- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

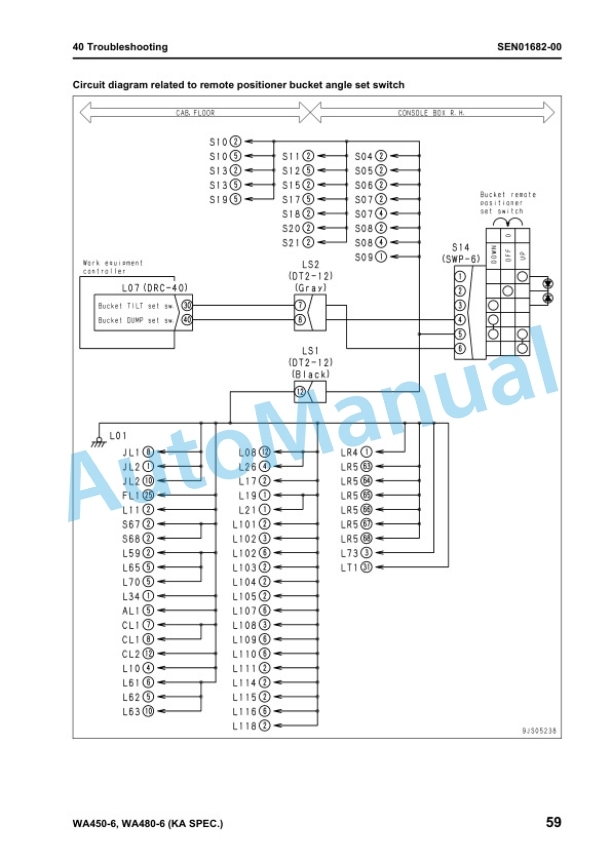

Komatsu WA450-6, WA480-6 Galeo Wheel Loader Shop Manual SEN00809-04

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN00809-04

- Format: PDF

- Size: 56.3MB

- Number of Pages: 1596

Category: Komatsu Shop Manual PDF

-

Model List:

- WA450-6 Galeo Wheel Loader

- WA480-6 Galeo Wheel Loader

- 1. MAIN MENU

- 2. COVER PAGE

- 3. Index and foreword

- 3.1. Index

- 3.1.1. Composition of shop manual

- 3.1.2. Table of contents

- 3.2. Foreword and general information

- 3.2.1. Safety notice

- 3.2.2. How to read the shop manual

- 3.2.3. Explanation of terms for maintenance standard

- 3.2.4. Handling electric equipment and hydraulic component

- 3.2.5. Precautions when carrying out operation

- 3.2.6. Method of disassembling and connecting pushpull type coupler

- 3.2.7. Standard tightening torque table

- 3.2.8. Conversion table

- 4. Specification

- 4.1. Specification and technical data

- 4.1.1. Specification and technical data

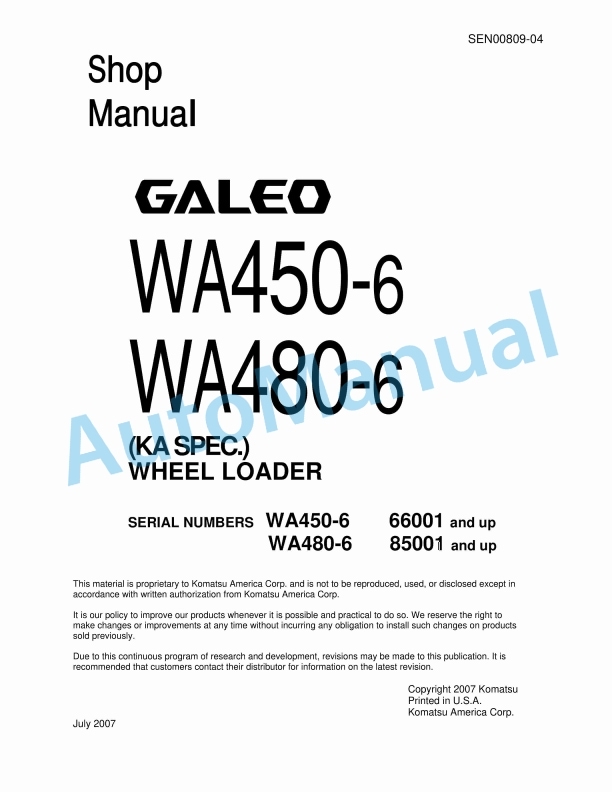

- 5. Structure, function and maintenance standard

- 5.1. Engine and cooling system

- 5.1.1. Engine and cooling system

- 5.1.2. Engine mount and transmission mount

- 5.1.3. Cooling system

- 5.1.4. Cooling fan pump

- 5.1.5. Cooling fan motor

- 5.2. Power train

- 5.2.1. Power train

- 5.3. Steering system

- 5.3.1. Steering system

- 5.4. Brake system

- 5.4.1. Brake system

- 5.5. Undercarriage and frame

- 5.5.1. Undercarriage and frame

- 5.5.2. Tires

- 5.6. Hydraulic system, Part 1

- 5.6.1. Hydraulic system, Part 1

- 5.6.2. Hydraulic piping diagram

- 5.6.3. Work equipment control lever linkage

- 5.6.4. Hydraulic tank

- 5.6.5. Power train pump

- 5.6.6. Work equipment pump

- 5.6.7. Work equipment control valve

- 5.6.8. CLSS

- 5.6.9. Each function and operation of each valve

- 5.7. Hydraulic system, Part 2

- 5.7.1. Hydraulic system, Part 2

- 5.8. Work equipment

- 5.8.1. Work equipment

- 5.9. Cab and its attachments

- 5.9.1. Cab and its attachments

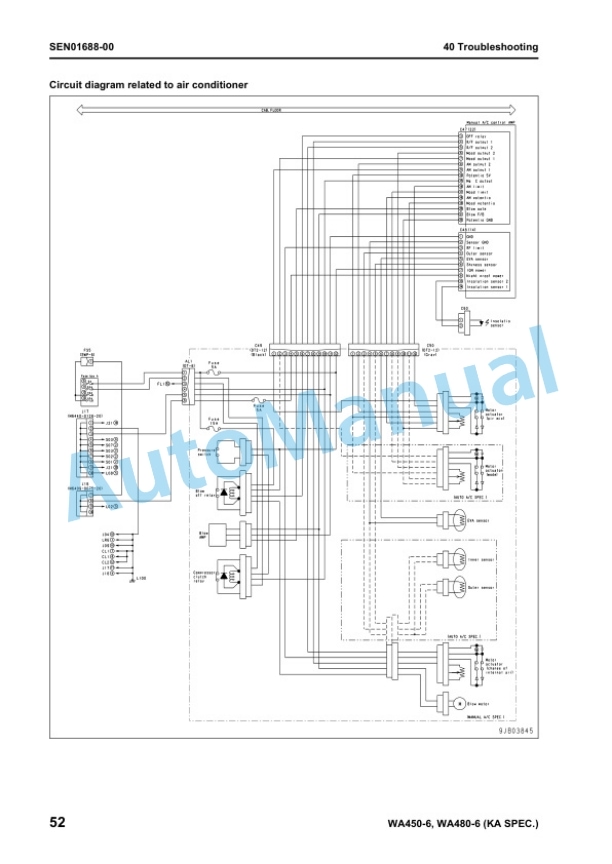

- 5.10. Electrical system, Part 1

- 5.10.1. Electrical system, Part 1

- 5.11. Electrical system, Part 2

- 5.11.1. Electrical system, Part 2

- 5.12. Electrical system, Part 3

- 5.12.1. Electrical system, Part 3

- 6. Standard value table

- 6.1. Standard service value table

- 6.1.1. Standard value table for engine

- 6.1.2. Standard value table for chassis

- 7. Testing and adjusting

- 7.1. Testing and adjusting, Part 1

- 7.1.1. Testing and adjusting, Part 1

- 7.2. Testing and adjusting, Part 2

- 7.2.1. Testing and adjusting, Part 2

- 7.3. Testing and adjusting, Part 3

- 7.3.1. Testing and adjusting, Part 3

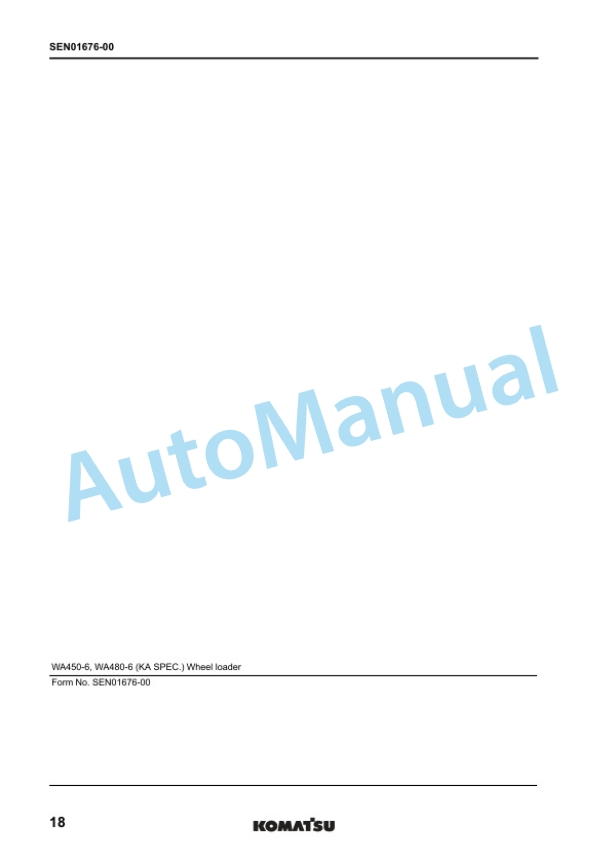

- 8. Troubleshooting

- 8.1. Failure code table and fuse locations

- 8.1.1. Failure code table and fuse locations

- 8.2. General information on troubleshooting

- 8.2.1. General information on troubleshooting

- 8.3. Troubleshooting by failure code (Display of code), Part 1

- 8.3.1. Troubleshooting by failure code (Display of code), Part 1

- 8.4. Troubleshooting by failure code (Display of code), Part 2

- 8.4.1. Troubleshooting by failure code (Display of code), Part 2

- 8.5. Troubleshooting by failure code (Display of code), Part 3

- 8.5.1. Troubleshooting by failure code (Display of code), Part 3

- 8.6. Troubleshooting by failure code (Display of code), Part 4

- 8.6.1. Troubleshooting by failure code (Display of code), Part 4

- 8.7. Troubleshooting by failure code (Display of code), Part 5

- 8.7.1. Troubleshooting by failure code (Display of code), Part 5

- 8.8. Troubleshooting by failure code (Display of code), Part 6

- 8.8.1. Troubleshooting by failure code (Display of code), Part 6

- 8.9. Troubleshooting by failure code (Display of code), Part 7

- 8.9.1. Troubleshooting by failure code (Display of code), Part 7

- 8.9.2. Failure code DHPCKX (Lift arm cylinder bottom pressure sensor Out of input signal range)

- 8.9.3. Failure code DHPDKX (Lift arm cylinder head pressure sensor Out ofinput signal range)

- 8.9.4. Failure code DHT1KX (Transmission cutoff pressure sensor Out of input signal range)

- 8.9.5. Failure code DHT8KA (Steering pump pressure sensor Disconnection)

- 8.9.6. Failure code DHT8KB (Steering pump pressure sensor Short circuit)

- 8.9.7. Failure code DK59KA (Lift arm EPC lever potentiometer (Main) Disconnection)

- 8.9.8. Failure code DK59KY (Lift arm EPC lever potentiometer (Main) Short circuit with power supply line)

- 8.9.9. Failure code DK59L8 (Lift arm EPC lever potentiometer (Main) Analog signals disagree)

- 8.9.10. Failure code DK5AKA (Lift arm EPC lever potentiometer (Sub) Disconnection)

- 8.9.11. Failure code DK5AKY (Lift arm EPC lever potentiometer (Sub) Short circuit with power supply line)

- 8.9.12. Failure code DK5BKA (Bucket EPC lever potentiometer (Main) Disconnection)

- 8.9.13. Failure code DK5BKY (Bucket EPC lever potentiometer (Main) Short circuit with power supply line)

- 8.9.14. Failure code DK5BL8 (Bucket EPC lever potentiometer (Main) Analog signals disagree)

- 8.9.15. Failure code DK5CKA (Bucket EPC lever potentiometer (Sub) Disconnection)

- 8.9.16. Failure code DK5CKY (Bucket EPC lever potentiometer (Sub) Short circuit with power supply line)

- 8.9.17. Failure code DK5DKA (3spool valve (attachment) EPC lever potentiometer (Main) Disconnection)

- 8.9.18. Failure code DK5DKY (3spool valve (attachment) EPC lever potentiometer (Main) Short circuit with power supply line)

- 8.9.19. Failure code DK5DL8 (3spool valve (attachment) EPC lever potentiometer (Main) Analog signals disagree)

- 8.9.20. Failure code DK5EKA (3spool valve (attachment) EPC lever potentiometer (Sub) Disconnection)

- 8.9.21. Failure code DK5EKY (3spool valve EPC lever potentiometer (Sub) Short circuit with power supply line)

- 8.10. Troubleshooting by failure code (Display of code), Part 8

- 8.10.1. Troubleshooting by failure code (Display of code), Part 8

- 8.11. Troubleshooting by failure code (Display of code), Part 9

- 8.11.1. Troubleshooting by failure code (Display of code), Part 9

- 8.12. Troubleshooting by failure code (Display of code), Part 10

- 8.12.1. Troubleshooting by failure code (Display of code), Part 10

- 8.13. Troubleshooting of electrical system (Emode)

- 8.13.1. Troubleshooting of electrical system (Emode)

- 8.14. Troubleshooting of hydraulic and mechanical system (Hmode)

- 8.14.1. Troubleshooting of hydraulic and mechanical system (Hmode)

- 8.15. Troubleshooting of engine (Smode)

- 8.15.1. Troubleshooting of engine (Smode)

- 8.15.2. Method of using troubleshooting chart

- 9. Disassembly and assembly

- 9.1. General information on disassembly andassembly

- 9.1.1. General information on disassembly and assembly

- 9.1.2. How to read this manual

- 9.1.3. Coating materials list

- 9.1.4. Special tools list

- 9.1.5. Sketches of special tools

- 9.2. Engine and cooling system

- 9.2.1. Engine and cooling system

- 9.3. Power train, Part 1

- 9.3.1. Power train, Part 1

- 9.4. Power train, Part 2

- 9.4.1. Power train, Part 2

- 9.5. Undercarriage and frame

- 9.5.1. Undercarriage and frame

- 9.6. Hydraulic system

- 9.6.1. Hydraulic system

- 9.6.2. Removal and installation of steering demand valve assembly

- 9.6.3. Removal and installation of work equipment valve assembly

- 9.6.4. Removal and installation of brake charge valve assembly

- 9.6.5. Removal and installation of hydraulic tank assembly

- 9.6.6. Removal and installation ofsteering and power train pump assembly

- 9.6.7. Removal and installation of workequipment and cooling fan pump assembly

- 9.7. Work equipment

- 9.7.1. Work equipment

- 9.8. Cab and its attachments

- 9.8.1. Cab and its attachments

- 9.9. Electrical system

- 9.9.1. Electrical system

- 10. Diagrams and drawings

- 10.1. Hydraulic diagrams and drawings

- 10.1.1. Hydraulic diagrams and drawings

- 10.1.2. Power train hydraulic circuit diagram

- 10.1.3. Hydraulic circuit diagram

- 10.2. Electrical diagrams and drawings

- 10.2.1. Electrical diagrams and drawings

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF