- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu Welding I Shop Manual SEBF14001

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBF14001

- Format: PDF

- Size: 26.2MB

- Number of Pages: 635

Category: Komatsu Shop Manual PDF

-

Model List:

- Welding I

- 1. WELDING I

- 1.1. CONTENTS

- 1.1.1. GENERAL INSTRUCTIONS

- 1.1.1.1. General description of welding techniques

- 1.1.1.2. Features of welding methods

- 1.1.1.3. Selecting welding methods

- 1.1.1.4. Preparation for welding

- 1.1.1.5. Welding techniques

- 1.1.1.6. Weld defects and countermeasures

- 1.1.1.7. How to distinguish materials and how to check welded areas

- 1.1.1.8. How to read welding symbols

- 1.1.1.9. How to handle gas (oxyacetylene) welders and cutters

- 1.1.1.10. Preventing accidents

- 1.1.1.11. Cost of welding consumables

- 1.1.1.12. Examples of troubles in welded structures and countermeasures

- 1.1.1.13. List of standards of welding rods by countries

- 1.1.1.14. List of standards of metal materials by countries

- 1.1.1.15. Melting temperatures of various base metals and alloys

- 1.1.1.16. Conversion table

- 1.1.1.17. Names of standards in various countries

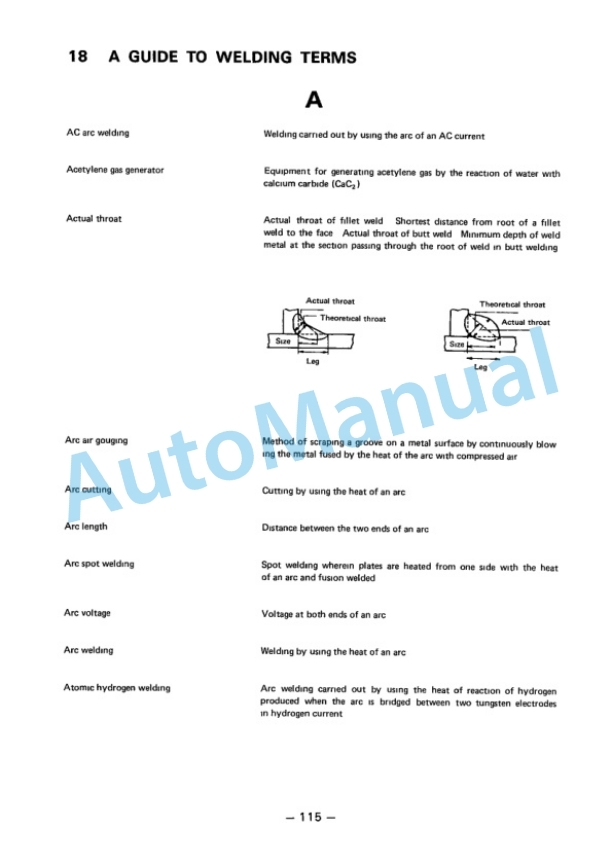

- 1.1.1.18. A guide to welding terms

- 1.1.2. BASIC WELDING

- 1.1.2.1. Items required for welding repairs

- 1.1.2.2. Procedure for checking for cracks

- 1.1.2.3. Preparation of edges by gouging

- 1.1.2.4. Welding procedure

- 1.1.2.5. Finishing procedure with a grinder

- 1.1.2.6. Peening procedure

- 1.1.2.7. Weldability of steel materials

- 1.1.2.8. Sections to be repaired by welding and selection of welding rods

- 1.1.2.9. List of major materials of bulldozers

- 1.1.2.10. Points for ensuring quality after welding

- 1.1.3. HARDFACING OF WEAR PARTS

- 1.1.3.1. Hard facing

- 1.1.3.2. Types of metal wear

- 1.1.3.3. Build up welding procedure

- 1.1.3.4. General precautions for build up welding

- 1.1.3.5. Examples of hard facing

- 1.1.4. REPAIR OF RADIATOR AND OIL COOLER

- 1.1.4.1. Procedure for repairing leakage of water from radiator core

- 1.1.4.2. Applicable range

- 1.1.4.3. Action to take when water starts leaking

- 1.1.4.4. Confirming location of water leakage

- 1.1.4.5. Factors causing water leakage

- 1.1.4.6. Removal

- 1.1.4.7. Disassembly

- 1.1.4.8. Repair tools and equipment

- 1.1.4.9. Repair procedure

- 1.1.4.10. Checking results

- 1.1.4.11. Assembly of core assembly

- 1.1.4.12. Pressurinzing check

- 1.1.4.13. Reassembly

- 1.1.5. REPAIR OF BULLDOZERS AND DOZER SHOVELS BY WELDING

- 1.1.5.1. MAIN FRAME(Example of D455A)

- 1.1.5.2. TRACK FRAME(Example of D455A)

- 1.1.5.3. BLADE

- 1.1.5.3.1. Type and uses of blades

- 1.1.5.3.2. Preventing wear of blades

- 1.1.5.3.3. Scheduled repair of blades

- 1.1.5.3.4. Repair and rebuilding of blades

- 1.1.5.4. BUCKET

- 1.1.5.4.1. Types and uses of buckets

- 1.1.5.4.2. Repair and rebuilding of buckets

- 1.1.5.4.3. Replacing a bucket edge

- 1.1.5.5. RIPPER ADAPTER SHANK

- 1.1.6. REPAIR OF DUMP TRUCKS BY WELDING

- 1.1.6.1. MAIN FRAME(Example of HD3202 and HD3252)

- 2. WELDING II

- 2.1. CONTENTS

- 2.1.1. SAFETY IN OPERATIONS

- 2.1.1.1. Safety in operations

- 2.1.2. WELDING EQUIPMENT AND BASIC WELDING TECHNICS

- 2.1.2.1. Purchassing priorities

- 2.1.2.2. Welding equipment groups

- 2.1.2.3. Arg air gouging

- 2.1.2.4. Vertical welding rod and uranami welding electrode

- 2.1.2.5. Comparison of CO2 semiautomatic welding and manual welding

- 2.1.2.6. Equipment part numbers

- 2.1.2.7. Gas cutting

- 2.1.2.8. Flat welding

- 2.1.2.9. Vertical welding

- 2.1.2.10. Procedure for checking for cracks

- 2.1.2.11. Welding procedure

- 2.1.2.12. Gas cutting work

- 2.1.2.13. CO2 gas shielded semiautomatic arc welding

- 2.1.2.14. Penetration welding

- 2.1.2.15. Finishing procedure with a grinder

- 2.1.3. WELDING DEFECTS

- 2.1.3.1. Defectives shape of bead

- 2.1.3.2. Lack of penetration

- 2.1.3.3. Welding blow through

- 2.1.3.4. Standard edge preparation

- 2.1.3.5. Strength of butt welding

- 2.1.3.6. Cracks

- 2.1.4. WELDING REPAIR

- 2.1.4.1. Basic flowchart for welding cracks

- 2.1.4.2. General precautions for welding repair work(summary)

- 2.1.4.3. Check points for welding repair

- 2.1.4.4. Selection of welding rods

- 2.1.4.5. Preheating,postheating

- 2.1.4.6. List of materials

- 2.1.4.7. Welding repair method for different structures

- 2.1.4.8. Reinforcement plate

- 2.1.4.9. Gouging

- 2.1.4.10. Method of inserting back plate in box frame

- 2.1.4.11. Results of bending fatigue test on box frame

- 2.1.4.12. Way of bending or setting reinforcement plate

- 2.1.4.13. Track welding

- 2.1.5. COLLECTION OF EXAMPLES

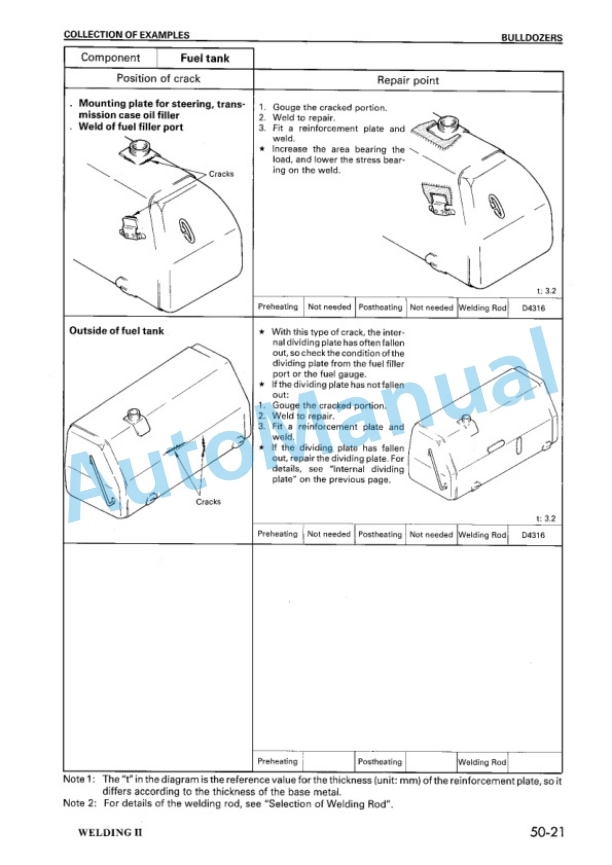

- 2.1.5.1. Bulldozers

- 2.1.5.2. Hydraulic excavators(Backhoe specification)

- 2.1.5.3. Hydraulic excavators(Loading shovel specification)

- 2.1.5.4. Dump trucks

- 2.1.5.5. Wheel loadors

- 2.1.5.6. Motor graders

- 2.1.5.7. Bulldozers

- 2.1.5.8. Hydraulic excavators(Loading shovel specification)

- 2.1.5.9. Dump trucks

- 2.1.5.10. Wheel loaders

- 2.1.5.11. Motor graders

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF