- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WF450-3, WF450T-3 Trash Compactor Shop Manual VEBM080100

$40.00

- Type Of Manual: Shop Manual

- Manual ID: VEBM080100

- Format: PDF

- Size: 20.5MB

- Number of Pages: 324

Category: Komatsu Shop Manual PDF

-

Model List:

- WF450-3 Trash Compactor

- WF450T-3 Trash Compactor

- 1. WF4503 / WF450T3

- 2. CONTENTS

- 3. SAFETY

- 3.1. Safety notice

- 3.1.1. Preparations for work

- 3.1.2. Precautions during work

- 3.2. Foreword

- 3.3. How to read the shop manual

- 3.3.1. Volumes

- 3.3.2. Distribution and updating

- 3.3.3. Filing method

- 3.3.4. Symbols

- 3.4. Hoisting instructions

- 4. STRUCTURE AND FUNCTION

- 4.1. Power train

- 4.2. Transmission

- 4.3. Transmission solenoid valve

- 4.4. Axle

- 4.4.1. Front axle

- 4.4.2. Rear axle

- 4.5. Differential

- 4.5.1. Front differential

- 4.5.2. Rear differential

- 4.6. Final drive

- 4.7. Axle mount, center hinge pin

- 4.8. Steering piping

- 4.9. Brake piping

- 4.10. Brake

- 4.11. Parking brake

- 4.12. Hydraulic component layout

- 4.13. Work equipment lever linkage

- 4.13.1. Operation of PPC valve at neutral

- 4.13.2. Function of PPC valve

- 4.14. Cutoff valve

- 4.14.1. WF4503

- 4.14.2. Operation of cutoff valve

- 4.15. Main control valve

- 4.15.1. WF450T3

- 4.15.2. WF4503

- 4.15.3. Main relief valve

- 4.15.4. Safety valve (with suction)

- 4.15.4.1. Operation

- 4.15.5. Suction valve

- 4.15.6. Float selector valve and unload valve

- 4.15.6.1. WF4503

- 4.15.7. Operation WF450T3

- 4.15.8. Operation WF4503

- 4.16. Bucket positioner and boom kickout

- 4.16.1. WF4503

- 4.16.1.1. Operation of proximity switch

- 4.16.1.2. Operation of proximity switch

- 4.17. Air conditioner

- 4.17.1. Air conditioner piping

- 4.18. Machine monitor system

- 4.19. Main monitor

- 4.19.1. Main monitor display function

- 4.19.2. Main monitor switch function

- 4.19.3. Preheating output function

- 4.19.4. Trouble data display mode (When optional controller are installed)

- 4.20. Maintenance monitor

- 4.20.1. Maintenance monitor display function

- 4.21. Engine starting circuit

- 4.22. Engine stop circuit

- 4.23. Preheating circuit

- 4.23.1. (Automatic preheating system)

- 4.24. Electric transmission control

- 4.24.1. WF450T3

- 4.24.2. WF4503

- 4.24.3. Combination switch

- 4.25. Kickdown switch

- 4.25.1. WF4503

- 4.25.1.1. Kickdown switch

- 4.26. Kickdown electric circuit diagram

- 4.26.1. WF4503

- 4.26.1.1. Normal operation

- 4.26.1.2. Kickdown switch operated (case I)

- 4.26.1.3. Canceling actuation of kickdown switch (Case I)

- 4.26.1.4. Canceling actuation of kickdown switch (Case II)

- 4.26.1.5. Canceling actuation of kickdown switch (Case III)

- 4.27. Standard value table for engine

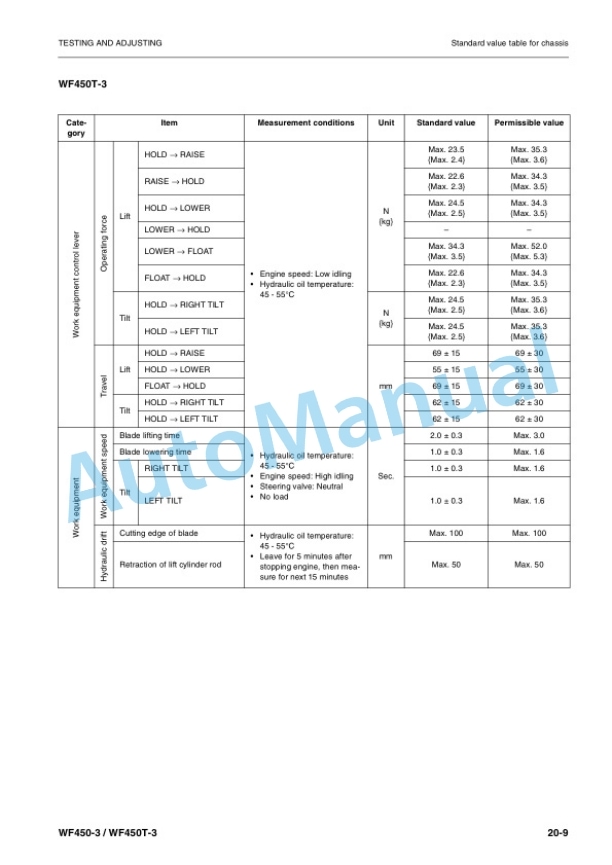

- 4.28. Standard value table for chassis

- 4.29. Standard value table for electrical parts

- 5. TESTING AND ADJUSTING

- 5.1. Tools for testing, adjusting, and troubleshooting

- 5.2. Testing steering wheel

- 5.2.1. Measuring play of steering wheel

- 5.2.2. Measuring operating force of steering wheel

- 5.2.3. Measuring operating time for steering wheel

- 5.3. Testing and adjusting steering control

- 5.4. Measuring steering oil pressure

- 5.5. Testing and adjusting accumulator charge pressure

- 5.6. Testing drop in wheel brake oil pressure

- 5.7. Measuring brake disc wear

- 5.8. Bleeding air from brake system

- 5.9. Measuring parking brake performance

- 5.10. Testing and adjusting work equipment hydraulic pressure

- 5.10.1. WF450T3

- 5.11. Measuring PPC hydraulic pressure

- 5.11.1. WF450T3

- 5.12. Measuring work equipment

- 5.12.1. WF450T3

- 5.13. Measuring hydraulic drift of work equipment

- 5.13.1. WF450T3

- 5.14. Adjusting main monitor (speedometer module)

- 6. TROUBLESHOOTING

- 6.1. Outline

- 7. TROUBLESHOOTING OF HYDRAULICAL AND MECHANICAL SYSTEM (H MODE)

- 7.1. Work Equipment WF450T3

- 7.1.1. H1 Blade does not rise

- 7.1.2. H2 Blade movement is slow or blade lacks lifting power

- 7.1.3. H3 When blade is raised, it moves slowly at a certain height

- 7.1.4. H4 Blade cannot be pushed with lift cylinder (blade floats)

- 7.1.5. H5 Excessive hydraulic drift of blade

- 7.1.6. H6 Blade and straight frame shake during operation

- 7.1.7. H7 Blade drops momentarily when control lever is operated from HOLD to RAISE

- 7.1.8. H8 Blade does not tilt

- 7.1.9. H9 Blade movement is slow or tilt lacks power

- 7.1.10. H10 Blade movement becomes slow during tilt operation

- 7.1.11. H11 Blade cannot be pushed with tilt cylinder

- 7.1.12. H12 Excessive hydraulic drift of blade

- 7.1.13. H13 Blade shakes during loading operation (main control valve at HOLD)

- 7.1.14. H14 Blade tilts momentarily to left when control lever is operated from HOLD to RIGHT TILT

- 7.1.15. H15 Blade control lever is heavy or does not move smoothly

- 7.2. Steering system

- 7.2.1. H16 Steering does not turn

- 7.2.2. H17 Steering wheel is heavy

- 7.2.3. H18 Steering wheel wobbles or there is excessive shock

- 7.2.4. H19 Machine steers to one side when traveling

- 7.2.5. H20 Turning radius to left and right is different

- 8. DISASSEMBLY AND ASSEMBLY

- 8.1. Special tool list

- 8.2. Removal and installation of rear axle assembly

- 8.3. Removal and installation of hydraulic pump, PPC pump assembly

- 8.3.1. WF4503

- 8.3.2. WF450T3

- 8.4. Disassembly and assembly of hydraulic cylinder assembly

- 8.4.1. WF4503

- 8.4.2. WF450T3

- 8.5. Main control valve assembly

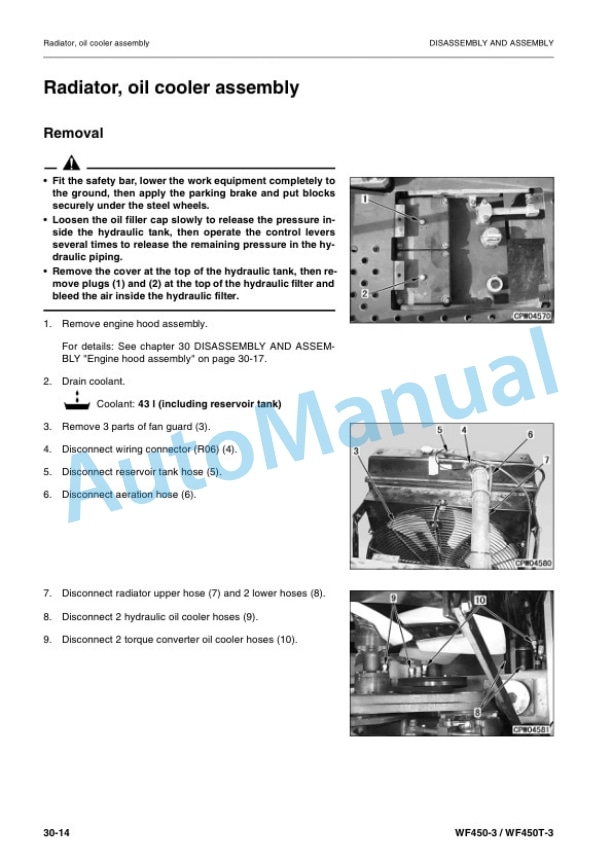

- 8.6. Radiator, oil cooler assembly

- 8.6.1. Removal

- 8.6.2. Installation

- 8.7. Engine hood assembly

- 8.7.1. Removal

- 8.7.2. Installation

- 8.8. Lift cylinder assembly

- 8.8.1. Removal

- 8.8.2. Installation

- 8.9. Tilt cylinder assembly

- 8.9.1. Removal

- 8.9.2. Installation

- 8.10. Work equipment assembly

- 8.10.1. Removal

- 8.10.2. Installation

- 8.10.3. Assembly

- 8.11. Front axle assembly

- 8.11.1. Removal (WF4503)

- 8.11.2. Installation (WF4503)

- 8.11.3. Removal (WF450T3)

- 8.11.4. Installation (WF450T3)

- 8.12. Removal and installation of rear axle assembly

- 8.13. Front differential assembly

- 8.13.1. Removal

- 8.13.2. Installation

- 8.14. Differential Assembly

- 8.14.1. Disassembly

- 8.14.2. Assembly

- 9. MAINTENANCE STANDARD

- 9.1. Engine mount, transmission mount

- 9.2. Torque converter

- 9.3. Transmission

- 9.3.1. (1/2)

- 9.3.2. (2/2)

- 9.3.3. Forward, 1st clutch

- 9.3.4. d, reverse clutch

- 9.3.5. d, 4th clutch

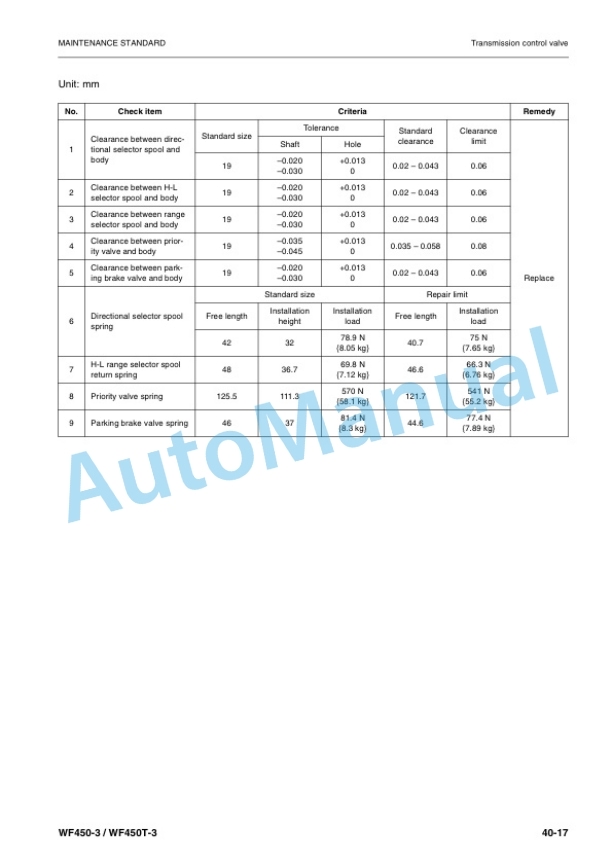

- 9.4. Transmission control valve

- 9.4.1. Modulation valve assembly

- 9.4.2. Upper valve assembly

- 9.4.3. Lower valve assembly

- 9.4.4. Flow valve

- 9.4.5. Accumulator valve

- 9.5. Drive shaft

- 9.6. Differential

- 9.7. Limited slip differential

- 9.8. Final drive

- 9.9. Axle mount

- 9.10. Center hinge pin

- 9.11. Steering column

- 9.12. Steering valve

- 9.13. Steering cylinder mount

- 9.14. Torque converter, transmission pump

- 9.14.1. SAR(3) 100

- 9.15. Steering, switch pump

- 9.15.1. SAR(3)71 50

- 9.16. Hydraulic, PPC pump

- 9.16.1. WF450T3 SAR(3)80 (1) 28

- 9.16.2. WF4503 SAR(4)140 (1) 28

- 9.17. Main control valve

- 9.18. Bucket cylinder

- 9.18.1. WF4503

- 9.19. Work equipment linkage

- 9.19.1. WF450T3

- 9.19.2. WF4503

- 9.20. Bucket positioner and boom kickout

- 9.20.1. WF4503

- 10. OTHERS

- 10.1. Transmission hydraulic circuit diagram

- 10.2. Brake hydraulic circuit diagram

- 10.3. Work equipment hydraulic circuit diagram (WF450T3)

- 10.4. Work equipment hydraulic circuit diagram (WF4503)

- 10.5. Electric circuit diagram 1/4) (WF450T3)

- 10.6. Electric circuit diagram 2/4) (WF450T3)

- 10.7. Electric circuit diagram 3/4) (WF450T3)

- 10.8. Electric circuit diagram 4/4) (WF450T3)

- 10.9. Electric circuit diagram 1/4) (WF4503)

- 10.10. Electric circuit diagram 2/4) (WF4503)

- 10.11. Electric circuit diagram 3/4) (WF4503)

- 10.12. Electric circuit diagram 4/4) (WF4503)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF