- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

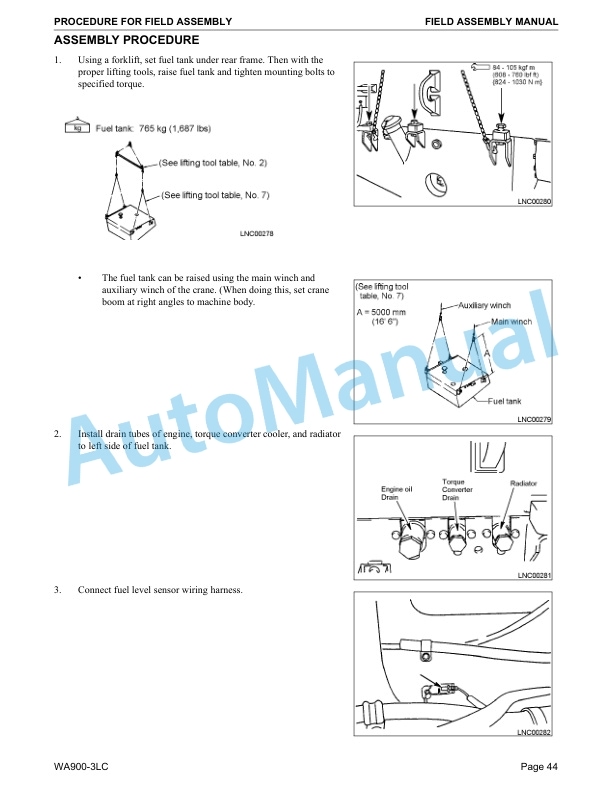

Komatsu WA900-3LC Wheel Loader Field Assembly Instruction CEAW000200

$20.00

- Type Of Manual: Field Assembly Instruction

- Manual ID: CEAW000200

- Format: PDF

- Size: 2.2MB

- Number of Pages: 112

-

Model List:

- WA900-3LC Wheel Loader

- 1. MAIN MENU

- 2. COVER

- 3. TABLE OF CONTENTS

- 4. CHART OF SEPERATED UNITS

- 5. DIMENSIONS AND WEIGHTS OF SEPARATED UNITS

- 6. TRANSPORTATION BY LAND

- 6.1. SPECIFICATIONS

- 6.2. WHEN TRAVELING UNDER OWN POWER

- 6.3. TRANSPORTATION BY TRAILER

- 6.4. TRAILERS REQUIRED TO MOVE MACHINE

- 7. SERVICE REFILL CAPACITIES

- 8. ORDER OF ASSEMBLY, FACILITIES TO USE, SCHEDULE FOR ASSEMBLY

- 9. WORK SPACE LAYOUT DIAGRAM

- 10. TOOLS AND EQUIPMENT REQUIRED

- 10.1. TOOLS REQUIRED

- 10.2. EQUIPMENT REQUIRED

- 10.3. LIFTING TOOLS REQUIRED

- 10.3.1. Front Frame Lifting Tool

- 10.3.2. Rear Frame Lifting Tool

- 10.3.3. Rear Axle Lifting Tool

- 10.3.4. Front, Rear Axle Lifting Tool

- 10.3.5. Fuel Tank Lifting Tool

- 10.3.6. Floor and Cab Lifting Tool

- 10.4. OIL, GREASE, FUEL, PAINT, ETC.

- 10.5. PROTECTIVE WEAR

- 10.6. LOCAL MANUFACTURING DIAGRAM FOR LIFTING TOOLS AND ROLLER

- 10.6.1. Axle Lifting Tool

- 10.6.2. Frame Lifting Tool

- 10.6.3. Roller for Moving Axle to Side

- 11. PROCEDURE FOR FIELD ASSEMBLY

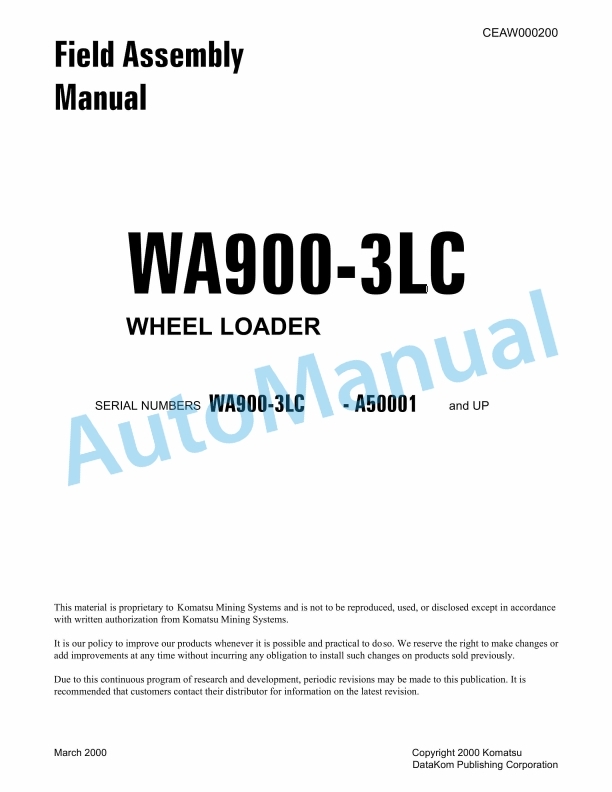

- 11.1. A1 SETTING BARE MACHINE ON SUPPORTS

- 11.1.1. Tools and Materials Required

- 11.1.2. Steel Stand Drawing

- 11.2. A2 ASSEMBLY OF REAR AXLE

- 11.2.1. OUTLINE

- 11.2.2. ASSEMBLY PROCEDURE

- 11.3. A3 ASSEMBLY OF FRONT AND REAR DRIVE SHAFTS

- 11.3.1. OUTLINE

- 11.3.2. ASSEMBLY PROCEDURE

- 11.4. A4 INSTALLATION OF FRONT AXLE

- 11.4.1. OUTLINE (INSTALLING FRONT AXLE)

- 11.4.2. ASSEMBLY PROCEDURE

- 11.4.3. OUTLINE (INSTALLING FRONT TIRE AND WHEEL ASSEMBLIES)

- 11.4.4. ASSEMBLY PROCEDURE (FRONT TIRE AND WHEEL ASSEMBLY)

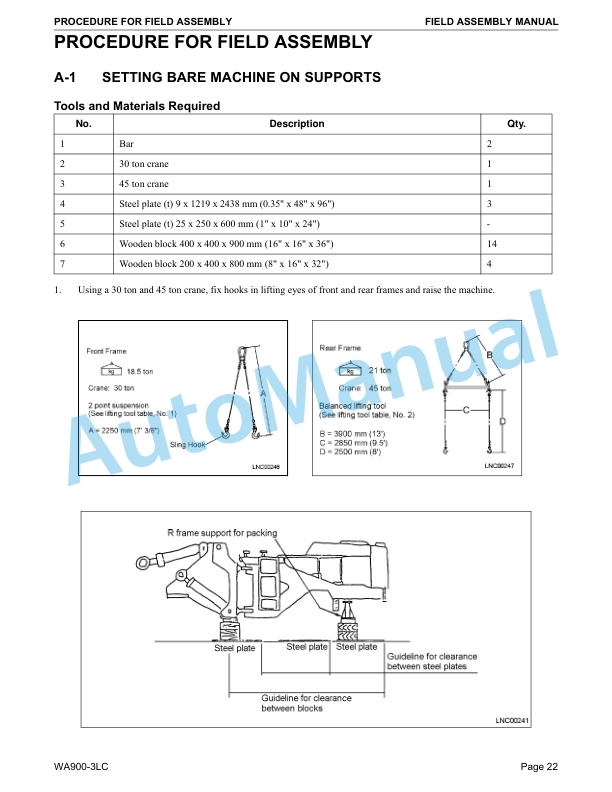

- 11.5. A5 ASSEMBLY OF FUEL TANK

- 11.5.1. OUTLINE

- 11.5.2. OPERATION FOR CONNECTING FUEL SUCTION AND RETURN HOSES

- 11.5.3. OPERATION FOR SECURING ENGINE DRAIN LINES

- 11.5.4. OPERATION FOR SECURING FUEL TANK VENT LINE

- 11.5.5. ASSEMBLY PROCEDURE

- 11.6. A6 ASSEMBLY OF LADDER (LEFT/RIGHT)

- 11.7. A7 ASSEMBLY OF CAB

- 11.7.1. ASSEMBLY PROCEDURE

- 11.8. A8 ASSEMBLY OF HAND RAIL

- 11.9. A9 ASSEMBLY OF REAR TIRE AND WHEEL ASSEMBLIES

- 11.9.1. ASSEMBLY PROCEDURE (REAR TIRE AND WHEEL ASSEMBLY)

- 11.10. A10 ASSEMBLY OF BATTERY BOXES

- 11.10.1. PROCEDURE FOR CONNECTING AND SECURING WIRING INSIDE BATTERY BOX

- 11.10.2. CIRCUIT DIAGRAM

- 11.10.3. OPERATION FOR INSTALLING BATTERY BOX COVERS

- 11.10.4. ASSEMBLY OF STEP ASSEMBLIES

- 11.11. A11 ASSEMBLY OF COUNTERWEIGHT

- 11.11.1. (STANDARD BOOM)

- 11.11.2. (HILIFT BOOM)

- 11.12. A12 ASSEMBLY OF EXHAUST PIPE

- 11.13. A13 ASSEMBLY OF HANDRAILS AND REAR ACCESS STEPS

- 11.13.1. ASSEMBLY OF HANDRAILS (RIGHT SIDE AND TOP OF HOOD)

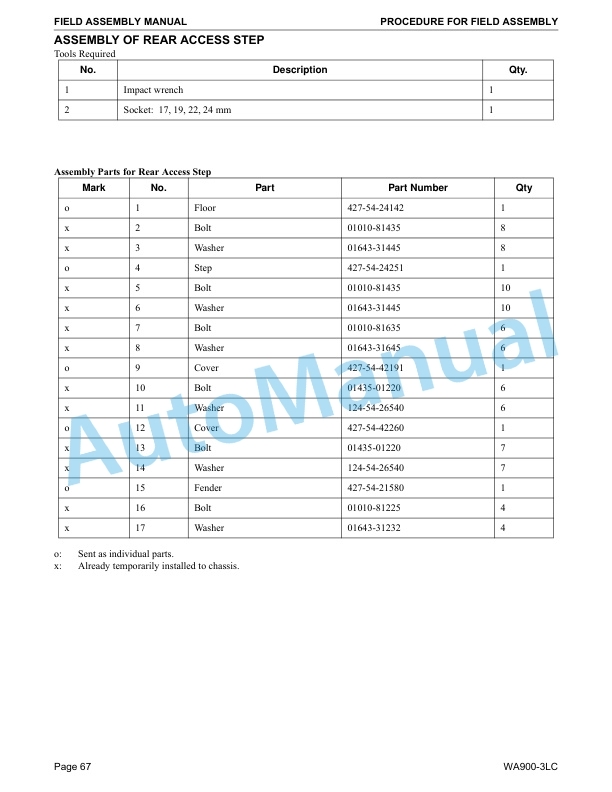

- 11.13.2. ASSEMBLY OF REAR ACCESS STEP

- 11.13.3. ASSEMBLY OF HANDRAIL (LEFT SIDE) AND MUDGUARD COVER

- 11.13.4. ASSEMBLY OF SAFETY CABLE AND MIRRORS

- 11.14. A14 ASSEMBLY OF BOOM

- 11.14.1. ASSEMBLY OF BOOM

- 11.14.2. CONNECTION OF REMOTE GREASE TUBE

- 11.14.3. ASSEMBLY PROCEDURE

- 11.15. A15 ASSEMBLY OF FRONT FENDERS

- 11.16. A16 ASSEMBLY OF FRONT LAMP ASSEMBLIES

- 11.17. A17 ASSEMBLY OF ROPS CANOPY

- 11.17.1. Operation for removal and installation of ROPS canopy support cover

- 11.17.2. Operation for installing ROPS canopy and wiring.

- 11.17.3. ASSEMBLY PROCEDURE

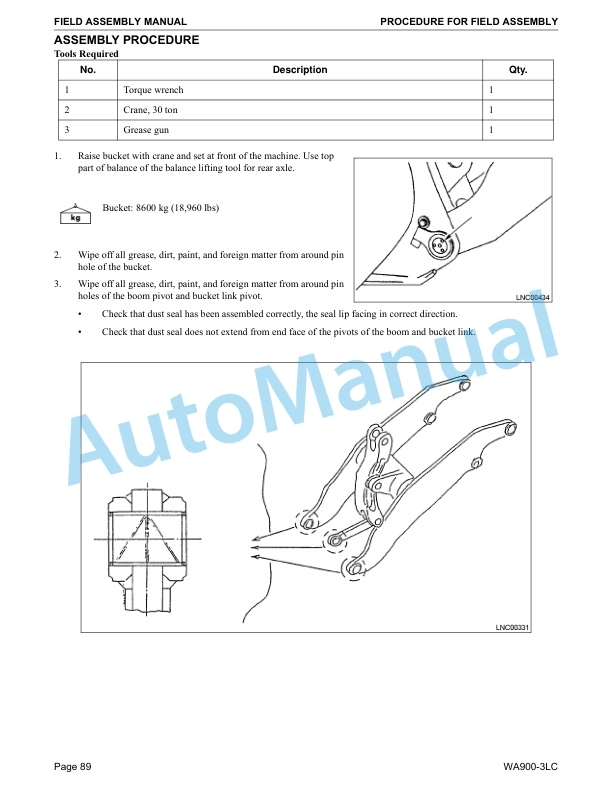

- 11.18. A18 ASSEMBLY OF BUCKET

- 11.18.1. Operation for Installation of Bucket Link

- 11.18.2. ASSEMBLY PROCEDURE

- 11.19. A19 ASSEMBLY OF FLOOR MAT

- 12. PROCEDURE FOR TESTING ASSEMBLED MACHINE

- 12.1. M1 BLEEDING AIR FROM WHEEL BRAKE CIRCUIT

- 12.1.1. Procedure for filling with oil.

- 12.1.2. Bleeding Air From Brake Circuit

- 12.2. M2 GREASING WORK EQUIPMENT AND CHASSIS

- 12.2.1. OUTLINE

- 12.3. M3 ADJUSTING BUCKET POSITIONER

- 12.3.1. OUTLINE

- 12.4. M4 ADJUSTING BOOM KICKOUT

- 12.4.1. OUTLINE

- 12.5. M5 PROCEDURE FOR STARTING ENGINE

- 12.5.1. OUTLINE

- 12.5.2. LONG TERM STORAGE

- 12.6. M6 INSPECTION OF ALL PARTS

- 12.6.1. OUTLINE

- 12.7. M7 PROCEDURE FOR BLEEDING AIR FROM PISTON PUMP

- 12.7.1. Procedure for bleeding air from piston pump.

- 12.8. M8 BLEEDING AIR FROM WORK EQUIPMENT CIRCUIT

- 12.8.1. Bleeding air from bucket and boom cylinders.

- 12.8.2. Bleeding air from PPC circuit.

- 13. INSPECTION REPORT

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF