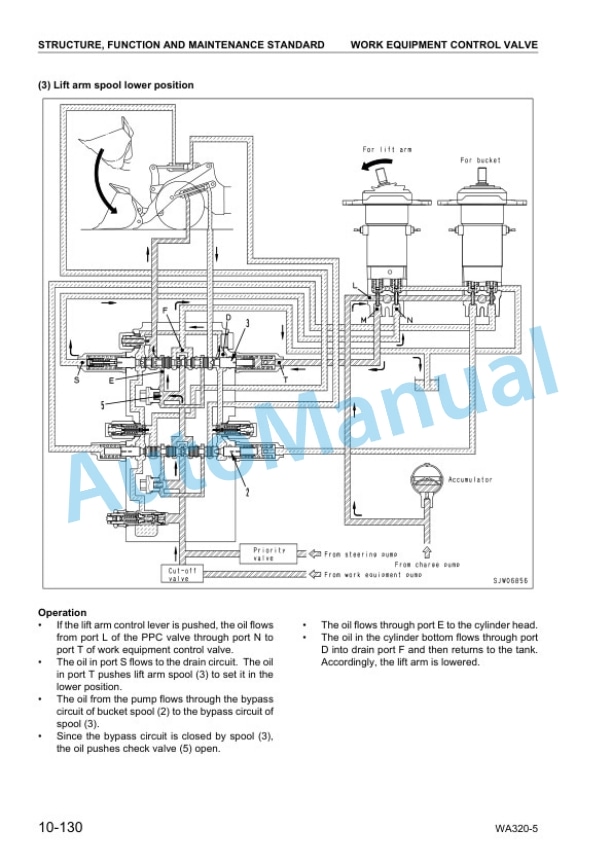

- 5.52. WORK EQUIPMENT CONTROL VALVE

- 5.53. WORK EQUIPMENT PPC VALVE

- 5.54. ATTACHMENT PPC VALVE

- 5.55. WORK EQUIPMENT LINKAGE

- 5.56. BUCKET

- 5.57. BUCKET POSITIONER AND BOOM KICKOUT

- 5.58. WORK EQUIPMENT CYLINDER

- 5.59. AIR CONDITIONER

- 5.60. MACHINE MONITORING SYSTEM

- 5.61. MACHINE MONITOR

- 5.62. LIST OF ITEMS DISPLAYED ON MONITOR

- 5.63. ELECTRICAL SYSTEM (HST CONTROLLER SYSTEM)

- 5.64. HST CONTROLLER

- 5.65. KOMTRAX SYSTEM

- 5.66. ENGINE START CIRCUIT

- 5.67. ENGINE STOP CIRCUIT

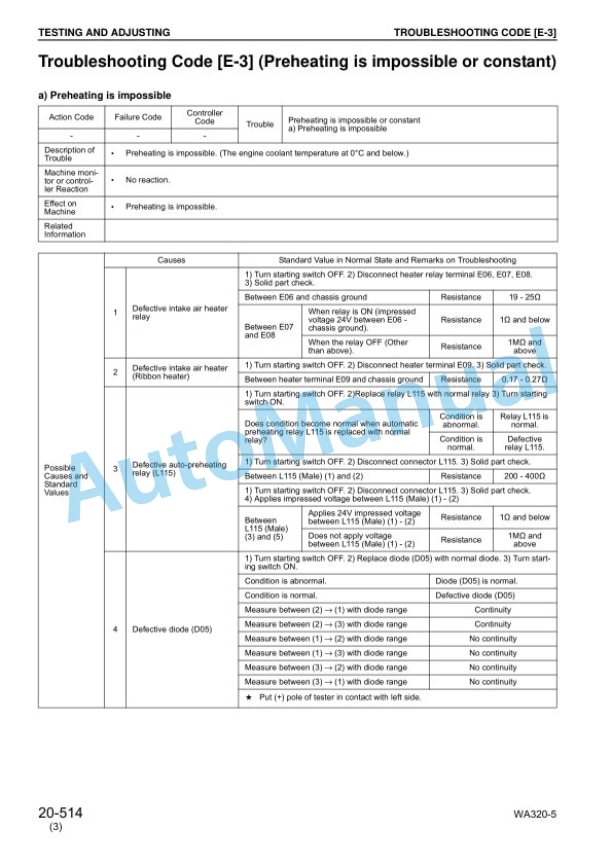

- 5.68. PREHEATING CIRCUIT (AUTOMATIC PREHEATING SYSTEM)

- 5.69. PARKING BRAKE CIRCUIT

- 5.70. ELECTRONICALLY CONTROLLED SUSPENSION SYSTEM

- 5.71. SENSORS

- 6. TESTING AND ADJUSTING

- 6.1. STANDARD VALUE TABLE FOR ENGINE

- 6.2. STANDARD VALUE TABLE FOR CHASSIS

- 6.3. TESTING AND ADJUSTING

- 6.3.1. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 6.3.2. MEASURING ENGINE SPEED

- 6.3.3. MEASURING EXHAUST GASCOLOR

- 6.3.4. ADJUSTING VALVECLEARANCE

- 6.3.5. MEASURING COMPRESSIONPRESSURE

- 6.3.6. MEASURING BLOWBYPRESSURE

- 6.3.7. TESTING AND ADJUSTINGFUEL INJECTION TIMING

- 6.3.8. MEASURING ENGINE OILPRESSURE

- 6.3.9. MEASURING, TESTINGOPERATING FORCE OFACCELERATOR PEDAL

- 6.3.10. ADJUSTING ENGINE STOPSOLENOID

- 6.3.11. TESTING AND ADJUSTINGAIR CONDITIONERCOMPRESSOR BELTTENSION

- 6.3.12. MEASURING DIRECTIONALLEVER

- 6.3.13. TESTING AND ADJUSTINGHST OIL PRESSURE

- 6.3.14. MEASURING CLUTCHCONTROL PRESSURE

- 6.3.15. TESTING AND ADJUSTINGSTEERING WHEEL

- 6.3.16. TESTING AND ADJUSTINGSTEERING OIL PRESSURE

- 6.3.17. BLEEDING AIR FROMSTEERING CIRCUIT

- 6.3.18. TESTING HYDRAULIC FAN

- 6.3.19. MEASURING BRAKE PEDAL

- 6.3.20. TESTING AND ADJUSTINGBRAKE PEDAL LINKAGE

- 6.3.21. MEASURING BRAKEPERFORMANC

- 6.3.22. TESTING AND ADJUSTINGACCUMULATOR CHARGEPRESSURE

- 6.3.23. MEASURING BRAKE OILPRESSURE

- 6.3.24. MEASURING WEAR OFBRAKE DISC

- 6.3.25. BLEEDING AIR FROM BRAKECIRCUIT

- 6.3.26. MEASURING PARKINGBRAKE PERFORMANCE

- 6.3.27. TESTING AND ADJUSTINGPARKING BRAKE LINKAGE

- 6.3.28. MEASURING AND ADJUSTINGWORK EQUIPMENT CONTROLLEVER

- 6.3.29. TESTING AND ADJUSTINGWORK EQUIPMENTHYDRAULIC PRESSURE

- 6.3.30. TESTING AND ADJUSTINGWORK EQUIPMENT PPC OILPRESSURE

- 6.3.31. BLEEDING AIR

- 6.3.32. RELEASING REMAININGPRESSURE IN HYDRAULICCIRCUIT

- 6.3.33. TESTING AND ADJUSTINGBUCKET POSITIONER

- 6.3.34. TESTING AND ADJUSTING OFBOOM KICKOUT

- 6.3.35. CHECKING PROXIMITYSWITCH ACTUATIONDISPLAY LAMP

- 6.3.36. PROCEDURE FOR CHECKINGDIODE

- 6.3.37. METHOD OF CONNECTINGTADAPTER FOR HSTCONTROLLER

- 6.3.38. STARTING KOMTRAX TERMINAL OPERATIONS

- 6.3.39. INDICATOR LAMPS OF KOMTRAX TERMINAL

- 6.3.40. SPECIAL FUNCTIONS OFMACHINE MONITOR

- 6.3.41. FLOW OF MODES ANDFUNCTIONS

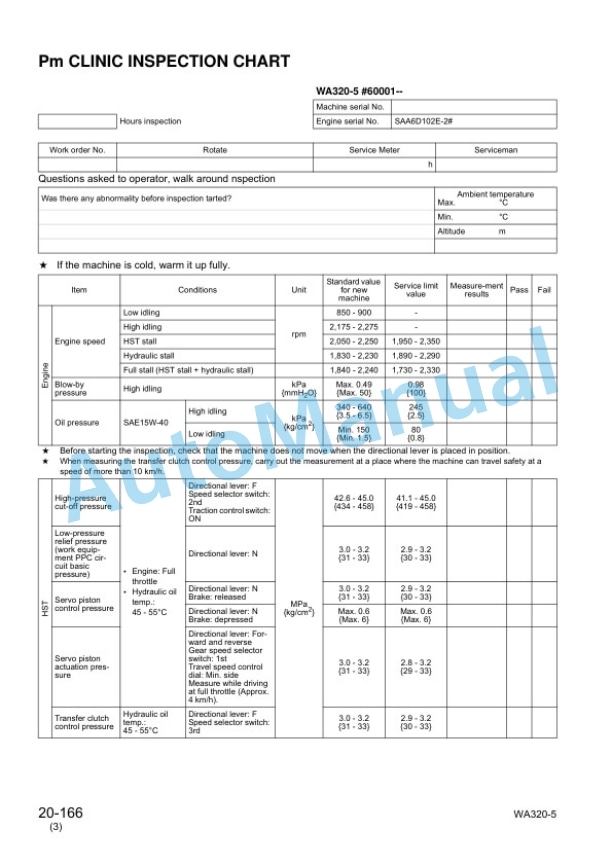

- 6.3.42. Pm CLINIC INSPECTION CHART

- 6.4. TROUBLESHOOTING

- 6.4.1. POINTS TO REMEMBERWHEN TROUBLESHOOTING

- 6.4.2. SEQUENCE OF EVENTS INTROUBLESHOOTING

- 6.4.3. PRECAUTIONS WHENCARRYING OUTMAINTENANCE

- 6.4.4. CHECK BEFORETROUBLESHOOTING

- 6.4.5. CATEGORIES, PROCEDURE,AND METHOD OF USINGTROUBLESHOOTING CHARTS

- 6.4.6. PHENOMENA CONSIDEREDTO BE FAILURES ANDTROUBLESHOOTING NO.

- 6.4.7. CONNECTION TABLE FORCONNECTOR PIN NUMBERS

- 6.4.8. TADAPTER TABLE

- 6.4.9. CONNECTOR TYPES ANDMOUNTING LOCATIONS

- 6.4.10. CONNECTOR LAYOUTDRAWING

- 7. DISASSEMBLY AND ASSEMBLY

- 7.1. HOW TO READ THIS MANUAL

- 7.2. PRECAUTIONS WHENCARRYING OUT OPERATION

- 7.3. SPECIAL TOOL LIST

- 7.4. SKETCH OF SPECIAL TOOLS

- 7.5. REMOVAL, INSTALLATION OFFUEL INJECTION PUMPASSEMBLY

- 7.6. REMOVAL, INSTALLATION OFNOZZLE HOLDER ASSEMBLY

- 7.7. REMOVAL, INSTALLATION OFCYLINDER HEAD ASSEMBLY

- 7.8. REMOVAL, INSTALLATION OFENGINE ASSEMBLY

- 7.9. REMOVAL, INSTALLATION OFRADIATOR ASSEMBLY

- 7.10. REMOVAL, INSTALLATION OFAIR AFTERCOOLER

- 7.11. REMOVAL, INSTALLATION OFHYDRAULIC OIL COOLERASSEMBLY

- 7.12. REMOVAL, INSTALLATION OFCOOLING FAN AND FANMOTOR ASSEMBLY

- 7.13. REMOVAL, INSTALLATION OFFUEL TANK ASSEMBLY

- 7.14. REMOVAL, INSTALLATION OFTRANSFER

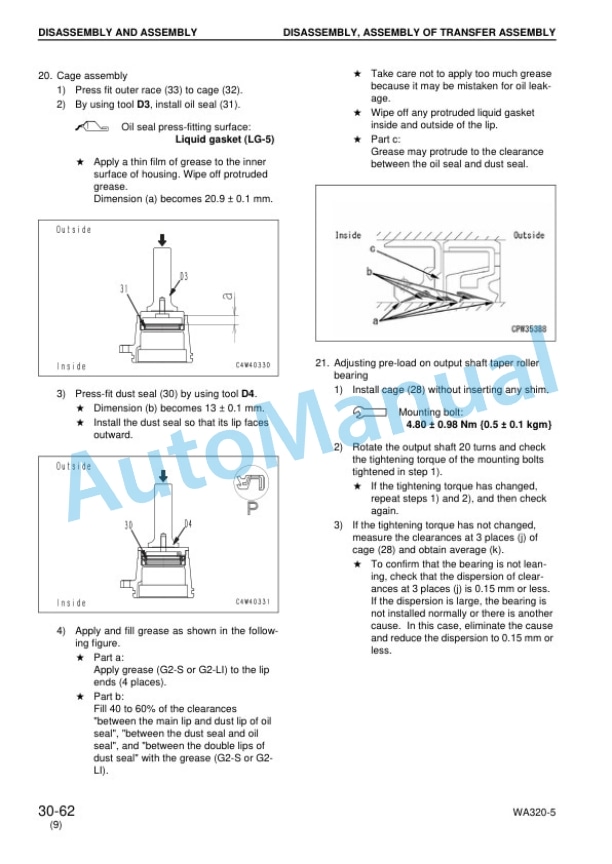

- 7.15. DISASSEMBLY, ASSEMBLYOF TRANSFER ASSEMBLY

- 7.16. REMOVAL, INSTALLATION OFPARKING BRAKE ASSEMBLY

- 7.17. DISASSEMBLY, ASSEMBLYOF PARKING BRAKEASSEMBLY

- 7.18. REMOVAL, INSTALLATION OFFRONT AXLE ASSEMBLY

- 7.19. REMOVAL, INSTALLATION OFREAR AXLE ASSEMBLY

- 7.20. DISASSEMBLY, ASSEMBLYOF AXLE HOUSINGASSEMBLY

- 7.21. DISASSEMBLY, ASSEMBLYOF DIFFERENTIALASSEMBLY

- 7.22. REMOVAL, INSTALLATION OFHST PUMP AND 4GEARPUMP ASSEMBLY

- 7.23. REMOVAL, INSTALLATION OFHST MOTOR 1 ASSEMBLY

- 7.24. REMOVAL, INSTALLATION OFHST MOTOR 2 ASSEMBLY

- 7.25. REMOVAL, INSTALLATION OFWORK EQUIPMENT CONTROLVALVE ASSEMBLY

- 7.26. REMOVAL, INSTALLATION OFTRAVEL DAMPER VALVEASSEMBLY (If equipped)

- 7.27. REMOVAL, INSTALLATION OFHYDRAULIC TANKASSEMBLY

- 7.28. REMOVAL, INSTALLATION OFWORK EQUIPMENTASSEMBLY

- 7.29. DISASSEMBLY ANDASSEMBLY OF HST PUMPASSEMBLY

- 7.30. DISASSEMBLY ANDASSEMBLY OF HST MOTORASSEMBLY

- 7.31. DISASSEMBLY, ASSEMBLYOF HYDRAULIC CYLINDERASSEMBLY

- 7.32. REMOVAL, INSTALLATION OFOPERATORS CABASSEMBLY

- 7.33. REMOVAL, INSTALLATION OFOPERATORS CAB GLASS(STUCK GLASS)

- 7.34. REMOVAL, INSTALLATION OFCENTER HINGE PIN

- 7.35. REMOVAL, INSTALLATION OFCOUNTERWEIGHT

- 7.36. REMOVAL, INSTALLATION OFAIR CONDITIONER UNITASSEMBLY

- 7.37. REMOVAL, INSTALLATION OFAIR CONDITIONERCOMPRESSOR ASSEMBLY

- 7.38. REMOVAL, INSTALLATION OFMONITOR PANEL

- 7.39. REMOVAL, INSTALLATION OFHST CONTROLLER ASSEMBLY

- 8. OTHERS

- 8.1. HYDRAULIC CIRCUIT DIAGRAM

- 8.2. ELECTRICAL CIRCUIT DIAGRAM 1/4 (1/4)

- 8.3. ELECTRICAL CIRCUIT DIAGRAM 1/4 (2/4)

- 8.4. ELECTRICAL CIRCUIT DIAGRAM 1/4 (3/4)

- 8.5. ELECTRICAL CIRCUIT DIAGRAM 1/4 (4/4)

- 8.6. ELECTRICAL CIRCUIT DIAGRAM 2/4

- 8.7. ELECTRICAL CIRCUIT DIAGRAM 3/4

- 8.8. ELECTRICAL CIRCUIT DIAGRAM 4/4

- 8.9. ELECTRICAL CIRCUIT DIAGRAM (A1 SIZE) WA3205

- 8.10. CONNECTORS TABLE AND ARRANGEMENT DRAWING (A1 SIZE)

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF