- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WB140-2N, WB150-2N Backhoe Loader Shop Manual CEBM012701

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM012701

- Format: PDF

- Size: 74.5MB

- Number of Pages: 660

Category: Komatsu Shop Manual PDF

-

Model List:

- WB140-2N Backhoe Loader

- WB150-2N Backhoe Loader

- 0.1. GENERAL

- 0.2. HOW TO READ THE SHOP MANUAL

- 0.2.1. VOLUMES

- 0.2.2. DISTRIBUTION AND UPDATING

- 0.2.3. FILING METHOD

- 0.2.4. REVISED EDITION MARK

- 0.2.5. REVISIONS

- 0.2.6. SYMBOLS

- 0.3. HOISTING INSTRUCTIONS

- 0.3.1. HOISTING

- 0.3.2. WIRE ROPES

- 0.4. PUSH PULL COUPLER

- 0.5. COATING MATERIALS

- 0.6. STANDARD TIGHTENING TORQUE

- 0.6.1. STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS

- 0.6.2. TIGHTENING TORQUE OF HOSE NUTS

- 0.6.3. TIGHTENING TORQUE OF SPLIT FLANGE BOLTS

- 0.6.4. TIGHTENING TORQUE FOR FLARED NUTS

- 0.6.5. TABLE OF TIGHTENING TORQUES FOR ORING BOSS PIPING JOINTS

- 0.6.6. TABLE OF TIGHTENING TORQUES FOR ORING BOSS PLUGS

- 0.6.7. TIGHTENING TORQUE TABLE FOR HOSES (TAPER SEAL TYPE AND FACE SEAL TYPE)

- 0.7. ELECTRIC WIRE CODE

- 0.7.1. CLASSIFICATION BY THICKNESS

- 0.7.2. CLASSIFICATION BY COLOR AND CODE

- 0.8. CONVERSION TABLES

- 0.8.1. METHOD OF USING THE CONVERSION TABLE

- 1. GENERAL

- 1.1. SPECIFICATIONS

- 1.2. WEIGHT TABLE

- 1.3. FUEL COOLANT AND LUBRICANTS

- 2. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 2.1. ENGINE MOUNTING

- 2.1.1. D MACHINES

- 2.2. TRANSMISSION DIAGRAM

- 2.2.1. D MACHINES

- 2.2.2. D MACHINES

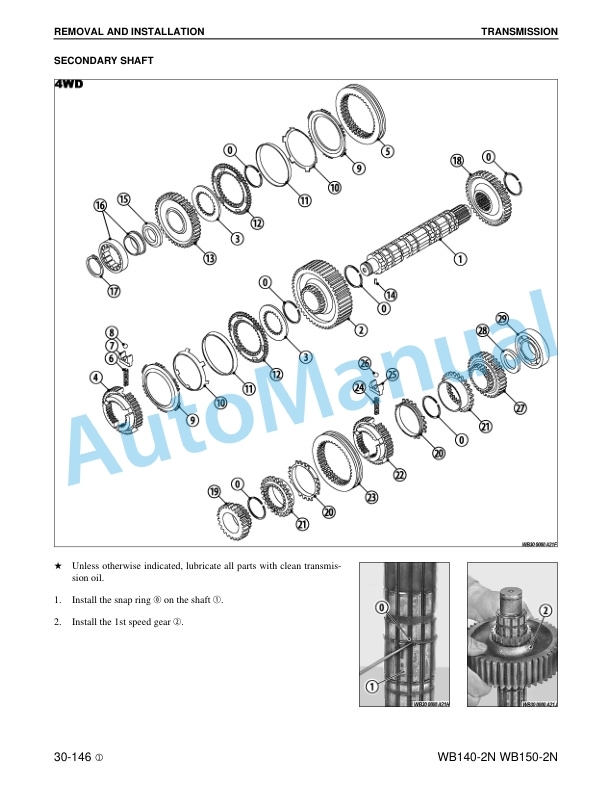

- 2.3. TRANSMISSION

- 2.3.1. COMPLETE ASSEMBLY

- 2.3.2. FORWARD REVERSE CLUTCH

- 2.3.3. T THROUGH 4TH SPEED SHAFT

- 2.3.4. D SHAFT

- 2.4. FRONT AXLE

- 2.5. REAR AXLE

- 2.5.1. COMPLETE ASSEMBLY

- 2.5.2. DIFFERENTIAL

- 2.5.3. PLANETARY

- 2.5.4. BRAKES

- 2.5.5. DIFFERENTIAL LOCK

- 2.5.6. PC VALVE, LS VALVE, SERVO PISTON

- 2.6. BACKHOE CONTROL VALVE

- 2.6.1. MECHANICAL CONTROL

- 2.6.2. EXCAVATOR CONTROL

- 2.7. CLSS

- 2.7.1. CHARACTERISTICS

- 2.7.2. STRUCTURE

- 2.7.3. OPERATING PRINCIPLES

- 2.7.4. UNLOADING VALVE

- 2.7.5. INTRODUCTION OF THE LS PRESSURE

- 2.7.6. DELIVERY COMPENSATION

- 2.7.7. LIFD CONTROL SYSTEM

- 2.7.8. LS DECOMPRESSION VALVE

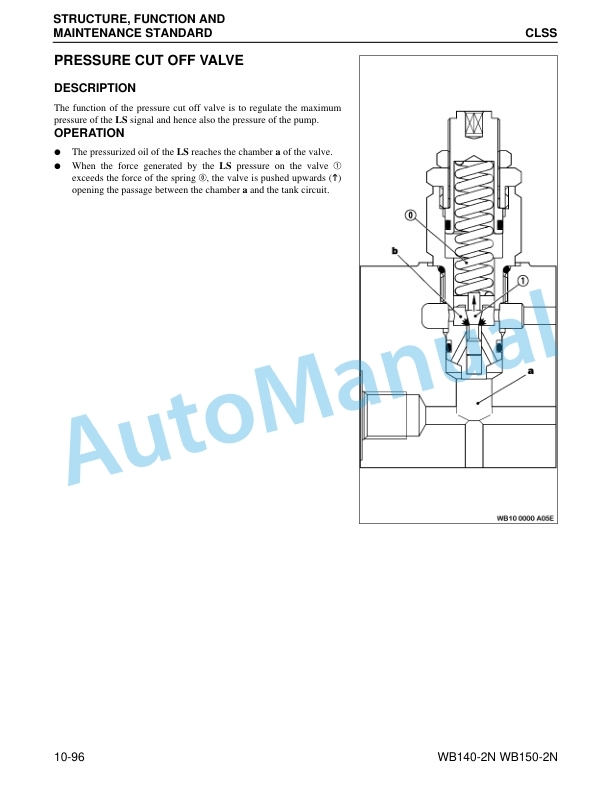

- 2.7.9. PRESSURE CUT OFF VALVE

- 2.7.10. DIFFERENTIAL LOCK BACKHOE BOOM LOCK

- 2.7.11. PPC SUPPLY VALVE ST2

- 2.7.12. PPC TELESCOPIC ARM

- 2.7.13. PPC HAMMER

- 2.7.14. PPC ARM AND HAMMER

- 2.8. LOADER CYLINDERS

- 2.8.1. BOOM ARM

- 2.8.2. BUCKET

- 2.8.3. MP BUCKET

- 2.9. BACKHOE CYLINDERS

- 2.9.1. BOOM

- 2.9.3. BUCKET

- 2.9.4. TELESCOPIC ARM CYLINDER

- 2.9.5. SWING

- 2.9.6. OUTRIGGER

- 2.9.7. BOOM LOCK CYLINDER

- 2.10. FRONT WORK EQUIPMENT

- 2.11. REAR WORK EQUIPMENT

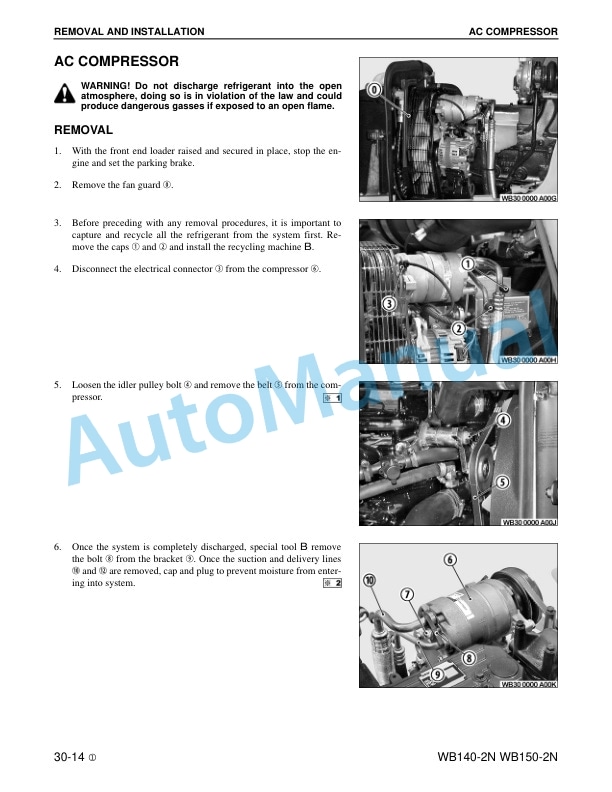

- 2.12. AIR CONDITIONING

- 3. TESTING, ADJUSTING AND TROUBLESHOOTING

- 3.1. STANDARD VALUE TABLES FOR ENGINE

- 3.2. STANDARD VALUE TABLES FOR CHASSIS

- 3.3. SPECIAL TOOLS

- 3.4. ENGINE SPEED

- 3.4.1. TIER I ENGINE

- 3.4.2. TIER II ENGINE

- 3.5. VALVE CLEARANCE

- 3.5.1. TIER I ENGINE

- 3.5.2. TIER II ENGINE

- 3.6. COMPRESSION PRESSURE

- 3.6.1. TIER I ENGINE

- 3.6.2. TIER II ENGINE

- 3.7. FUEL INJECTION TIMING

- 3.7.1. TIER I ENGINE

- 3.7.2. TIER II ENGINE

- 3.8. FAN BELT

- 3.8.1. TENSION CHECK

- 3.8.2. TENSION ADJUSTMENT

- 3.9. COMPRESSOR DRIVE BELT

- 3.9.1. CHECKING TENSION

- 3.9.2. TENSION ADJUSTMENT

- 3.10. ACCELERATOR PEDAL AND LEVER

- 3.10.1. ACCELERATOR PEDAL TRAVEL

- 3.10.2. ACCELERATOR LEVER TRAVEL

- 3.11. BRAKE PEDAL TRAVEL

- 3.11.1. TIER I ENGINE

- 3.11.2. TIER II ENGINE

- 3.12. BLEEDING AIR

- 3.12.1. HYDRAULIC PUMP

- 3.12.2. CYLINDERS

- 3.12.3. HYDRAULIC OIL TANK

- 3.12.4. HYDRAULIC OIL TANK PRESSURIZATION

- 3.12.5. WORK CIRCUITS

- 3.12.6. BRAKE CIRCUIT

- 3.12.7. CHECK BRAKE CIRCUIT

- 3.13. HYDRAULIC CIRCUIT

- 3.13.1. INTRODUCTION

- 3.13.2. LOADER CONTROL VALVES

- 3.13.3. BACKHOE CONTROLS STYLE VALVE

- 3.13.4. EXCAVATOR CONTROLS STYLE VALVE

- 3.14. MAIN RELIEF VALVES

- 3.14.1. TESTING

- 3.14.2. SETTING RELIEF PRESSURE

- 3.15. LOADER CIRCUIT RELIEF VALVES

- 3.15.1. TESTING PRESSURE

- 3.15.2. SETTING PRESSURE

- 3.16. BACKHOE CIRCUIT RELIEF VALVES

- 3.16.1. TESTING PRESSURE

- 3.16.2. SETTING PRESSURE

- 3.17. UNLOADING VALVE

- 3.17.1. TESTING

- 3.17.2. ADJUSTMENT

- 3.18. LOAD SENSING (LS) VALVE

- 3.18.1. CLEANING PRIORITY VALVE

- 3.19. STEERING SYSTEM

- 3.19.1. TESTING

- 3.19.2. SETTING

- 3.20. BRAKE SYSTEM

- 3.20.1. CIRCUIT AND BRAKE PUMP TEST

- 3.20.2. BRAKING GROUP LEAK TEST

- 3.21. ENGINE SPEED UNDER LOAD

- 3.21.1. PREPARING THE MACHINE

- 3.21.2. TORQUE CONVERTER STALL

- 3.21.3. TORQUE CONVERTER AND HYDRAULIC STALL

- 3.22. POWER TRAIN GROUP

- 3.22.1. PREPARING THE MACHINE

- 3.22.2. CONVERTER OIL PRESSURE

- 3.22.3. CLUTCH PRESSURE

- 3.22.4. ADDITIONAL PRESSURES

- 3.23. DIRECTIONAL CLUTCHES

- 3.23.1. PREPARATION OF THE MACHINE

- 3.23.2. TESTING

- 3.24. RETURN TO DIG DEVICE

- 3.25. HYDRAULIC DRIFT

- 3.25.1. LOADER

- 3.25.2. BACKHOE

- 3.26. AIR CONDITIONING UNIT

- 3.26.1. TESTING THE WORKING TEMPERATURE

- 3.26.2. CHECKING THE UNIT

- 3.26.3. EMPTYING THE AC UNIT

- 3.27. TROUBLESHOOTING GUIDE

- 3.27.1. FRONT AXLE

- 3.27.2. REAR AXLE

- 3.27.3. TRANSMISSION

- 4. REMOVAL AND INSTALLATION

- 4.1. METHOD OF USING THIS MANUAL

- 4.1.1. REMOVAL OR INSTALLATION OF PARTS OR ASSEMBLIES

- 4.2. PRECAUTIONS DURING SERVICE OPERATIONS

- 4.2.1. REMOVAL PRECAUTIONS

- 4.2.2. INSTALLATION PRECAUTIONS

- 4.3. SPECIAL TOOLS

- 4.3.1. LISTING

- 4.3.2. SKETCHES

- 4.4. ENGINE COMPONENTS

- 4.5. LOADER CYLINDER LOCK

- 4.5.1. LOCKING PROCEDURES

- 4.6. INJECTION NOZZLE

- 4.7. BATTERY DISCONNECT SWITCH

- 4.8. RADIATOR OIL COOLERS

- 4.9. ENGINE AND TRANSMISSION

- 4.10. TORQUE CONVERTER

- 4.11. COLUMN CONTROL SWITCHES

- 4.11.1. REMOVAL

- 4.11.2. INSTALLATION

- 4.12. MASTER BRAKE CYLINDER

- 4.12.1. REMOVAL

- 4.12.2. INSTALLATION

- 4.13. LOADER CONTROL VALVE

- 4.14. LOADER CYLINDERS

- 4.14.1. BOOM

- 4.14.2. BUCKET

- 4.14.3. INSTALLATION

- 4.14.4. MP BUCKET CYLINDER

- 4.15. FRONT EQUIPMENT

- 4.15.1. BUCKET

- 4.15.2. BOOM

- 4.16. BACKHOE CONTROL VALVE

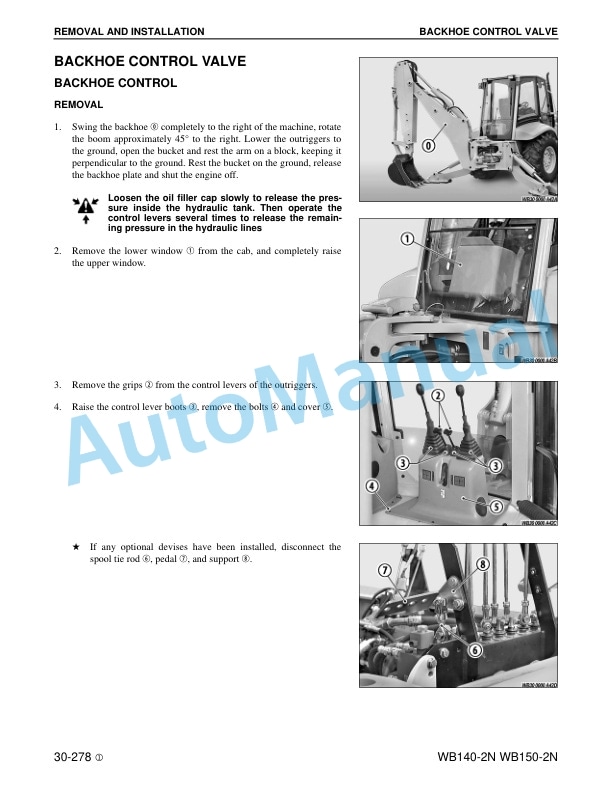

- 4.16.1. BACKHOE CONTROL

- 4.16.2. INSTALLATION

- 4.16.3. EXCAVATOR CONTROLS

- 4.17. PPC CONTROLS

- 4.17.1. PPC VALVE

- 4.17.2. SUPPORT RELEASE CABLES

- 4.17.3. SUPPORT RETURN GAS SPRING

- 4.17.4. SOLENOID VALVE

- 4.17.5. SERVO CONTROL FEED VALVE

- 4.18. BACKHOE CYLINDERS

- 4.19. BACKHOE WORK EQUIPMENT

- 4.19.1. INNER ARM GUIDES

- 4.19.2. BOOM

- 4.19.3. SWING BRACKET

- 4.19.4. OUTRIGGERS

- 5. OTHER

- 5.1. HYDRAULIC CIRCUIT

- 5.1.1. STANDARD CONTROLS FOR WB1402N SHEET 1 OF 2

- 5.1.2. STANDARD CONTROLS FOR WB1402N SHEET 2 OF 2

- 5.1.3. STANDARD CONTROLS FOR WB1502N SHEET 1 OF 2

- 5.1.4. STANDARD CONTROLS FOR WB1502N SHEET 2 OF 2

- 5.1.5. PPC SYSTEM FOR WB1402N SHEET 1 OF 3

- 5.1.6. PPC SYSTEM FOR WB1402N SHEET 2 OF 3

- 5.1.7. PPC SYSTEM FOR WB1402N SHEET 3 OF 3

- 5.1.8. PPC SYSTEM FOR WB1502N SHEET 1 OF 3

- 5.1.9. PPC SYSTEM FOR WB1502N SHEET 2 OF 3

- 5.1.10. PPC SYSTEM FOR WB1502N SHEET 3 OF 3

- 5.2. ELECTRICAL

- 5.2.1. CAB WIRING SCHEMATIC SHEET 1 OF 5

- 5.2.2. CAB WIRING SCHEMATIC SHEET 2 OF 5

- 5.2.3. CAB WIRING SCHEMATIC SHEET 3 OF 5

- 5.2.4. CAB WIRING SCHEMATIC SHEET 4 OF 5

- 5.2.5. CAB WIRING SCHEMATIC SHEET 5 OF 5

- 5.2.6. LEGEND FOR CAB WIRING SCHEMATIC

- 5.2.7. CANOPY WIRING SCHEMATIC SHEET 1 OF 5

- 5.2.8. CANOPY WIRING SCHEMATIC SHEET 2 OF 5

- 5.2.9. CANOPY WIRING SCHEMATIC SHEET 3 OF 5

- 5.2.10. CANOPY WIRING SCHEMATIC SHEET 4 OF 5

- 5.2.11. CANOPY WIRING SCHEMATIC SHEET 5 OF 5

- 5.2.12. LEGEND FOR CANOPY WIRING SCHEMATIC

- 5.2.13. TIER I ENGINE HARNESS

- 5.2.14. TIER II ENGINE HARNESS

- 5.2.15. LEGEND FOR TIER I AND II ENGINE HARNESSES

- 5.2.16. FRONT HARNESS

- 5.2.17. LEGEND FOR FRONT HARNESS

- 5.2.18. LATERAL HARNESS AND SIDE DASHBOARD

- 5.2.19. PPC FRAME AND SIDE DASH BOARD HARNESS

- 5.2.20. WORK LIGHT HARNESS

- 5.2.21. FUSE AND RELAY PANEL

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF