- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA380-5 Wheel Loader Shop Manual SEBM024716

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM024716

- Format: PDF

- Size: 75.8MB

- Number of Pages: 1244

Category: Komatsu Shop Manual PDF

-

Model List:

- WA380-5 Wheel Loader

- 1. CONTENTS

- 2. GENERAL

- 2.1. GENERAL ASSEMBLY DRAWING

- 2.2. SPECIFICATIONS

- 2.3. WEIGHT TABLE

- 2.4. LIST OF LUBRICANT AND COOLANT

- 3. STRUCTURE AND FUNCTION, MAINTENANCE STANDARD

- 3.1. COOLING SYSTEM

- 3.2. ENGINE MOUNT, TRANSMISSION MOUNT

- 3.3. POWER TRAIN

- 3.4. POWER TRAIN SYSTEM DIAGRAM

- 3.5. DRIVE SHAFT (PROPELLER SHAFT)

- 3.6. TORQUE CONVERTER, TRANSMISSION PIPING

- 3.7. TORQUE CONVERTER

- 3.8. TRANSMISSION

- 3.9. TRANSMISSION CONTROL VALVE

- 3.10. AXLE

- 3.11. DIFFERENTIAL

- 3.12. FINAL DRIVE

- 3.13. AXLE MOUNTING,CENTER HINGE PIN

- 3.14. STEERING PIPING

- 3.15. STEERING COLUMN, ORBITROLL

- 3.16. STEERING VALVE

- 3.17. ORBITROLL VALVE

- 3.18. STOP VALVE

- 3.19. STEERING PUMP, SWITCH PUMP

- 3.20. EMERGENCY STEERING PUMP (IF EQUIPPED)

- 3.21. EMERGENCY STEERING MOTOR (IF EQUIPPED)

- 3.22. STEERING CYLINDER

- 3.23. JOYSTICK STEERING LEVER (IF EQUIPPED)

- 3.24. STEERING LEVER (IF EQUIPPED)

- 3.25. STEERING SWITCH VALVE (IF EQUIPPED)

- 3.26. BRAKE PIPING

- 3.27. BRAKE VALVE

- 3.28. CHARGE VALVE

- 3.29. ACCUMULATOR (FOR BRAKE)

- 3.30. BRAKE

- 3.31. PARKING BRAKE CONTROL

- 3.32. PARKING BRAKE

- 3.33. PARKING BRAKE SOLENOID VALVE

- 3.34. PARKING BRAKE EMERGENCY RELEASE VALVE

- 3.35. HYDRAULI PIPING

- 3.36. WORK EQUIPMENT CONTROL LEVER

- 3.37. HYDRAULIC TANK

- 3.38. TORQUE CONVERTER CHARGING, WORK EQUIPMENT, AND PILOT CONTROL PUMPS

- 3.39. PPC RELIEF VALVE

- 3.40. VALVE (IF EQUIPPED)

- 3.41. WORK EQUIPMENT CONTROL VALVE

- 3.42. WORK EQUIPMENT PPC VALVE

- 3.43. PPC VALVE (FOR MULTI FUNCTION MONO LEVER)

- 3.44. EPC SOLENOID VALVE (IF EQUIPPED)

- 3.45. SHUT OFF VALVE (IF EQUIPPED)

- 3.46. ATTACHMENT PPC VALVE (IF EQUIPPED)

- 3.47. COOLING FAN MOTOR

- 3.48. COOLING FAN MOTOR DRIVE PUMP

- 3.49. WORK EQUIPMENT LINKAGE

- 3.50. BUCKET

- 3.51. BUCKET POSITIONER, LIFT ARM KICKOUT

- 3.52. WORK EQUIPMENT CYLINDER

- 3.54. AIR CONDITIONER (IF EQUIPPED)

- 3.55. MACHINE MONITORING SYSTEM

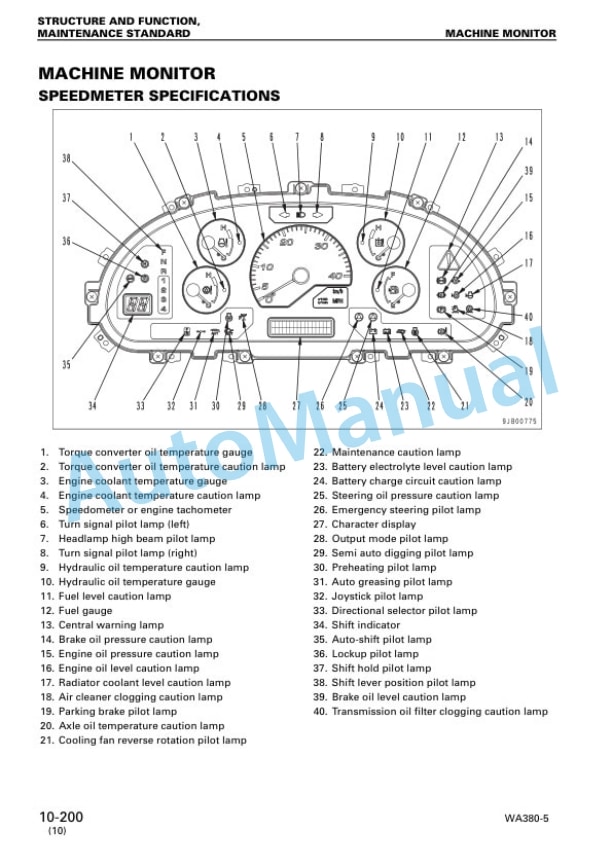

- 3.56. MACHINE MONITOR

- 3.57. TRANSMISSION CONTROL SYSTEM

- 3.58. TRANSMISSION CONTROLLER

- 3.59. WORK EQUIPMENT CONTROL SYSTEM (IF EQUIPPED)

- 3.60. WORK EQUIPMENT CONTROLLER (IF EQUIPPED)

- 3.61. ELECTRIC TRANSMISSION CONTROL

- 3.62. KICK DOWN, HOLD SWITCH

- 3.63. ENGINE STARTING CIRCUIT

- 3.64. ENGINE STOP CIRCUIT

- 3.65. PREHEATING CIRCUIT

- 3.66. ENGINE POWER MODE SELECTOR CIRCUIT

- 3.67. PARKING BRAKE CIRCUIT

- 3.68. SENSORS

- 4. TESTING AND ADJUSTING

- 4.1. STANDARD VALUE TABLE FOR ENGINE

- 4.2. STANDARD VALUE TABLE FOR CHASSIS

- 4.3. TESTING AND ADJUSTING

- 4.3.1. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 4.3.2. MEASURING ENGINE SPEED

- 4.3.3. MEASURING EXHAUST COLOR

- 4.3.4. MEASURING EXHAUST TEMPERATURE

- 4.3.5. ADJUSTING VALVE CLEARANCE

- 4.3.6. MEASURING COMPRESSION PRESSURE

- 4.3.7. MEASURING BLOWBY PRESSURE

- 4.3.8. MEASURING ENGINE OIL PRESSURE

- 4.3.9. MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)

- 4.3.10. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 4.3.11. ADJUSTING ENGINE SPEED SENSOR

- 4.3.12. BLEEDING AIR FROM FUEL CIRCUIT

- 4.3.13. ADJUSTING ENGINE STOP SOLENOID

- 4.3.14. ADJUSTING ACCELERATOR PEDAL

- 4.3.15. ADJUSTING TRANSMISSION SPEED SENSOR

- 4.3.16. TESTING AND ADJUSTING POWER TRAIN OIL PRESSURE

- 4.3.17. DRAWING OF SPECIAL TOOL

- 4.3.18. PROCEDURE FOR FLUSHING TORQUE CONVERTER, TRANSMISSION HYDRAULIC CIRCUIT

- 4.3.19. PROCEDURE FOR MOVING MACHINE WHEN TRANSMISSION VALVE FAILS

- 4.3.20. TESTING AND ADJUSTING STEERING CONTROL

- 4.3.21. TESTING AND ADJUSTING STEERING OIL PRESSURE

- 4.3.22. TESTING HYDRAULIC FAN

- 4.3.23. MEASURING BRAKE OIL PRESSURE

- 4.3.24. TESTING WEAR OF WHEEL BRAKE DISC

- 4.3.25. BLEEDING AIR FROM BRAKE CIRCUIT

- 4.3.26. TESTING WEAR OF PARKING BRAKE DISC

- 4.3.27. MANUAL RELEASE METHOD FOR PARKING BRAKE

- 4.3.28. TESTING AND ADJUSTING ACCUMULATOR CHARGE PRESSURE

- 4.3.29. TESTING AND ADJUSTING WORKING EQUIPMENT PPC OIL PRESSURE

- 4.3.30. TESTING AND ADJUSTING WORK EQUIPMENT HYDRAULIC PRESSURE

- 4.3.31. TESTING AND ADJUSTING BUCKET POSITIONER

- 4.3.32. TESTING AND ADJUSTING LIFT ARM KICKOUT

- 4.3.33. CHECKING PROXIMITY SWITCH ACTUATION PILOT LAMP

- 4.3.34. ADJUSTING MACHINE MONITOR

- 4.3.35. TESTING AND ADJUSTING LOAD METER

- 4.3.36. BLEEDING AIR

- 4.3.37. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 4.3.38. RELEASING REMAINING PRESSURE IN E.C.S.S. CIRCUIT

- 4.3.39. PM CLINIC INSPECTION TABLE

- 4.4. TROUBLESHOOTING

- 4.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 4.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 4.4.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 4.4.4. CHECKS BEFORE TROUBLESHOOTING

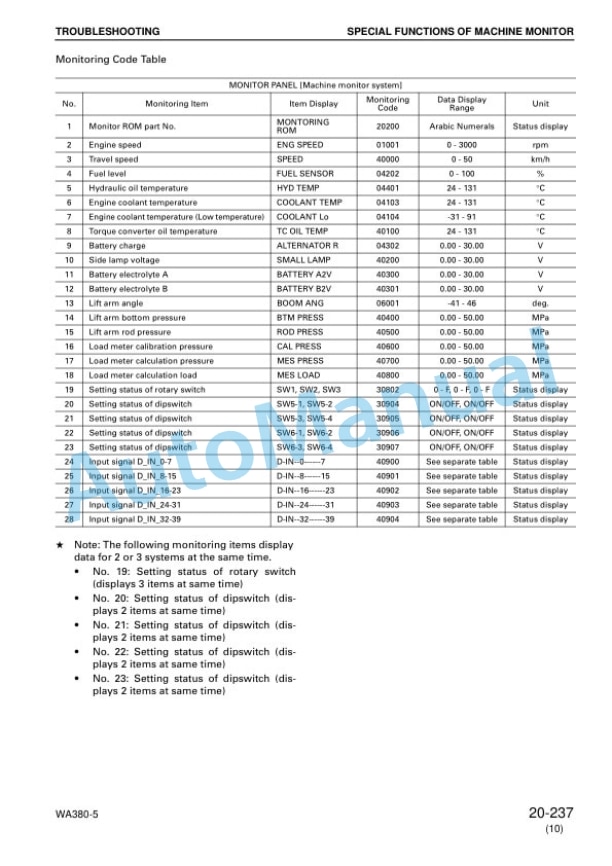

- 4.4.5. SPECIAL FUNCTIONS OF MACHINE MONITOR

- 4.4.6. CATEGORIES, PROCEDURE, AND METHOD OF USING TROUBLESHOOTING CHARTS

- 4.4.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 4.4.8. TADAPTER TABLE

- 4.4.9. TROUBLESHOOTING OF TRANSMISSION CONTROL SYSTEM (TM MODE)

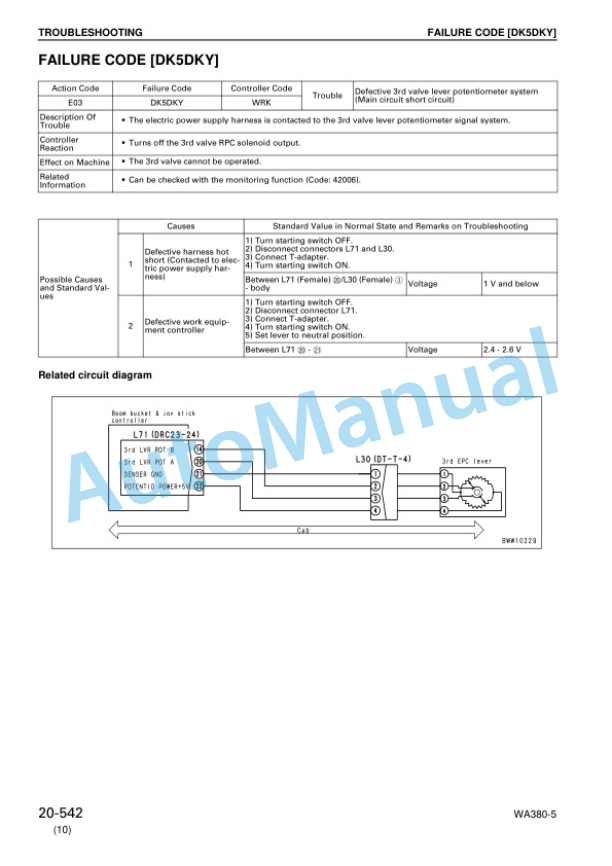

- 4.4.10. TROUBLESHOOTING OF WORK EQUIPMENT CONTROL SYSTEM (WRK MODE)

- 4.4.11. TROUBLESHOOTING OF MONITOR SYSTEM (MON MODE)

- 4.4.12. TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H MODE)

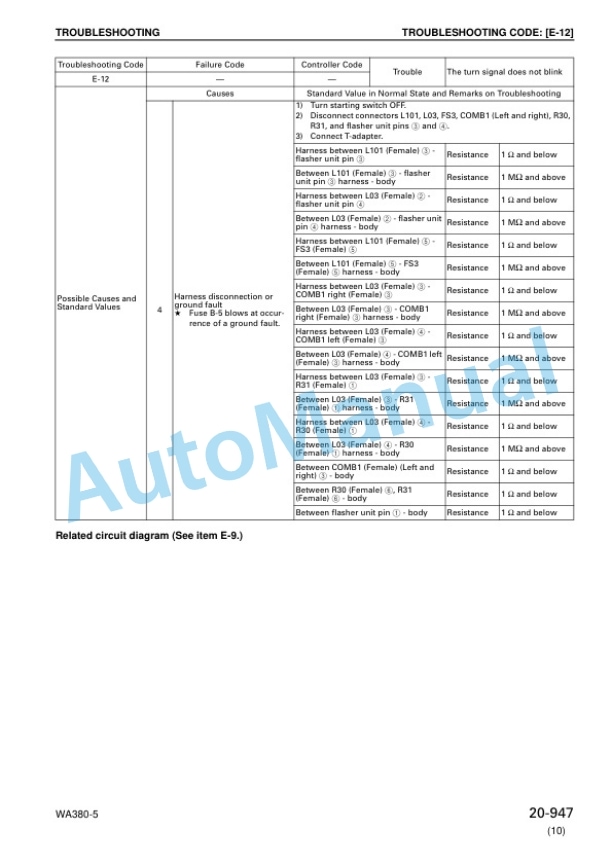

- 4.4.13. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 4.4.14. TROUBLESHOOTING OF ENGINE (S MODE)

- 5. DISASSEMBLY AND ASSEMBLY

- 5.1. How To Read This Manual

- 5.2. Precautions When Carrying Out Operation

- 5.3. Special tool list

- 5.4. Removal and Installation of Engine Assembly

- 5.5. Removal and Installation of Cylinder Head Assembly

- 5.6. Removal and Installation of Radiator and Fan Motor Assembly

- 5.7. Removal and Installation of Aftercooler Assembly

- 5.8. Removal and Installation of Fuel Injection Pump

- 5.9. Removal and Installation of Nozzle Holder Assembly

- 5.10. Removal and installation of fan and fan motorassembly

- 5.11. Removal and Installation of Fuel Tank Assembly

- 5.12. Removal and Installation of Parking Brake Disc Plate

- 5.13. Removal and Installation of Torque Converter and Transmission Assembly

- 5.14. Disassembly and Assembly of Transmission Assembly

- 5.15. Disassembly and Assembly of Transmission Clutch Pack Assembly

- 5.16. Disassembly and Assembly of Parking Brake Assembly

- 5.17. Disassembly and Assembly of Torque Converter Assembly (Standard Specification)

- 5.18. Disassembly and Assembly of Torque Converter Assembly (LockUp Specification)

- 5.19. Removal and Installation of Rear Axle Assembly

- 5.20. Removal and Installation of Front Axle Assembly

- 5.21. Disassembly and Assembly of Axle Housing Assembly

- 5.22. Disassembly and Assembly of Differential Assembly

- 5.23. Removal and Installation of Center Hinge Pin

- 5.24. Removal and Installation of Cab Assembly

- 5.25. Removal and Installation of Cab and Floor Frame Assembly

- 5.26. Removal and installation of operators cab glass (Stuck glass)

- 5.27. Removal and Installation of Transmission, Work Equipment, and PPC Pump Assembly

- 5.28. Removal and Installation of Steering, Switching, and Fan Pump Assembly

- 5.29. Removal and Installation of Steering Demand Valve Assembly

- 5.30. Removal and installation of steering valve oil seal

- 5.31. Removal and Installation of E.C.S.S. Valve Assembly

- 5.32. Removal and Installation of Work Equipment Valve Assembly

- 5.33. Disassembly and Assembly of Hydraulic Cylinder Assembly (Steering, Lift, and Bucket Cylinder Assembly)

- 5.34. Removal and Installation of Hydraulic Tank Assembly

- 5.35. Removal and Installation of Work Equipment Assembly

- 5.36. Removal and Installation of Counter Weight

- 5.37. Removal and Installation of Air Conditioner Unit Assembly

- 5.38. Removal and Installation of Air Conditioner Compressor Assembly

- 5.39. Disassembly, Assembly of Operators Seat Assembly

- 6. OTHERS

- 6.1. POWER TRAIN OIL CIRCUIT DIAGRAM (WITHOUT TORQUE CONVERTER LOCKUP CLUTCH)

- 6.2. POWER TRAIN OIL CIRCUIT DIAGRAM (WITH TORQUE CONVERTER LOCKUP CLUTCH)

- 6.3. BRAKE OIL CIRCUIT DIAGRAM

- 6.4. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM

- 6.5. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (FOR ELECTRIC WORK EQUIPMENT LEVER)

- 6.6. ELECTRICAL CIRCUIT DIAGRAM

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF