- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

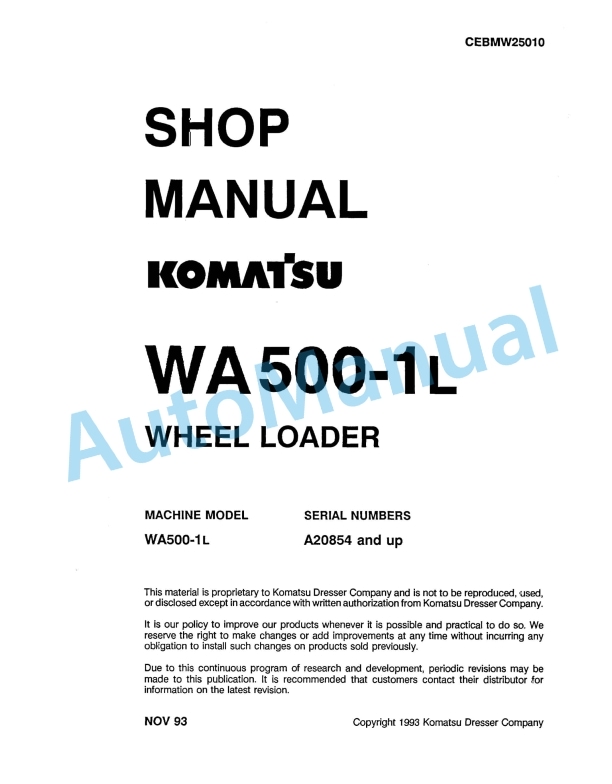

Komatsu WA500-1L Wheel Loader Shop Manual CEBMW25010

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBMW25010

- Format: PDF

- Size: 55.2MB

- Number of Pages: 1004

Category: Komatsu Shop Manual PDF

-

Model List:

- WA500-1L Wheel Loader

- 1. MAIN MENU

- 2. CONTENTS

- 3. ENGINE

- 3.1. TESTING AND ADJUSTING

- 3.1.1. STANDARD VALUE TABLE

- 3.1.2. TOOL LIST

- 3.1.3. VALVE CLEARANCE

- 3.1.4. COMPRESSION PRESSURE

- 3.1.5. FUEL INJECTION

- 3.1.6. BLOWBY PRESSURE

- 3.1.7. ALTERNATOR FAN BELT

- 3.1.8. ENGINE FAN BELT

- 3.1.9. EXHAUST GAS COLOR

- 3.1.10. OIL PRESSURE

- 3.1.11. OIL TEMPERATURE

- 3.1.12. ACCELERATOR PEDAL

- 3.2. DISASSEMBLY AND ASSEMBLY

- 3.2.1. STARTING MOTOR

- 3.2.2. FUEL INJECTION PUMP

- 3.2.3. AIR COMPRESSOR

- 3.3. MAINTENANCE STANDARD

- 3.3.1. ENGINE MOUNT

- 4. POWER TRAIN

- 4.1. STRUCTURE AND FUNCTION

- 4.1.1. GENERAL

- 4.1.2. DAMPER

- 4.1.3. TORQUE CONVERTER AND TRANSMISSION PIPING

- 4.1.4. RADIATOR AND OIL COOLER

- 4.1.5. TORQUE CONVERTER AND PTO

- 4.1.6. TORQUE CONVERTER OIL FILTER

- 4.1.7. TRANSMISSION

- 4.1.8. TRANSMISSION CONTROL VALVE

- 4.1.9. TRANSMISSION SOLENOID VALVE

- 4.1.10. TRANSMISSION PILOT OIL FILTER

- 4.1.11. TRANSFER

- 4.1.12. DRIVE SHAFT

- 4.1.13. CENTER SUPPORT

- 4.1.14. FINAL DRIVE

- 4.1.15. AXLE MOUNT

- 4.1.16. TIRE AND WHEEL

- 4.2. TESTING AND ADJUSTING

- 4.2.1. STANDARD VALUE TABLE

- 4.2.2. TOOL LIST

- 4.2.3. ENGINE STALL SPEED

- 4.2.4. TORQUE CONVERTER AND TRANSMISSION OIL PRESSURE

- 4.2.5. SHIFT LEVER

- 4.2.6. EMERGENCY MANUAL SPOOL

- 4.2.7. TIRE AND WHEEL

- 4.2.8. TROUBLESHOOTING

- 4.3. DISASSEMBLY AND ASSEMBLY

- 4.3.1. TORQUE CONVERTER CHARGING PUMP

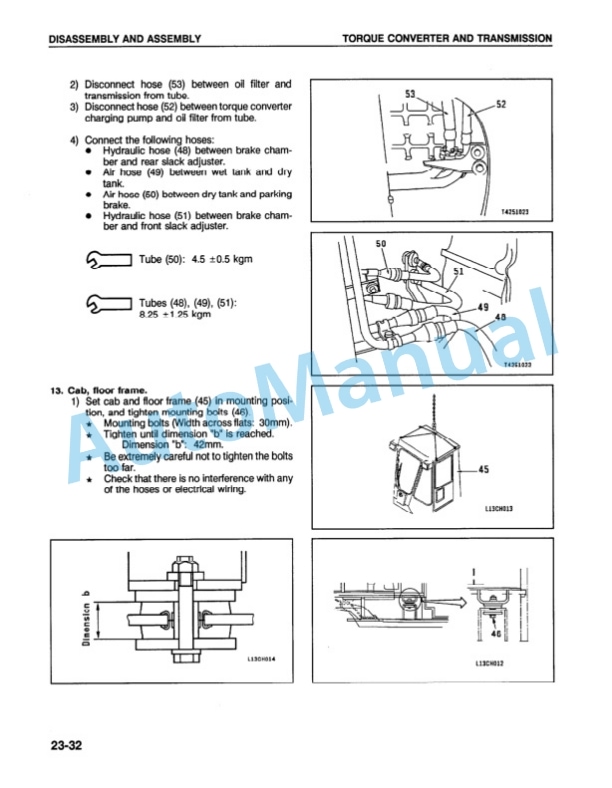

- 4.3.2. TORQUE CONVERTER AND TRANSMISSION

- 4.3.3. TORQUE CONVERTER ASSEMBLY

- 4.3.4. TRANSMISSION ASSEMBLY

- 4.3.5. TRANSFER CASE ASSEMBLY

- 4.3.6. TRANSMISSION CONTROL VALVE

- 4.3.7. FRONT DIFFERENTIAL

- 4.3.8. REAR AXLE

- 4.3.9. REAR DIFFERENTIAL

- 4.3.10. DIFFERENTIAL GEAR ASSEMBLY

- 4.3.11. FINAL DRIVE

- 4.4. MAINTENANCE STANDARD

- 4.4.1. TRANSMISSION MOUNT

- 4.4.2. DAMPER

- 4.4.3. TORQUE CONVERTER CHARGING PUMP

- 4.4.4. TORQUE CONVERTER AND PTO

- 4.4.5. TRANSMISSION

- 4.4.6. TRANSMISSION CONTROL VALVE

- 4.4.7. TRANSFER

- 4.4.8. DIFFERENTIAL

- 4.4.9. FINAL DRIVE

- 4.4.10. DRIVE SHAFT

- 4.4.11. CENTER SUPPORT

- 4.4.12. AXLE MOUNT

- 5. STEERING SYSTEM

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. CENTER HINGE PIN

- 5.1.2. STEERING PIPING

- 5.1.3. STEERING CIRCUIT DIAGRAM

- 5.1.4. STEERING COLUMN AND GEAR BOX

- 5.1.5. STEERING LINKAGE

- 5.1.6. STEERING CONTROL SYSTEM

- 5.1.7. TWOWAY RESTRICTOR VALVE

- 5.2. TESTING AND ADJUSTING

- 5.2.1. STANDARD VALUE TABLE

- 5.2.2. TOOL LIST

- 5.2.3. STEERING WHEEL PLAY

- 5.2.4. OPERATING FORCE OF STEERING WHEEL

- 5.2.5. OPERATING TIME OF STEERING WHEEL

- 5.2.6. STEERING OIL PRESSURE

- 5.2.7. STEERING LINKAGE

- 5.2.8. TROUBLESHOOTING TABLES

- 5.3. DISASSEMBLY AND ASSEMBLY

- 5.3.1. STEERING GEAR

- 5.3.2. STEERING GEAR BOX

- 5.3.3. STEERING AND PPC PUMP

- 5.3.4. STEERING VALVE

- 5.3.5. STEERING CYLINDER

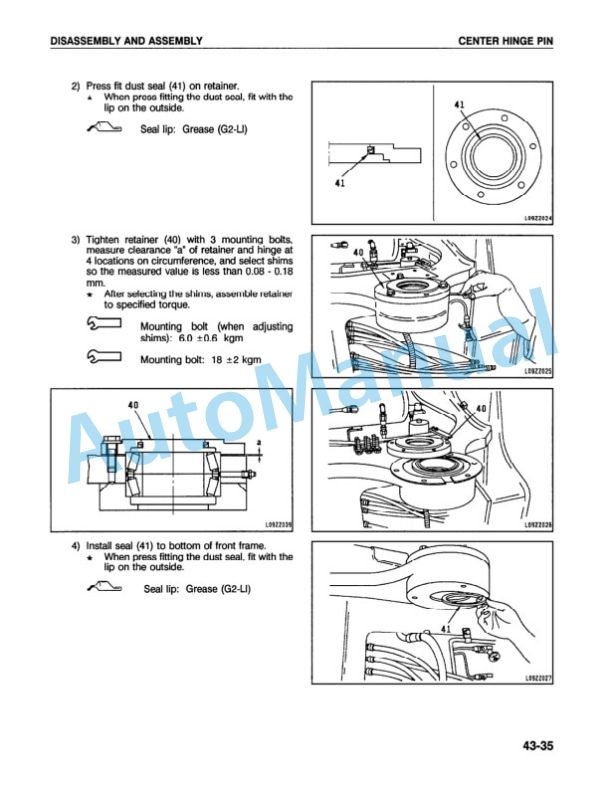

- 5.3.6. CENTER HINGE PIN

- 5.4. MAINTENANCE STANDARD

- 5.4.1. CENTER HINGE PIN

- 5.4.2. STEERING LINKAGE AND STEERING COLUMN

- 5.4.3. STEERING GEAR BOX

- 5.4.4. STEERING PUMP

- 5.4.5. STEERING CYLINDER MOUNT

- 5.4.6. STEERING VALVE

- 6. BRAKE AND AIR SYSTEM

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. GENERAL

- 6.1.2. BRAKE AND AIR SCHEMATICS

- 6.1.3. AIR TANK

- 6.1.4. SAFETY VALVE

- 6.1.5. BRAKE VALVE

- 6.1.6. AIR GOVERNOR

- 6.1.7. TWOWAY VALVE

- 6.1.8. BRAKE CHAMBER

- 6.1.9. SLACK ADJUSTER

- 6.1.10. CHECK VALVE

- 6.1.11. BRAKE

- 6.1.12. PARKING BRAKE

- 6.1.13. PARKING BRAKE SOLENOID VALVE

- 6.1.14. SPRING CYLINDER

- 6.1.15. BRAKE CALIPER

- 6.2. TESTING AND ADJUSTING

- 6.2.1. STANDARD VALUE TABLE

- 6.2.2. TOOL LIST

- 6.2.3. BRAKE PEDAL

- 6.2.4. AIR PRESSURE

- 6.2.5. BRAKE PERFORMANCE

- 6.2.6. BRAKE OIL PRESSURE

- 6.2.7. BRAKE DISC

- 6.2.8. AIR BLEEDING FROM BRAKE LINE

- 6.2.9. PARKING BRAKE

- 6.2.10. TROUBLESHOOTING

- 6.3. DISASSEMBLY AND ASSEMBLY

- 6.3.1. SLACK ADJUSTER

- 6.3.2. BRAKE ASSEMBLY

- 6.3.3. SPRING CYLINDER

- 6.3.4. PARKING BRAKE

- 6.3.5. PARKING BRAKE PAD

- 6.3.6. AIR GOVERNOR

- 6.4. MAINTENANCE STANDARD

- 6.4.1. BRAKE VALVE

- 6.4.2. BRAKE CHAMBER

- 6.4.3. SLACK ADJUSTER

- 6.4.4. BRAKE

- 6.4.5. PARKING BRAKE

- 6.4.6. SPRING CYLINDER

- 7. WORK EQUIPMENT SYSTEM

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. GENERAL

- 7.1.2. HYDRAULIC PIPING

- 7.1.3. HYDRAULIC CIRCUIT

- 7.1.4. HYDRAULIC TANK

- 7.1.5. PROPORTIONAL PRESSURE CONTROL VALVE (PPC VALVE)

- 7.1.6. MAIN CONTROL VALVE

- 7.1.7. ACCUMULATOR

- 7.1.8. OPERATION OF MAIN CONTROL VALVE

- 7.1.9. BUCKET LINKAGE

- 7.1.10. BUCKET

- 7.1.11. BUCKET POSITIONER AND BOOM KICKOUT

- 7.1.12. WORK EQUIPMENT LEVER LINKAGE

- 7.2. TESTING AND ADJUSTING

- 7.2.1. STANDARD VALUE TABLE

- 7.2.2. TOOL LIST

- 7.2.3. EMERGENCY MANUAL SPOOL

- 7.2.4. DUMP AND LIFT CONTROL LEVER

- 7.2.5. HYDRAULIC CIRCUIT FLUSHING

- 7.2.6. PPC RELIEF VALVE

- 7.2.7. WORK EQUIPMENT

- 7.2.8. BUCKET POSITIONER

- 7.2.9. BOOM KICKOUT

- 7.2.10. TROUBLESHOOTING

- 7.3. DISASSEMBLY AND ASSEMBLY

- 7.3.1. HYDRAULIC TANK

- 7.3.2. HYDRAULIC FILTER

- 7.3.3. WORK EQUIPMENT PUMP

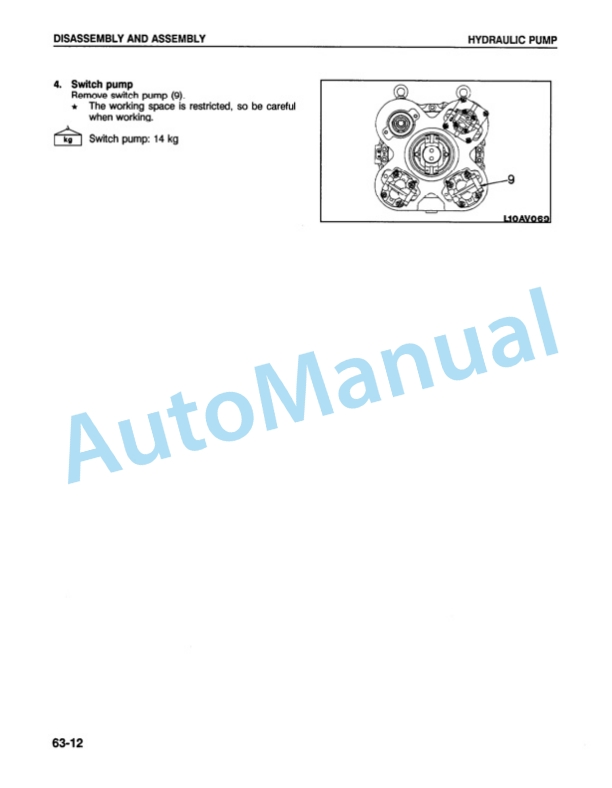

- 7.3.4. SWITCH PUMP

- 7.3.5. PPC VALVE ASSEMBLY

- 7.3.6. MAIN CONTROL VALVE

- 7.3.7. LIFT AND DUMP CYLINDERS

- 7.3.8. WORK EQUIPMENT

- 7.3.9. COUNTERWEIGHT

- 7.4. MAINTENANCE STANDARD

- 7.4.1. HYDRAULIC AND SWITCH PUMP

- 7.4.2. PPC PUMP

- 7.4.3. PPC VALVE

- 7.4.4. MAIN CONTROL VALVE

- 7.4.5. HYDRAULIC CYLINDERS

- 7.4.6. BUCKET LINKAGE

- 7.4.7. BUCKET

- 7.4.8. BUCKET POSITIONER AND BOOM KICKOUT

- 8. ELECTRIC AND ELECTRONIC SYSTEM

- 8.1. STRUCTURE AND FUNCTION

- 8.1.1. ELECTRICAL WIRING DIAGRAM

- 8.1.2. ENGINE STARTING CIRCUIT

- 8.1.3. ENGINE STOP CIRCUIT

- 8.1.4. PREHEATING CIRCUIT

- 8.1.5. COMBINATION SWITCH

- 8.1.6. TRANSMISSION CUTOFF SWITCH

- 8.1.7. TRANSMISSION CUTOFF SELECTOR SWITCH

- 8.1.8. NEUTRALIZER RELAY

- 8.1.9. KICKDOWN SWITCH

- 8.1.10. ELECTRICAL PARKING BRAKE CONTROL

- 8.1.11. BUCKET POSITIONER AND BOOM KICKOUT

- 8.1.12. PROXIMITY SWITCH

- 8.1.13. ELECTRICAL CIRCUIT DIAGRAM FOR AIR GAUGE

- 8.1.14. ELECTRICAL CIRCUIT DIAGRAM FOR INTERMITTENT WIPER

- 8.1.15. ELECTRONIC VEHICLE MONITORING SYSTEM (EVMS)

- 8.1.16. SENSORS

- 8.2. TESTING AND ADJUSTING

- 8.2.1. STANDARD VALUE TABLE FOR ELECTRICAL SYSTEM

- 8.2.2. MACHINE MONITOR (SPEEDOMETER MODULE)

- 8.2.3. TROUBLESHOOTING

- 8.2.4. TROUBLESHOOTING CHART FOR ELECTRIC SYSTEM

- 8.2.5. TROUBLESHOOTING

- 8.2.6. TROUBLESHOOTING CHART FOR ELECTRONIC VEHICLE MONITORING SYSTEM

- 8.2.7. TROUBLESHOOTING

- 8.3. DISASSEMBLY AND ASSEMBLY

- 8.3.1. MACHINE MONITOR

- 9. OTHERS

- 9.1. STRUCTURE AND FUNCTION

- 9.1.1. GENERAL

- 9.1.2. PIPING DIAGRAM

- 9.1.3. ELECTRIC WIRING DIAGRAM

- 9.1.4. COMPRESSOR (CRANK TYPE)

- 9.1.5. MAGNETIC CLUTCH

- 9.1.6. CONDENSER

- 9.1.7. RECEIVER W/SIGHT GLASS

- 9.1.8. AIR CONDITIONER UNIT

- 9.1.9. CONTROL PANEL

- 9.2. TESTING AND ADJUSTING

- 9.2.1. SERVICE TOOLS

- 9.2.2. MAINTENANCE PROCEDURE

- 9.2.3. TROUBLESHOOTING

- 9.2.4. TROUBLESHOOTING USING GAUGE MANIFOLD

- 9.3. DISASSEMBLY AND ASSEMBLY

- 9.3.1. SPECIAL TOOLS

- 9.3.2. MAGNETIC CLUTCH

- 9.3.3. AIR CONDITIONER UNIT

- 9.3.4. BLOWER UNIT

- 9.3.5. CONDENSER

- 9.4. GEAR PUMP

- 9.4.1. GENERAL

- 9.4.2. SA SERIES

- 9.5. METRIC CONVERSIONS

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF