Komatsu WP142-5 Backhoe Loader Shop Manual CEBM018903

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM018903

- Format: PDF

- Size: 71.0MB

- Number of Pages: 506

Category: Komatsu Shop Manual PDF

-

Model List:

- WP142-5 Backhoe Loader

- 0.1. GENERAL

- 0.2. HOW TO READ THE SHOP MANUAL

- 0.2.1. VOLUMES

- 0.2.2. DISTRIBUTION AND UPDATING

- 0.2.3. FILING METHOD

- 0.2.4. REVISED EDITION MARK

- 0.2.5. REVISIONS

- 0.2.6. SYMBOLS

- 0.3. HOISTING INSTRUCTIONS

- 0.3.1. HOISTING

- 0.3.2. WIRE ROPES

- 0.4. EXPLANATION OF TERMS FOR MAINTENANCE STANDARD

- 0.5. COATING MATERIALS

- 0.6. STANDARD TIGHTENING TORQUE

- 0.6.1. STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS

- 0.6.2. TIGHTENING TORQUE OF HOSE NUTS

- 0.6.3. TIGHTENING TORQUE OF SPLIT FLANGE BOLTS

- 0.6.4. TIGHTENING TORQUE FOR FLARED NUTS

- 0.7. CONNECTING PUSHPULL TYPE COUPLER.

- 0.8. CONVERSION TABLES

- 0.8.1. METHOD OF USING THE CONVERSION TABLE

- 1. GENERAL

- 1.1. SPECIFICATION DRAWING

- 1.1.1. SPECIFICATIONS

- 1.1.2. BACKHOE ARM

- 1.2. MACHINE SYSTEMS SPECIFICATIONS

- 1.2.1. BACKHOE ARM

- 1.2.2. ENGINE

- 1.2.3. ELECTRICAL SYSTEM

- 1.2.4. SERVICE REFILL CAPACITIES

- 1.2.5. TRANSMISSION

- 1.2.6. TOTAL MASS

- 1.2.7. STANDARD BUCKET CAPACITY

- 1.2.8. LOADER

- 1.2.9. TIRE PRESSURE

- 1.3. WEIGHT TABLE

- 1.4. FUEL, COOLANT, AND LUBRICANTS

- 1.4.1. PROPER SELECTION ACCORDING TO THE AMBIENT TEMPERATURE

- 1.4.2. GREASE

- 1.4.3. FUEL AND ENGINE OIL REMARKS

- 1.5. HOMOLOGATED (HEES) SYNTHETIC LUBRICANTS

- 1.6. LUBRICATION DIAGRAMS

- 1.6.1. GENERAL VIEW

- 2. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 2.1. POWER TRAIN

- 2.1.1. SYSTEM OVERVIEW

- 2.1.2. WHEEL DRIVE SYSTEM

- 2.1.3. TRANSMISSION COMPONENTS

- 2.1.4. CONVERTER AND TRANSMISSION CIRCUIT DIAGRAM

- 2.2. TRANSMISSION

- 2.2.1. CASE

- 2.2.2. TRANSMISSION INTERNAL VIEW

- 2.2.3. GEAR SHIFTER AND FILTERING SYSTEM

- 2.2.4. CLUTCH PACKS AND DRIVEN GEAR SET

- 2.2.5. WHEEL DRIVE SHAFT

- 2.2.6. CONTROL VALVE BLOCK

- 2.2.7. TRANSMISSION CASE SPECIFICATIONS

- 2.2.8. INTERNAL SPECIFICATIONS

- 2.2.9. GEAR SHIFTER AND COMPONENTS SPECIFICATIONS

- 2.3. FRONT AXLE ASSEMBLY

- 2.3.1. DIFFERENTIAL

- 2.3.2. FINAL DRIVE END

- 2.3.3. STEERING CYLINDER

- 2.3.4. AXLE CARRIER SPECIFICATIONS

- 2.3.5. AXLE END SPECIFICATIONS

- 2.3.6. STEERING UNIT CYLINDER SPECIFICATIONS

- 2.4. REAR AXLE ASSEMBLY

- 2.4.1. DIFFERENTIAL

- 2.4.2. AXLE END

- 2.4.3. AXLE CARRIER SPECIFICATIONS

- 2.4.4. AXLE END SPECIFICATIONS

- 2.5. REAR BRAKES

- 2.5.1. BRAKE SPECIFICATIONS

- 2.6. DIFFERENTIAL LOCK

- 2.6.1. LOCK SPECIFICATIONS

- 2.7. HYDRAULIC SYSTEM

- 2.7.1. HYDRAULIC CIRCUIT DIAGRAM

- 2.7.2. HYDRAULIC PUMP

- 2.7.3. LOADER 3 SPOOL VALVE

- 2.7.4. LOADER SPOOL VIEW

- 2.7.5. BACKHOE CONTROL VALVE

- 2.7.6. BACKHOE SPOOL VIEW

- 2.8. SOLENOID VALVE

- 2.8.1. (ST1 VALVE LOCK DIFFERENTIAL LOCK BACKHOE BOOM LOCK)

- 2.9. MASTER CYLINDER (BRAKES)

- 2.9.1. SPECIFICATIONS

- 2.10. LOADER CYLINDERS

- 2.10.1. ARM CYLINDERS

- 2.10.2. BUCKET CYLINDER

- 2.10.3. ARM CYLINDER TOLERANCE

- 2.10.4. BUCKET CYLINDER TOLERANCE

- 2.11. BACKHOE CYLINDERS

- 2.11.1. BOOM cylinder

- 2.11.2. ARM cylinder

- 2.11.3. BUCKET SPECIFICATIONS

- 2.11.4. OUTRIGGER SPECIFICATIONS

- 2.11.5. BOOM SWING SPECIFICATIONS

- 2.11.6. BOOM CYLINDER TOLERANCE

- 2.11.7. ARM CYLINDER TOLERANCE

- 2.11.8. BUCKET CYLINDER TOLERANCE

- 2.11.9. BOOM SWING CYLINDER TOLERANCE

- 2.11.10. OUTRIGGERS TOLERANCE

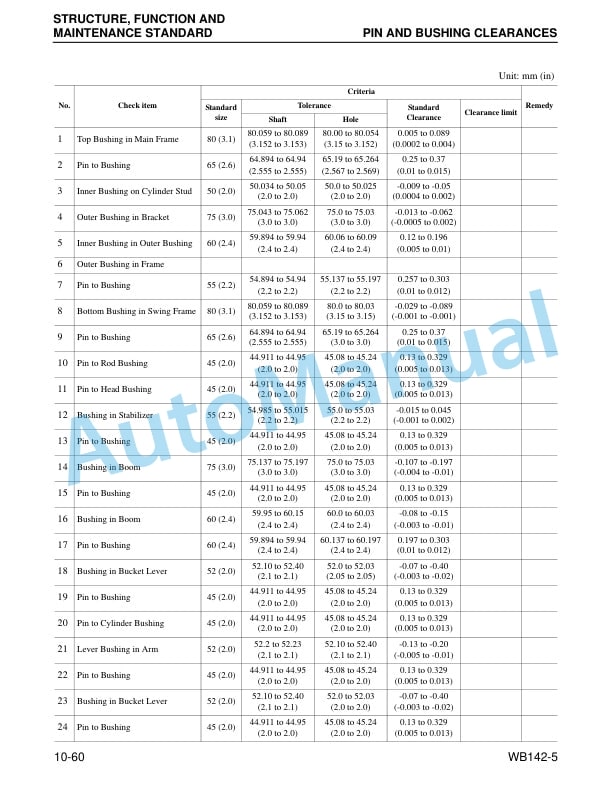

- 2.12. PIN AND BUSHING CLEARANCES

- 2.12.1. LOADER WORK EQUIPMENT

- 2.12.2. BACKHOE WORK EQUIPMENT

- 3. STANDARD VALUE TABLES

- 3.1. STANDARD VALUE TABLE FOR ENGINE

- 3.2. STANDARD VALUE TABLE FOR CHASSIS

- 4. TESTING AND ADJUSTING

- 4.1. BLEED AIR FROM CIRCUITS

- 4.1.1. BLEED AIR FROM BRAKING CIRCUIT

- 4.1.2. RELEASING RESIDUAL PRESSURE

- 4.2. ACCELERATOR PEDAL AND THROTTLE LEVER

- 4.2.1. ACCELERATOR PEDAL TRAVEL

- 4.2.2. THROTTLE LEVER TRAVEL

- 4.3. PARKING BRAKE ADJUSTMENT

- 4.4. HYDRAULIC CIRCUIT

- 4.4.1. INTRODUCTION

- 4.4.2. MAIN RELIEF VALVE

- 4.4.3. CHECKING LOAD SENSING SIGNAL (LS VALVE)

- 4.4.4. CHECKING COMPENSATED FLOW VALVE

- 4.4.5. OPERATION OF THE PRIORITY VALVE

- 4.4.6. TESTING AND SETTING STEERING SYSTEM PRESSURE

- 4.4.7. CHECKING FOR LEAKS IN THE STEERING CYLINDERS

- 4.5. POWER TRAIN

- 4.5.1. CONVERTER OIL PRESSURE

- 4.5.2. CLUTCH ENGAGEMENT PRESSURE

- 4.5.3. CLUTCH FUNCTION

- 4.6. HYDRAULIC DRIFT

- 5. TROUBLESHOOTING

- 5.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 5.3.1. PRECAUTIONS WHEN HANDLING ELECTRICAL EQUIPMENT

- 5.3.2. HANDLING ELECTRONIC CONTROL UNIT

- 5.3.3. POINTS TO REMEMBER WHEN TROUBLESHOOTING ELECTRICAL CIRCUITS

- 5.3.4. HOW TO READ ELECTRIC WIRE CODE

- 5.3.5. CLASSIFICATION BY COLOR AND CODE

- 5.3.6. POINTS TO REMEMBER WHEN LHANDLING HUYDRAULIC EQUIPMENT

- 5.4. CHECKS BEFORE TROUBLESHOOTING

- 5.5. TROUBLESHOOTING GUIDE

- 5.5.1. FRONT AXLE

- 5.5.2. REAR AXLE

- 5.5.3. TRANSMISSION

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. HOW TO USE THIS MANUAL

- 6.1.1. REMOVAL AND INSTALLATION OF COMPONENTS

- 6.1.2. OVERHAUL OF COMPONENTS

- 6.2. PRECAUTIONS WHEN CARRYING OUT AN OPERATION

- 6.3. SPECIAL TOOL LIST.

- 6.4. CONNECTOR REPAIR PROCEDURES

- 6.4.1. CONTACT TERMINAL REMOVAL (HD30 TYPE)

- 6.4.2. CRIMPING CONTACT TERMINAL (HD30 TYPE)

- 6.4.3. INSERTION OF CONTACT TERMINAL (HD30 TYPE)

- 6.4.4. CONTACT TERMINAL REMOVAL (DT TYPE)

- 6.4.5. CRIMPING CONTACT TERMINAL (DT TYPE)

- 6.4.6. INSERTION OF CONTACT TERMINAL (DT TYPE)

- 6.4.7. STRIPPING INSULATION

- 6.5. SIDE PANEL AND INSTRUMENT GROUP

- 6.5.1. LOWER ELECTRICAL GROUP

- 6.5.2. DASH BEZEL AND COVER

- 6.6. STEERING AND FRONT DASH ASSEMBLY

- 6.6.1. STEERING WHEEL

- 6.6.2. FRONT DASH ASSEMBLY

- 6.6.3. BLEED AIR FROM BRAKING CIRCUIT

- 6.7. HYDRAULIC OIL TANK

- 6.8. TRANSMISSION OVERHAUL PROCEDURES

- 6.8.1. TORQUE CONVERTER

- 6.8.2. PLUGS AND FILTERS

- 6.8.3. WHEEL DRIVE SOLENOID VALVE

- 6.8.4. TRANSMISSION HOUSING

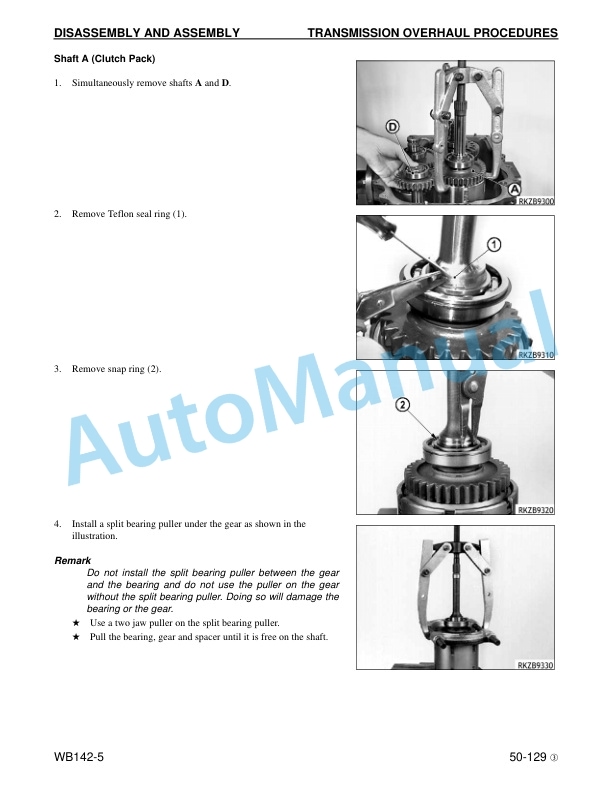

- 6.8.5. CLUTCH PACK (A) AND GEAR SHAFT (D)

- 6.8.6. GEAR SHAFTS (B) AND (C)

- 6.8.7. GEAR SHAFT (E)

- 6.8.8. SHIFTER TOWER AND FORKS

- 6.9. BACKHOE CONTROL VALVE

- 6.9.1. REMOVAL

- 6.9.2. INSTALLATION

- 6.10. FRONT AXLE ASSEMBLY

- 6.10.1. REMOVAL

- 6.10.2. INSTALLATION

- 6.11. FRONT AXLE OVERHAUL PROCEDURES

- 6.11.1. STEERING CYLINDER ASSEMBLY

- 6.11.2. FRONT AXLE END PLANETARY ASSEMBLY

- 6.11.3. AXLE END HUB ASSEMBLY

- 6.12. REAR AXLE ASSEMBLY

- 6.12.1. REMOVAL

- 6.12.2. INSTALLATION

- 6.13. REAR AXLE OVERHAUL PROCEDURES

- 6.13.1. PARKING BRAKE ASSEMBLY

- 6.13.2. SERVICE BRAKE ASSEMBLY

- 6.13.3. REAR AXLE END PLANETARY ASSEMBLY

- 6.13.4. DIFFERENTIAL

- 6.13.5. DIFFERENTIAL LOCK

- 6.14. FRONT LOADER CONTROL VALVE ASSEMBLY

- 6.14.1. REMOVAL

- 6.14.2. INSTALLATION

- 6.15. SOLENOID VALVE ASSEMBLY

- 6.15.1. REMOVAL

- 6.15.2. INSTALLATION

- 6.16. FRONTEND LOADER ASSEMBLY

- 6.16.1. LOADER BOOM CYLINDERS

- 6.16.2. BUCKET CYLINDER AND MONOLINK

- 6.16.3. LOADER BUCKET

- 6.16.4. LOADER BOOM ASSEMBLY

- 6.17. BACKHOE ASSEMBLY

- 6.17.1. BUCKET CYLINDER

- 6.17.2. SWING CYLINDERS

- 6.17.3. BOOM LOCK CYLINDER

- 6.17.4. BACKHOE SWING FRAME

- 6.17.5. OUTRIGGER CYLINDERS

- 6.17.6. OUTRIGGER ARMS

- 6.18. WORK EQUIPMENT CYLINDER OVERHAUL PROCEDURES

- 6.18.1. LOADER AND BACKHOE CYLINDERS

- 6.18.2. SWING CYLINDERS

- 7. OTHERS

- 7.1. ELECTRICAL SCHEMATIC

- 7.1.1. CONNECTOR DESCRIPTION

- 7.1.2. SIDE INSTRUMENT PANEL

- 7.1.3. FRONT INSTRUMENT PANEL

- 7.1.4. FUSES, SWITCHES AND RELAYS

- 7.1.5. WIRE HARNESS

- 7.1.6. SWITCHES (1)

- 7.1.7. SWITCHES (2)

- 7.1.8. TRANSMISSION HARNESS

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00