Bomag BW 191 AD-5, BW 206 AD-5 Tandem Vibratory Rollers Service Manual 00840101

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00840101

- Format: PDF

- Size: 32.0MB

- Number of Pages: 784

- Serial Number:

101921201001 and up

101921211001 and up

Category: Bomag Service Manual PDF

-

Model List:

- BW 191 AD-5 Tandem Vibratory Roller

- BW 206 AD-5 Tandem Vibratory Roller

- 1. Table of contents

- 2. General

- 2.1. General

- 2.2. Concerning your safety

- 2.2.1. General prerequisites

- 2.2.2. Definition of responsible persons

- 2.2.3. Fundamentals for safe operation

- 2.2.4. Handling fuels and lubricants

- 2.2.5. Regeneration of exhaust gas aftertreatment system

- 2.2.6. What to do in events of emergency

- 2.2.7. Park the machine in secured condition.

- 2.2.8. Maintenance and repair

- 2.3. Fuels and lubricants

- 2.3.1. Fuels and lubricants

- 2.4. List of fuels and lubricants

- 2.4.1. List of fuels and lubricants

- 3. Technical data

- 3.1. Technical data, BW 191 AD5

- 3.1.1. Technical data

- 3.2. Technical data, BW 206 AD5

- 3.2.1. Technical data

- 3.3. Additional technical data

- 4. Overview of machine

- 4.1. Overview of electric system

- 4.2. Diesel engine

- 4.3. Overview of hydraulics

- 4.3.1. Pump overview

- 4.4. Overview of water spraying system

- 4.4.1. AD, ADO AM

- 4.4.2. Pump overview

- 4.5. Overview of air conditioning system

- 4.6. Overview, AD drum

- 4.7. Stickers and decals

- 5. Electric systems

- 5.1. Overview of electric system

- 5.2. Table of fuels and lubricants

- 5.3. Wiring

- 5.4. CAN BUS overview

- 5.5. Power board

- 5.6. Control console cabin

- 5.7. Fuse assignment

- 5.7.1. Notes on safety

- 5.7.2. Central electrics

- 5.7.3. Engine compartment

- 5.7.4. Fuse, cabin

- 5.7.5. Fuses ROPS

- 5.7.6. Fuses ROPS with swivel seat

- 5.8. Operators stand

- 5.8.1. Instrument cluster

- 5.9. Telemecanique switch

- 5.10. Deutsch plug, series DT and DTM

- 5.11. Servicing the battery, checking the main battery switch

- 5.11.1. Battery service

- 5.11.2. Checking the main battery switch

- 5.12. Starting the engine with jump leads

- 5.13. Electric steering wheel

- 5.14. Hydraulic cylinder with path measuring system

- 5.15. Asphalt temperature sensor, B106

- 5.16. Acceleration transducer, B84 B85

- 5.17. Switching on the pressure sprinkler system

- 5.18. Switching the emulsion sprinkling system on

- 5.19. Data collector, A80

- 5.20. Differential pressure switch for hydraulic oil filter, B21

- 5.21. Air filter vacuum switch, B03

- 5.22. Sensor, water in fuel filter, B124

- 5.23. Float switch, coolant compensation tank, B55

- 5.24. Charge control lamp

- 6. Diesel engine

- 6.1. Overview of diesel engine

- 6.2. Lubrication oil circuit TCD 4.1 / 6.1

- 6.3. Coolant circuit TCD 4.1 / 6.1

- 6.4. Common Rail System (CRS)

- 6.5. Wastegate charge pressure controller

- 6.6. Exhaust gas recirculation

- 6.7. EAT Exhaust Aftertreatment System

- 6.7.1. Selective Catalytic Reduction, SCR

- 6.7.2. Description of the SCR system components

- 6.7.3. SCR system warning strategy

- 6.8. DPFregeneration

- 6.8.1. Preliminary remarks and safety notes

- 6.8.2. Information codes

- 6.8.3. Suppressing DPFregeneration

- 6.8.4. Running regeneration at standstill

- 6.9. Engine electrics

- 6.9.1. CAN BUS overview

- 6.9.2. EMR4 system overview

- 6.9.3. EMR4 system components

- 6.10. Inspection and maintenance work

- 6.10.1. Maintenance Table

- 6.10.2. Checks prior to start up

- 6.10.3. Every 250 operating hours

- 6.10.4. Every 500 operating hours

- 6.10.5. Every 1000 operating hours

- 6.10.6. Every 2000 operating hours

- 6.10.7. Every 4000 operating hours

- 6.10.8. Every 6000 operating hours

- 6.10.9. As required

- 7. Hydraulic system

- 7.1. Overview of hydraulics

- 7.1.1. Pump overview

- 7.2. Open and closed hydraulic circuit

- 7.3. Hydraulic units

- 7.3.1. Travel pump, A4VG71 EP

- 7.3.2. Vibration pump, A10VG28 EP

- 7.3.3. Swash plate principle, pump

- 7.3.4. Drum drive motor

- 7.3.5. Vibration motor

- 7.3.6. External gear pumps

- 7.3.7. Outer gear motors nonreversible

- 7.3.8. Steering valve

- 7.4. Charge circuit and fan circuit

- 7.5. Travel circuit

- 7.6. Vibration circuit

- 7.7. Steering and crabwalk

- 7.8. Steering and crabwalk using slidable swivel seat

- 7.9. Edge cutter

- 7.10. Chip spreader

- 7.10.1. Mounting / removing the precision spreader

- 7.11. Tests and adjustments

- 7.11.1. Pump overview

- 7.11.2. Activate service mode

- 7.11.3. Driving against the closed brake

- 7.11.4. Pressure tests in the travel circuit

- 7.11.5. Checking / adjusting the neutral positions of the travel pump

- 7.11.6. Checking the setting of the high pressure relief valves in the travel circuit

- 7.11.7. Pressure tests in the front vibration circuit

- 7.11.8. Pressure tests in the rear vibration circuit

- 7.11.9. Checking the high pressure relief valves in the front vibration circuit

- 7.11.10. Checking the high pressure relief valves in the rear vibration circuit

- 7.12. Flushing and bleeding

- 7.12.1. Flushing general

- 7.12.2. Flushing diagram for front drum drive

- 7.12.3. Flushing the front drum drive

- 7.12.4. Flushing diagram for rear drum drive

- 7.12.5. Flushing the rear drum drive

- 7.12.6. Flushing diagram for front vibration drive

- 7.12.7. Flushing the front vibration circuit

- 7.12.8. Flushing diagram for rear vibration circuit

- 7.12.9. Flushing the rear vibration circuit

- 7.12.10. Bleeding the travel circuit

- 7.12.11. Bleeding the vibration circuit

- 7.13. Inspection and maintenance work

- 7.13.1. Maintenance Table

- 7.13.2. Check prior to start up

- 7.13.3. Every 500 operating hours

- 7.13.4. Every 1000 operating hours

- 7.13.5. Every 2000 operating hours

- 8. Water spraying system

- 8.1. Overview of water spraying system

- 8.1.1. AD, ADO AM

- 8.1.3. Pump overview

- 8.2. Inspection and maintenance work

- 8.2.1. Maintenance Table

- 8.2.2. Check prior to start up

- 8.2.3. As required

- 9. Air conditioning

- 9.1. Overview of air conditioning system

- 9.2. Physical principles

- 9.3. Refrigerant R134a

- 9.4. Compressor oil / refrigeration oil

- 9.5. Working principle of the air conditioning system

- 9.6. Monitoring devices

- 9.7. Description of components

- 9.8. Compressor

- 9.9. Emptying in case of repair

- 9.10. Drying and evacuation

- 9.11. Filling instructions

- 9.12. Steam table for R134a

- 9.13. Inspection and maintenance work

- 9.13.1. Maintenance Table

- 9.13.2. Every 250 operating hours

- 9.13.3. Every 500 operating hours

- 9.13.4. Every 1000 operating hours

- 9.13.5. As required

- 10. Drum

- 10.1. Overview, AD drum

- 10.2. Inspection and maintenance work

- 10.2.1. Maintenance Table

- 10.2.2. Check prior to start up

- 10.2.3. Every 500 operating hours

- 10.2.4. Every 1000 operating hours

- 11. Troubleshooting

- 11.1. Preliminary remarks

- 11.2. Emergency procedures

- 11.2.1. Actuating the emergency stop switch

- 11.2.2. Disconnecting the battery

- 11.2.3. Towing the machine

- 11.2.4. After towing

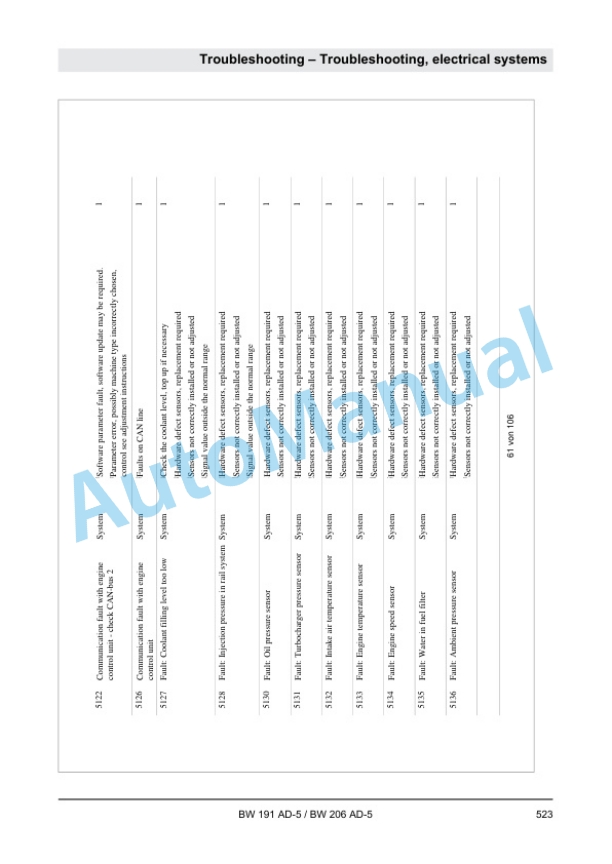

- 11.3. Troubleshooting, electrical systems

- 11.3.1. Preliminary remarks

- 11.3.2. Starting the engine with jump leads

- 11.3.3. Checking the main battery switch

- 11.3.4. Fuse assignment

- 11.3.5. Understanding electric circuit diagrams

- 11.3.6. Measuring method

- 11.3.7. ESX, checking the electric power supply

- 11.3.8. Diagnostics concept

- 11.3.9. Electrics training machine control

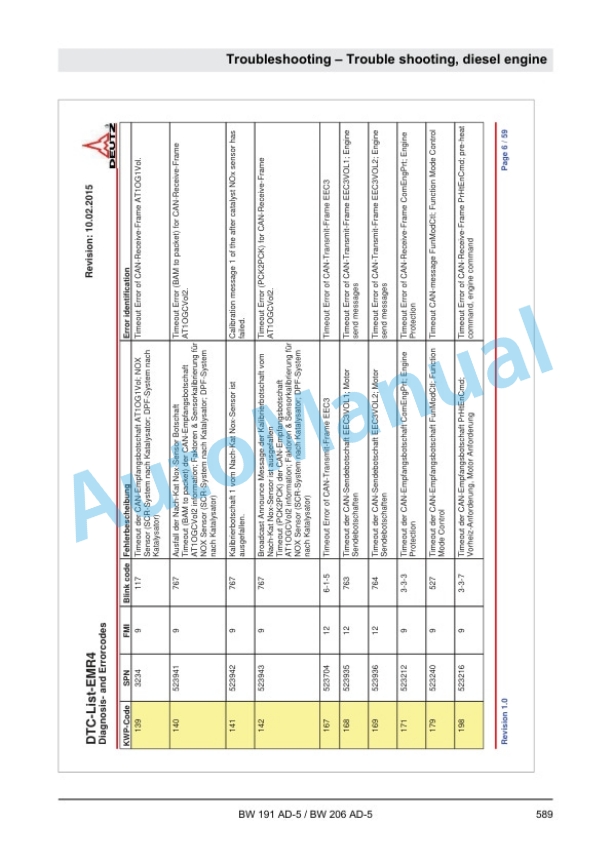

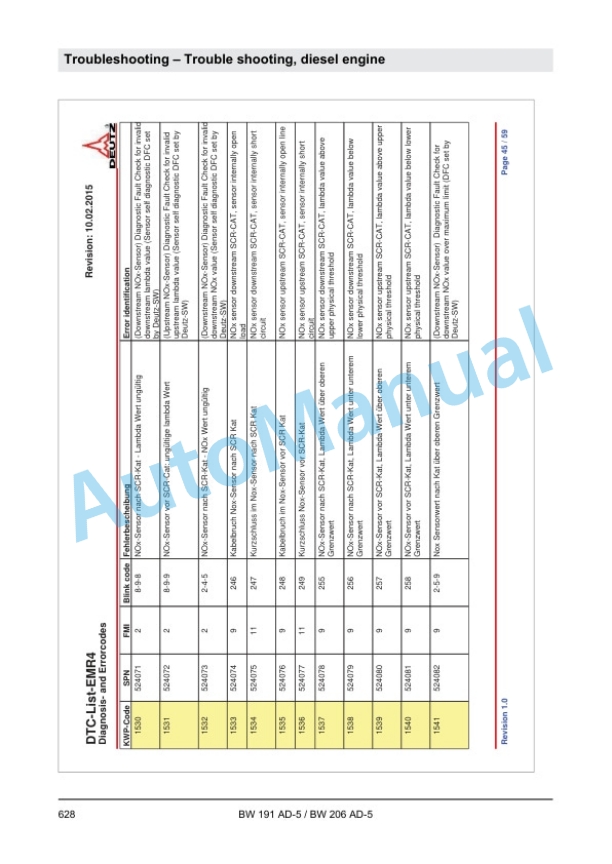

- 11.4. Trouble shooting, diesel engine

- 11.4.1. Starting the engine with jump leads

- 11.4.2. Engine faults

- 11.4.3. SCR system warning strategy

- 11.4.4. DTC error code list, EMR4

- 11.5. Trouble shooting, hydraulics

- 11.5.1. Insufficient hydraulic power

- 11.5.2. Trouble shooting axial piston pumps

- 11.5.3. Trouble shooting axial piston motors

- 11.6. Trouble shooting, air conditioning system

- 11.6.1. Trouble shooting in refrigerant circuit, basic principles

- 11.6.2. Trouble shooting procedure

- 11.6.3. Leak test

- 11.6.4. Checking the magnetic clutch

- 12. Special tools

- 12.1. Special tools, electrics

- 12.2. Special tools, hydraulic system

- 12.2.1. Special tools, tests and adjustments

- 12.2.2. Special tools for flushing

- 12.3. List of special tools

- 13. Index

- 14. Appendix

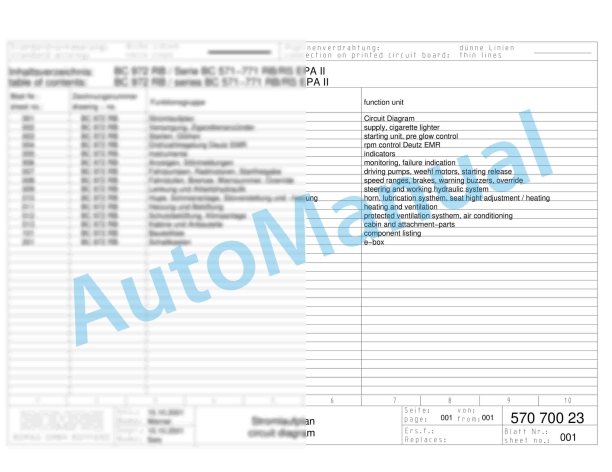

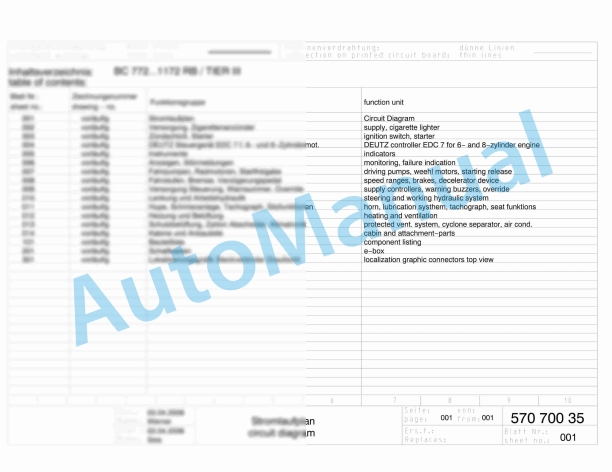

- 14.1. A Circuit diagrams

- 14.1.1. A Hydraulic diagram 921 130 76

- 14.1.2. B Wiring diagram 280

Rate this product

You may also like

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930051001 – 101930051010

$30.00

Bomag Service Manual PDF

Bomag BC 572 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570631001 – 101570631163

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 473 RB-3 Refuse Compactor Electric Schematics Diagram 101930131001 – 101930139999

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 462 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930031001 – 101930031042

$30.00