- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA380-3 Wheel Loader Shop Manual VEBM460104

$40.00

- Type Of Manual: Shop Manual

- Manual ID: VEBM460104

- Format: PDF

- Size: 40.1MB

- Number of Pages: 970

Category: Komatsu Shop Manual PDF

-

Model List:

- WA380-3 Wheel Loader

- 1. Contents

- 1.1. General

- 1.1.1. Up to SN WA380H20500

- 1.1.2. Dimensions and weights

- 1.1.3. Dimensions and weights highlift

- 1.1.4. Specifications

- 1.1.5. Weight table

- 1.1.6. List of lubricant and water

- 1.1.7. SN WA380H20501 and up

- 1.1.8. Dimensions and weights

- 1.1.9. Specifications

- 1.1.10. Weight table

- 1.1.11. List of lubricant and water

- 1.1.12. Outlines of service

- 1.1.13. General view of controls and gauges

- 1.1.14. Torque list

- 1.2. Structure and function

- 1.2.1. Power train

- 1.2.2. Power train system

- 1.2.3. Torque converter, transmission piping

- 1.2.4. Transmission hydraulic circuit diagram

- 1.2.5. Torque converter

- 1.2.6. Torque converter oil filter

- 1.2.7. Transmission

- 1.2.8. Transmission control valve

- 1.2.9. Upper valve

- 1.2.10. Transmission solenoid valve

- 1.2.11. Pilot reducing valve

- 1.2.12. Main relief valve

- 1.2.13. Torque converter outlet port valve

- 1.2.14. Priority valve

- 1.2.15. Directional selector valve

- 1.2.16. HL selector valve and range selector valve

- 1.2.17. Emergency manuel spool

- 1.2.18. Electronic control modulation valve (ECMV)

- 1.2.19. Pilot oil filter

- 1.2.20. Accumulator valve

- 1.2.21. Flow control valve

- 1.2.22. Axle mount, center hinge pin

- 1.2.23. Steering piping

- 1.2.24. Steering control, orbit roll

- 1.2.25. Orbit roll valve

- 1.2.26. Steering valve

- 1.2.27. Overload relief valve

- 1.2.28. Steering relief valve

- 1.2.29. Operation of demand valve

- 1.2.30. Emergency steering

- 1.2.31. Brake piping

- 1.2.32. Park brake and foot brake circuits

- 1.2.33. Brake valve

- 1.2.34. Accumulator charge valve

- 1.2.35. Accumulator for brake system

- 1.2.36. Brake circuit diagram

- 1.2.37. Brake

- 1.2.38. Parking brake control

- 1.2.39. Parking brake

- 1.2.40. Parking brake valve

- 1.2.41. Hydraulic piping

- 1.2.42. Work equipment hydraulic system diagram

- 1.2.43. Work equipment lever linkage

- 1.2.44. Hydraulic tank

- 1.2.45. Oil filter bypass valve

- 1.2.46. PPC valve

- 1.2.47. Operation of PPC valve

- 1.2.48. PPC relief valve

- 1.2.49. Accumulator (for PPC valve)

- 1.2.50. Main control valve (up to H20383)

- 1.2.51. Relief valve (up to H20383)

- 1.2.52. Safety valve with suction (up to H20383)

- 1.2.53. Suction valve (up to H20383)

- 1.2.54. Main control valve (from H20384 up to H20836)

- 1.2.55. Safety valve with suction (H20384 and up)

- 1.2.56. Antcavitation valve (H20384 and up)

- 1.2.57. Safety valve (H20384 and up)

- 1.2.58. Main control valve (H20837 and up)

- 1.2.59. Operation of cutoff valve (up to H20383)

- 1.2.60. Work equipment valve operation

- 1.2.61. Hydraulic safety system (up to H20836)

- 1.2.62. Hydraulic safety system location (up to H20836)

- 1.2.63. Hydraulic safety valve (up to H20836)

- 1.2.64. Work equipment linkage

- 1.2.65. Bucket

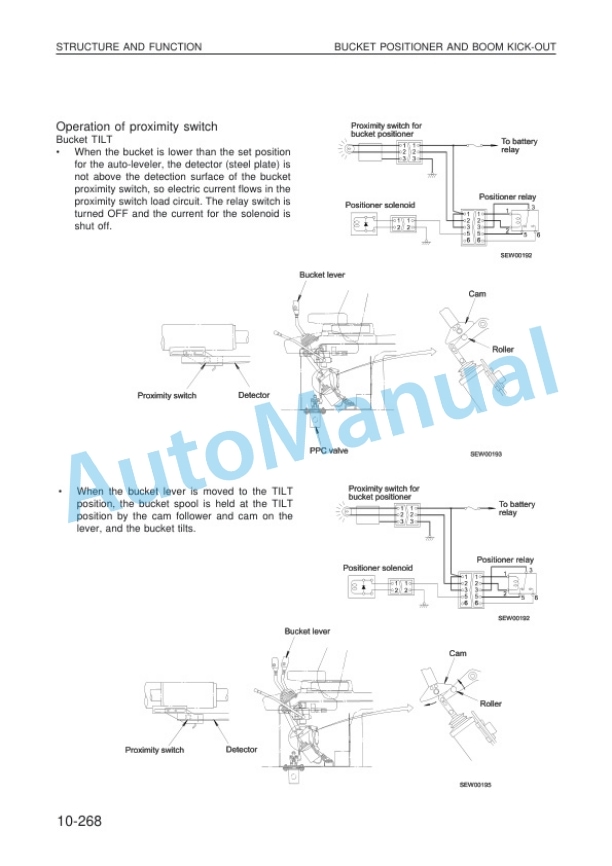

- 1.2.66. Bucket positioner and boom kickout

- 1.2.67. Wiring diagrams

- 1.2.68. Machine monitor system

- 1.2.69. Transmission auotshift control system

- 1.2.70. Transmission controller

- 1.2.71. ECSS (ALS electronic)

- 1.2.72. Sensors

- 1.2.73. Engine starting circuit

- 1.2.74. Engine stop circuit

- 1.2.75. Preheating circuit

- 1.2.76. Electric transmission

- 1.2.77. Combination switch

- 1.2.78. Kickdown, hold switch

- 1.2.79. Kickdown electric circuit diagram

- 1.2.80. Transmission cutoff function

- 1.2.81. Parking brake transmission neutralizer

- 1.2.82. Air conditioner

- 1.3. Testing and adjusting

- 1.3.1. Standard value table for engine

- 1.3.2. Standard value table for chassis

- 1.3.3. Tesz certificate

- 1.3.4. Standard value table for electrical system

- 1.3.5. Tools for testing, adjusting and troubleshooting

- 1.3.6. Adjusting valve clearance

- 1.3.7. Measuring compression pressure

- 1.3.8. Measuring blowby pressure

- 1.3.9. Testing and adjusting fuel injection timing

- 1.3.10. Measuring intake air pressure

- 1.3.11. Measuring engine oil pressure

- 1.3.12. Measuring engine speed

- 1.3.13. Measuring stall speed

- 1.3.14. Testing the fan belt tension

- 1.3.15. Measuring turbocharger clearance

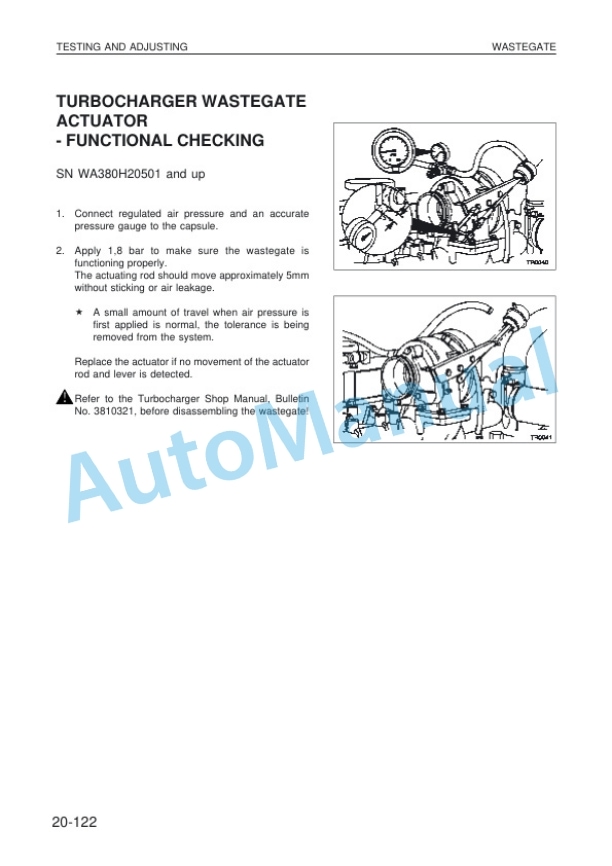

- 1.3.16. Turbocharger wastegate actuator visual inspection

- 1.3.17. Turbocharger wastegate actuator functional checking

- 1.3.18. Adjusting valve clearance

- 1.3.19. Measuring compression pressure

- 1.3.20. Measuring blowby pressure

- 1.3.21. Testing and adjusting fuel injection timing

- 1.3.22. Measuring exhaust color

- 1.3.23. Measuring inkake air pressure (boost pressure)

- 1.3.24. Measuring exhaust gas pressure

- 1.3.25. Measuring engine oil pressure

- 1.3.26. Measuring engine speed

- 1.3.27. Testing and adjusting fan belt tension

- 1.3.28. Method for adjusting engine stop cable

- 1.3.29. Measuring accelerator pedal

- 1.3.30. Basic adjustment of accelerator pedal

- 1.3.31. Measuring operating force, travel of speed lever

- 1.3.32. Measuring stall speed

- 1.3.33. Measuring torque converter, transmission, parking brake oil pressure

- 1.3.34. Method of operating emergency manual spool

- 1.3.35. Measuring clearance between tire and wheel

- 1.3.36. Measuring steering oil pressure

- 1.3.37. Measuring operating force, travel of brake pedal

- 1.3.38. Measuring brake performance

- 1.3.39. Testing brake oil pressure

- 1.3.40. Testing for brake disk wear

- 1.3.41. Bleeding air from brake system

- 1.3.42. Measuring parking brake performance

- 1.3.43. Manual release method for parking brake

- 1.3.44. Testing wear of parking brake disk

- 1.3.45. Measuring work equipment control lever

- 1.3.46. Measuring work equipment hydraulic pressure

- 1.3.47. Measuring PPCvalve pressure

- 1.3.48. Measuring work equipment

- 1.3.49. Testing and adjusting bucket positioner

- 1.3.50. Testing and adjusting boom kickout

- 1.3.51. Adjusting main monitor

- 1.3.52. Gas side test and topping up gas pressure

- 1.3.53. Hydraulic accumulator

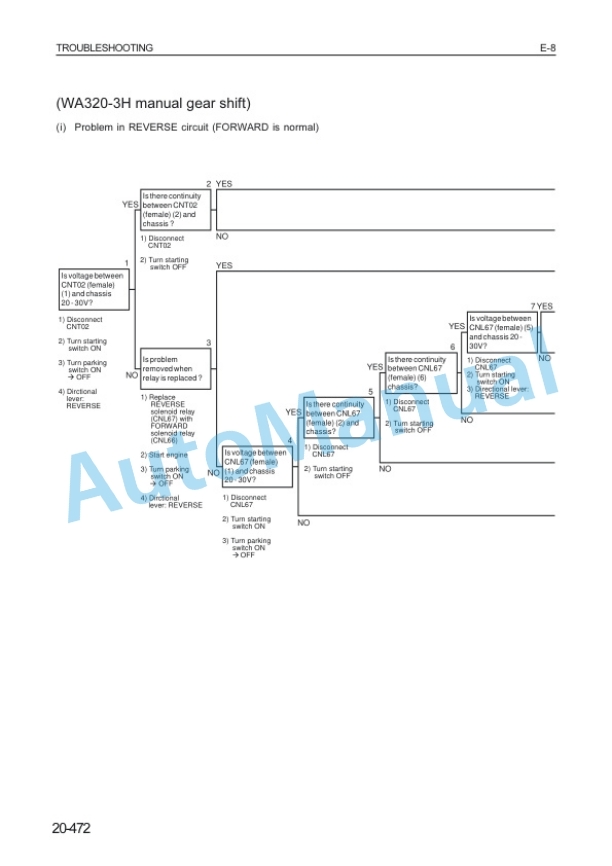

- 1.3.54. Troubleshooting

- 1.4. Disassembly and assembly

- 1.4.1. Precautions when carrying out operations

- 1.4.2. Special tool list

- 1.4.3. Starting motor

- 1.4.4. Alternator

- 1.4.5. Engine oil cooler

- 1.4.6. Fuel injection pump

- 1.4.7. Torque converter charging pump

- 1.4.8. Torque converter, transmission

- 1.4.9. Torque converter

- 1.4.10. Transmission

- 1.4.11. Transmission clutch pack

- 1.4.12. Transmission control valve

- 1.4.13. Transmission accumulator valve

- 1.4.14. Center hinge pin

- 1.4.15. Steering gear

- 1.4.16. Steering valve

- 1.4.17. Steering cylinder

- 1.4.18. Brake valve

- 1.4.19. Right brake valve (tandem)

- 1.4.20. Left brake valve (single)

- 1.4.21. Parking brake disc

- 1.4.22. Hydraulic tank

- 1.4.23. Hydraulic filter

- 1.4.24. Hydraulic, steering, switch, PPC pump

- 1.4.25. Main control valve

- 1.4.26. PPC valve

- 1.4.27. Bucket cylinder

- 1.4.28. Boom cylinder

- 1.4.29. Hydraulic cylinder

- 1.4.30. Work equipment

- 1.4.31. Counterweight

- 1.4.32. Fuel tank

- 1.4.33. Cab, floor frame

- 1.4.35. Main monitor

- 1.4.36. Maintenance monitor

- 1.4.37. Air conditioner unit

- 1.4.38. Air conditioner condenser

- 1.4.39. Dry receiver

- 1.4.40. Air conditioner condenser compressor

- 1.5. Maintenance standard

- 1.5.1. Engine mount, transmission mount

- 1.5.2. Torque converter charging pump

- 1.5.3. Torque converter

- 1.5.4. Transmission

- 1.5.5. Transmission control valve

- 1.5.6. Flow control valve

- 1.5.7. Accumulator valve

- 1.5.8. Drive shaft

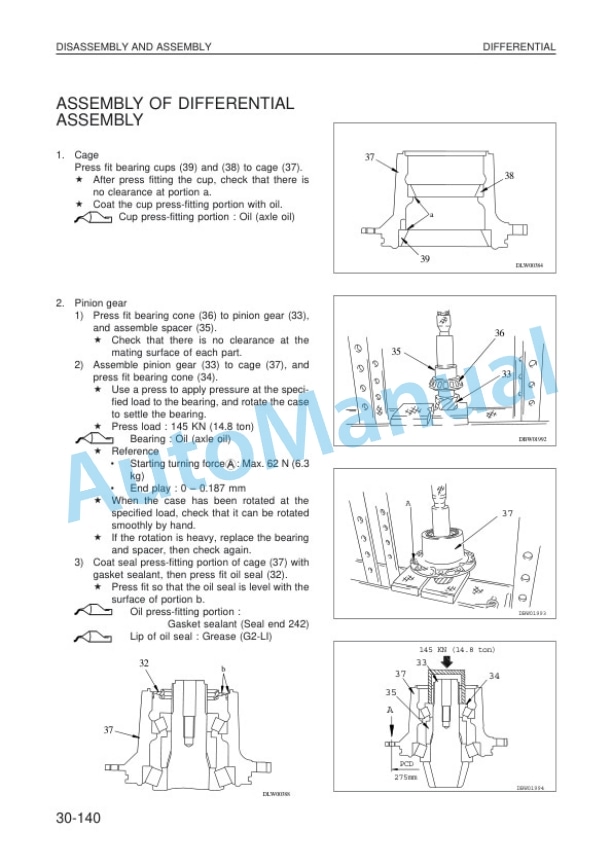

- 1.5.9. Differential

- 1.5.10. Final drive

- 1.5.11. Axle mount

- 1.5.12. Center hinge pin

- 1.5.13. Steering column

- 1.5.14. Steering valve

- 1.5.15. Steering cylinder mount

- 1.5.16. Brake

- 1.5.17. Brake valve

- 1.5.18. Parking brake

- 1.5.19. Hydraulic pump

- 1.5.20. Main control valve

- 1.5.21. PPC valve

- 1.5.22. Hydraulic cylinder

- 1.5.23. Work equipment linkage

- 1.5.24. Bucket

- 1.5.25. Bucket positioner and boom kickout

- 2. Diagrams

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF