Bomag BF 300 C Road Finisher Service Training 00892207

$30.00

- Type Of Manual: Service Training

- Manual ID: 00892207

- Format: PDF

- Size: 35.3MB

- Number of Pages: 1050

- Serial Number:

821837571001, 821837691001, 821837821001, 821891031001, 821891041001

Category: Bomag Service Manual PDF

-

Model List:

- BF 300 C Road Finisher

- 1. BF 300_C

- 1.1. BF 300_C

- 2.

- 2.1.

- 3. General

- 3.1. General

- 3.2. Introduction

- 3.3. General

- 3.4. General

- 3.5. Transport work with cranes and lifting tackle

- 3.6. Precautions and codes of conduct for welding work

- 3.7. Operation of highvoltage systems

- 3.8. Old oils

- 3.9. Hydraulics

- 3.10. Hot fuels

- 3.11. Synthetic rubber

- 3.12. Poisonous substances

- 3.13. Battery

- 3.14. Special safety regulations

- 3.15. The values specified in the table apply for screws

- 3.16. The values specified in the table apply for screws

- 3.17. The values specified in the table apply for screws

- 3.18. The values specified in the table apply for screws

- 3.19. The values specified in the table apply for screws

- 3.20. The values specified in the table apply for screws

- 3.21. The values specified in the table apply for screws

- 3.22. The values specified in the table apply for screws

- 3.23. The values specified in the table apply for screws

- 3.24. The values specified in the table apply for screws

- 3.25. The values specified in the table apply for screws

- 3.26. The values specified in the table apply for screws

- 3.27. The values specified in the table apply for screws

- 4. Technical data

- 4.1. Technical data

- 4.2.

- 4.3.

- 5. Maintenance

- 5.1. Maintenance

- 5.2. General notes on maintenance

- 5.3. Fuels and lubricants

- 5.4. Coolant

- 5.5. Mineral oil based hydraulic oil

- 5.6. Gear oil

- 5.7. Lubrication grease

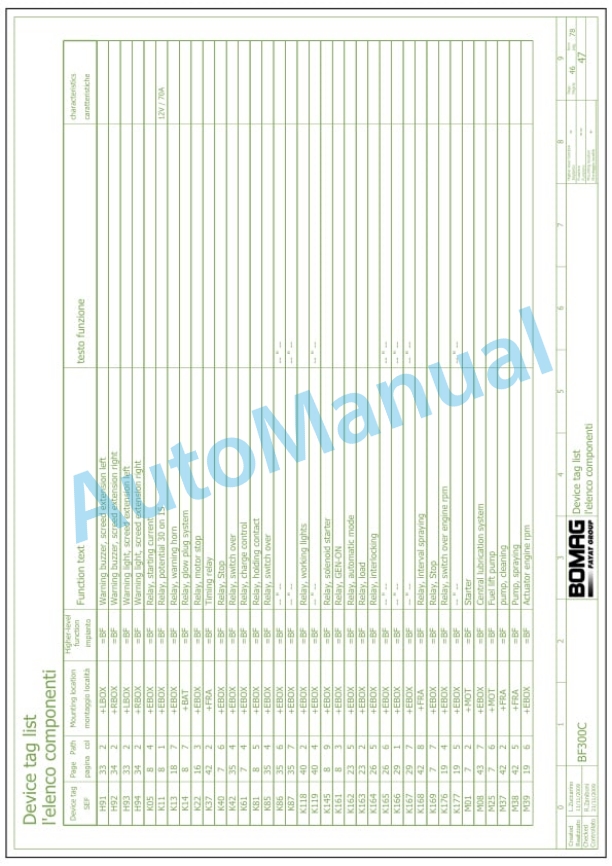

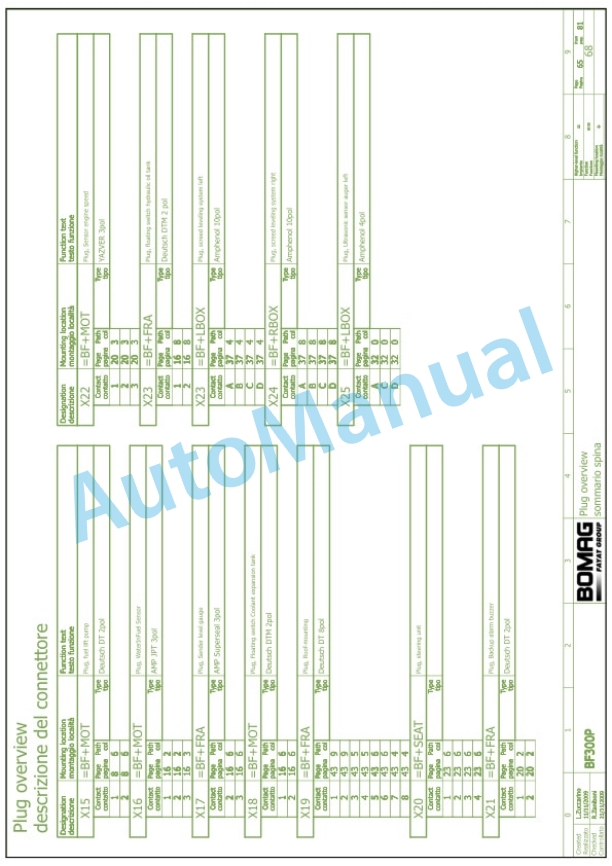

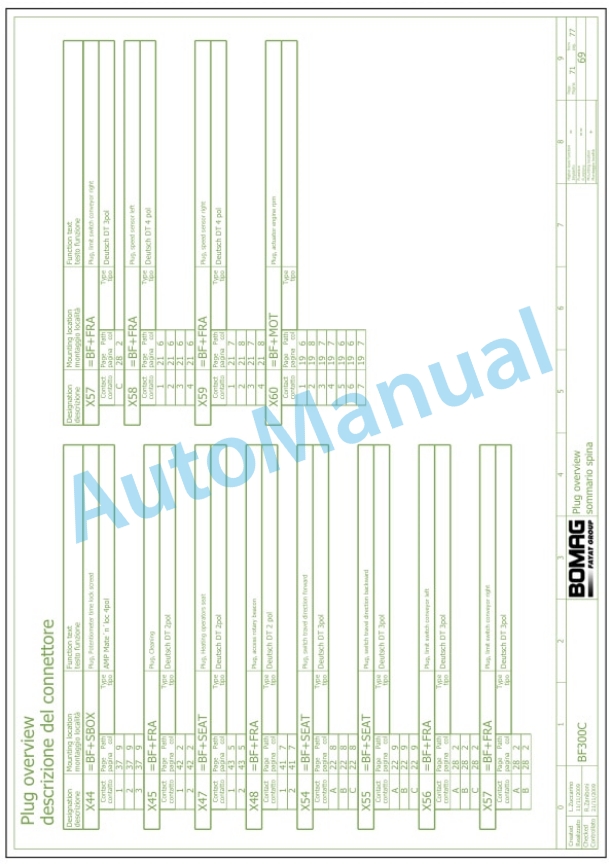

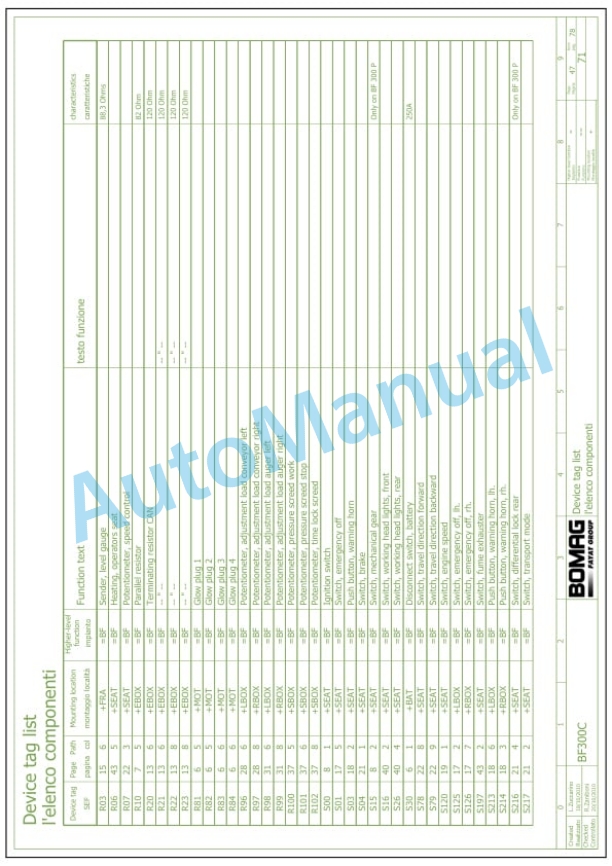

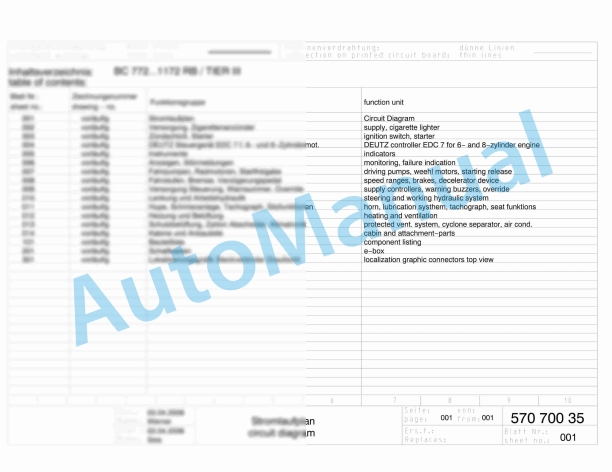

- 6. EPlan wiring diagrams

- 6.1. EPlan wiring diagrams

- 7. Electrics

- 7.1. Electrics

- 7.2.

- 7.3.

- 7.4.

- 7.5.

- 7.6.

- 7.7.

- 7.8.

- 7.9.

- 7.10.

- 7.11.

- 7.12.

- 7.13.

- 7.14. Component overview

- 7.15. View of operators stand

- 7.16. View of operators stand

- 7.17. View of operators stand

- 7.18.

- 7.19. Pressure gauge for relief pressure

- 7.20. Pressure gauge for relief pressure

- 7.21. Pressure gauge for relief pressure

- 7.22. Pressure gauge for relief pressure

- 8. Input codes

- 8.1. Input codes

- 9. Replacement of components

- 9.1. Replacement of components

- 10. Engine

- 10.1. Engine

- 10.2. Check the coolant level

- 10.3. Check the coolant level

- 10.4. Check the coolant level

- 10.5. Check the coolant level

- 10.6. Check the coolant level

- 10.7. Check the antifreeze concentration and the condition of the coolant

- 10.8. Change the coolant

- 10.9. Checking radiator hoses and hose clamps

- 10.10. Clean the cooling fins on engine and hydraulic oil cooler

- 10.11. Checking the engine oil level

- 10.12. Changing engine oil and oil filter cartridge

- 10.13. Replace the fuel filter

- 10.14. Replace the fuel filter

- 10.15. Checking, cleaning the water separator

- 10.16. Changing the fuel filter, bleeding the fuel system

- 10.17. Check fuel lines and clamps

- 10.18. Check the fuel injection nozzles

- 10.19. Check the fuel injection timing

- 10.20. Check the fuel injection pump

- 10.21. Servicing the generator Vbelt

- 10.22. Air filter maintenance

- 10.23. Check the engine mounts

- 10.24. Engine conservation

- 10.25. Check, adjust the valve clearance

- 11. Material hopper, description

- 11.1. Material hopper, description

- 12. Vibrating screed, description

- 12.1. Vibrating screed, description

- 13. Travel drive, description

- 13.1. Travel drive, description

- 14. Cleaning kit, description

- 14.1. Cleaning kit, description

- 15. Hydraulics

- 15.1. Hydraulics

- 15.2. Variable displacement pumps, A10VG28/45/56 EP

- 15.3. Variable displacement pumps, A10VG28/45/56 EP

- 15.4. Variable displacement pumps, A10VG28/45/56 EP

- 15.5. Swash plate principle, pump

- 15.6. Component overview hydraulics

- 15.7. Check the hydraulic oil level

- 15.8. Check the hydraulic oil level

- 15.9. Check the hydraulic oil level

- 15.10. Check the hydraulic oil level

- 15.11. Check the hydraulic oil level

- 15.12. Check the hydraulic oil level

- 15.13. Changing hydraulic oil and filter

- 16. Tests and adjustments

- 16.1. Tests and adjustments

- 16.2. Checking and adjusting the vibration

- 16.3. Checking and adjusting the vibration

- 16.4. Checking/adjusting tamping

- 16.5. Checking/adjusting the scraper belts

- 16.6. Checking/adjusting the augers

- 16.7. Checking/adjusting the main screed

- 16.8. Checking/adjusting the screed levelling

- 16.9. Checking/adjusting the hopper wings

- 16.10. Checking/adjusting the mobile screed

- 17. Central lubrication system

- 17.1. Central lubrication system

- 18. Circuit diagrams

- 18.1. Circuit diagrams

- 18.2.

- 18.3.

- 19.

- 19.1.

Rate this product

You may also like

Bomag Service Manual PDF

Bomag BC 462 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930071001 – 101930071002

$30.00

Bomag Service Manual PDF

Bomag BC 463 RB-3 Refuse Compactor Electric Schematics Diagram 101930121001 – 101930129999

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930011002 – 101930011011

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930001002 – 101930001058

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00