Bomag BM 500-15, BM 600-15 Compact Milling Machine Service Training 00892162

$30.00

- Type Of Manual: Service Training

- Manual ID: 00892162

- Format: PDF

- Size: 45.8MB

- Number of Pages: 802

- Serial Number:

101882001001, 101882011001, 101882101001, 101882111001

-

Model List:

- BM 500-15 Compact Milling Machine

- BM 600-15 Compact Milling Machine

- 1. BM 500/15

- 1.1. BM 500/15

- 2. General

- 2.1. General

- 2.2. Introduction

- 2.3. General

- 2.4. General

- 2.5. Transport work with cranes and lifting tackle

- 2.6. Precautions and codes of conduct for welding work

- 2.7. Operation of highvoltage systems

- 2.8. Old oils

- 2.9. Hydraulics

- 2.10. Hot fuels

- 2.11. Synthetic rubber

- 2.12. Poisonous substances

- 2.13. Battery

- 2.14. Special safety regulations

- 2.15. The values specified in the table apply for screws

- 2.16. The values specified in the table apply for screws

- 2.17. The values specified in the table apply for screws

- 2.18. The values specified in the table apply for screws

- 2.19. The values specified in the table apply for screws

- 2.20. The values specified in the table apply for screws

- 2.21. The values specified in the table apply for screws

- 2.22. The values specified in the table apply for screws

- 2.23. The values specified in the table apply for screws

- 2.24. The values specified in the table apply for screws

- 2.25. The values specified in the table apply for screws

- 2.26. The values specified in the table apply for screws

- 2.27. The values specified in the table apply for screws

- 3. Technical data

- 3.1. Technical data

- 3.2.

- 3.3.

- 4. Maintenance

- 4.1. Maintenance

- 4.2. General notes on maintenance

- 4.3. Fuels and lubricants

- 4.4. Coolant

- 4.5. Mineral oil based hydraulic oil

- 4.6. Biodegradable hydraulic oil

- 4.7. Gear oil

- 4.8. Lubrication grease

- 5. Electrics

- 5.1. Electrics

- 5.2. Battery service

- 5.3. Starting with jump wires

- 5.4.

- 5.5.

- 5.6.

- 5.7.

- 5.8.

- 5.9.

- 5.10. Component overview

- 5.11. Overview

- 5.12. Overview

- 5.13. Overview

- 5.14. Functional conditions left side plate

- 5.15. Functional conditions left side plate

- 5.16. Functional conditions left side plate

- 5.17. Functional conditions left side plate

- 5.18. Functional conditions left side plate

- 5.19. Functional conditions left side plate

- 5.20. Functional conditions left side plate

- 5.21. Functional conditions left side plate

- 5.22. Functional conditions left side plate

- 5.23. Functional conditions left side plate

- 5.24. Functional conditions left side plate

- 5.25. Functional conditions left side plate

- 5.26. Functional conditions left side plate

- 5.27. Functional conditions left side plate

- 5.28. Functional conditions left side plate

- 5.29. Functional conditions left side plate

- 5.30. Functional conditions left side plate

- 5.31. Functional conditions left side plate

- 5.32. Functional conditions left side plate

- 5.33. Functional conditions left side plate

- 5.34. Functional conditions right side plate

- 5.35. Functional conditions for holddown

- 5.36. Functional conditions for scraper

- 5.37. Functional conditions support wheel rear left

- 5.38. Functional condition support wheel rear right

- 5.39. Conditions for milling

- 6. Codes general information

- 6.1. Codes general information

- 6.2. Query codes general information

- 6.3. Query codes general information

- 6.4. Input codes general information

- 7. Error codes

- 7.1. Error codes

- 8. Query codes

- 8.1. Query codes

- 9. Input codes

- 9.1. Input codes

- 10. Replacement of components

- 10.1. Replacement of components

- 11. Engine

- 11.1. Engine

- 11.2. Checking the engine oil level

- 11.3. Checking the engine oil level

- 11.4. Checking the engine oil level

- 11.5. Checking the engine oil level

- 11.6. Checking the engine oil level

- 11.7. Checking the engine oil level

- 11.8. Checking the engine oil level

- 11.9. Checking the engine oil level

- 11.10. Checking the engine oil level

- 11.11. Change engine oil and oil filter cartridge

- 11.12. Checking, cleaning the water separator

- 11.13. Replacing the fuel prefilter cartridge, bleed the fuel system

- 11.14. Replace the fuel filter cartridges

- 11.15. Air filter maintenance

- 11.16. Checking the coolant level

- 11.17. Check the antifreeze agent concentration

- 11.18. Changing the coolant

- 11.19. Clean the cooling fins on engine and hydraulic oil cooler

- 11.20. Checking / replacing the ribbed Vbelt

- 11.21. Check the engine mounts

- 11.22. Adjust the valve clearance

- 11.23. Adjusting the control piston play

- 12. Engine electrics

- 12.1. Engine electrics

- 13. Milling drive, description

- 13.1. Milling drive, description

- 14. Milling drum, description

- 14.1. Milling drum, description

- 15. Milling drum housing, description

- 15.1. Milling drum housing, description

- 16. Conveyor belt, description

- 16.1. Conveyor belt, description

- 17. Travel drive, description

- 17.1. Travel drive, description

- 18. Hydraulics general

- 18.1. Hydraulics general

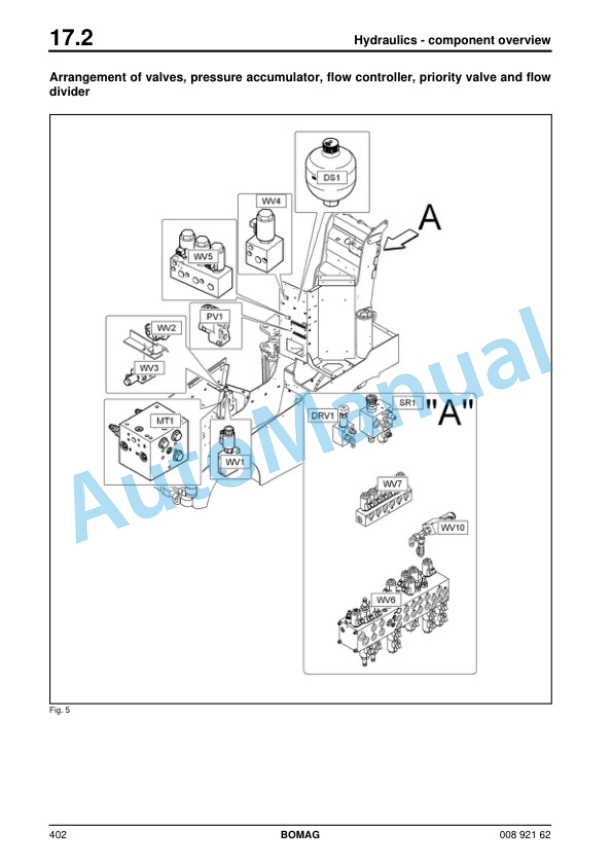

- 18.2. Hydraulics component overview

- 18.3. Hydraulics component overview

- 18.4. Variable displacement pumps, A10VG28/45/56 EP

- 18.5. Variable displacement pumps, A10VG28/45/56 EP

- 18.6. Swash plate principle

- 18.7. Travel pump viewed on the machine

- 18.8. Travel pump viewed on the machine

- 18.9. External gear pumps

- 18.10. External gear pumps

- 18.11. Working pump viewed on the machine

- 18.12. Working pump viewed on the machine

- 18.13. External gear pumps

- 18.14. External gear pumps

- 18.15. Multiple gear pumps

- 18.16. Tandem pump viewed on the machine

- 18.17. Tandem pump viewed on the machine

- 18.18. Crosssectional drawing of radial piston motor MKE

- 18.19. Crosssectional drawing of radial piston motor MKE

- 18.20. Functional principle of radial piston motors

- 18.21. Rear travel motors viewed on the machine

- 18.22. Rear travel motors viewed on the machine

- 18.23. Description of function

- 18.24. Description of function

- 18.25. Front travel motors viewed on the machine

- 18.26. Front travel motors viewed on the machine

- 18.27. Checking the hydraulic oil level

- 18.28. Checking hydraulic hoses and electric cables

- 18.29. Changing the hydraulic oil

- 18.30. Change the hydraulic oil filter

- 19. Hydraulics travel circuit

- 19.1. Hydraulics travel circuit

- 19.2. Travel system

- 19.3. Travel system

- 19.4. Folding the right hand wheel

- 19.5. Folding the right hand wheel

- 19.6. Levelling

- 19.7. Steering circuit

- 20. Hydraulics milling operation

- 20.1. Hydraulics milling operation

- 20.2. Clutch viewed on the machine

- 20.3. Clutch viewed on the machine

- 20.4. Side plates and holddowns

- 20.5. Side plates and holddowns

- 20.6. Scraper

- 21. Hydraulics further functions

- 21.1. Hydraulics further functions

- 21.2. Conveyor belt hydraulics

- 21.3. Conveyor belt hydraulics

- 21.4. Connection

- 21.5. Connection

- 22. Tests and adjustments

- 22.1. Tests and adjustments

- 22.2. Checking and adjusting the levelling

- 22.3. Checking and adjusting the levelling

- 22.4. Checking/adjusting the roof adjustment

- 22.5. Checking and adjusting the clutch operating pressure

- 22.6. Checking/adjusting the brake releasing pressure

- 22.7. Checking and adjusting the steering pressure

- 22.8. Checking and adjusting working hydraulics MP

- 22.9. Checking and adjusting working hydraulics MP1

- 22.10. Checking/adjusting the scraper pressure

- 22.11. Conveyor belt Checking and adjusting the pressure

- 22.12. Hydraulic breaker Checking and adjusting the pressure

- 22.13. Checking / adjusting the maximum pressure of the travel pump

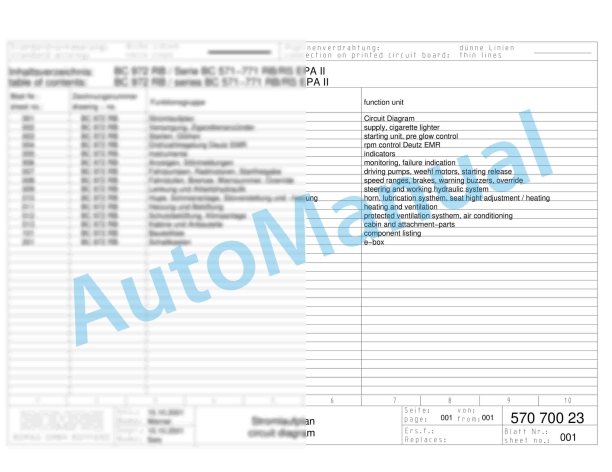

- 23. Circuit diagrams

- 23.1. Circuit diagrams

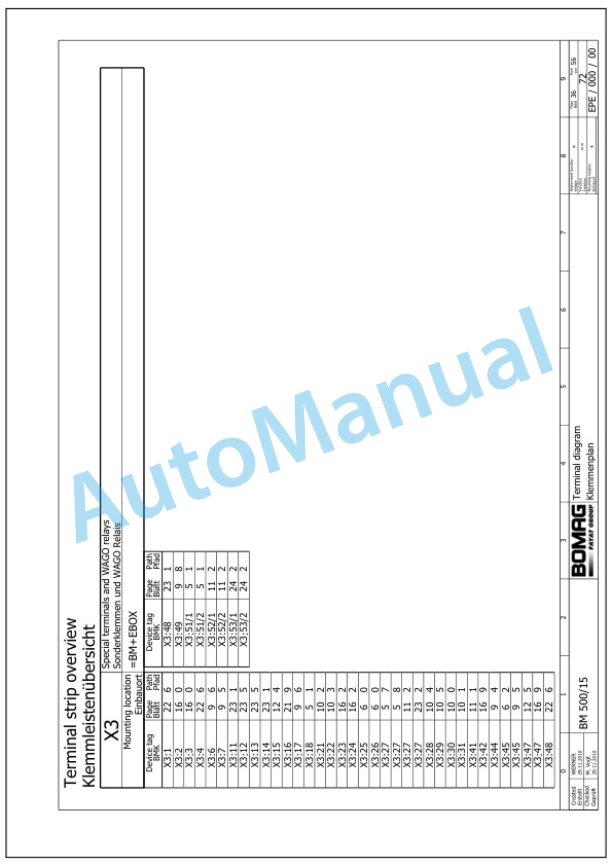

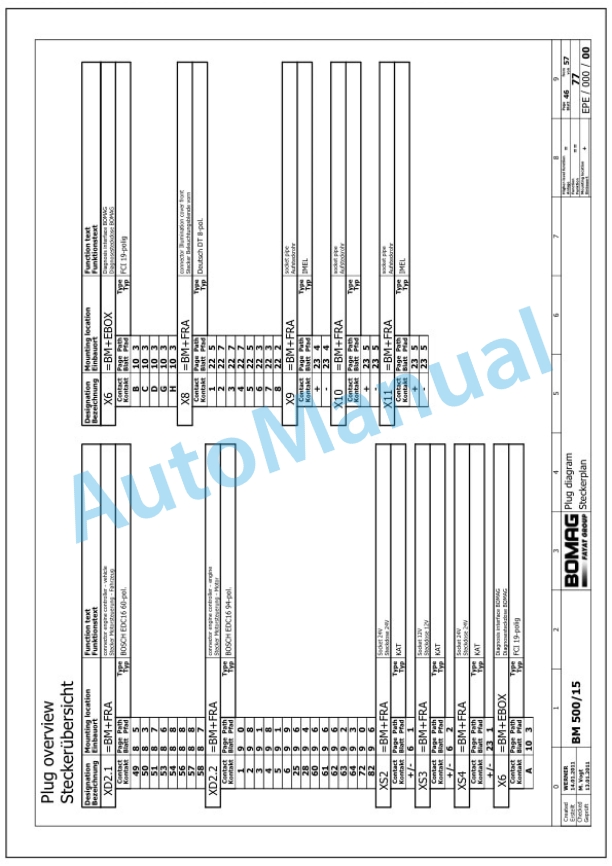

- 23.2. S/N Wiring diagram 72

- 23.3. S/N Wiring diagram 72

- 23.4. S/N Wiring diagram 77

- 23.5. S/N Wiring diagram 77

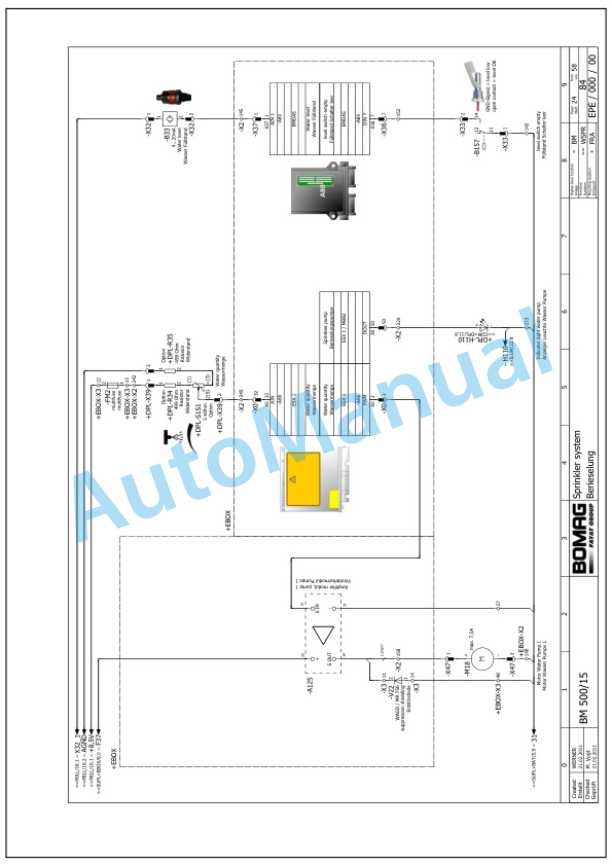

- 23.6. S/N Wiring diagram 84

- 23.7. S/N Wiring diagram 84

- 23.8. S/N Wiring diagram 98

- 23.9. S/N Wiring diagram 98

- 23.10. S/N Wiring diagram 108

- 23.11. S/N Wiring diagram 108

- 24.

- 24.1.

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930061001 – 101930061001

Bomag Service Manual PDF

Bomag BC 462 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930071001 – 101930071002

Bomag Service Manual PDF

Bomag BC 572 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570631001 – 101570631163

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 473 EB-3 Refuse Compactor Electric Schematics Diagram 101930151001 – 101930159999

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930041001 – 101930041022

Bomag Service Manual PDF

Bomag BC 473 RB-3 Refuse Compactor Electric Schematics Diagram 101930131001 – 101930139999