- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA320PT-5L Parallel Tool Carrier Shop Manual CEBM013602

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM013602

- Format: PDF

- Size: 68.9MB

- Number of Pages: 1215

Category: Komatsu Shop Manual PDF

-

Model List:

- WA320PT-5L Parallel Tool Carrier

- 1. CEBM013602 WA320PT5L S/N A39001 and up

- 2. CONTENTS

- 3. REVISION PAGES

- 4. GENERAL

- 4.1. GENERAL INFORMATION

- 4.2. LUBRICANTS

- 5. STRUCTURE AND FUNCTION

- 5.1. ENGINE AND DRIVE SYSTEM

- 5.2. HST HYDRAULIC SYSTEM

- 5.3. HST MOTOR (HYDROSTATIC TRANSMISSION)

- 5.4. TRANSFER

- 5.5. CLUTCH SOLENOID VALVE

- 5.6. DRIVE AXLES

- 5.7. LIMITEDSLIP DIFFERENTIALS

- 5.8. AXLE MOUNTING AND CENTER HINGE

- 5.9. STEERING SYSTEM

- 5.10. EMERGENCY STEERING

- 5.11. PARKING BRAKE

- 5.12. WORK EQUIPMENT

- 5.13. BASIC HYDRAULIC SYSTEM

- 5.14. Valve

- 5.15. HYDRAULIC COOLING SYSTEM

- 5.16. WORK EQUIPMENT CONTROL VALVE

- 5.17. WORK EQUIPMENT PPC VALVES

- 5.18. WA3205L MECHANICAL AND WORK EQUIPMENT

- 5.19. WA320PT5L MECHANICAL AND WORK EQUIPMENT

- 5.20. BUCKET POSITIONER, BOOM KICKOUT AND DUMP SPEED

- 5.21. WORK EQUIPMENT CYLINDERS

- 5.22. HEATING AND AIR CONDITIONER PIPING

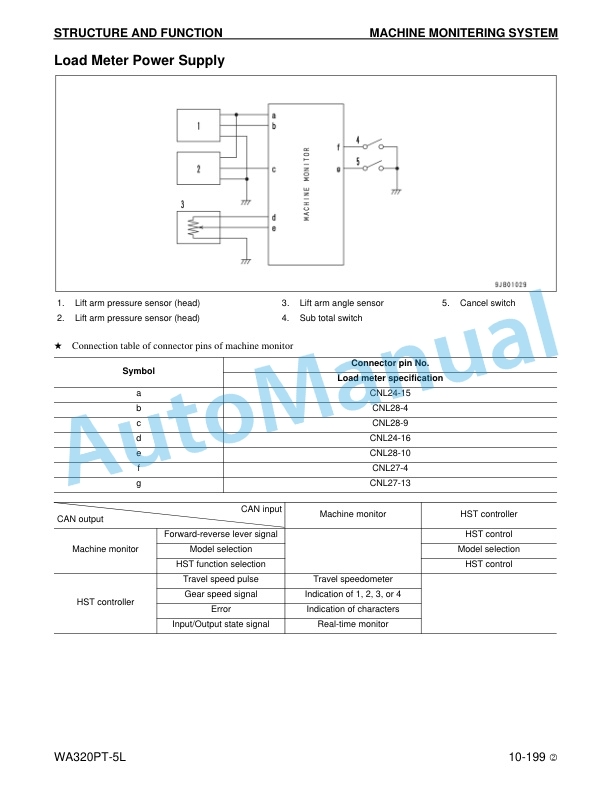

- 5.23. MACHINE MONITERING SYSTEM

- 5.24. MACHINE MONITOR

- 5.25. LIST OF ITEMS DISPLAYED ON MONITOR

- 5.26. HST SYSTEM ELECTRICAL CONTROLLER

- 5.27. KOMTRAX SYSTEM

- 6. TESTING, ADJUSTING AND TROUBLESHOOTING

- 6.1. STANDARD VALUE TABLE

- 6.2. SPECIAL TOOLS

- 6.3. ENGINE COMPONENTS

- 6.4. ACCELERATOR PEDAL

- 6.5. ADJUSTING ENGINE STOP SOLENOID

- 6.6. ADJUSTING ENGINE SPEED SENSOR

- 6.7. REFRIGERENT COMPRESSOR BELT

- 6.8. DIRECTIONAL LEVER

- 6.9. HST OIL PRESSURE

- 6.10. CLUTCH CONTROL PRESSURE

- 6.11. STEERING WHEEL

- 6.12. STEERING OIL PRESSURE

- 6.13. HYDRAULIC FAN

- 6.14. MEASURING BRAKE PEDAL

- 6.15. BRAKE PEDAL LINKAGE

- 6.16. MEASURING BRAKE PERFORMANCE

- 6.17. ACCUMULATOR CHARGE PRESSURE

- 6.18. BRAKE OIL PRESSURE

- 6.19. MEASURING WEAR OF BRAKE DISC

- 6.20. BLEEDING AIR FROM BRAKE CIRCUIT

- 6.21. PARKING BRAKE PERFORMANCE

- 6.22. PARKING BRAKE LINKAGE

- 6.23. WORK EQUIPMENT CONTROL LEVER

- 6.24. WORK EQUIPMENT PRESSURE

- 6.25. WORK EQUIPMENT PPC OIL PRESSURE

- 6.26. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 6.27. BUCKET POSITIONER

- 6.28. BOOM KICKOUT

- 6.29. PROXIMITY SWITCH ACTUATION DISPLAY LAMP

- 6.30. PROCEDURE FOR CHECKING DIODE

- 6.31. SPECIAL FUNCTIONS OF MACHINE MONITOR

- 6.32. FLOW OF MODES AND FUNCTIONS

- 6.33. SETTING MACHINE MONITOR (EMMS)

- 6.34. REALTIME MONITORING ITEMS

- 6.35. PM CLINIC INSPECTION CHART

- 7. TROUBLESHOOTING (GENERAL)

- 7.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 7.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 7.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 7.4. CHECKS BEFORE TROUBLESHOOTING

- 7.5. TABLE FOR CONNECTOR PIN NUMBERS

- 7.6. TADAPTER TABLE

- 7.7. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 7.8. CONNECTOR LAYOUT DRAWING

- 8. TROUBLESHOOTING OF HST CONTROLLER SYSTEM (HST MODE)

- 8.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM

- 8.2. ERROR CODE AND POSSIBLE CAUSE TABLE

- 8.3. FUSE SYSTEM CHECK

- 8.4. INFORMATION CONTAINED IN TESTING PROCEDURES

- 8.5. 989F00

- 8.6. DHH1KX

- 8.7. DLE2LC

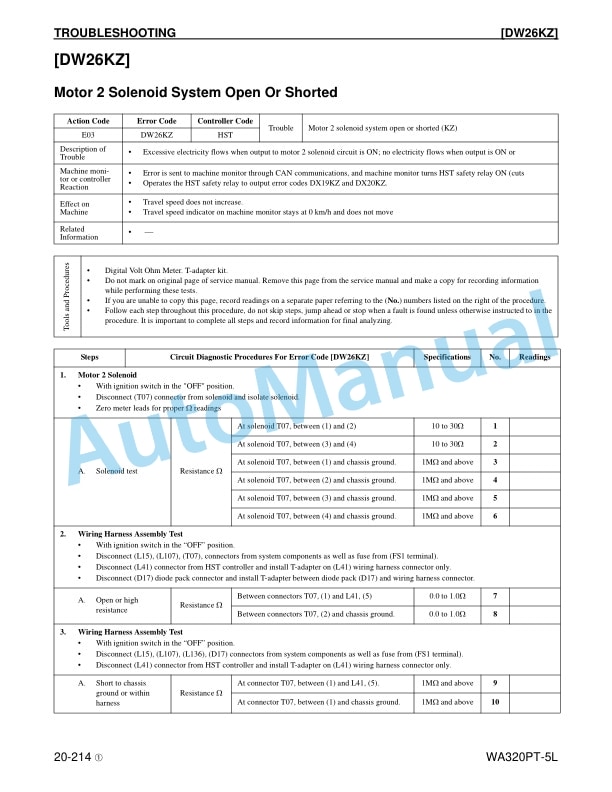

- 8.8. DW26KZ

- 8.9. DX19KZ

- 8.10. DX20KZ

- 8.11. HST1

- 8.12. HST2

- 8.13. HST3

- 8.14. HST4

- 8.15. HST5

- 9. TROUBLESHOOTING OF TRAVEL DAMPENER SYSTEM (ECSS MODE)

- 9.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 9.2. ECSS1

- 10. TROUBLESHOOTING OF HST MONITOR SYSTEM (MON MODE)

- 10.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 10.2. ERROR CODE AND POSSIBLE CAUSE TABLE

- 10.3. FUSE SYSTEM CHECK

- 10.4. INFORMATION CONTAINED IN TESTING PROCEDURES

- 10.5. 15B0NX

- 10.6. 2G42ZG

- 10.7. 989F00

- 10.8. 989FN1

- 10.9. AA1ANX

- 10.10. AB00L6

- 10.11. AB00MA

- 10.12. BBAZG

- 10.13. BBAZK

- 10.14. BBCNS

- 10.15. BBCZK

- 10.16. BC7NS

- 10.17. BCRNS

- 10.18. D5ZHL6

- 10.19. DAF3KK

- 10.20. DAF5KP

- 10.21. DAF6KP

- 10.22. DAF0KT

- 10.23. DAJ0KR

- 10.24. D182KZ

- 10.25. D1B0KB

- 10.26. DD1CLD

- 10.27. DD15LD

- 10.28. DD16LD

- 10.29. DD17LD

- 10.30. DD18LD

- 10.31. DDK3KB

- 10.32. DDS5L6

- 10.33. DDY0LD

- 10.34. DGE2KX

- 10.35. DGE3L6

- 10.36. DGH1KX

- 10.37. DGR4KA

- 10.38. DGR4KX

- 10.39. DHE4L6

- 10.40. DHPCKX

- 10.41. DHPDKX

- 10.42. DKA0KX

- 10.43. DV00KB

- 10.44. MON1

- 10.45. MON2

- 10.46. MON3

- 10.47. MON4

- 10.48. MON5

- 10.49. MON6

- 10.50. MON7

- 10.51. MON8

- 10.52. MON9

- 10.53. MON10

- 10.54. MON11

- 10.55. MON12

- 10.56. MON13

- 10.57. MON14

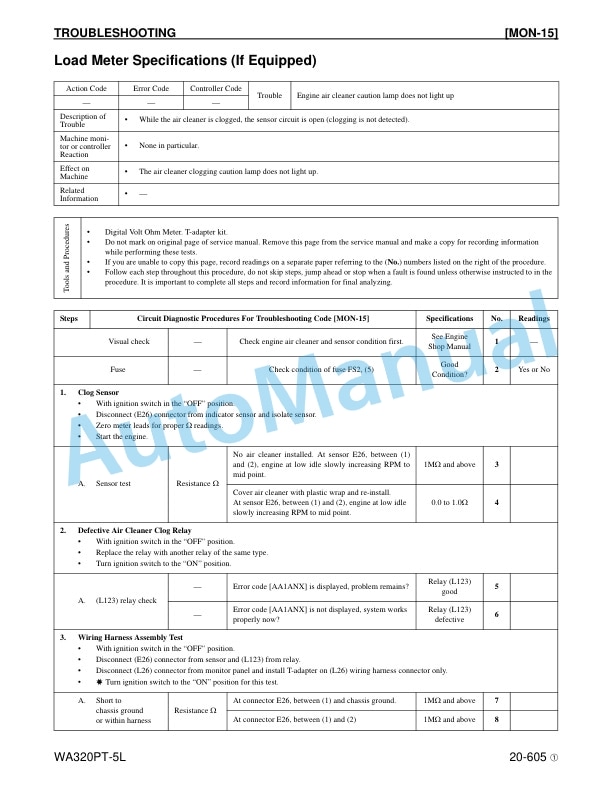

- 10.58. MON15

- 10.59. MON16

- 10.60. MON17

- 10.61. MON18

- 10.62. MON19

- 10.63. MON20

- 10.64. MON21

- 11. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 11.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 11.2. FUSE SYSTEM CHECK

- 11.3. INFORMATION CONTAINED IN TESTING PROCEDURES

- 11.4. (E1)

- 11.5. (E2)

- 11.6. (E3)

- 11.7. (E4)

- 11.8. (E5)

- 11.9. (E6)

- 11.10. (E7)

- 11.11. (E8)

- 11.12. (E9)

- 11.13. (E10)

- 11.14. (E11)

- 11.15. (E12)

- 11.16. (E13)

- 11.17. DEFECTIVE COOLING (MECHANICAL)

- 11.18. DEFECTIVE HEATING (MECHANICAL)

- 11.19. ABNORMAL NOISE IS HEARD FROM SYSTEM (MECHANICAL)

- 11.20. WATER LEAKS FROM SYSTEM (MECHANICAL)

- 12. TROUBLESHOOTING OF HYDRAULIC MECHANICAL SYSTEM (H MODE)

- 12.1. METHOD OF USING TROUBLESHOOTING CHART

- 12.2. FAILURE CODE AND CAUSE TABLE

- 12.3. (H1)

- 12.4. (H2)

- 12.5. (H3)

- 12.6. (H4)

- 12.7. (H5)

- 12.8. (H6)

- 12.9. (H7)

- 12.10. (H8)

- 12.11. (H10)

- 12.12. (H11)

- 12.13. (H12)

- 12.14. (H13)

- 12.15. (H14)

- 12.16. (H15)

- 12.17. (H16)

- 12.18. (H17)

- 12.19. (H18)

- 12.20. (H19)

- 12.21. (H20)

- 12.22. (H21)

- 12.23. (H22)

- 12.24. (H23)

- 12.25. (H24)

- 12.26. (H25)

- 12.27. (H26)

- 12.28. (H27)

- 13. TROUBLESHOOTING OF ENGINE SYSTEM (S MODE)

- 13.1. METHOD OF USING TROUBLESHOOTING CHARTS

- 13.2. (S1) ENGINE STARTING PERFORMANCE IS POOR

- 13.3. (S2) ENGINE HAS STARTING PROBLEMS

- 13.4. (S3) ENGINE DOES NOT RUN SMOOTHLY

- 13.5. (S4) ENGINE STOPS DURING OPERATIONS

- 13.6. (S5) ENGINE SPEED HUNTS

- 13.7. (S6) ENGINE LACKS POWER

- 13.8. (S7) EXHAUST SMOKE IS BLACK

- 13.9. (S8) OIL CONSUMPTION IS EXCESSIVE OR EXHAUST SMOKE IS BLUE

- 13.10. (S9) OIL BECOMES CONTAMINATED QUICKLY

- 13.11. (S10) FUEL CONSUMPTION IS EXCESSIVE

- 13.12. (S11) OIL FOUND IN COOLANT, OR COOLANT SPURTS FROM RADIATOR

- 13.13. (S12) OIL PRESSURE CAUTION LAMP LIGHTS UP

- 13.14. (S13) OIL LEVEL RISES (COOLANT OR FUEL FOUND IN OIL)

- 13.15. (S14) COOLANT TEMPERATURE TOO HIGH (OVERHEATING)

- 13.16. (S15) ABNORMAL NOISE IS HEARD WHEN ENGINE IS RUNNUNG

- 13.17. (S16) EXCESSIVE VIBRATION WHEN ENGINE IS RUNNING

- 14. DISASSEMBLY AND ASSEMBLY

- 14.1. HOW TO USE THIS MANUAL

- 14.2. PRECAUTIONS WHEN CARRYING OUT AN OPERATION

- 14.3. SPECIAL TOOL LIST

- 14.4. CONNECTOR REPAIR PROCEDURES

- 14.5. ENGINE ASSEMBLY

- 14.6. RADIATOR AND AFTERCOOLER

- 14.7. COOLING FAN AND FAN MOTOR ASSEMBLY

- 14.8. FUEL TANK ASSEMBLY

- 14.9. TRANSFER ASSEMBLY

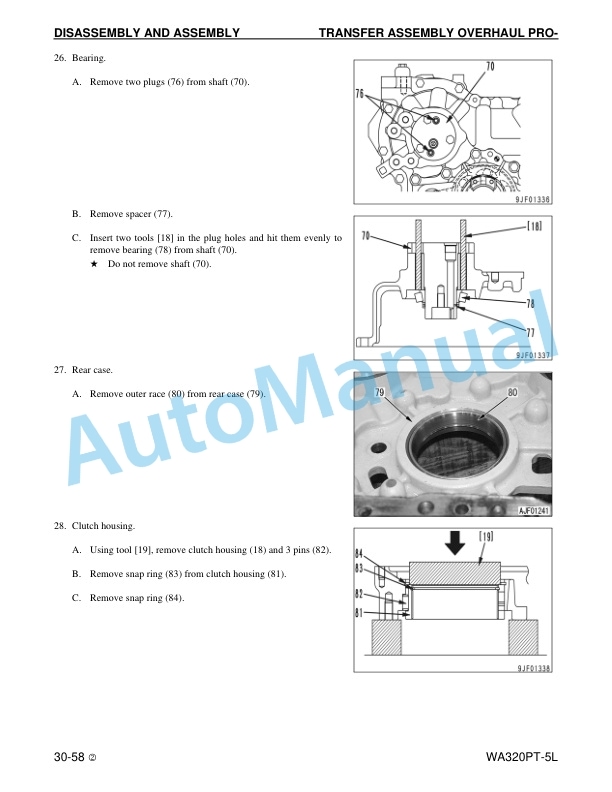

- 14.10. TRANSFER ASSEMBLY OVERHAUL PROCEDURES

- 14.11. PARKING BRAKE ASSEMBLY

- 14.12. PARKING BRAKE ASSEMBLY OVERHAUL PROCEDURES

- 14.13. FRONT AXLE ASSEMBLY

- 14.14. REAR AXLE ASSEMBLY

- 14.15. FRONT AND REAR AXLE HOUSING OVERHAUL PROCEDURES

- 14.16. DIFFERENTIAL CARRIER OVERHAUL PROCEDURES

- 14.17. HST AND 4GEAR PUMP ASSEMBLY

- 14.18. HST MOTOR 1 ASSEMBLY

- 14.19. HST MOTOR 2 ASSEMBLY

- 14.20. WORK EQUIPMENT CONTROL VALVE ASSEMBLY

- 14.21. TRAVEL DAMPER VALVE ASSEMBLY

- 14.22. HYDRAULIC TANK ASSEMBLY

- 14.23. HST PUMP OVERHAUL PROCEDURES

- 14.24. HST MOTOR OVERHAUL PROCEDURES

- 14.25. CYLINDERS

- 14.26. CYLINDER OVERHAUL PROCEDURES

- 14.27. WORK EQUIPMENT ASSEMBLY

- 14.28. OPERATORS CAB ASSEMBLY

- 14.29. OPERATORS CAB GLASS

- 14.30. CENTER HINGE PIN

- 14.31. REAR COUNTERWEIGHT

- 14.32. AIR CONDITIONER UNIT

- 14.33. REFRIGERENT COMPRESSOR ASSEMBLY

- 14.34. MONITOR PANEL

- 14.35. HST CONTROLLER

- 14.36. KOMTRAX TERMINAL ASSEMBLY

- 15. OTHER

- 15.1. HYDRAULIC CIRCUIT DIAGRAM

- 15.2. ELECTRICAL CIRCUIT DIAGRAM

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF