- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WB97S-8 Backhoe Loader Shop Manual WENBM00200

$40.00

- Type Of Manual: Shop Manual

- Manual ID: WENBM00200

- Format: PDF

- Size: 55.2MB

- Number of Pages: 536

Category: Komatsu Shop Manual PDF

-

Model List:

- WB97S-8 Backhoe Loader

- 1. INDEX AND FOREWORD

- 1.1. INDEX

- 1.2. FOREWORD, SAFETY, BASIC INFORMATION

- 1.2.1. HOW TO READ THE SHOP MANUAL

- 1.2.2. SAFETY NOTICE FOR OPERATION

- 1.2.3. PRECAUTIONS TO PREVENT FIRE

- 1.2.4. ACTIONS IF FIRE OCCURS

- 1.2.5. PRECAUTIONS FOR DISPOSING OF WASTE MATERIALS

- 1.2.6. ACTIONS TAKEN TO MEET EXHAUST GAS REGULATIONS

- 1.2.7. PRECAUTIONS FOR DEF

- 1.2.8. STORE AdBlue/DEF

- 1.2.9. PRECAUTIONS FOR HANDLING HYDRAULIC EQUIPMENT

- 1.2.10. PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF PIPINGS

- 1.2.11. PRECAUTIONS FOR HANDLING ELECTRICAL EQUIPMENT

- 1.2.12. PRECAUTIONS FOR HANDLING FUEL SYSTEM EQUIPMENT

- 1.2.13. PRECAUTIONS FOR HANDLING INTAKE SYSTEM EQUIPMENT

- 1.2.14. PRACTICAL USE OF KOMTRAX

- 1.2.15. DISCONNECT AND CONNECT PUSHPULL TYPE COUPLER

- 1.2.16. PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF CONNECTORS

- 1.2.17. METHOD FOR DISCONNECTING AND CONNECTING DEUTSCH CONNECTOR

- 1.2.18. METHOD FOR DISCONNECTING AND CONNECTING SLIDE LOCK TYPE CONNECTOR

- 1.2.19. METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PULL

- 1.2.20. METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PUSH

- 1.2.21. METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH HOUSING TO ROTATE

- 1.2.22. HOW TO READ ELECTRICAL WIRE CODE

- 1.2.23. EXPLANATION OF TERMS FOR MAINTENANCE STANDARD

- 1.2.24. STANDARD TIGHTENING TORQUE TABLE

- 1.2.25. CONVERSION TABLE

- 1.2.26. ABBREVIATION LIST

- 2. SPECIFICATIONS

- 2.1. CONTENTS

- 2.2. SPECIFICATIONS

- 2.2.1. SPECIFICATION DRAWING

- 2.2.2. SPECIFICATIONS

- 2.2.3. WEIGHT TABLE

- 2.2.4. FUEL, COOLANT, LUBRICANTS

- 3. STRUCTURE AND FUNCTION

- 3.1. CONTENTS

- 3.2. UREA SCR SYSTEM

- 3.2.1. LAYOUT DRAWING OF UREA SCR SYSTEM

- 3.2.2. UREA SCR SYSTEM DIAGRAM

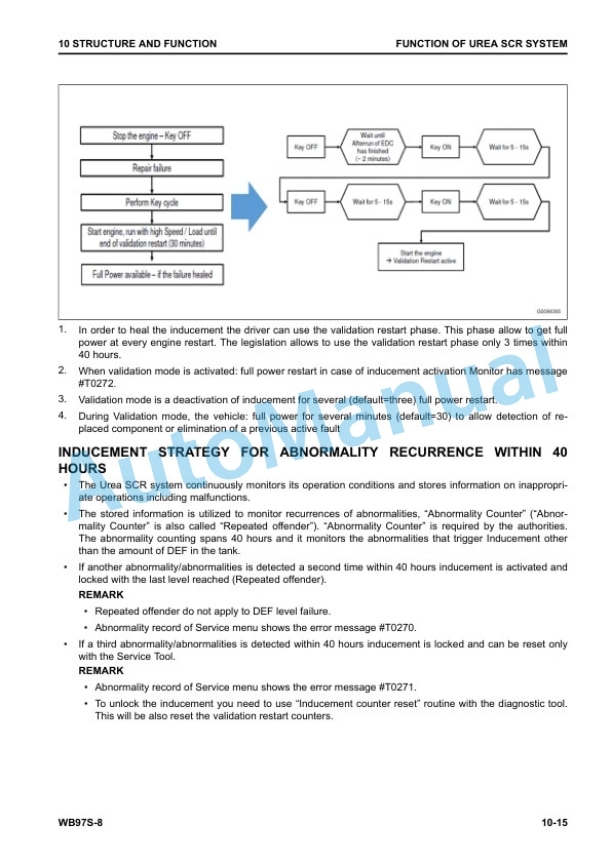

- 3.2.3. FUNCTION OF UREA SCR SYSTEM

- 3.2.4. COMPONENT PARTS OF UREA SCR SYSTEM

- 3.3. HYDRAULIC SYSTEM

- 3.3.1. LAYOUT DRAWING OF HYDRAULIC SYSTEM

- 3.3.2. CLSS

- 3.3.3. COMPONENT PARTS OF HYDRAULIC SYSTEM

- 3.4. POWER TRAIN SYSTEM

- 3.4.1. LAYOUT DRAWING OF POWER TRAIN SYSTEM

- 3.4.2. OPERATION OF POWER TRAIN SYSTEM

- 3.4.3. COMPONENT PARTS OF POWER TRAIN SYSTEM

- 3.4.4. OPERATION OF STEERING SYSTEM

- 3.5. WORK EQUIPMENT SYSTEM

- 3.5.1. LAYOUT DRAWING OF WORK EQUIPMENT SYSTEM

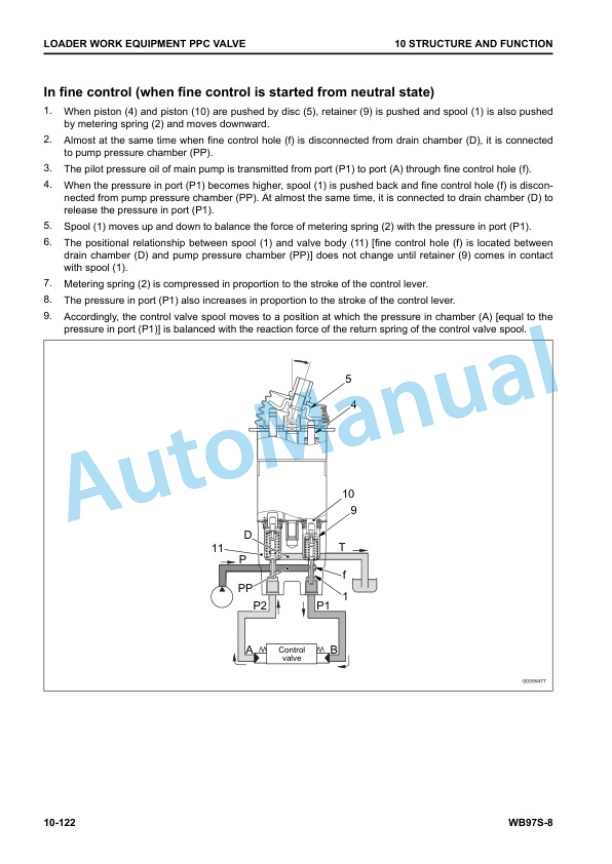

- 3.5.2. LOADER WORK EQUIPMENT PPC VALVE

- 3.5.3. BACKHOE PPC VALVE

- 3.5.4. OUTRIGGER PPC VALVE

- 3.5.5. STEERING UNIT

- 3.5.6. BRAKE PUMP

- 3.5.7. SOLENOID VALVES

- 3.5.8. PPC CIRCUIT ACCUMULATOR

- 3.5.9. SAFETY VALVES

- 3.6. WORK EQUIPMENT

- 3.6.1. STRUCTURE OF LOADER WORK EQUIPMENT

- 3.6.2. STRUCTURE OF BACKHOE WORK EQUIPMENT

- 3.6.3. FUNCTION OF WORK EQUIPMENT CLEARANCE ADJUSTMENT SHIM

- 4. STANDARD VALUE TABLE

- 4.1. CONTENTS

- 4.2. STANDARD VALUE TABLE FOR ENGINE

- 4.2.1. STANDARD VALUE TABLE FOR ENGINE WB97S8

- 4.3. STANDARD VALUE TABLE FOR MACHINE

- 4.3.1. STANDARD VALUE TABLE FOR MACHINE WB97S8

- 4.3.2. MACHINE POSTURE AND PROCEDURES TO MEASURE PERFORMANCE

- 5. TROUBLESHOOTING

- 5.1. CONTENTS

- 5.2. RELATED INFORMATION TO TROUBLESHOOT

- 5.2.1. PRECAUTIONS FOR TROUBLESHOOTING

- 5.2.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.2.3. GENERAL TROUBLESHOOTING POINTS

- 5.2.4. TROUBLESHOOTING POINTS FOR UREA SCR SYSTEM

- 5.2.5. CHECKS BEFORE TROUBLESHOOTING

- 5.2.6. INSPECTION PROCEDURE BEFORE TROUBLESHOOTING

- 5.2.7. TESTING IN ACCORDANCE WITH TESTING PROCEDURE

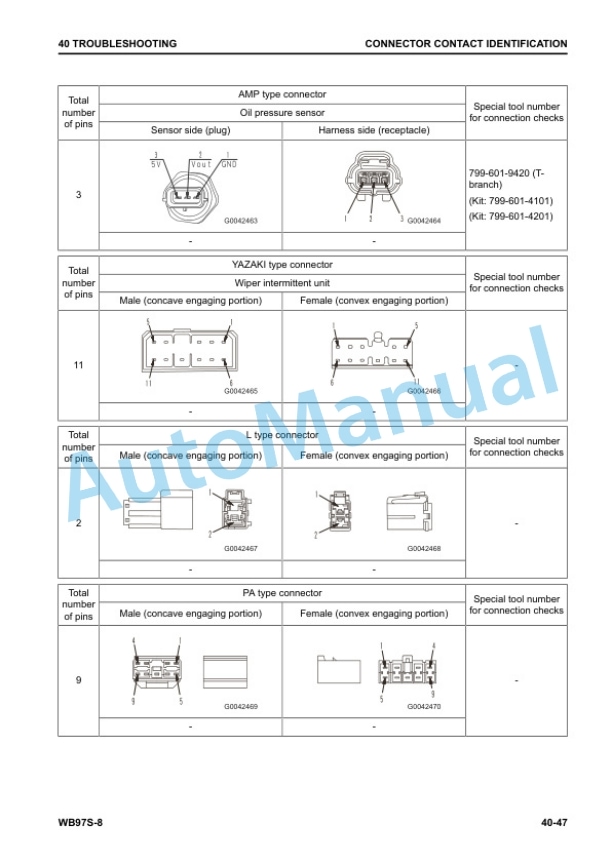

- 5.2.8. CONNECTOR CONTACT IDENTIFICATION

- 5.2.9. TBRANCH BOX AND TBRANCH ADAPTER TABLE

- 5.2.10. FUSE LOCATION TABLE

- 5.2.11. FAILURE CODE TABLE

- 5.3. TROUBLESHOOTING BY FAILURE CODE (DISPLAY OF CODE)

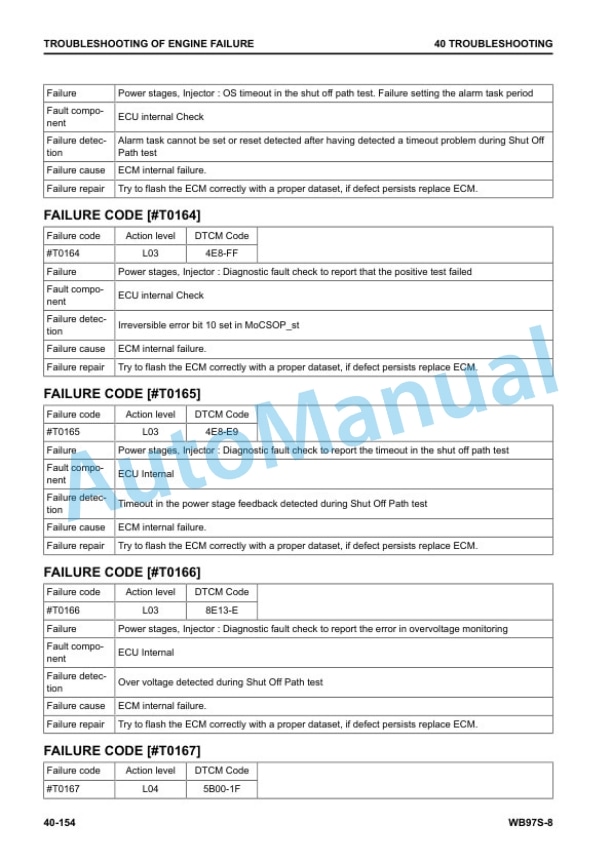

- 5.3.1. TROUBLESHOOTING OF ENGINE FAILURE

- 6. MAINTENANCE STANDARD

- 6.1. CONTENTS

- 6.2. ENGINE AND COOLING SYSTEM

- 6.2.1. MAINTENANCE STANDARD OF ENGINE MOUNT

- 6.2.2. MAINTENANCE STANDARD OF COOLING SYSTEM

- 6.3. POWER TRAIN

- 6.3.1. MAINTENANCE STANDARD OF TRANSMISSION

- 6.3.2. MAINTENANCE STANDARD OF FRONT AXLE

- 6.3.3. MAINTENANCE STANDARD OF REAR AXLE

- 6.4. HYDRAULIC SYSTEM

- 6.4.1. MAINTENANCE STANDARD OF MAIN PUMP

- 6.4.2. MAINTENANCE STANDARD OF CONTROL VALVE

- 6.5. WORK EQUIPMENT

- 6.5.1. MAINTENANCE STANDARD OF LOADER WORK EQUIPMENT PPC VALVE

- 6.5.2. MAINTENANCE STANDARD OF SWING BRACKET

- 6.5.3. MAINTENANCE STANDARD OF LOADER WORK EQUIPMENT

- 6.5.4. MAINTENANCE STANDARD OF BACKHOE WORK EQUIPMENT

- 6.5.5. MAINTENANCE STANDARD OF WORK EQUIPMENT CYLINDERS

- 7. CIRCUIT DIAGRAMS

- 7.1. CONTENTS

- 7.2. HOW TO READ THE CODES FOR ELECTRIC CABLE

- 7.3. HYDRAULIC CIRCUIT DIAGRAM

- 7.3.1. SYMBOLS USED IN HYDRAULIC CIRCUIT DIAGRAM

- 7.3.2. HYDRAULIC CIRCUIT DIAGRAM FOR WORK EQUIPMENT (1/2)

- 7.3.3. HYDRAULIC CIRCUIT DIAGRAM FOR WORK EQUIPMENT (2/2)

- 7.4. ELECTRICAL CIRCUIT DIAGRAM

- 7.4.1. SYMBOLS USED IN ELECTRIC CIRCUIT DIAGRAM

- 7.4.2. ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (1/12)

- 7.4.3. ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (2/12)

- 7.4.4. ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (3/12)

- 7.4.5. ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (4/12)

- 7.4.6. ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (5/12)

- 7.4.7. ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (6/12)

- 7.4.8. ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (7/12)

- 7.4.9. ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (8/12)

- 7.4.10. ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (9/12)

- 7.4.11. ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (10/12)

- 7.4.12. ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (11/12)

- 7.4.13. ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (12/12)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF