- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WB146-5 Backhoe Loader Shop Manual CEBM016503

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM016503

- Format: PDF

- Size: 78.3MB

- Number of Pages: 586

Category: Komatsu Shop Manual PDF

-

Model List:

- WB146-5 Backhoe Loader

- 1. COVER

- 2. FOREWORD

- 2.1. CONTENTS

- 2.1.1. LIST OF REVISED PAGES

- 2.2. SAFETY

- 2.2.1. SAFETY NOTICE

- 2.3. GENERAL

- 2.4. HOW TO READ THE SHOP MANUAL

- 2.4.1. VOLUMES

- 2.4.2. DISTRIBUTION AND UPDATING

- 2.4.3. FILING METHOD

- 2.4.4. REVISED EDITION MARK

- 2.4.5. REVISIONS

- 2.4.6. SYMBOLS

- 2.5. HOISTING INSTRUCTIONS

- 2.5.1. HOISTING

- 2.5.2. WIRE ROPES

- 2.6. PUSH PULL COUPLER

- 2.6.1. TYPE 1

- 2.6.2. TYPE 2

- 2.6.3. TYPE 3

- 2.7. COATING MATERIALS

- 2.8. STANDARD TIGHTENING TORQUE

- 2.8.1. STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS

- 2.8.2. TIGHTENING TORQUE OF HOSE NUTS

- 2.8.3. TIGHTENING TORQUE OF SPLIT FLANGE BOLTS

- 2.8.4. TIGHTENING TORQUE FOR FLARED NUTS

- 2.8.5. TABLE OF TIGHTENING TORQUES FOR ORING BOSS PIPING JOINTS

- 2.8.6. TABLE OF TIGHTENING TORQUES FOR ORING BOSS PLUGS

- 2.8.7. TIGHTENING TORQUE TABLE FOR HOSES (TAPER SEAL TYPE AND FACE SEAL TYPE)

- 2.9. ELECTRIC WIRE CODE

- 2.9.1. CLASSIFICATION BY THICKNESS

- 2.9.2. CLASSIFICATION BY COLOR AND CODE

- 2.10. CONVERSION TABLES

- 2.10.1. METHOD OF USING THE CONVERSION TABLE

- 3. GENERAL

- 3.1. SPECIFICATION DRAWING

- 3.1.1. SPECIFICATIONS

- 3.1.2. BACKHOE ARM

- 3.2. MACHINE SYSTEMS SPECIFICATIONS

- 3.2.1. ENGINE

- 3.2.2. ELECTRICAL SYSTEM

- 3.2.3. SERVICE REFILL CAPACITIES

- 3.3. FUEL, COOLANT, AND LUBRICANTS

- 3.3.1. PROPER SELECTION ACCORDING TO THE AMBIENT TEMPERATURE

- 3.3.2. GREASE

- 3.3.3. FUEL REMARKS

- 3.4. HOMOLOGATED (HEES) SYNTHETIC LUBRICANTS

- 3.5. LUBRICATION DIAGRAMS

- 3.5.1. GENERAL VIEW

- 4. STRUCTURE, FUNCTION AND MAINTENANCE

- 4.1. POWER TRAIN

- 4.1.1. DESCRIPTION

- 4.1.2. POWER FLOW

- 4.2. TRANSMISSION DIAGRAM

- 4.3. TRANSMISSION

- 4.3.1. COMPLETE ASSEMBLY

- 4.3.2. FORWARD REVERSE CLUTCH

- 4.3.3. T THROUGH 4TH SPEED SHAFT

- 4.3.4. D SHAFT

- 4.4. FRONT AXLE

- 4.4.1. COMPLETE ASSEMBLY

- 4.4.2. DIFFERENTIAL

- 4.4.3. PLANETARY

- 4.5. REAR AXLE

- 4.5.1. COMPLETE ASSEMBLY

- 4.5.2. DIFFERENTIAL

- 4.5.3. PLANETARY

- 4.5.4. WORK BRAKES

- 4.5.5. DIFFERENTIAL LOCK

- 4.6. DELIVERY CONTROL VALVE

- 4.6.1. LS VALVE FUNCTION

- 4.6.2. PC VALVE FUNCTION

- 4.6.3. PC VALVE OPERATION

- 4.7. MAIN CONTROL VALVE

- 4.8. CLSS

- 4.8.1. DESCRIPTION

- 4.8.2. OPERATING PRINCIPLES

- 4.9. OUTRIGGER

- 4.9.1. OPERATION

- 4.10. BACKHOE

- 4.10.1. LEFT VALVE

- 4.10.2. RIGHT VALVE

- 4.11. SOLENOID VALVE

- 4.11.1. HYDRAULIC CONTROLS W/O MP BUCKET

- 4.11.2. HYDRAULIC CONTROLS WITH MP BUCKET

- 4.12. LOADER CYLINDERS

- 4.12.1. BOOM

- 4.12.2. BUCKET

- 4.12.3. MP BUCKET

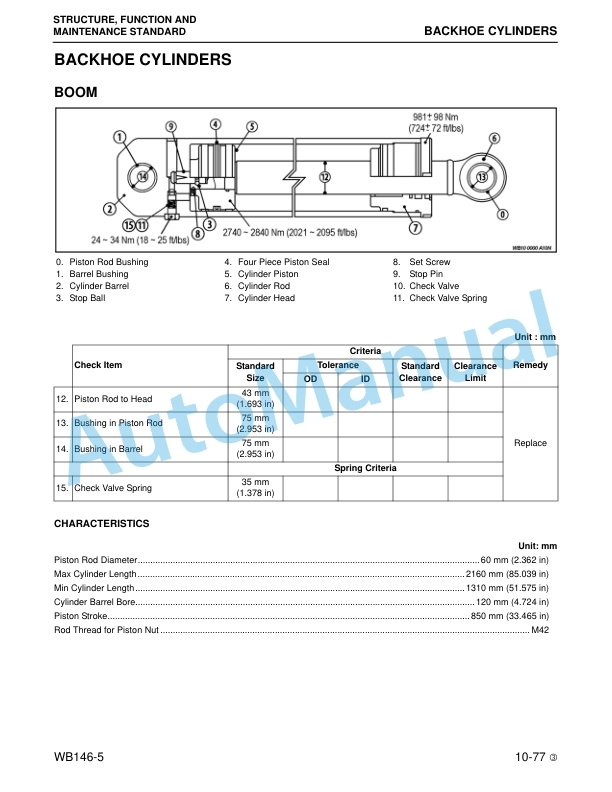

- 4.13. BACKHOE CYLINDERS

- 4.13.1. BOOM

- 4.13.3. BUCKET

- 4.13.4. TELESCOPIC ARM CYLINDER

- 4.13.5. SWING

- 4.13.6. OUTRIGGER

- 4.14. WORK EQUIPMENT

- 4.14.1. LOADER

- 4.14.2. BACKHOE

- 4.15. AIR CONDITIONING

- 5. TESTING, ADJUSTING ANDTROUBLESHOOTING

- 5.1. STANDARD VALUE TABLE

- 5.1.1. ENGINE

- 5.1.2. CHASSIS

- 5.2. SPECIAL TOOLS

- 5.3. ENGINE SPEED

- 5.3.1. ENGINE WITHOUT LOAD

- 5.4. VALVE CLEARANCE

- 5.5. AC COMPRESSOR BELT TENSION

- 5.6. BLEED AIR FROM CIRCUITS

- 5.6.1. BLEED AIR FROM HYDRAULIC CIRCUIT

- 5.6.2. BLEED AIR FROM BRAKING CIRCUIT

- 5.6.3. RELEASING RESIDUAL PRESSURE

- 5.7. ACCELERATOR PEDAL AND LEVER

- 5.7.1. ACCELERATOR PEDAL TRAVEL

- 5.7.2. ACCELERATOR LEVER TRAVEL

- 5.8. PARKING BRAKE ADJUSTMENT

- 5.9. HYDRAULIC CIRCUIT

- 5.9.1. INTRODUCTION

- 5.10. RELIEF VALVES

- 5.10.1. TESTING

- 5.11. SETTING RELIEF VALVES

- 5.11.1. MAIN RELIEF VALVE

- 5.11.2. CIRCUIT RELIEF VALVES

- 5.12. LS DIFFERENTIAL PRESSURE

- 5.12.1. CONTROL

- 5.12.2. ADJUSTMENT

- 5.13. PPC SUPPLY PRESSURE

- 5.13.1. CHECK

- 5.13.2. ADJUSTMENT

- 5.14. PC VALVE

- 5.14.1. ADJUSTMENT

- 5.15. STEERING CONTROL SYSTEM

- 5.15.1. CONTROL

- 5.15.2. SETTING

- 5.16. STEERING CYLINDER

- 5.17. POWER TRAIN GROUP

- 5.17.1. CONVERTER OIL PRESSURE

- 5.17.2. CLUTCH ENGAGEMENT PRESSURE

- 5.17.3. SUPPLY PRESSURE

- 5.18. TRANSMISSION CLUTCH FUNCTION

- 5.18.1. MACHINE PREPARATION

- 5.18.2. CONTROL

- 5.19. HYDRAULIC DRIFT

- 5.20. AIR CONDITIONING

- 5.20.1. WORK TEMPERATURE

- 5.20.2. UNIT CHECK

- 5.20.3. EMPTYING THE AC UNIT

- 5.21. TROUBLESHOOTING GUIDE

- 5.21.1. FRONT AXLE

- 5.21.2. REAR AXLE

- 5.21.3. TRANSMISSION

- 5.22. FUSES AND RELAYS

- 5.22.1. FUSE AND RELAY PANEL LOCATION

- 5.22.2. FUSE AND RELAY PANEL LAYOUT

- 5.22.3. HEATING AND AIR CONDITIONING FUSES AND RELAYS

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. HOW TO USE THIS MANUAL

- 6.1.1. REMOVAL AND INSTALLATION OF COMPONENTS

- 6.1.2. OVERHAUL OF COMPONENTS

- 6.2. PRECAUTIONS WHEN PERFORMING OPERATIONS

- 6.3. SPECIAL TOOL LIST

- 6.4. CONNECTOR REPAIR PROCEDURES

- 6.4.1. CONTACT TERMINAL REMOVAL (HD30 TYPE)

- 6.4.2. CRIMPING CONTACT TERMINAL (HD30 TYPE)

- 6.4.3. INSERTION OF CONTACT TERMINAL (HD30 TYPE)

- 6.4.4. CONTACT TERMINAL REMOVAL (DT TYPE)

- 6.4.5. CRIMPING CONTACT TERMINAL (DT TYPE)

- 6.4.6. INSERTION OF CONTACT TERMINAL (DT TYPE)

- 6.4.7. STRIPPING INSULATION

- 6.5. BLEED AIR FROM CIRCUITS

- 6.5.1. BLEED AIR FROM HYDRAULIC CIRCUIT

- 6.5.2. BLEED AIR FROM BRAKING CIRCUIT

- 6.5.3. RELEASING RESIDUAL PRESSURE

- 6.6. AIR CONDITIONING CONDENSER

- 6.7. REFRIGERANT COMPRESSOR

- 6.7.1. REMOVAL

- 6.7.2. INSTALLATION

- 6.8. REFRIGERANT COMPRESSOR BELT

- 6.9. OPERATORS SEAT

- 6.9.1. REMOVAL

- 6.9.2. INSTALLATION

- 6.10. CAB HEATING AND COOLING SYSTEM

- 6.11. STEERING AND FRONT DASH ASSEMBLY

- 6.11.1. STEERING WHEEL

- 6.11.2. FRONT DASH ASSEMBLY

- 6.12. HYDRAULIC OIL TANK

- 6.13. TRANSMISSION OVERHAUL PROCEDURES

- 6.13.1. TORQUE CONVERTER

- 6.13.2. PLUGS AND FILTERS

- 6.13.3. WHEEL DRIVE SOLENOID VALVE

- 6.13.4. TRANSMISSION HOUSING

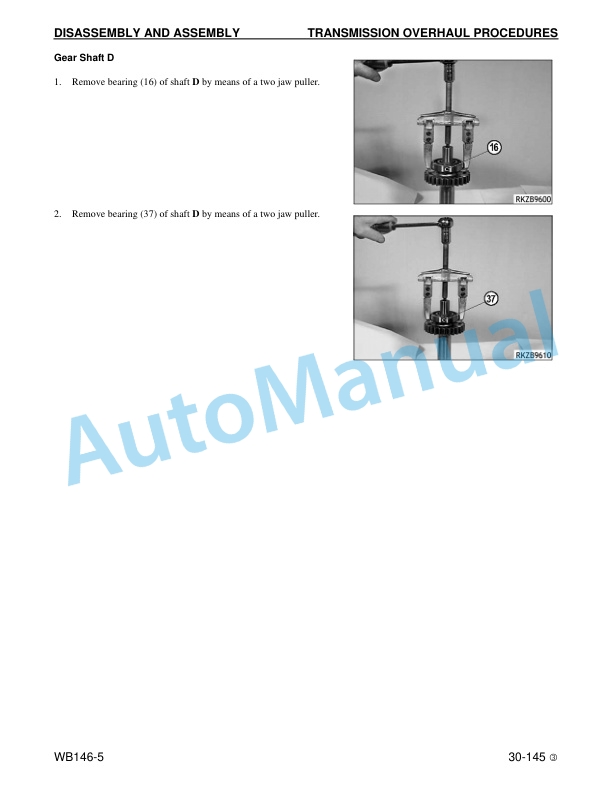

- 6.13.5. CLUTCH PACK (A) AND GEAR SHAFT (D)

- 6.13.6. GEAR SHAFTS (B) AND (C)

- 6.13.7. GEAR SHAFT (E)

- 6.13.8. SHIFTER TOWER AND FORKS

- 6.14. ENGINE

- 6.14.1. REMOVAL

- 6.14.2. INSTALLATION

- 6.15. STEERING SOLENOID VALVE

- 6.15.1. REMOVAL

- 6.15.2. INSTALLATION

- 6.16. FRONT AXLE ASSEMBLY

- 6.16.1. REMOVAL

- 6.16.2. INSTALLATION

- 6.17. FRONT AXLE OVERHAUL PROCEDURES

- 6.17.1. STEERING CYLINDER ASSEMBLY

- 6.17.2. FRONT AXLE END PLANETARY ASSEMBLY

- 6.17.3. AXLE END HUB ASSEMBLY

- 6.18. REAR AXLE ASSEMBLY

- 6.18.1. REMOVAL

- 6.18.2. INSTALLATION

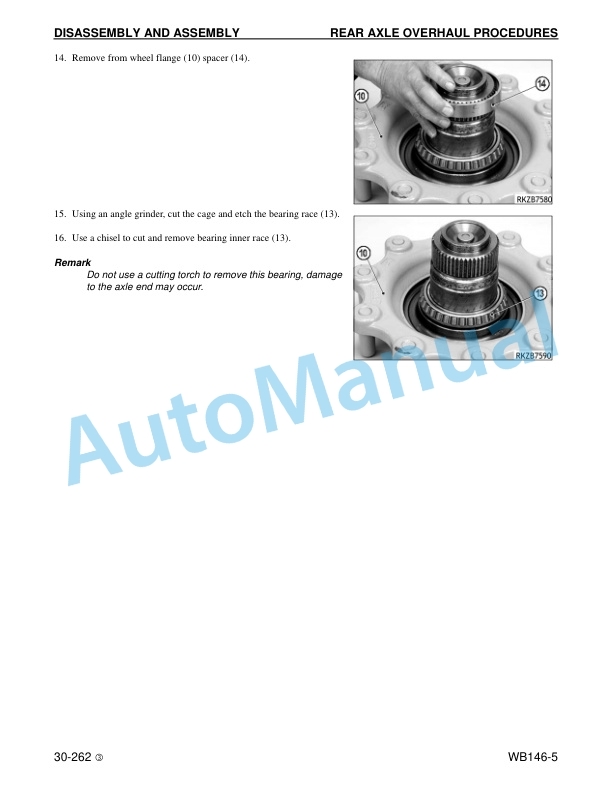

- 6.19. REAR AXLE OVERHAUL PROCEDURES

- 6.19.1. PARKING BRAKE ASSEMBLY

- 6.19.2. SERVICE BRAKE ASSEMBLY

- 6.19.3. REAR AXLE END PLANETARY ASSEMBLY

- 6.19.4. DIFFERENTIAL

- 6.19.5. DIFFERENTIAL LOCK

- 6.20. FRONT LOADER PPC VALVE

- 6.20.1. REMOVAL

- 6.20.2. INSTALLATION

- 6.21. FRONTEND LOADER ASSEMBLY

- 6.21.1. LOADER BOOM CYLINDERS

- 6.21.2. INSTALLATION

- 6.21.3. BUCKET CYLINDERS

- 6.21.4. FRONT LOADER BUCKET

- 6.21.5. LOADER BOOM ASSEMBLY

- 6.22. BACKHOE PPC VALVE

- 6.22.1. REMOVAL

- 6.22.2. INSTALLATION

- 6.23. PPC VALVE SUPPORT RELEASE CABLES

- 6.23.1. REMOVAL

- 6.23.2. INSTALLATION AND ADJUSTING

- 6.24. PPC VALVE GAS STRUT

- 6.25. BACKHOE ASSEMBLY

- 6.25.1. BUCKET CYLINDER

- 6.25.2. EXTENDABLE ARM CYLINDER

- 6.25.3. SWING CYLINDERS

- 6.25.4. BOOM LOCK CYLINDER

- 6.25.5. EXTENDABLE ARM GIBS

- 6.25.6. BACKHOE BOOM

- 6.25.7. BACKHOE SWING FRAME

- 6.25.8. OUTRIGGER CYLINDERS

- 6.25.9. OUTRIGGER ARMS

- 6.26. WORK EQUIPMENT CYLINDER OVERHAUL

- 6.26.1. LOADER AND BACKHOE CYLINDERS

- 6.26.2. SWING CYLINDERS

- 7. OTHERS

- 7.1. HYDRAULIC CIRCUIT

- 7.1.1. OF 4

- 7.1.2. OF 4

- 7.1.3. OF 4

- 7.1.4. OF 4

- 7.2. ELECTRICAL SCHEMATIC

- 7.2.1. WIRING 1 OF 7

- 7.2.2. WIRING 2 OF 7

- 7.2.3. WIRING 3 OF 7

- 7.2.4. WIRING 4 OF 7

- 7.2.5. WIRING 5 OF 7

- 7.2.6. WIRING 6 OF 7

- 7.2.7. WIRING 7 OF 7

- 7.2.8. LEGEND FOR WIRING SCHEMATIC

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF