- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA430-5 Wheel Loader Shop Manual SEBM025406

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM025406

- Format: PDF

- Size: 81.3MB

- Number of Pages: 1216

Category: Komatsu Shop Manual PDF

-

Model List:

- WA430-5 Wheel Loader

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL ASSEMBLY DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. LIST OF LUBRICANT AND COOLANT

- 4. STRUCTURE AND FUNCTION,MAINTENANCE STANDARD

- 4.1. COOLING SYSTEM

- 4.2. ENGINE MOUNT, TRANSMISSION MOUNT

- 4.3. POWER TRAIN

- 4.4. POWER TRAIN SYSTEM DIAGRAM

- 4.5. DRIVE SHAFT (PROPELLER SHAFT)

- 4.6. TORQUE CONVERTER,TRANSMISSION PIPING

- 4.7. TORQUE CONVERTER

- 4.8. TRANSMISSION

- 4.9. TRANSMISSION CONTROL VALVE

- 4.10. AXLE

- 4.11. DIFFERENTIAL

- 4.12. FINAL DRIVE

- 4.13. AXLE MOUNTING,CENTER HINGE PIN

- 4.14. STEERING PIPING

- 4.15. STEERING COLUMN,ORBITROLL

- 4.16. STEERING VALVE

- 4.17. ORBITROLL VALVE

- 4.18. STOP VALVE

- 4.19. STEERING PUMP, SWITCH PUMP

- 4.20. EMERGENCY STEERING PUMP(OP)

- 4.21. EMERGENCY STEERING MOTOR(OP)

- 4.22. STEERING CYLINDER

- 4.23. JOYSTICK STEERING LEVER (OP)

- 4.24. STEERING LEVER (OP)

- 4.25. STEERING SWITCH VALVE (OP)

- 4.26. BRAKE PIPING

- 4.27. BRAKE VALVE

- 4.28. CHARGE VALVE

- 4.29. ACCUMULATOR (FOR BRAKE)

- 4.30. BRAKE

- 4.31. PARKING BRAKE CONTROL

- 4.32. PARKING BRAKE

- 4.33. PARKING BRAKE SOLENOID VALVE

- 4.34. PARKING BRAKE EMERGENCY RELEASE VALVE

- 4.35. HYDRAULIC PIPING

- 4.36. WORK EQUIPMENT CONTROL LEVER

- 4.37. HYDRAULIC TANK

- 4.38. TORQUE CONVERTER CHARGING,WORK EQUIPMENT,AND PILOT CONTROL PUMPS

- 4.39. PPC RELIEF VALVE

- 4.40. S .VALVE (OP)

- 4.41. WORK EQUIPMENT CONTROL VALVE

- 4.42. WORK EQUIPMENT PPC VALVE

- 4.43. PPC VALVE (FOR MULTI FUNCTION MONO LEVER)

- 4.44. OPERATION

- 4.45. EPC SOLENOID VALVE(OP)

- 4.46. SHUT OFF VALVE (OP)

- 4.47. ATTACHMENT PPC VALVE(OP)

- 4.48. COOLING FAN MOTOR

- 4.49. COOLING FAN MOTOR DRIVE PUMP

- 4.50. WORK EQUIPMENT LINKAGE

- 4.51. BUCKET

- 4.52. BUCKET POSITIONER,LIFT ARM KICKOUT

- 4.53. WORK EQUIPMENT CYLINDER

- 4.55. AIR CONDITIONER (OP)

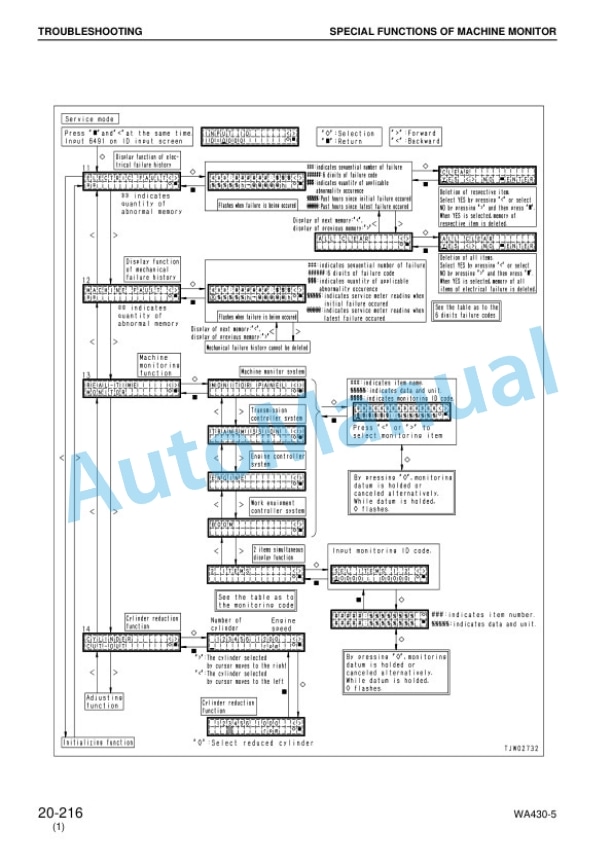

- 4.56. MACHINE MONITORING SYSTEM

- 4.57. MACHINE MONITOR

- 4.58. TRANSMISSION CONTROL SYSTEM

- 4.59. TRANSMISSION CONTROLLER

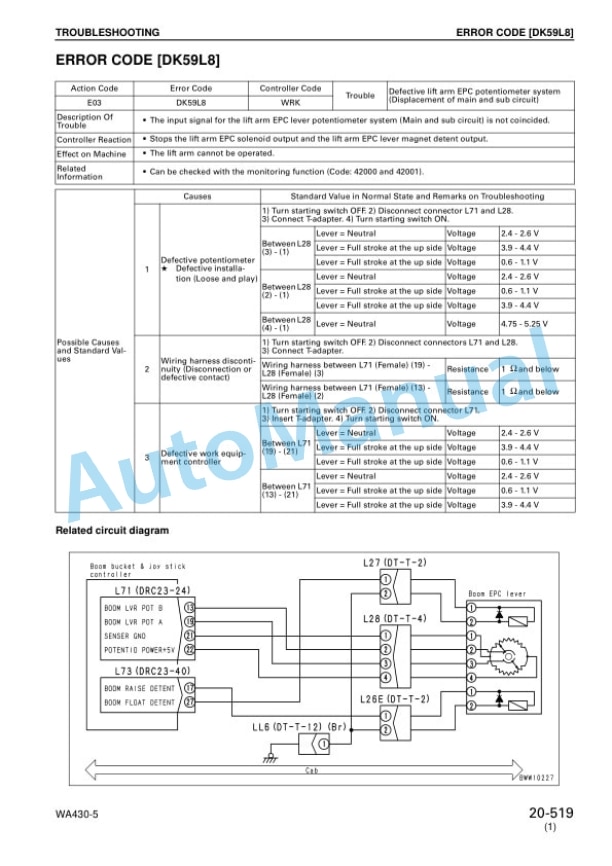

- 4.60. WORK EQUIPMENT CONTROL SYSTEM (OP)

- 4.61. WORK EQUIPMENT CONTROLLER

- 4.62. ELECTRIC TRANSMISSION CONTROL

- 4.63. KICK DOWN,HOLD SWITCH

- 4.64. ENGINE STARTING CIRCUIT

- 4.65. ENGINE STOP CIRCUIT

- 4.66. PREHEATING CIRCUIT

- 4.67. ENGINE POWER MODE SELECTOR CIRCUIT

- 4.68. PARKING BRAKE CIRCUIT

- 4.69. SENSORS

- 5. TESTING AND ADJUSTING

- 5.1. TESTING AND ADJUSTING DATA

- 5.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.3. TESTING AND ADJUSTING

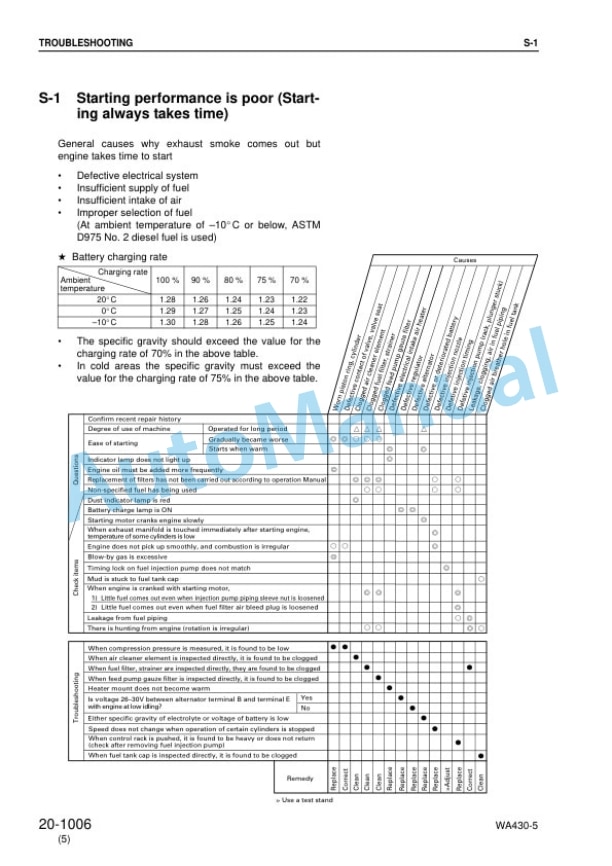

- 5.4. TROUBLESHOOTING

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. HOW TO READ THIS MANUAL

- 6.2. PRECAUTIONS WHEN PERFORMING OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. REMOVAL AND INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY

- 6.5. REMOVAL AND INSTALLATION OF NOZZLE HOLDER ASSEMBLY

- 6.6. REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY

- 6.7. REMOVAL AND INSTALLATION OF ENGINE ADDEMBLY

- 6.8. REMOVAL AND INSTALLATION OF AFTER COOLER ASSEMBLY

- 6.9. REMOVAL AND INSTALLATION OF RADIATOR, FAN MOTOR AND AFTER COOLER ASSEMBLY

- 6.10. REMOVAL AND INSTALLATION FUEL TANK ASSEMBLY

- 6.11. REMOVAL AND INSTALLATION OF PARKING BRAKE DISC AND PLATE

- 6.12. REMOVAL AND INSTALLATION OF TORQUE CONVERTER AND TRANSMISSION ASSEMBLY

- 6.13. DISASSEMBLY AND ASSEMBLY OF TRANSMISSION ASSEMBLY

- 6.14. DISASSEMBLY AND ASSEMBLY OF TRANSMISSION CLUTCH PACK ASSEMBLY

- 6.15. DISASSEMBLY AND ASSEMBLY OF PARKING BRAKE ASSEMBLY

- 6.16. DISASSEMBLY AND ASSEMBLY OF TORQUE CONVERTER ASSEMBLY (STANDARD SPECIFICATION)

- 6.17. DISASSEMBLY AND ASSEMBLY OF TORQUE CONVERTER ASSEMBLY(LOCKUP SPECIFICATION)

- 6.18. REMOVAL AND INSTALLATION OF FRONT AXLE ASSEMBLY

- 6.19. REMOVAL AND INSTALLATION OF REAR AXLE ASSEMBLY

- 6.20. DISASSEMBLY AND ASSEMBLY OF AXLE HOUSING ASSEMBLY

- 6.21. DISASSEMBLY AND ASSEMBLY OF DIFFERENTIAL ASSEMBLY

- 6.22. REMOVAL AND INSTALLATION OF CENTER HING PIN

- 6.23. REMOVAL AND INSTALLATION OF CAB ASSEMBLY

- 6.24. REMOVAL AND INSTALLATION OF CAB AND FLOOR FRAME ASSEMBLY

- 6.25. REMOVAL AND INSTALLATION OF OPERATORS CAB GLASS(STUCK GLASS)

- 6.26. REMOVAL AND INSTALLATION OF TORQUE CONVERTER WORK EQUIPMENT AND PILOT CONTROL PUMP ASSEMBLY

- 6.27. REMOVAL AND INSTALLATION OF STEERING, SWITCH AND FAN PUMP ASSEMBLY

- 6.28. REMOVAL AND INSTALLATION OF STEERING DEMAND VALVE ASSEMBLY

- 6.29. REMOVAL AND INSTALLATION OF STEERING VALVE OIL SEAL

- 6.30. REMOVAL AND INSTALLATION OF TRAVEL DUMPER VALVE ASSEMBLY

- 6.31. REMOVAL AND INSTALLATION OF WORK EQUIPMENT VALVE ASSEMBLY

- 6.32. REMOVAL AND INSTALLATION OF HYDRAULIC TANK

- 6.33. REMOVAL AND INSTALLATION OF HYDRAULIC TANK

- 6.34. DISASSEMBLY AD ASSEMBLY OF HYDRAULIC CYLINDER

- 6.35. REMOVAL AND INSTALLATION OF COUNTER WEIGHT

- 6.36. REMOVAL AND INSTALLATION OF AIR CONDITIONER UNIT

- 6.37. REMOVAL AND INSTALLATION OF AIR CONDITIONER COMPRESSOR ASSEMBLY

- 6.38. DISASSEMBLY, ASSEMBLY OF OPERATORS SEAT ASSEMBLY

- 7. OTHERS

- 7.1. POWER TRAIN OIL CIRCUIT DIAGRAM(WITHOUT TORQUE CONVERTER LOCKUP CLUTCH)

- 7.2. POWER TRAIN OIL CIRCUIT DIAGRAM(WITH TORQUE CONVERTER LOCKUP CLUTCH)

- 7.3. BRAKE OIL CIRCUIT DIAGRAM

- 7.4. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM

- 7.5. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM(FOR ELECTRIC WORK EQUIPMENT LEVER)

- 7.6. ELECTRICAL CIRCUIT DIAGRAM(1/8)(1/4)

- 7.7. ELECTRICAL CIRCUIT DIAGRAM(1/8)(2/4)

- 7.8. ELECTRICAL CIRCUIT DIAGRAM(1/8)(3/4)

- 7.9. ELECTRICAL CIRCUIT DIAGRAM(1/8)(4/4)

- 7.10. ELECTRICAL CIRCUIT DIAGRAM(2/8)(1/4)

- 7.11. ELECTRICAL CIRCUIT DIAGRAM(2/8)(2/4)

- 7.12. ELECTRICAL CIRCUIT DIAGRAM(2/8)(3/4)

- 7.13. ELECTRICAL CIRCUIT DIAGRAM(2/8)(4/4)

- 7.14. ELECTRICAL CIRCUIT DIAGRAM(3/8)

- 7.15. ELECTRICAL CIRCUIT DIAGRAM(4/8)

- 7.16. ELECTRICAL CIRCUIT DIAGRAM(5/8)

- 7.17. ELECTRICAL CIRCUIT DIAGRAM(6/8)

- 7.18. ELECTRICAL CIRCUIT DIAGRAM(7/8)

- 7.19. ELECTRICAL CIRCUIT DIAGRAM(8/8)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF