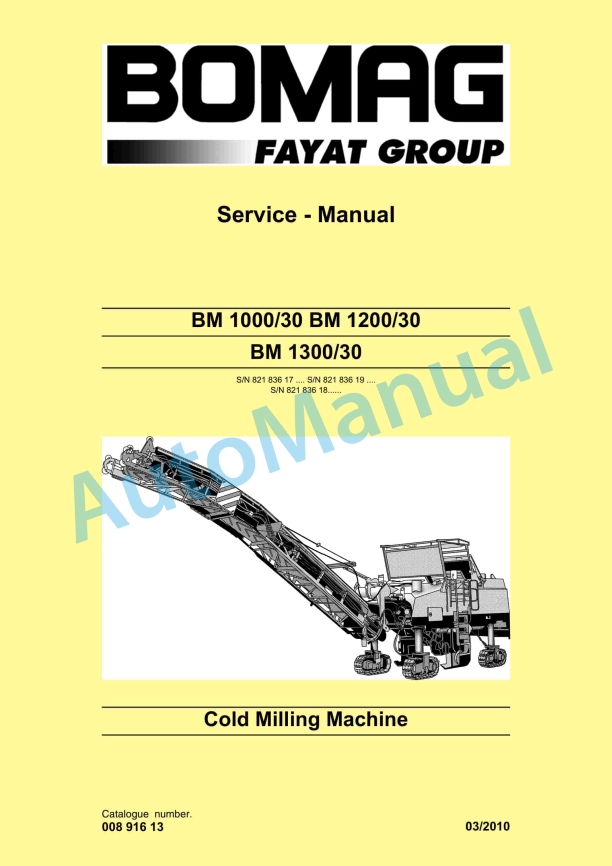

Bomag BM 1000-30, BM 1200-30, BM 1300-30 Cold Milling Machine Service Manual 00891613

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00891613

- Format: PDF

- Size: 55.9MB

- Number of Pages: 872

- Serial Number:

82183617, 82183619, 82183618

Category: Bomag Service Manual PDF

-

Model List:

- BM 1000-30 Cold Milling Machine

- BM 1200-30 Cold Milling Machine

- BM 1300-30 Cold Milling Machine

- 1. BM 1000/30 BM 1200/30

- 1.1. BM 1000/30 BM 1200/30

- 2.

- 2.1.

- 3. General

- 3.1. General

- 3.2. Introduction

- 3.3. General

- 3.4. General

- 3.5. Transport work with cranes and lifting tackle

- 3.6. Precautions and codes of conduct for welding work

- 3.7. Old oils

- 3.8. Hydraulics

- 3.9. Hot fuels

- 3.10. Synthetic rubber

- 3.11. Poisonous substances

- 3.12. Battery

- 3.13. Special safety regulations

- 3.14. The values specified in the table apply for screws

- 3.15. The values specified in the table apply for screws

- 3.16. The values specified in the table apply for screws

- 3.17. The values specified in the table apply for screws

- 3.18. The values specified in the table apply for screws

- 3.19. The values specified in the table apply for screws

- 3.20. The values specified in the table apply for screws

- 3.21. The values specified in the table apply for screws

- 3.22. The values specified in the table apply for screws

- 3.23. The values specified in the table apply for screws

- 3.24. The values specified in the table apply for screws

- 3.25. The values specified in the table apply for screws

- 3.26. The values specified in the table apply for screws

- 4. Technical data

- 4.1. Technical data

- 4.2.

- 4.3.

- 4.4.

- 4.5.

- 5. Maintenance

- 5.1. Maintenance

- 5.2. General notes on maintenance

- 5.3. Fuels and lubricants

- 6. Electrics

- 6.1. Electrics

- 6.2. Understanding circuit diagrams

- 6.3. Battery service

- 6.4. Battery service

- 6.5. Battery service

- 6.6. Battery service

- 6.7. Battery service

- 6.8. Starting with jump wires

- 6.9. Operating conditions for height regulation

- 6.10. Operating conditions for height regulation

- 6.11. Differential pressure switch for hydraulic oil

- 6.12. Replacing fuses

- 6.13.

- 6.14.

- 6.15.

- 6.16. Pin assignment for control

- 7. Engine

- 7.1. Engine

- 7.2. Engine attachment parts

- 7.3. Engine attachment parts

- 7.4. Checking the cylinder head ground cable

- 7.5. Checking the cylinder head ground cable

- 7.6. Check the engine oil level

- 7.7. Change engine oil and oil filter cartridge

- 7.8. Check, clean the water separator

- 7.9. Change the fuel prefilter cartridge

- 7.10. Replace the fuel filter cartridge

- 7.11. Service the combustion air filter

- 7.12. Checking the combustion air filter

- 7.13. Check the coolant level

- 7.14. Checking the condition of the coolant hoses

- 7.15. Change the coolant

- 7.16. Clean the cooling fins on engine and hydraulic oil cooler

- 7.17. Check, tighten, replace the generator Vbelt

- 7.18. Checking, tensioning the V belt for the generator system

- 7.19. Cleaning the crankcase ventilation

- 7.20. Check the engine mounts

- 7.21. Checking the valve clearance

- 8. Pump drive

- 8.1. Pump drive

- 8.2. Check, tighten, replace the hydraulic drive Vbelt

- 8.3. Check, tighten, replace the hydraulic drive Vbelt

- 8.4. Check, tighten, replace the hydraulic drive Vbelt

- 9. Milling drive, mechanics

- 9.1. Milling drive, mechanics

- 9.2. Checking, replacing the milling drum Vbelt

- 9.3. Checking, replacing the milling drum Vbelt

- 9.4. Change the oil in the milling drum reduction gear

- 9.5. Oil change in milling drum bearing

- 9.6. Checking/replacing cutting tools, scraper

- 9.7. Retightening the tool holder fastening screws

- 10. Conveyor belts, mechanics

- 10.1. Conveyor belts, mechanics

- 10.2. Conveyor belts

- 10.3. Checking, tightening the conveyor belts

- 10.4. Checking the safety ropes

- 10.5. Lubricating the conveyor belts

- 10.6. Folding / unfolding the loading conveyor belt

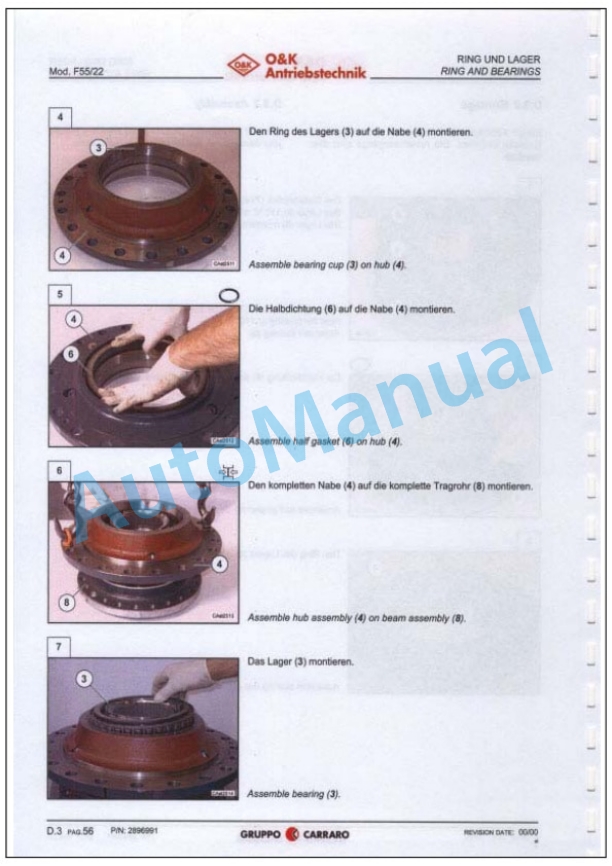

- 11. Travel drive, mechanics

- 11.1. Travel drive, mechanics

- 11.2. Checking the track plates

- 11.3. Checking the track plates

- 11.4. Retightening the track shoe fastening screws

- 11.5. Checking the track drive

- 11.6. Lubricating the travel drive

- 11.7. Lubricating the steering system

- 11.8. Oil change in track drive gear

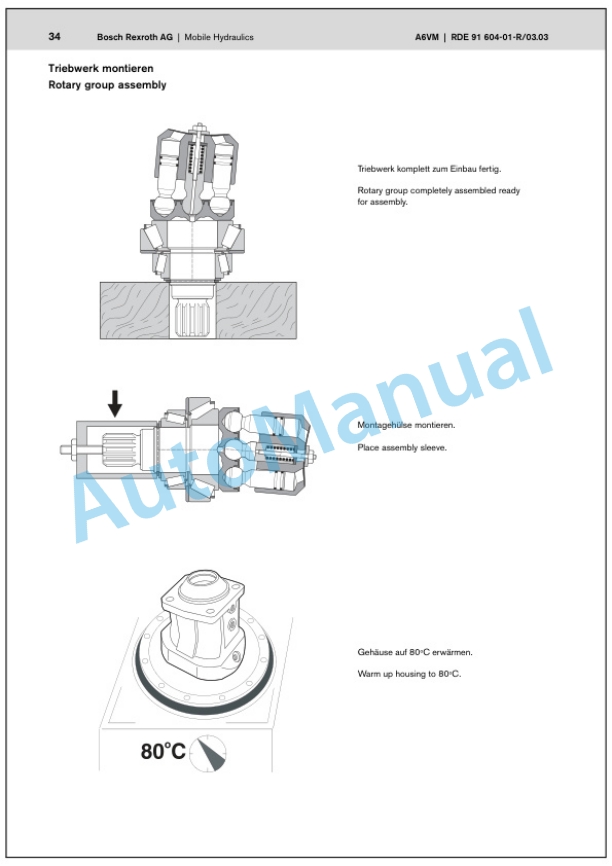

- 12. Service Training Hydraulics

- 12.1. Service Training Hydraulics

- 12.2.

- 12.3.

- 12.4.

- 12.5.

- 13. Hydraulic cylinder

- 13.1. Hydraulic cylinder

- 13.2. Repairing hydraulic cylinders

- 14. Suppliers documentation

- 14.1. Suppliers documentation

- 14.2.

- 14.3.

- 14.4.

- 14.5.

- 14.6.

- 14.7.

- 14.8.

- 14.9.

- 14.10.

- 14.11.

- 14.12.

- 14.13.

- 14.14.

- 14.15.

- 14.16.

- 14.17.

- 14.18.

- 14.19.

- 14.20.

- 14.21.

- 14.22.

- 14.23.

- 14.24.

- 14.25.

- 14.26.

- 14.27.

- 14.28.

- 14.29.

- 15. Circuit diagrams

- 15.1. Circuit diagrams

- 16.

- 16.1.

Rate this product

You may also like

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930041001 – 101930041022

$30.00

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930061001 – 101930061001

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 473 EB-4 Refuse Compactor Electric Schematics Diagram 101930111001 – 101930119999

$30.00

Bomag Service Manual PDF

Bomag BC 473 RB-3 Refuse Compactor Electric Schematics Diagram 101930131001 – 101930139999

$30.00