Bomag BMF 2500 S Service Manual 00840148

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00840148

- Format: PDF

- Size: 37.0MB

- Number of Pages: 610

- Serial Number:

101940001001 and up

101940011001 and up

Category: Bomag Service Manual PDF

-

Model List:

- BMF 2500 S

- 1. Table of contents

- 2. General

- 2.1. Introduction

- 2.2. Concerning your safety

- 2.2.1. Basic prerequisites

- 2.2.1.1. General

- 2.2.1.2. Explanation of warning signs

- 2.2.1.3. Personal protective equipment

- 2.2.1.4. Intended use

- 2.2.1.5. Improper use

- 2.2.2. Definition of responsible persons

- 2.2.2.1. Operating company

- 2.2.2.2. Expert / qualified person

- 2.2.2.3. Driver / operator

- 2.2.3. Basic safety regulations for safe operation

- 2.2.3.1. Remaining dangers, remaining risks

- 2.2.3.2. Regular safety inspections

- 2.2.3.3. Modifications and alterations to the machine

- 2.2.3.4. Damage, defects, misuse of safety devices

- 2.2.4. Handling fuels and lubricants

- 2.2.4.1. Preliminary remarks

- 2.2.4.2. Safety regulations and environmental protection regulations for handling diesel fuel

- 2.2.4.3. Safety regulations and environmental protection regulations for handling AdBlue/DEF

- 2.2.4.4. Safety regulations and environmental protection regulations for handling oil

- 2.2.4.5. Safety regulations and environmental protection regulations for handling hydraulic oil

- 2.2.4.6. Safety regulations and environmental protection regulations for handling coolants

- 2.2.4.7. Safety regulations and environmental protection regulations for handling battery acid

- 2.2.5. Emergency procedures

- 2.2.5.1. Actuating the emergency stop switch

- 2.2.5.2. Disconnecting the battery

- 2.2.5.3. Towing the machine

- 2.2.6. Maintenance and repair

- 2.2.6.1. Preliminary remarks and safety notes

- 2.2.6.2. Work on hydraulic lines

- 2.2.6.3. Working on the engine

- 2.2.6.4. Maintenance work on electric components and battery

- 2.2.6.5. Cleaning work

- 2.2.7. Operating the machine, working operation

- 2.2.7.1. Persons in the danger area

- 2.2.7.2. Driving the machine

- 2.2.7.3. Driving on inclinations and slopes

- 2.2.7.4. Cross slope

- 2.2.7.5. Parking the machine

- 2.2.8. Safety features

- 2.3. Fuels and lubricants

- 2.3.1. Engine oil

- 2.3.1.1. Oil viscosity

- 2.3.1.2. Oil change intervals

- 2.3.2. Fuel

- 2.3.2.1. Fuel quality

- 2.3.2.2. Winter fuel

- 2.3.2.3. Storage

- 2.3.3. AdBlue/DEF

- 2.3.3.1. AdBlue/DEF quality

- 2.3.3.2. Low outside temperatures

- 2.3.3.3. Storage

- 2.3.3.4. Cleanliness

- 2.3.4. Coolant

- 2.3.4.1. General

- 2.3.4.2. Water quality

- 2.3.5. Hydraulic oil

- 2.3.5.1. Mineral oil based hydraulic oil

- 2.3.5.2. Biodegradable hydraulic oil

- 2.3.6. Gear oil SAE 75W90

- 2.3.7. Gear oil SAE 80W140

- 2.4. Notes on repair

- 2.4.1. General repair instructions

- 2.4.1.1. Repair notes for electrics

- 2.4.1.2. Repair notes for hydraulics

- 2.4.1.3. Repair notes for Common Rail engines

- 2.4.1.4. Repair notes for gaskets and mating surfaces

- 2.4.1.5. Repair notes for ball and roller bearings

- 2.4.1.6. Feather keys and keyways

- 2.4.1.7. Repair notes for cotter pins

- 2.4.1.8. Repair notes for screws and nuts

- 2.4.1.9. Strength classes, metric screws and nuts

- 2.4.1.10. Identification of UNFthreads

- 2.4.2. Tightening torques

- 2.5. Description

- 2.5.1. Description of use

- 2.5.2. Assembly groups and description of function

- 2.5.3. Machine description

- 3. Overview of machine

- 3.1. Component overview Electrics

- 3.2. Component overview hydraulics

- 3.3. Lubrication points

- 4. Electric systems

- 4.1. Wiring looms

- 4.2. CAN overview

- 4.3. Overview

- 4.4. Display

- 4.4.1. Changing the diesel engine speed

- 4.4.2. Display of typical engine data

- 4.5. Component description

- 4.5.1. Steering angle sensor

- 4.6. BOMAG Telematic

- 4.7. Trouble shooting

- 4.7.1. Calling up the fault log

- 4.7.2. Fault code lists

- 4.8. Starting the engine with jump leads

- 4.9. Deutsch plug, series DT and DTM

- 5. Diesel engine

- 5.1. Description

- 5.1.1. General information

- 5.1.2. Cooling system

- 5.1.2.1. Description of thermostat

- 5.1.3. Engine oil system

- 5.1.4. Air intake system

- 5.1.5. Fuel system

- 5.1.6. Exhaust system

- 5.1.7. Engine electrics

- 5.1.7.1. Intake air pressure and temperature sensor

- 5.1.7.2. Coolant temperature sensor

- 5.1.7.3. Rotary speed sensors

- 5.1.7.4. Injectors

- 5.1.7.5. Sensor, water in fuel

- 5.1.7.6. Rail pressure sensor

- 5.1.7.7. Sensor DEFfilling level and temperature

- 5.1.7.8. Coolant control valve DEFtank

- 5.1.7.9. Sensor DEFquality

- 5.1.7.10. NOxsensor before exhaust gas aftertreatment system

- 5.1.7.11. NOxsensor after exhaust gas aftertreatment system

- 5.1.7.12. SCR temperature sensor

- 5.1.7.13. Heating 1 DEFline

- 5.1.7.14. DEFdosing valve

- 5.2. Repairs

- 5.2.1. Thermostat disassembly/assembly

- 5.2.2. Check the thermostat

- 5.2.3. Check starter

- 5.2.4. Starter disassembly/assembly

- 5.2.5. Injector disassembly/assembly

- 5.2.6. Checking the injector

- 5.2.7. Injector supply line disassembly/assembly

- 5.2.8. Checking the injector supply line

- 5.2.9. Injector feed pipe disassembly/assembly

- 5.2.10. Checking the injector feed pipe

- 5.2.11. Valve cover gasket disassembly/assembly

- 5.2.12. Valve cover seal

- 5.2.13. Valve cover disassembly/assembly

- 5.2.14. Checking the valve cover

- 5.3. Trouble shooting, diesel engine

- 5.3.1. Fuel consumption too high

- 5.3.2. Oil consumption too high

- 5.3.3. Engine oil pressure too high

- 5.3.4. Engine oil pressure too low

- 5.3.5. Engine oil loss

- 5.3.6. Engine oil contaminated

- 5.3.7. Fuel in engine oil

- 5.3.8. Coolant temperature too high (gradually)

- 5.3.9. Coolant temperature too high (suddenly)

- 5.3.10. Coolant temperature too low

- 5.3.11. Frequent blockage of the air filter

- 5.3.12. The diesel engine turns poorly or not at all (starter)

- 5.3.13. The diesel engine turns poorly or not at all

- 5.3.14. The diesel engine starts poorly or not at all (no smoke)

- 5.3.15. The diesel engine does not reach its nominal speed

- 5.3.16. The diesel engine stops again after starting

- 5.3.17. Insufficient engine power

- 5.3.18. Poor acceleration or response of the engine

- 5.3.19. Irregular engine operation in idling speed

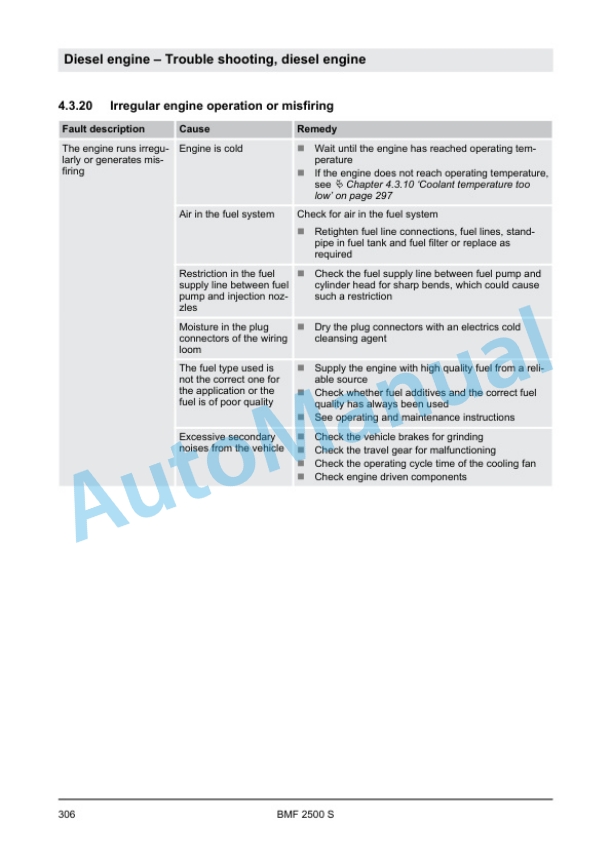

- 5.3.20. Irregular engine operation or misfiring

- 5.3.21. Engine speed fluctuates in lower and upper idle speed

- 5.3.22. The rotary speed fluctuates under load

- 5.3.23. The diesel engine stops unexpectedly

- 5.3.24. The diesel engine emits secondary noises

- 5.3.25. The diesel engine emits secondary noises (during combustion)

- 5.3.26. Excessive engine vibrations

- 5.3.27. Increased DEF consumption

- 5.3.28. Generator does not run or only poorly

- 6. Hydraulic system

- 6.1. Open and closed hydraulic circuit

- 6.2. Hydraulic units

- 6.2.1. Control valve block

- 6.2.2. Hydraulic oil tank

- 6.2.3. Conveyor belt pump H1

- 6.2.4. Conveyor belt motor MCR

- 6.3. Fan circuit

- 6.4. Working circuit

- 6.5. Conveyor belt circuit

- 6.6. Travel circuit

- 6.7. Trouble shooting, hydraulics

- 6.7.1. Insufficient hydraulic power

- 6.7.2. Trouble shooting axial piston pumps

- 6.7.3. Trouble shooting axial piston motors

- 7. Assembly groups

- 7.1. Hopper

- 7.1.1. Description

- 7.2. Conveyor belt

- 7.2.1. Description

- 7.2.2. Repair

- 7.2.2.1. Changing the conveyor belt

- 7.3. Conveyor belt, slewable B01 (optional equipment)

- 7.3.1. Description

- 7.3.2. Repair

- 7.3.2.1. Assembly conveyor belt, slewable

- 7.3.2.2. Assembly chute

- 7.3.2.3. Disassembly chute

- 7.4. Cooling system

- 7.4.1. Description

- 8. Trouble shooting

- 8.1. Preliminary remarks

- 8.2. Emergency procedures

- 8.2.1. Actuating the emergency stop switch

- 8.2.2. Disconnecting the battery

- 8.2.3. Towing the machine

- 9. Special tools

- 9.1. Special tools, electrics

- 9.2. Special tools, hydraulic system

- 9.2.1. Special tools, tests and adjustments

- 9.2.2. Special tools for flushing

- 9.3. List of special tools

- 10. Index

- 11. Appendix

- 11.1. A Supplier documentation

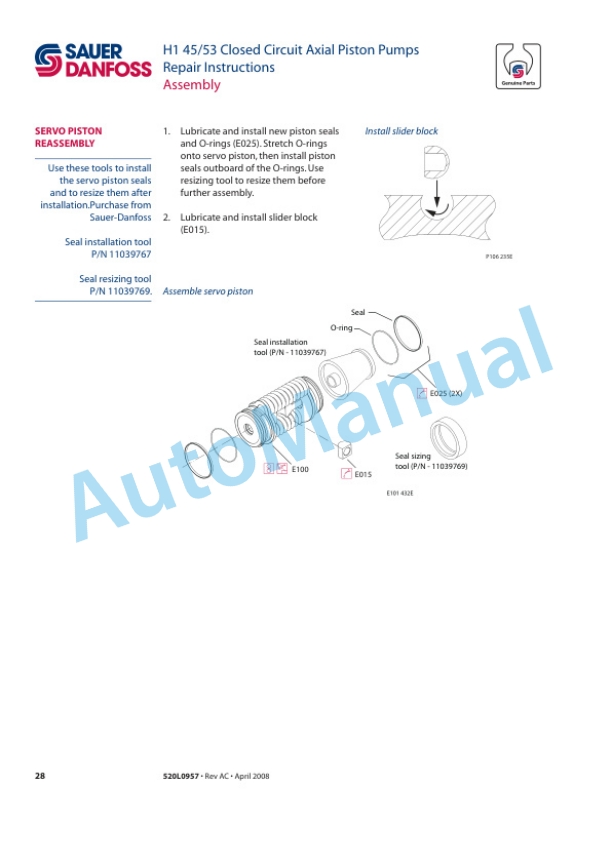

- 11.1.1. A Conveyor belt pump

- 11.1.2. B Conveyor belt motor

- 11.1.3. C Optical sensor

- 11.2. B Circuit diagrams

- 11.2.1. A Wiring diagram 94013136

Rate this product

You may also like

Bomag Service Manual PDF

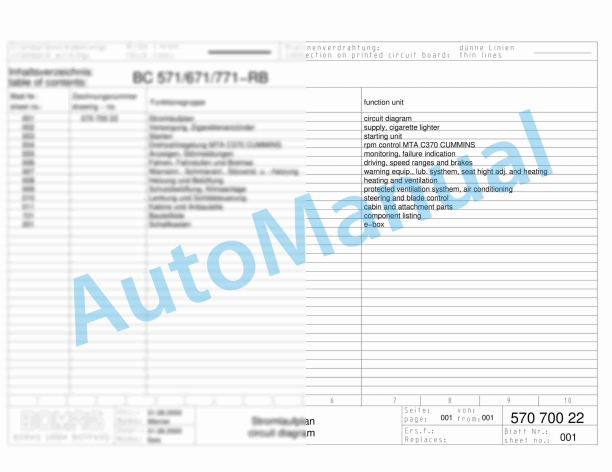

Bomag BC 571 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570621033 – 101570621062

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 462 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930071001 – 101930071002

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 473 EB-4 Refuse Compactor Electric Schematics Diagram 101930111001 – 101930119999

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

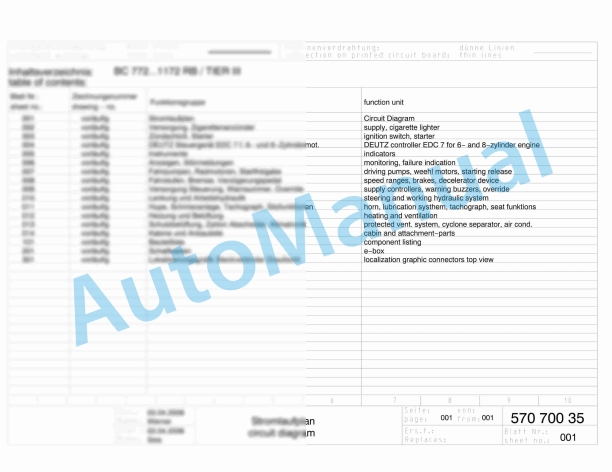

Bomag BC 473 RB-3 Refuse Compactor Electric Schematics Diagram 101930131001 – 101930139999

$30.00