- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA500-1 Wheel Loader Shop Manual SEBM04250107

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM04250107

- Format: PDF

- Size: 136.0MB

- Number of Pages: 933

Category: Komatsu Shop Manual PDF

-

Model List:

- WA500-1 Wheel Loader

- 1. MAIN MENU

- 2. CONTENTS

- 3. ENGINE

- 3.1. STRUCTURE AND FUNCTION

- 3.1.1. ENGINE MOUNT

- 3.1.2. RADIATOR

- 3.1.3. FUEL TANK AND PIPING

- 3.1.4. ENGINE CONTROL

- 3.2. TESTING AND ADJUSTING

- 3.2.1. STANDARD VALUE TABLE

- 3.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 3.2.3. ADJUSTING VALVE CLEARANCE

- 3.2.4. MEASURING COMPRESSION PRESSURE

- 3.2.5. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 3.2.6. MEASURING BLOWBY PRESSURE

- 3.2.7. TESTING AND ADJUSTING BELT TENSION

- 3.2.8. MEASURING EXHAUST GAS COLOR

- 3.2.9. MEASURING ENGINE OIL PRESSURE AND TEMPERATURE

- 3.2.10. ADJUSTING FUEL CUT SOLENOID

- 3.2.11. MEASURING ACCELERATOR PEDAL OPERATING FORCE AND OPERATING ANGLE

- 3.3. DISASSEMBLY AND ASSEMBLY

- 3.3.1. STARTING MOTOR

- 3.3.2. FUEL INJECTION PUMP

- 3.3.3. AIR COMPRESSOR

- 3.4. MAINTENANCE STANDARD

- 3.4.1. ENGINE MOUNT

- 4. POWER TRAIN

- 4.1. STRUCTURE AND FUNCTION

- 4.1.1. GENERAL

- 4.1.2. DAMPER

- 4.1.3. TORQUE CONVERTER AND TRANSMISSION PIPING

- 4.1.4. TORQUE CONVERTER CHARGING PUMP

- 4.1.5. TORQUE CONVERTER OIL COOLER

- 4.1.6. TORQUE CONVERTER OIL FILTER

- 4.1.7. TORQUE CONVERTER

- 4.1.8. TRANSMISSION MOUNT

- 4.1.9. TORQUE CONVERTER RELIEF VALVE

- 4.1.10. TRANSMISSION

- 4.1.11. TRANSMISSION CONTROL VALVE

- 4.1.12. PILOT OIL FILTER

- 4.1.13. TRANSFER

- 4.1.14. DRIVE SHAfT

- 4.1.15. CENTER SUPPORT

- 4.1.16. AXLE MOUNT

- 4.1.17. AXLE AND DIFFERENTIAL

- 4.1.18. FINAL DRIVE

- 4.1.19. TIRE AND WHEEL

- 4.2. TESTING AND ADJUSTING

- 4.2.1. STANDARD VALUE TABLE

- 4.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 4.2.3. MEASURING ENGINE STALL SPEED

- 4.2.4. MEASURING OIL PRESSURE OF TORQUE CONVERTER AND TRANSMISSION

- 4.2.5. MEASURING SHIFT LEVER

- 4.2.6. METHOD FOR OPERATION OF SPOOL EMERGENCY MANUAL

- 4.2.7. TIRE AND WHEEL

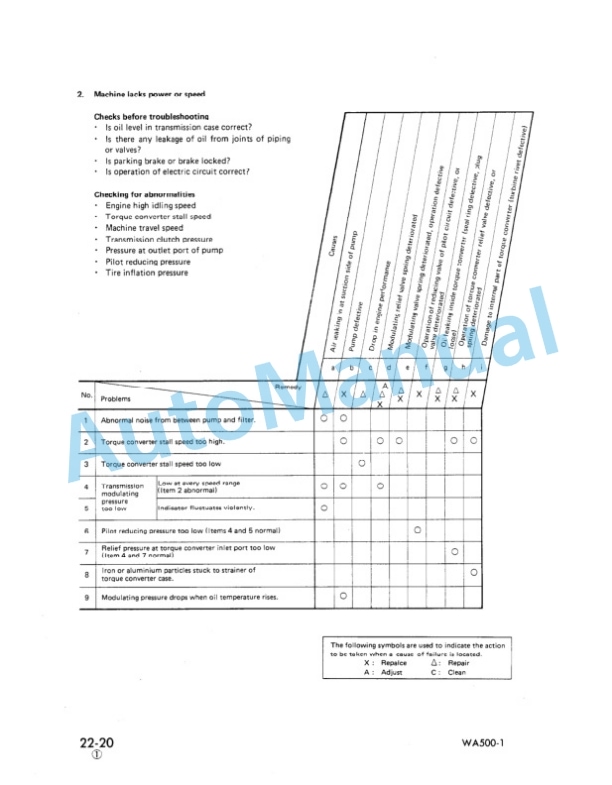

- 4.2.8. TROUBLESHOOTING

- 4.3. DISASSEMBLY AND ASSEMBLY

- 4.3.1. TORQUE CONVERTER CHARGING PUMP

- 4.3.2. TORQUE CONVERTER AND TRANSMISSION

- 4.3.3. TORQUE CONVERTER

- 4.3.4. TRANSMISSION CONTROL VALVE

- 4.3.5. FRONT DIFFERENTIAL

- 4.3.6. REAR DIFFERENTIAL

- 4.3.7. DIFFERENTIAL GEAR

- 4.3.8. DRIVE SHAFT Serial No. 10001 10222

- 4.3.9. DRIVE SHAFT Serial No. 10223 and up

- 4.3.10. FINAL DRIVE

- 4.4. MAINTENANCE STANDARD

- 4.4.1. TRANSMISSION MOUNT

- 4.4.2. TORQUE CONVERTER CHARGING PUMP

- 4.4.3. DAMPER

- 4.4.4. TORQUE CONVERTER

- 4.4.5. TRANSMISSION

- 4.4.6. TRANSFER

- 4.4.7. DRIVE SHAFT

- 4.4.8. CENTER SUPPORT

- 4.4.9. DIFFERENTIAL

- 4.4.10. AXLE MOUNT

- 4.4.11. FINAL DRIVE

- 5. STEERING SYSTEM

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. GENERAL

- 5.1.2. HYDRAULIC CIRCUIT FOR STEERING

- 5.1.3. STEERING CONTROL SYSTEM

- 5.1.4. STEERING CYLINDER

- 5.1.5. STEERING COLUMN AND GEAR BOX

- 5.1.6. STEERING LINKAGE

- 5.1.7. STEERING PUMP

- 5.1.8. CENTER HINGE PIN

- 5.2. TESTING AND ADJUSTING

- 5.2.1. STANDARD VALUE TABLE

- 5.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 5.2.3. MEASURING STEERING WHEEL PLAY

- 5.2.4. MEASURING OPERATING FORCE OF STEERING WHEEL

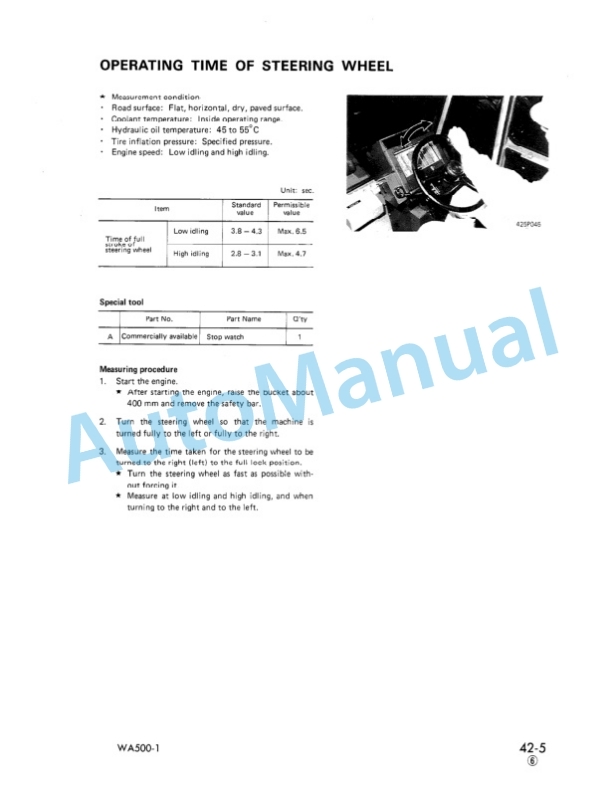

- 5.2.5. OPERATING TIME OF STEERING WHEEL

- 5.2.6. TESTING STEERING LINKAGE

- 5.2.7. ADJUSTING STEERING LINKAGE

- 5.2.8. STEERING OIL PRESSURE

- 5.2.9. TROUBLESHOOTING

- 5.3. DISASSEMBLY AND ASSEMBLY

- 5.3.1. STEERING GEAR BOX

- 5.3.2. STEERING VALVE

- 5.3.3. STEERING PUMP AND POC PUMP

- 5.3.4. STEERING CYLINDER

- 5.3.5. CENTER HINGE PIN

- 5.4. MAINTENANCE STANDARD

- 5.4.1. STEERING LINKAGE

- 5.4.2. STEERING COLUMN AND GEAR BOX

- 5.4.3. STEERING PUMP

- 5.4.4. STEERING VALVE

- 5.4.5. STEERING CYLINDER MOUNT

- 5.4.6. STEERING CYLINDER

- 5.4.7. CENTER HINGE PIN

- 6. BRAKE AND AIR SYSTEM

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. AIR GOVERNOR

- 6.1.2. TWOWAY VALVE

- 6.1.3. BRAKE CHAMBER

- 6.1.4. SLACK ADJUSTER

- 6.1.5. BRAKE

- 6.1.6. PARKING BRAKE

- 6.1.7. PARKING BRAKE SOLENOID VALVE

- 6.1.8. SPRING CYLINDER

- 6.1.9. BRAKE CALIPER

- 6.2. TESTING AND ADJUSTING

- 6.2.1. STANDARD VALUE TABLE

- 6.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 6.2.3. MEASURING BRAKE PEDAL

- 6.2.4. MEASURING AIR

- 6.2.5. BRAKE PERFORMANCE

- 6.2.6. CHECKING BRAKE PISTON LEAKAGE

- 6.2.7. MEASURING WEAR OF BRAKE DISC

- 6.2.8. AIR BLEEDING FROM BRAKE LINE

- 6.2.9. PARKING BRAKE PERFORMANCE

- 6.2.10. CHECKING AND ADJUSTING PARKING BRAKE

- 6.2.11. TROUBLESHOOTING

- 6.3. DISASSEMBLY AND ASSEMBLY

- 6.3.1. SPRING CYLINDER

- 6.3.2. PARKING BRAKE

- 6.3.3. PARKING BRAKE PAD

- 6.4. MAINTENANCE STANDARD

- 6.4.1. BRAKE VALVE

- 6.4.2. BRAKE CHAMBER

- 6.4.3. SLACK ADJUSTER

- 6.4.4. BRAKE

- 6.4.5. PARKING BRAKE

- 6.4.6. SPRING CYLINDER

- 7. WORK EQUIPMENT SYSTEM

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. GENERAL

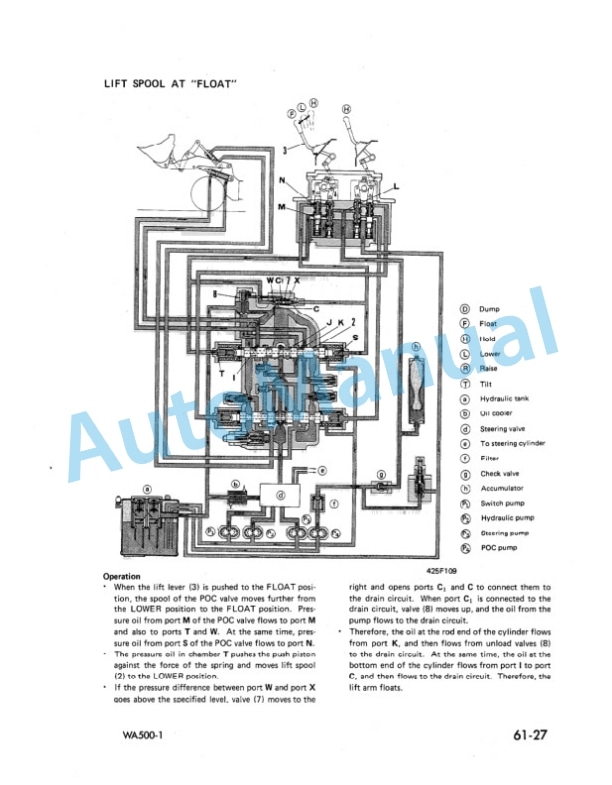

- 7.1.2. HYDRAULIC CIRCUIT SYSTEM

- 7.1.3. HYDRAULIC CIRCUIT DIAGRAM

- 7.1.4. WORK EQUIPMENT LEVER LINKAGE

- 7.1.5. HYDRAULK TANK

- 7.1.6. HYDRAULIC PUMPS

- 7.1.7. POC VALVE

- 7.1.8. MAIN CONTROL VALVE

- 7.1.9. HYDRAULIC CYLINDER

- 7.1.10. BUCKET POSITIONER AND BOOM KICKOUT

- 7.1.11. BUCKET LINKAGE

- 7.1.12. BUCKET

- 7.1.13. ACCUMULATOR

- 7.2. TESTING AND ADJUSTING

- 7.2.1. STANDARD VALUE TABLE

- 7.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 7.2.3. MEASURING DUMP AND LIFT CONTROL LEVERS

- 7.2.4. ADJUSTING DUMP AND LIFT CONTROL LEVERS

- 7.2.5. MEASURING HYDRAULIC PRESSURE OF WORKEQUIPME,NT

- 7.2.6. MEASURING WORK EQUIPMENT

- 7.2.7. MEASURING HYDRAULIC DRIFT OF WORK EQUIPMENT

- 7.2.8. ADJUSTING BUCKET POSITIONER

- 7.2.9. ADJUSTING BOOM KICKOUT

- 7.2.10. TROUBLESHOOTING

- 7.3. DISASSEMBLY AND ASSEMBLY

- 7.3.1. HYDRAULIC FILTER

- 7.3.2. MAIN CONTROL VALVE

- 7.3.3. LIFT AND DUMP CYLINDERS

- 7.4. MAINTENANCE STANDARD

- 7.4.1. MAIN CONTROL VALVE

- 7.4.2. DUMP CYLINDER

- 7.4.3. LIFT CYLINDER

- 7.4.4. BUCKET LINKAGE

- 7.4.5. BUCKET POSITIONER AND BOOM KICKOUT

- 7.4.6. BUCKET

- 7.4.7. HYDRAULIC AND SWlTCH PUMP

- 7.4.8. POC PUMP

- 7.4.9. POC VALVE

- 8. ELECTRIC AND ELECTRONIC SYSTEM

- 8.1. STRUCTURE AND FUNCTION

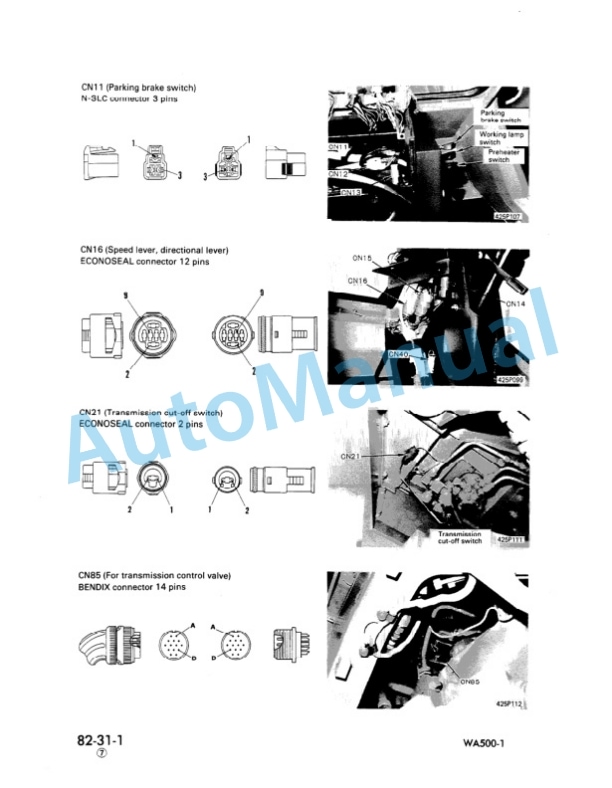

- 8.1.1. ELECTRIC AND ELECTRONIC SYSTEM

- 8.1.2. ELECTRICAL WIRING DIAGRAM CIRCUIT

- 8.1.3. ELECTRICAL CIRCUIT DIAGRAM FOR INTERMITTENT WIPER

- 8.1.4. ENGINE STARTING CIRCUIT

- 8.1.5. ENGINE STOP CIRCUIT

- 8.1.6. PREHEATING CIRCUIT

- 8.1.7. COMBINATION SWITCH

- 8.1.8. ELECTRICAL TRANSMISSION CONTROL

- 8.1.9. ELECTRICAL PARKING BRAKE CONTROL

- 8.1.10. ELECTRONIC VEHICLE MONITORING SYSTEM (EVMS)

- 8.1.11. OPERATION OF CONTACT SWITCH

- 8.2. TESTING AND ADJUSTING

- 8.2.1. STANDARD VALUE TABLE FOR ELECTRICAL SYSTEM

- 8.2.2. ADJUSTING SPEEDOMETER MODULE OF MACHINE MONITOR

- 8.2.3. CHECKING FOR ABNORMALITY IN FUEL LEVEL SENSOR

- 8.2.4. TROUBLESHOOTING

- 8.3. DISASSEMBLY AND ASSEMBLY

- 8.3.1. MONITOR MACHINE

- 9. OTHERS

- 9.1. OTHERS

- 9.1.2. AIR CONDITIONER

- 9.2. DISASSEMBLY AND ASSEMBLY

- 9.2.2. AIR CONDITIONER UNIT (If equipped)

- 9.2.3. AIR CONDITIONER CONDENSER

- 9.2.4. DRY RESERVOIR

- 9.2.5. COMPRESSOR FOR AIR CONDITIONER

- 9.3. GEAR PUMP SA SERIES

- 9.3.1. STRUCTURE

- 9.3.2. TESTING AND ADJUSTING

- 9.3.3. DISASSEMBLY

- 9.3.4. ASSEMBLY

- 9.3.5. MAINTENANCE STANDARD

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF