- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA320-5 Wheel Loader Shop Manual SEBM034612

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM034612

- Format: PDF

- Size: 84.6MB

- Number of Pages: 872

Category: Komatsu Shop Manual PDF

-

Model List:

- WA320-5 Wheel Loader

- 1. COVER

- 2. CONTENTS

- 3. LIST OF REVISED PAGES

- 4. GENERAL

- 4.1. GENERAL ASSEMBLY DRAWINGS

- 4.2. SPECIFICATIONS

- 4.3. WEIGHT TABLE

- 4.4. LIST OF LUBRICANT AND COOLANT

- 5. STRUCTURE,FUNCTION AND MAINTENANCE STANDARD

- 5.1. ENGINE MOUNT AND TRANSFER MOUNT

- 5.2. DAMPER

- 5.3. COOLING SYSTEM

- 5.4. POWER TRAIN

- 5.5. POWER TRAIN SYSTEM DIAGRAM

- 5.6. DRIVE SHAFT (PROPELLER SHAFT)

- 5.7. HST HYDRAULIC PIPING DIAGRAM

- 5.8. HST PUMP

- 5.9. HIGHPRESSURE RELIEF VALVE

- 5.10. LOWPRESSURE RELIEF VALVE

- 5.11. HST CHARGE PUMP

- 5.12. SPEEDRELATED VALVE (DA VALVE)

- 5.13. HIGHPRESSURE CUTOFF VALVE

- 5.14. HST MOTOR

- 5.15. EP SERVO VALVE

- 5.16. HA SERVO VALVE

- 5.17. FORWARDREVERSE SHUTTLE VALVE

- 5.18. TRANSFER

- 5.19. CLUTCH SOLENOID VALVE

- 5.20. AXLE

- 5.21. DIFFERENTIAL

- 5.22. LIMITEDSLIP DIFFERENTIAL

- 5.23. FINAL DRIVE

- 5.24. AXLE MOUNTING AND CENTER HINGE PIN

- 5.25. STEERING PIPING

- 5.26. STEERING COLUMN

- 5.27. PRIORITY VALVE

- 5.28. ORBITROLL VALVE

- 5.29. CUSHION VALVE

- 5.30. STEERING CYLINDER

- 5.31. EMERGENCY STEERING PIPING

- 5.32. EMERGENCY STEERING VALVE

- 5.33. BRAKE PIPING

- 5.34. BRAKE VALVE

- 5.35. INCHING VALVE

- 5.36. CHARGE VALVE

- 5.37. ACCUMULATOR (FOR BRAKE)

- 5.38. SLACK ADJUSTER

- 5.39. BRAKE

- 5.40. PARKING BRAKE CONTROL

- 5.41. PARKING BRAKE

- 5.42. HYDRAULIC PIPING

- 5.43. WORK EQUIPMENT LEVEL LINKAGE

- 5.44. HYDRAULIC TANK

- 5.45. GEAR PUMP UNIT

- 5.46. ACCUMULATOR (FOR PPC CIRCUIT)

- 5.47. LOCK VALVE

- 5.48. VALVE

- 5.49. ACCUMULATOR (FOR E.C.S.S.)

- 5.50. HYDRAULIC PIPING OF COOLING SYSTEM

- 5.51. COOLING FAN MOTOR

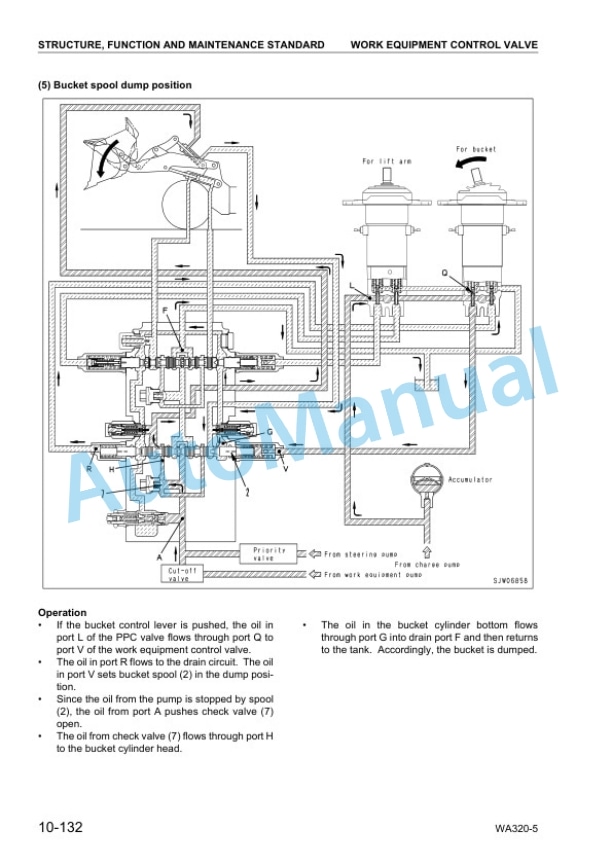

- 5.52. WORK EQUIPMENT CONTROL VALVE

- 5.53. WORK EQUIPMENT PPC VALVE

- 5.54. ATTACHMENT PPC VALVE

- 5.55. WORK EQUIPMENT LINKAGE

- 5.56. BUCKET

- 5.57. BUCKET POSITIONER AND BOOM KICKOUT

- 5.58. WORK EQUIPMENT CYLINDER

- 5.59. AIR CONDITIONER

- 5.60. MACHINE MONITORING SYSTEM

- 5.61. MACHINE MONITOR

- 5.62. LIST OF ITEMS DISPLAYED ON MONITOR

- 5.63. ELECTRICAL SYSTEM (HST CONTROLLER SYSTEM)

- 5.64. HST CONTROLLER

- 5.65. KOMTRAX SYSTEM

- 5.66. ENGINE START CIRCUIT

- 5.67. ENGINE STOP CIRCUIT

- 5.68. PREHEATING CIRCUIT (AUTOMATIC PREHEATING SYSTEM)

- 5.69. PARKING BRAKE CIRCUIT

- 5.70. ELECTRONICALLY CONTROLLED SUSPENSION SYSTEM

- 5.71. SENSORS

- 6. TESTING AND ADJUSTING

- 6.1. STANDARD VALUE TABLE FOR ENGINE

- 6.2. STANDARD VALUE TABLE FOR CHASSIS

- 6.3. TESTING AND ADJUSTING

- 6.3.1. TOOLS FOR TESTING, ADJUSTING,AND TROUBLESHOOTING

- 6.3.2. MEASURING ENGINE SPEED

- 6.3.3. MEASURING EXHAUST GAS COLOR

- 6.3.4. ADJUSTING VALVE CLEARANCE

- 6.3.5. MEASURING COMPRESSION PRESSURE

- 6.3.6. MEASURING BLOWBY PRESSURE

- 6.3.7. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 6.3.8. MEASURING ENGINE OIL PRESSURE

- 6.3.9. MEASURING, TESTING OPERATION FORCE OF ACCELERATOR PEDAL

- 6.3.10. ADJUSTING ENGINE STOP SOLENOID

- 6.3.11. ADJUSTING ENGINE SPEED SENSOR

- 6.3.12. TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION

- 6.3.13. MEASURING DIRECTIONAL LEVER

- 6.3.14. TESTING AND ADJUSTING HST OIL PRESSURE

- 6.3.15. MEASURING CLUTCH CONTROL PRESSURE

- 6.3.16. TESTING AND ADJUSTING STEERING WHEEL

- 6.3.17. TESTING AND ADJUSTING STEERING OIL PRESSURE

- 6.3.18. BLEEDING AIR FROM STEERING CIRCUIT

- 6.3.19. TESTING HYDRAULIC FAN

- 6.3.20. MEASURING BRAKE PEDAL

- 6.3.21. TESTING AND ADJUSTING BRAKE PEDAL LINKAGE

- 6.3.22. MEASURING BRAKE PERFORMANCE

- 6.3.23. TESTING AND ADJUSTING ACCUMULATOR CHARGE PRESSURE

- 6.3.24. MEASURING BRAKE OIL PRESSURE

- 6.3.25. MEASURING WEAR OF BRAKE DISC

- 6.3.26. BLEEDING AIR FROM BRAKE CIRCUIT

- 6.3.27. MEASURING PARKING BRAKE PERFORMANCE

- 6.3.28. TESTING AND ADJUSTING PARKING BRAKE LINKAGE

- 6.3.29. MEASURING AND ADJUSTING WORK EQUIPMENT CONTROL LEVER

- 6.3.30. TESTING AND ADJUSTING WORK EQUIPMENT HYDRAULIC PRESSURE

- 6.3.31. TESTING AND ADJUSTING WORK EQUIPMENT PPC OIL PRESSURE

- 6.3.32. BLEEDING AIR

- 6.3.33. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 6.3.34. TESTING AND ADJUSTING BUCKET POSITIONER

- 6.3.35. TESTING AND ADJUSTING OF BOOM KICKOUT

- 6.3.36. CHECKING PROXIMITY SWITCH ACTUATION DISPLAY LAMP

- 6.3.37. PROCEDURE FOR CHECKING DIODE

- 6.3.38. METHOD OF CONNECTING TADAPTER FOR HST CONTROLLER

- 6.3.39. STARTING KOMTRAX TERMINAL OPERATIONS

- 6.3.40. INDICATOR LAMPS OF KOMTRAX TERMINAL

- 6.3.41. SPECIAL FUNCTIONS OF MACHINE MONITOR

- 6.3.42. FLOW OF MODES AND FUNCTIONS

- 6.3.43. FAILURE CODE TABLE

- 6.3.44. PM CLINIC INSPECTION CHART

- 6.4. TROUBLESHOOTING

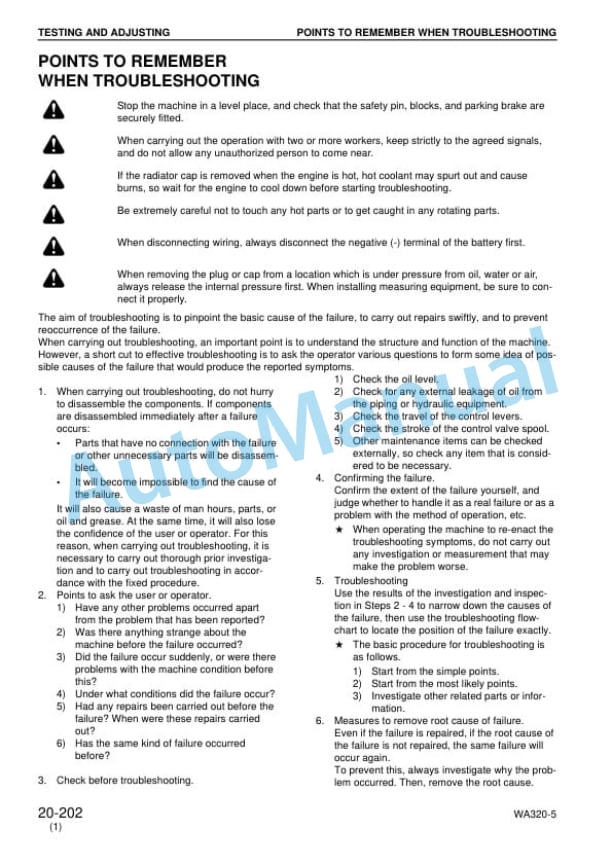

- 6.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 6.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 6.4.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 6.4.4. CHECKS BEFORE TROUBLESHOOTING

- 6.4.5. CATEGORIES,PROCEDURE,AND METHOD OF USING TROUBLESHOOTING CHARTS

- 6.4.6. PHENOMENA CONSIDERED TO BE FAILURES AND TROUBLESHOOTING NO.

- 6.4.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 6.4.8. TADAPTER TABLE

- 6.4.9. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 6.4.10. CONNECTOR LAYOUT DRAWING

- 6.4.11. TROUBLESHOOTING OF HST CONTROLLER SYSTEM (HST MODE)

- 6.4.12. TROUBLESHOOTING OF TRAVEL DAMPER SYSTEM(ECSS MODE)

- 6.4.13. TROUBLESHOOTING OF MONITOR SYSTEM(MON MODE)

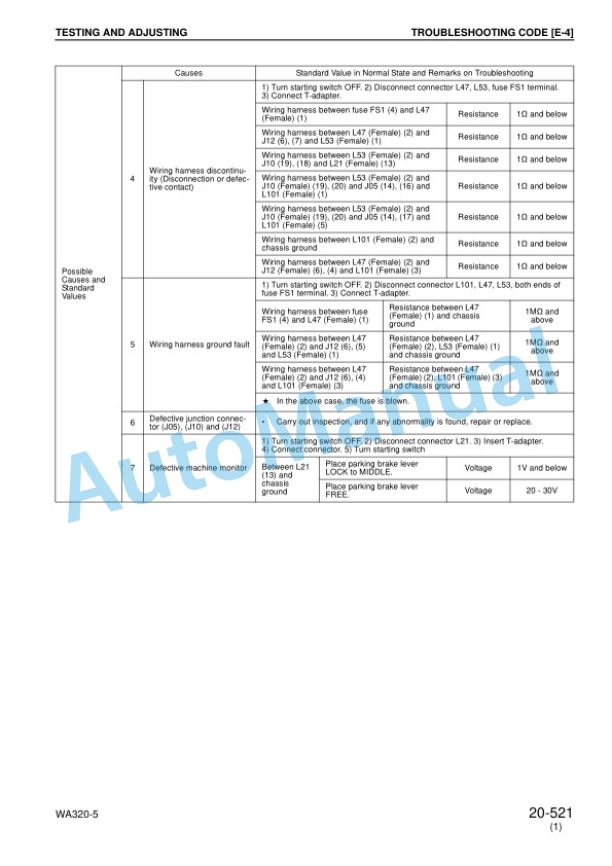

- 6.4.14. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 6.4.15. TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM(H MODE)

- 6.4.16. TROUBLESHOOTING OF ENGINE (S MODE)

- 7. DISASSEMBLY AND ASSEMBLY

- 7.1. How to read this manual

- 7.2. Precautions when carrying out operation

- 7.3. Special tool list

- 7.4. Sketch of special tools

- 7.5. Removal, installation of fuel injection pump assembly

- 7.6. Removal, installation of nozzle holder assembly

- 7.7. Removal, installation of cylinder head assembly

- 7.8. Removal, installation of engine assembly

- 7.9. Removal, installation of radiator assembly

- 7.10. Removal, installation of air aftercooler

- 7.11. Removal, installation of hydraulic oil cooler assembly

- 7.12. Removal, installation of cooling fan and fan motor assembly

- 7.13. Removal, installation of fuel tank assembly

- 7.14. Removal, installation of transfer

- 7.15. Disassembly, assembly of transfer assembly

- 7.16. Removal, installation of parking brake assembly

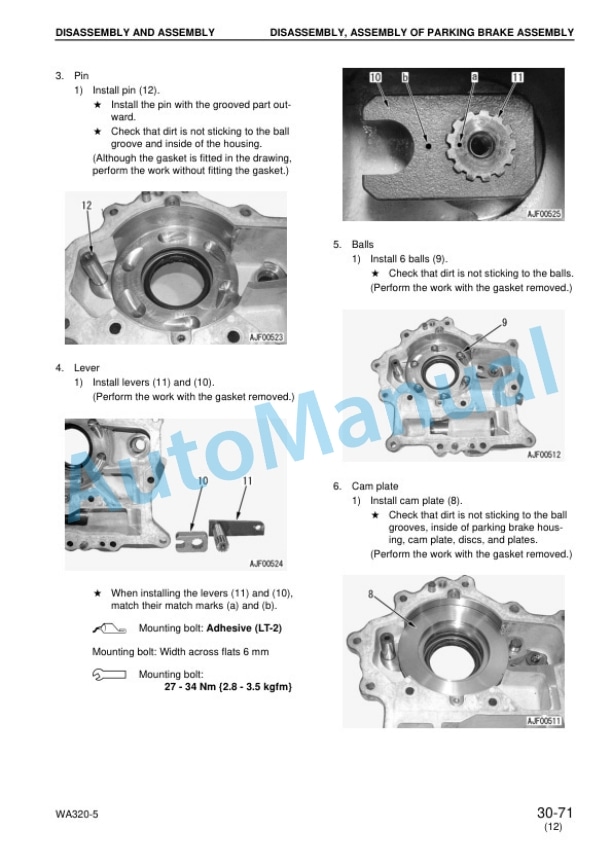

- 7.17. Disassembly, assembly of parking brake assembly

- 7.18. Removal, installation of front axle assembly

- 7.19. Removal, installation of rear axle assembly

- 7.20. Disassembly, assembly of axle housing assembly

- 7.21. Disassembly, assembly of differential assembly

- 7.22. Removal, installation of HST pump and 4gear pump assembly

- 7.23. Removal, installation of HST motor 1 assembly

- 7.24. Removal, installation of HST motor 2 assembly

- 7.25. Removal, installation of work equipment control valve assembly

- 7.26. Removal, installation of travel damper valve assembly (If equipped)

- 7.27. Removal, installation of hydraulic tank assembly

- 7.28. Removal, installation of work equipment assembly

- 7.29. Disassembly and assembly of HST pump assembly

- 7.30. Disassembly and assembly of HST motor assembly

- 7.31. Disassembly, assembly of hydraulic cylinder assembly

- 7.32. Removal, installation of operators cab assembly

- 7.33. Removal, installation of operators cab glass (Stuck glass)

- 7.34. Removal, installation of center hinge pin

- 7.35. Removal, installation of counterweight

- 7.36. Removal, installation of air conditioner unit assembly

- 7.37. Removal, installation of air conditioner compressor assembly

- 7.38. Removal, installation of monitor panel

- 7.39. Removal, installation of HST controller assembly

- 8. OTHERS

- 8.1. HYDRAULIC CIRCUIT DIAGRAM

- 8.2. ELECTRICAL CIRCUIT DIAGRAM 1/4(1/4)

- 8.3. ELECTRICAL CIRCUIT DIAGRAM 1/4(2/4)

- 8.4. ELECTRICAL CIRCUIT DIAGRAM 1/4(3/4)

- 8.5. ELECTRICAL CIRCUIT DIAGRAM 1/4(4/4)

- 8.6. ELECTRICAL CIRCUIT DIAGRAM 2/4

- 8.7. ELECTRICAL CIRCUIT DIAGRAM 3/4

- 8.8. ELECTRICAL CIRCUIT DIAGRAM 4/4

- 8.9. ELECTRICAL CIRCUIT DIAGRAM (A1 SIZE)

- 8.10. CONNECTORS TABLE AND ARRANGEMENT DRAWING (A1 SIZE)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF