- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA700-3 Wheel Loader Shop Manual SEBM032802

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM032802

- Format: PDF

- Size: 23.0MB

- Number of Pages: 809

Category: Komatsu Shop Manual PDF

-

Model List:

- WA700-3 Wheel Loader

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 0.4. COATING MATERIALS

- 0.5. STANDARD TIGHTENING TORQUE

- 0.6. ELECTRIC WIRE CODE

- 0.7. CONVERSION TABLE

- 0.8. UNITS

- 1. GENERAL

- 1.1. GENERAL ASSEMBLY DRAWING

- 1.2. SPECIFICATIONS

- 1.3. WEIGHT TABLE

- 1.4. LIST OF LUBRICANT AND WATER

- 2. STRUCTURE AND FUNCTION

- 2.1. OUTLINE

- 2.2. POWER TRAIN SYSTEM

- 2.3. DAMPER

- 2.4. RADIATOR AND OIL COOLER

- 2.5. TORQUE CONVERTER AND TRANSMISSION PIPING

- 2.6. TRANSMISSION HYDRAULIC SYSTEM DIAGRAM

- 2.7. TRANSMISSION HYDRAULIC CIRCUIT DIAGRAM

- 2.8. TORQUE CONVERTER AND PTO

- 2.9. TORQUE CONVERTER REGULATOR VALVE

- 2.10. TRANSMISSION

- 2.11. TRANSMISSION CONTROL VALVE

- 2.12. TORQUE CONVERTER OIL COOLER

- 2.13. TRANSMISSION OIL FILTER

- 2.14. CENTER HINGE PIN

- 2.15. JOYSTICK STEERING LINKAGE

- 2.16. STEERING AND SWITCH PUMP

- 2.17. SWITCH PUMP CUTOFF SOLENOID

- 2.18. STEERING DEMAND VALVE

- 2.19. EPC VALVE

- 2.20. ROTARY VALVE

- 2.21. TWO WAY RESTRICTOR VALVE

- 2.22. DIVERTER VALVE

- 2.23. BRAKE PIPING

- 2.24. BRAKE CIRCUIT DIAGRAM

- 2.25. BRAKE VALVE

- 2.26. CHARGE VALVE

- 2.27. ACCUMULATOR (FOR BRAKE)

- 2.28. SLACK ADJUSTER

- 2.29. BRAKE

- 2.30. PARKING BRAKE

- 2.31. SPRING CYLINDER

- 2.32. PARKING BRAKE SOLENOID VALVE

- 2.33. HYDRAULIC PIPING

- 2.34. HYDRAULIC CIRCUIT DIAGRAM

- 2.35. MAIN PISTON PUMP

- 2.36. ES CO VALVE

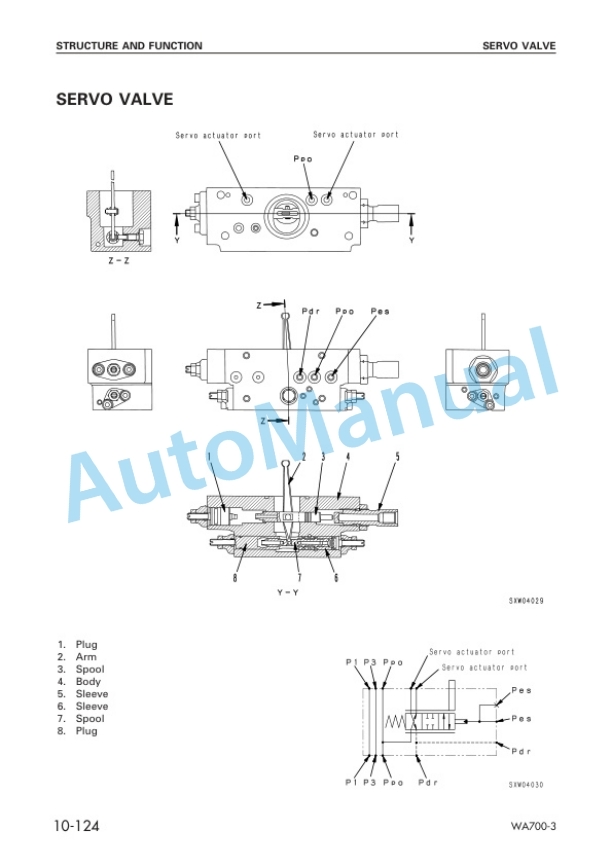

- 2.37. SERVO VALVE

- 2.38. PRESSURE DIFFERENTIAL VALVE

- 2.39. PPC VALVE (PROPORTIONAL PRESSURE VALVE)

- 2.40. PPC RELIEF VALVE

- 2.41. ACCUMULATOR (FOR PPC VALVE)

- 2.42. MAIN CONTROL VALVE

- 2.43. LUBRICATION OF WORK EQUIPMENT

- 2.44. WORK EQUIPMENT LINKAGE

- 2.45. BUCKET POSITIONER AND BOOM KICKOUT

- 2.46. OPERATION OF PROXIMITY SWITCH

- 2.47. AIR CONDITIONER

- 2.48. ELECTRIC CIRCUIT DIAGRAM

- 2.49. MACHINE MONITOR SYSTEM

- 2.50. MAIN MONITOR

- 2.51. MAINTENANCE MONITOR

- 2.52. AUTOMATIC TRANSMISSION SYSTEM (ATM)

- 2.53. AJSS (ADVANCED JOYSTICK STEERING SYSTEM)

- 2.54. TRANSMISSION AND JOYSTICK CONTROLLER

- 2.55. ENGINE STARTING CIRCUIT

- 2.56. ENGINE STOP CIRCUIT

- 2.57. PREHEATING CIRCUIT

- 2.58. FUEL SYSTEM

- 2.59. KICKDOWN, HOLD SWITCH

- 2.60. ELECTRIC PARKING BRAKE CONTROL

- 2.61. ELECTRIC CIRCUIT OF ACTIVE POWER MAXIMIZING FUNCITON

- 2.62. RELATED TO VHMS CONTROLLER

- 2.62.1. VHMS CONTROLLER

- 2.62.2. BLOWBY PRESSURE SENSOR

- 2.62.3. ENGINE OIL TEMPERATURE SENSOR

- 2.62.4. EXHAUST TEMPERATURE SENSOR/AMP

- 2.62.5. AMBIENT TEMPERATURE SENSOR

- 2.62.6. TRANSMISSION PUMP OIL PRESSURE SENSOR

- 2.62.7. BRAKE OIL TEMPERATURE SENSOR AND HYDRAULIC OIL TEMPERATURE SENSOR

- 2.62.8. BRAKE OIL PRESSURE SENSOR, STEERING OIL PRESSURE SENSOR AND WORK EQUIPMENT PUMP OIL PRESSURE SENSOR

- 2.62.9. COMMUNICATIONS (ORB ORBCOMM) CONTROLLER/ANTENNA

- 3. TESTING AND ADJUSTING

- 3.1. STANDARD VALUE TABLE FOR ENGINE

- 3.2. STANDARD VALUE TABLE FOR CHASSIS

- 3.3. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 3.4. TESTING AND ADJUSTING

- 3.4.1. TABLE OF TOOLS FOR TESING, ADJUSTING, AND TROUBLESHOOTING

- 3.4.2. ADJUSTING VALVE CLEARANCE

- 3.4.3. MEASURING COMPRESSION PRESSURE

- 3.4.4. MEASURING BLOWBY PRESSURE

- 3.4.5. MEASURING EXHAUST GAS COLOR

- 3.4.6. MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)

- 3.4.7. MEASURING EXHAUST TEMPERATURE

- 3.4.8. MEASURING ENGINE SPEED

- 3.4.9. ADJUSTING SET LOAD OF INJECTOR

- 3.4.10. TROUBLESHOOTING OF INJECTOR

- 3.4.11. MEASURING FUEL CIRCUIT PRESSURE

- 3.4.12. HANDLING EQUIPMENT IN FUEL CIRCUIT

- 3.4.13. BLEEDING AIR FROM FUEL CIRCUIT

- 3.4.14. ADJUSTING SPEED SENSORS

- 3.4.15. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 3.4.16. TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION

- 3.4.17. MEASURING ACCELERATOR PEDAL

- 3.4.18. ADJUSTING ACCELERATOR PEDAL TRAVEL, POTENTIOMETER

- 3.4.19. ADJUSTING ACCELERATOR PEDAL MICRO SWITCH

- 3.4.20. MEASURING TORQUE CONVERTER, TRANSMISSION HYDRAULIC PRESSURE

- 3.4.21. METHOD FOR OPERATION OF EMERGENCY MANUAL SPOOL

- 3.4.22. TESTING AND ADJUSTING STEERING OIL PRESSURE

- 3.4.23. ADJUSTING STEERING STOPPER BOLT

- 3.4.24. ADJUSTING JOYSTICK STEERING

- 3.4.25. ADJUSTING JOYSTICK LEVER NEUTRAL DETECTION SWITCH

- 3.4.26. TESTING BRAKE OIL PRESSURE

- 3.4.27. MEASURING WEAR OF BRAKE DISC

- 3.4.28. MEASURING BRAKE PERFORMANCE

- 3.4.29. TESTING AND ADJUSTING PARKING BRAKE

- 3.4.30. TESTING AND ADJUSTING ACCUMULATOR CHARGE PRESSURE

- 3.4.31. MEASURING PPC RELIEF VALVE HYDRAULIC PRESSURE

- 3.4.32. TESTING AND ADJUSTING WORK EQUIPMENT HYDRAULIC PRESSURE

- 3.4.33. BLEEDING AIR FROM THE PISTON PUMP

- 3.4.34. ADJUSTING WORK EQUIPMENT LEVER LINKAGE

- 3.4.35. TESTING AND ADJUSTING BUCKET POSITIONER

- 3.4.36. TESTING AND ADJUSTING BOOM KICKOUT

- 3.4.37. TESTING AND ADJUSTING PROXIMITY SWITCH FOR ACTIVE POWER MAXIMIZING FUNCTION

- 3.4.38. TESTING PROXIMITY SWITCH ACTUATION PILOT LAMP

- 3.4.39. ADJUSTING MAIN MONITOR (SPEEDOMETER MODULE)

- 3.4.40. BLEEDING AIR

- 3.4.41. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 3.4.42. PM CLINIC INSPECTION TABLE

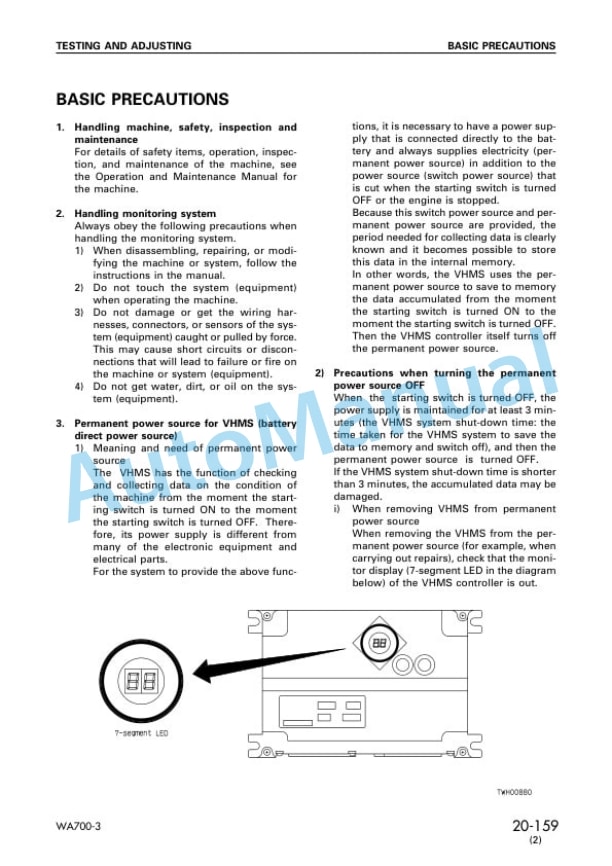

- 3.4.43. BASIC PRECAUTIONS

- 3.4.44. OUTLINE

- 3.4.45. SETTING UP VHMS CONTROLLER

- 3.4.46. COLLECTION, TRANSMISSION OF DATA

- 3.4.47. INSPECTION AND MAINTENANCE

- 3.4.48. REPLACING PARTS

- 3.5. TROUBLESHOOTING

- 3.5.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 3.5.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 3.5.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 3.5.4. CHECKS BEFORE TROUBLESHOOTING

- 3.5.5. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 3.5.6. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 3.5.7. TBRANCH BOX AND TBRANCH TABLE

- 3.5.8. METHOD OF DISPLAYING ACTION CODE AND FAILURE CODE

- 3.5.9. CHART OF ACTION CODES AND FAILURE CODES, AND REENACTION

- 3.5.10. TRANSMISSION CONTROLLER LED DISPLAY

- 3.5.11. METHOD OF USING TROUBLESHOOTING CHARTS

- 3.5.12. TROUBLESHOOTING OF ENGINE SYSTEM (S MODE)

- 3.5.13. TROUBLESHOOTING OF MAIN MONITOR SYSTEM (M MODE)

- 3.5.14. TROUBLESHOOTING OF MAINTENANCE MONITOR SYSTEM (K MODE)

- 3.5.15. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 3.5.16. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)

- 3.5.17. TROUBLESHOOTING OF TRANSMISSION CONTROLLER SYSTEM (T MODE)

- 3.5.18. TROUBLESHOOTING OF AJSS (ADVANCED JOYSTICK STEERING SYSTEM CONTROL SYSTEM) (J MODE)

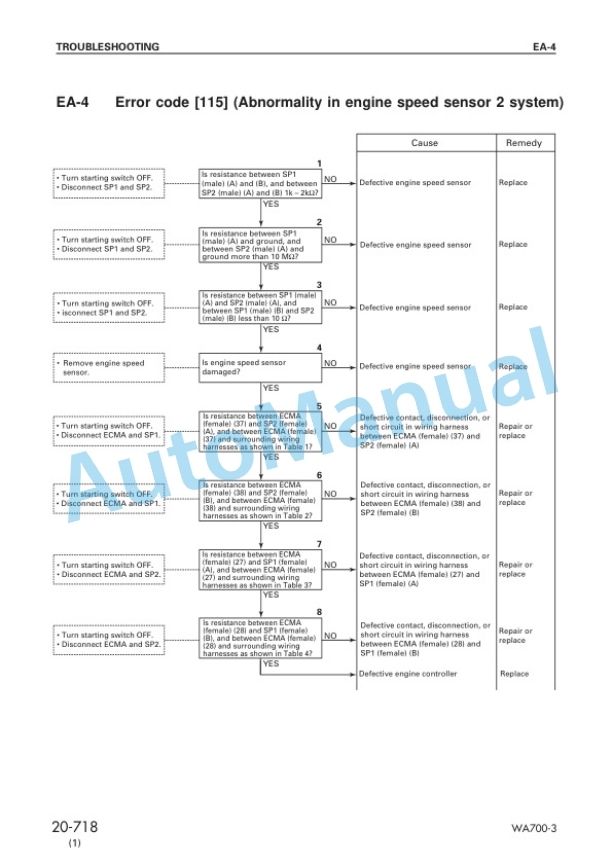

- 3.5.19. TROUBLESHOOTING OF ENGINE CONTROL SYSTEM (EA MODE)

- 3.5.20. TROUBLESHOOTING OF VHMS CONTROLLER SYSTEM (VHMS MODE)

- 4. MAINTENANCE STANDARD

- 4.1. ENGINE AND TRANSMISSION MOUNT

- 4.2. DAMPER

- 4.3. TORQUE CONVERTER AND PTO

- 4.4. TORQUE CONVERTER REGULATOR VALVE

- 4.5. TRANSMISSION

- 4.6. TRANSMISSION CONTROL VALVE

- 4.7. CENTER HINGE PIN

- 4.8. STEERING DEMAND VALVE

- 4.9. DIVERTER VALVE

- 4.10. STEERING CYLINDER MOUNT

- 4.11. EMERGENCY STEERING PUMP

- 4.12. STEERING AND SWITCH PUMP

- 4.13. MAIN PISTON PUMP

- 4.14. MAIN CONTROL VALVE

- 4.15. PPC VALVE

- 4.16. PPC RELIEF VALVE

- 4.17. HYDRAULIC CYLINDER

- 4.18. WORK EQUIPMENT LINKAGE

- 4.19. BUCKET

- 4.20. BUCKET POSITIONER AND BOOM KICKOUT

- 5. OTHERS

- 5.1. ELECTRIC CIRCUIT DIAGRAM (1/7)

- 5.2. ELECTRIC CIRCUIT DIAGRAM (2/7)

- 5.3. ELECTRIC CIRCUIT DIAGRAM (3/7)

- 5.4. ELECTRIC CIRCUIT DIAGRAM (4/7)

- 5.5. ELECTRIC CIRCUIT DIAGRAM (5/7)

- 5.6. ELECTRIC CIRCUIT DIAGRAM (6/7)

- 5.7. ELECTRIC CIRCUIT DIAGRAM (7/7)

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF