Bomag BW 211 DE-40 Single Drum Roller Service Manual 00891950

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00891950

- Format: PDF

- Size: 97.6MB

- Number of Pages: 1434

- Serial Number:

10158345

-

Model List:

- BW 211 DE-40 Single Drum Roller

- 1. BW 211 DE40

- 1.1. BW 211 DE40

- 2.

- 2.1.

- 3. General

- 3.1. General

- 3.2. Introduction

- 3.3. General

- 3.4. General

- 3.5. Transport work with cranes and lifting tackle

- 3.6. Precautions and codes of conduct for welding work

- 3.7. Operation of highvoltage systems

- 3.8. Old oils

- 3.9. Hydraulics

- 3.10. Hot fuels

- 3.11. Synthetic rubber

- 3.12. Poisonous substances

- 3.13. Air conditioning system

- 3.14. Battery

- 3.15. Special safety regulations

- 3.16. The values specified in the table apply for screws

- 3.17. The values specified in the table apply for screws

- 3.18. The values specified in the table apply for screws

- 3.19. The values specified in the table apply for screws

- 3.20. The values specified in the table apply for screws

- 3.21. The values specified in the table apply for screws

- 3.22. The values specified in the table apply for screws

- 3.23. The values specified in the table apply for screws

- 3.24. The values specified in the table apply for screws

- 3.25. The values specified in the table apply for screws

- 3.26. The values specified in the table apply for screws

- 3.27. The values specified in the table apply for screws

- 3.28. The values specified in the table apply for screws

- 3.29. The values specified in the table apply for screws

- 4. Technical data

- 4.1. Technical data

- 4.2.

- 4.3.

- 4.4.

- 5. Maintenance

- 5.1. Maintenance

- 5.2. General notes on maintenance

- 5.3. Fuels and lubricants

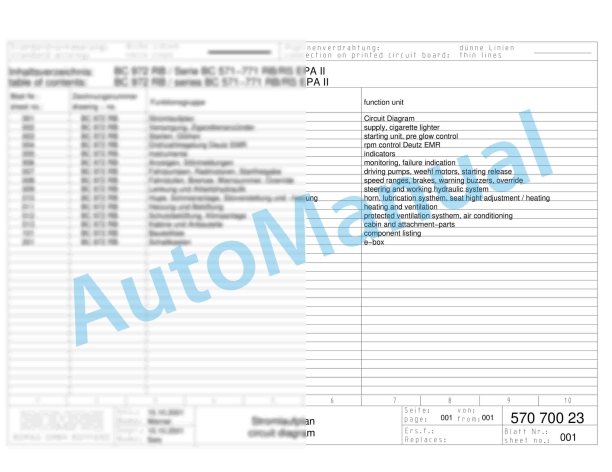

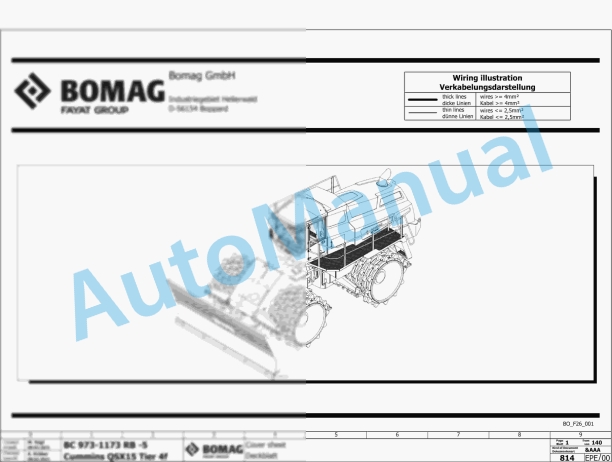

- 6. EPlan wiring diagrams

- 6.1. EPlan wiring diagrams

- 7. Electrics

- 7.1. Electrics

- 7.2. DTM Series

- 7.3. DTM Series

- 7.4. DTM Series

- 7.5. DTM Series

- 7.6. DTM Series

- 7.7. DTM Series

- 7.8. DTM Series

- 7.9. DTM Series

- 7.10. DTM Series

- 7.11. DTM Series

- 7.12. DTM Series

- 7.13. DTM Series

- 7.14. DTM Series

- 7.15. DTM Series

- 7.16. DTM Series

- 7.17. DTM Series

- 7.18. Service the battery

- 7.19. Service the battery

- 7.20. Service the battery

- 7.21. Service the battery

- 7.22. Service the battery

- 7.23. Service the battery

- 7.24. Service the battery

- 7.25. Service the battery

- 7.26. Service the battery

- 7.27. Service the battery

- 7.28.

- 7.29.

- 7.30. Starting with jump wires

- 7.31. Heating flange on engine

- 7.32. Heating flange on engine

- 7.33. Heating flange on engine

- 7.34.

- 7.35.

- 7.36.

- 7.37.

- 7.38.

- 7.39. S00, start switch

- 7.40.

- 7.41.

- 7.42.

- 7.43.

- 7.44.

- 7.45.

- 7.46.

- 8. Electronic modules

- 8.1. Electronic modules

- 8.2.

- 8.3.

- 8.4.

- 8.5.

- 9. Speedometer Module

- 9.1. Speedometer Module

- 10. dust protection / 582 502 16 gasket

- 10.1. dust protection / 582 502 16 gasket

- 11. Hydraulics

- 11.1. Hydraulics

- 11.2. Variable displacement pumps, 90R055 and 90R075

- 11.3. Variable displacement pumps, 90R055 and 90R075

- 11.4. Variable displacement pumps, 90R055 and 90R075

- 11.5. Variable displacement pumps, 90R055 and 90R075

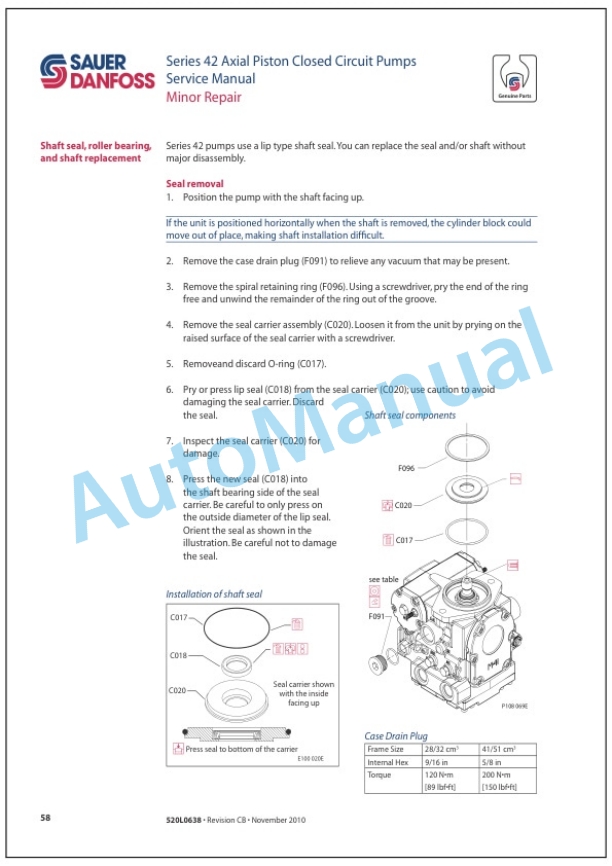

- 11.6. Variable displacement pump, 42R 041

- 11.7. Variable displacement pump, 42R 041

- 11.8. Swash plate principle, pump

- 11.9. Swash plate principle, pump

- 11.10. Swash plate motor with variable displacement, series 51

- 11.11. Swash plate motor with variable displacement, series 51

- 11.12. Functional principle radial piston motors, MS/MSE without brake

- 11.13. Functional principle radial piston motors, MS/MSE without brake

- 11.14. Vibration motor

- 11.15. Vibration motor

- 11.16. Swash plate principle, motor

- 11.17. Swash plate principle, motor

- 11.18. External gear pumps

- 11.19. External gear pumps

- 11.20. Brake control

- 11.21. Stopping the machine, operating the parking brake

- 11.22. Towing in case of an engine failure

- 11.23. Adjust the parking brake

- 11.24. Articulated joint

- 11.25. Check the hydraulic oil level

- 11.26. Changing hydraulic oil and breather filter

- 11.27. Changing the hydraulic oil filter

- 12. Tests and adjustments

- 12.1. Tests and adjustments

- 12.2. Checking the rotation speeds

- 12.3. Checking the rotation speeds

- 12.4. Checking / adjusting the neutral positions of the travel pump

- 12.5. Pressure tests in the travel circuit

- 12.6. Checking / adjusting the vibrator shaft speeds

- 12.7. Pressure measurements in the vibration circuit

- 12.8. Check the leakage rate of the vibration motor

- 12.9. Pressure test in steering circuit

- 13. Flushing and bleeding

- 13.1. Flushing and bleeding

- 13.2. Special tools for flushing

- 13.3. Bleeding the vibration circuit

- 13.4. Bleeding the vibration circuit

- 13.5. Bleeding the vibration circuit

- 14. Air conditioning system

- 14.1. Air conditioning system

- 14.2. Checking, replacing the refrigerant compressor Vbelt

- 14.3. Checking, replacing the refrigerant compressor Vbelt

- 14.4. Checking, replacing the refrigerant compressor Vbelt

- 14.5. Checking, replacing the refrigerant compressor Vbelt

- 14.6. Air conditioning

- 14.7. Service the air conditioning

- 15. Cabin assembly

- 15.1. Cabin assembly

- 15.2. General safety regulations for assembly

- 15.3. Changes and conversions to the cabin/ machine

- 15.4. Notes on safety in the assembly instructions

- 15.5. Information and safety stickers/decals on the cabin

- 15.6. Work on heating lines

- 15.7. Working on electric parts of the machine

- 15.8. Preparations

- 15.9. Cabin assembly

- 15.10. Final function tests and checks

- 16. Replacing the cab window panes

- 16.1. Replacing the cab window panes

- 17. Drum

- 17.1. Drum

- 17.2. Special tools, drum, single drum rollers

- 18. Oscillating articulated joint

- 18.1. Oscillating articulated joint

- 18.2. Special tools, oscillating articulated joint (BW177 to BW 216)

- 19. Suppliers documentation

- 19.1. Suppliers documentation

- 19.2.

- 19.3.

- 19.4.

- 19.5.

- 19.6.

- 19.7.

- 19.8.

- 19.9.

- 19.10.

- 19.11.

- 19.12.

- 19.13.

- 19.14.

- 19.15.

- 19.16.

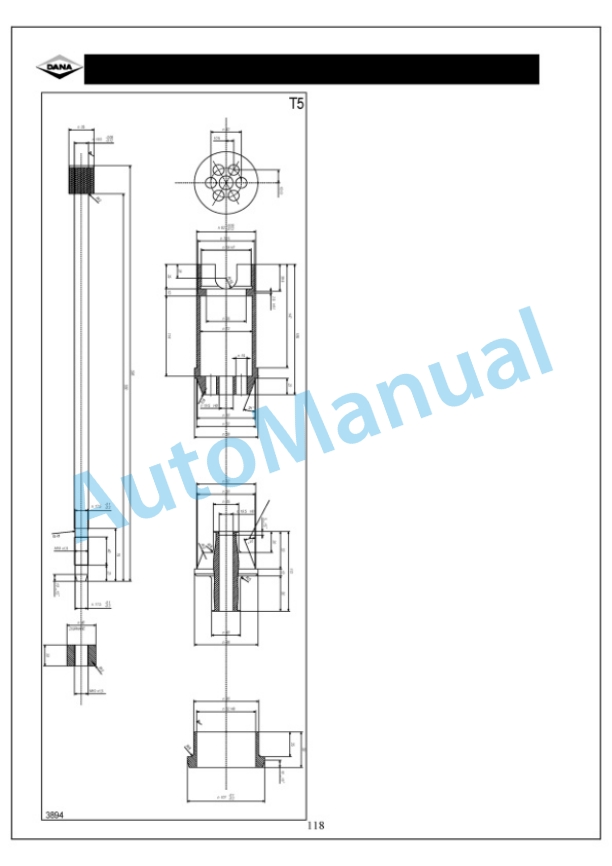

- 19.17. Axle

- 19.18. Axle

- 19.19. Axle

- 19.20. Axle

- 19.21. Axle

- 19.22. Axle

- 19.23. Axle

- 19.24. Axle

- 19.25.

- 19.26.

- 20. Circuit diagrams

- 20.1. Circuit diagrams

- 20.4. S/N Wiring diagram 9

- 20.5. S/N Wiring diagram 9

- 20.6. S/N Wiring diagram 9

- 20.7. S/N Wiring diagram 9

- 20.8. S/N Wiring diagram 9

- 20.9. S/N Wiring diagram 9

- 21.

- 21.1.

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 473 RB-3 Refuse Compactor Electric Schematics Diagram 101930131001 – 101930139999

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 572 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570631001 – 101570631163

Bomag Service Manual PDF

Bomag BC 463 RB-3 Refuse Compactor Electric Schematics Diagram 101930121001 – 101930129999

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930041001 – 101930041022

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 462 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930071001 – 101930071002

Bomag Service Manual PDF