Bomag BW 226 BVC-5, BW 226 DI-5 Single Drum Roller Service Manual 00840086

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00840086

- Format: PDF

- Size: 86.4MB

- Number of Pages: 1022

- Serial Number:

101586441001 and up

101586531001 and up

-

Model List:

- BW 226 BVC-5 Single Drum Roller

- BW 226 DI-5 Single Drum Roller

- 1. Table of contents

- 2. General

- 2.1. Introduction

- 2.2. Concerning your safety

- 2.2.1. Basic prerequisites

- 2.2.2. Definition of responsible persons

- 2.2.3. Fundamentals for safe operation

- 2.2.4. Handling fuels and lubricants

- 2.2.5. Load/transport the machine

- 2.2.6. Startup procedure

- 2.2.7. Driving the machine working operation

- 2.2.8. Refuelling

- 2.2.9. Emergency procedures

- 2.2.10. Maintenance work

- 2.2.11. Repair

- 2.2.12. Signage

- 2.3. Maintenance and repair

- 2.3.1. Notes on repair

- 2.3.2. Preliminary remarks and safety notes

- 2.3.3. Preparations / concluding work

- 2.3.4. Parking the machine in secured condition

- 3. Technical data

- 3.1. Technical data, BW 226 BVC5

- 3.1.1. Technical data

- 3.2. Technical data, BW 226 DI5

- 3.2.1. Technical data

- 3.3. Additional technical data

- 3.4. Terms and basis of calculation

- 3.5. Fuels and lubricants

- 3.5.1. Engine oil

- 3.5.2. Fuel

- 3.5.3. Coolant

- 3.5.4. Hydraulic oil

- 3.5.5. Gear oil SAE 75W90

- 3.5.6. Gear oil SAE 80W140

- 3.6. List of fuels and lubricants

- 4. Overview of machine

- 4.1. General information

- 4.1.1. BCM 05

- 4.1.2. BCM start

- 4.1.3. BCM net

- 4.1.4. BOMAG Telematic

- 4.2. Electric systems

- 4.3. Hydraulic system

- 4.4. Machine assemblies

- 4.4.1. Diesel engine

- 4.4.2. Drum

- 4.4.3. Air conditioning

- 4.4.4. Auxiliary heating, AIRTRONIC

- 5. Electric systems

- 5.1. Basic principles

- 5.1.1. Measuring method

- 5.1.2. Understanding electric circuit diagrams

- 5.1.3. Telemecanique switch

- 5.1.4. Deutsch plug, series DT and DTM

- 5.2. Overview of electric system

- 5.2.1. Central electrics

- 5.2.2. Operators stand

- 5.2.3. Wiring

- 5.2.4. CAN BUS overview

- 5.2.5. Table of fuels and lubricants

- 5.3. Starting the engine with jump leads

- 5.4. Fuse assignment

- 5.4.1. Notes on safety

- 5.4.2. Central electrics

- 5.4.3. Main fuses

- 5.4.4. Control console cabin

- 5.5. Central electrics

- 5.6. Description of electrical components

- 5.6.1. Control console cabin

- 5.6.2. Acceleration transducer, B62 B171

- 5.6.3. Differential pressure switch for hydraulic oil filter, B21

- 5.6.4. Air filter vacuum switch, B03

- 5.6.5. Sensor, water in fuel, B124

- 5.6.6. Float switch coolant tank, B55

- 5.6.7. Level sensor in diesel tank (R03)

- 5.6.8. Charge control light

- 5.6.9. Electric module, A108

- 5.7. Training of electric system

- 5.7.1. Electrics training machine control

- 5.7.2. Electrics training metrology control

- 5.8. Inspection and maintenance work

- 5.8.1. Maintenance Table

- 5.8.2. Every 500 operating hours

- 5.8.3. As required

- 6. Hydraulic system

- 6.1. Basic principles

- 6.1.1. Open and closed hydraulic circuit

- 6.1.2. Swash plate principle, pump

- 6.1.3. Swash plate principle, motor

- 6.1.4. External gear pumps

- 6.2. Overview of hydraulics

- 6.3. Description of hydraulic components

- 6.3.1. Travel / vibration pump, H1

- 6.3.2. Travel motor, H1

- 6.3.3. Vibration motor A2FM

- 6.3.4. Steering valve

- 6.3.5. Diaphragm type pressure accumulator

- 6.3.6. Slewing motor

- 6.4. Description of hydraulic circuits

- 6.4.1. Charge circuit

- 6.4.2. Travel circuit

- 6.4.3. Vibration circuit

- 6.4.4. Steering circuit

- 6.4.5. Bypass flow filter

- 6.5. Flushing and bleeding

- 6.5.1. Flushing general

- 6.5.2. Drum drive

- 6.5.3. Axle drive

- 6.5.4. Vibration circuit

- 6.5.5. Bleeding the travel circuit

- 6.5.6. Bleeding the vibration circuit

- 6.6. Inspection and maintenance work

- 6.6.1. Maintenance Table

- 6.6.2. Checks prior to start up

- 6.6.3. Every 500 operating hours

- 6.6.4. Every 1000 operating hours

- 6.6.5. Every 2000 operating hours

- 7. Machine assemblies

- 7.1. Diesel engine

- 7.1.1. Overviews

- 7.1.2. Lubrication oil circuit TCD 4.1 / 6.1

- 7.1.3. Coolant circuit TCD 4.1 / 6.1

- 7.1.4. Common Rail System (CRS)

- 7.1.5. Wastegate charge pressure controller

- 7.1.6. Exhaust gas recirculation

- 7.1.7. Engine electrics

- 7.1.8. Inspection and maintenance work

- 7.2. BOMAG, Variocontrol

- 7.2.1. Variocontrol

- 7.2.2. Vibration circuit

- 7.2.3. Potentiometer on slewing motor, B97

- 7.3. Drum

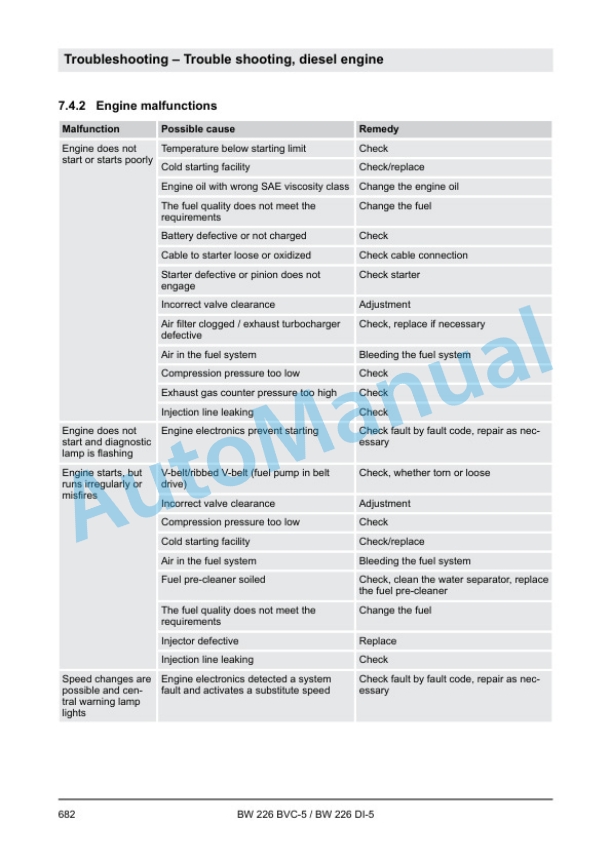

- 7.3.1. Overview drum

- 7.3.2. Removing the exciter unit

- 7.3.3. Installing the exciter unit

- 7.3.4. Assembling the vibrator unit

- 7.3.5. Changing the rubber buffers, adjusting the pretension

- 7.3.6. Smooth drum scraper installation and removal

- 7.3.7. Pad foot scraper installation and removal

- 7.3.8. Padfoot shell installation and removal

- 7.3.9. Inspection and maintenance work

- 7.4. Oscillating articulated joint

- 7.4.1. Overview

- 7.4.2. Dismantling the oscillating articulated joint

- 7.4.3. Assembly of oscillating articulated joint

- 7.5. Drive axle

- 7.5.1. Drive axle

- 7.5.2. Checks prior to start up

- 7.5.3. Every 250 operating hours

- 7.5.4. Every 1000 operating hours

- 7.5.5. As required

- 7.6. Air conditioning

- 7.6.1. Overview of air conditioning system

- 7.6.2. Physical principles

- 7.6.3. Refrigerant R134a

- 7.6.4. Compressor oil / refrigeration oil

- 7.6.5. Working principle of the air conditioning system

- 7.6.6. Monitoring devices

- 7.6.7. Description of components

- 7.6.8. Compressor

- 7.6.9. Emptying in case of repair

- 7.6.10. Drying and evacuation

- 7.6.11. Filling instructions

- 7.6.12. Steam table for R134a

- 7.6.13. Inspection and maintenance work

- 7.7. Auxiliary heating, AIRTRONIC

- 7.7.1. Overview

- 7.7.2. Inspection and maintenance work

- 7.8. Cabin assembly

- 7.8.1. Safety

- 7.8.2. Preparations

- 7.8.3. Cabin assembly

- 7.8.4. Final function tests and checks

- 7.9. ROPS/FOPS assembly

- 7.9.1. Safety

- 7.9.2. Preparations

- 7.9.3. ROPS/FOPS assembly

- 7.9.4. Final work

- 8. Troubleshooting

- 8.1. Preliminary remarks

- 8.2. Emergency procedures

- 8.2.1. Actuating the emergency stop switch

- 8.2.2. Disconnecting the battery

- 8.2.3. Emergency exit

- 8.2.4. Towing the machine

- 8.2.5. After towing

- 8.3. Troubleshooting, electrical systems

- 8.3.1. Preliminary remarks

- 8.3.2. Starting the engine with jump leads

- 8.3.3. Servicing the battery, checking the main battery isolation

- 8.3.4. Fuse assignment

- 8.3.5. ESX, checking the electric power supply

- 8.3.6. Diagnostics concept

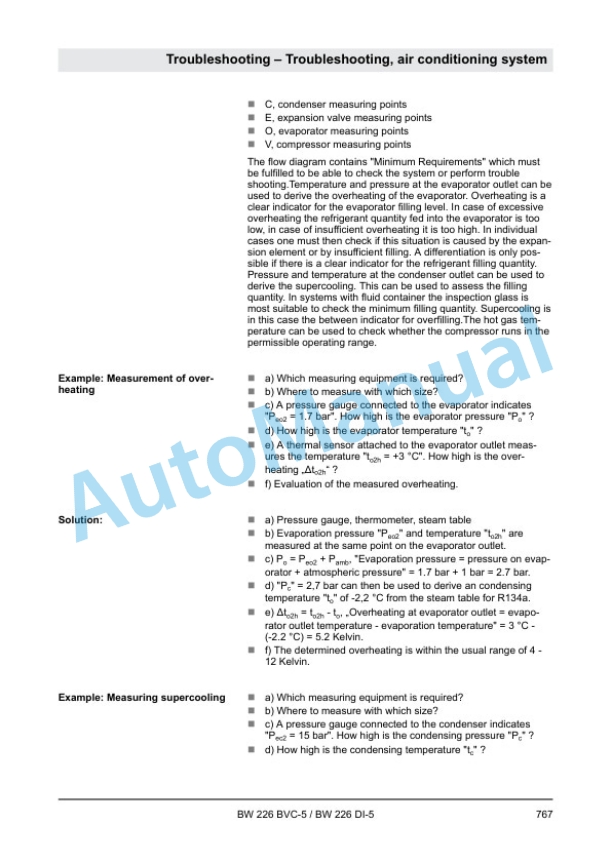

- 8.4. Trouble shooting, diesel engine

- 8.4.1. Starting the engine with jump leads

- 8.4.2. Engine malfunctions

- 8.4.3. DTC fault code list, EMR4

- 8.5. Trouble shooting, hydraulics

- 8.5.1. Insufficient hydraulic power

- 8.5.2. Trouble shooting axial piston pumps

- 8.5.3. Trouble shooting axial piston motors

- 8.5.4. Fault table hydraulic components

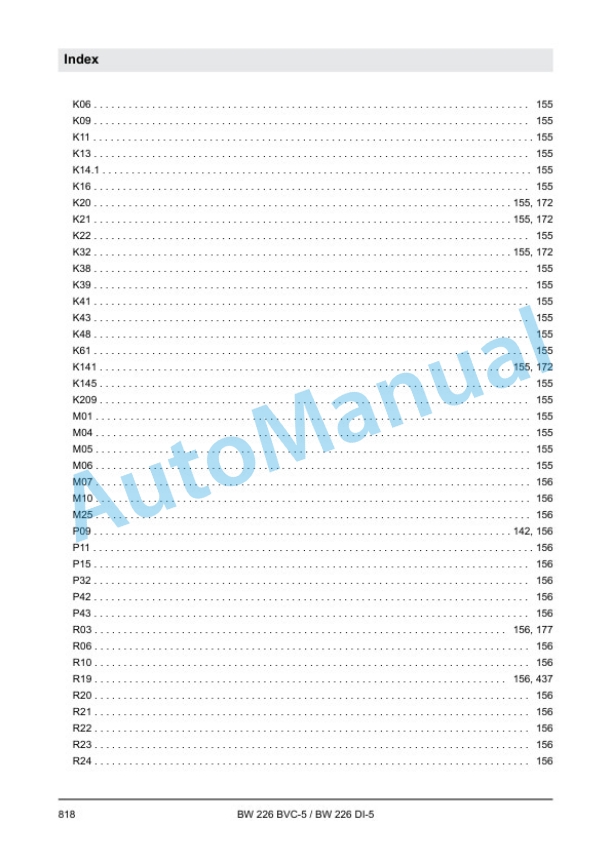

- 8.6. Troubleshooting, air conditioning system

- 8.6.1. Trouble shooting in refrigerant circuit, basic principles

- 8.6.2. Trouble shooting procedure

- 8.6.3. Leak test

- 8.6.4. Checking the magnetic clutch

- 8.7. Troubleshooting, auxiliary heating

- 8.7.1. Control and safety elements

- 8.7.2. Trouble shooting

- 8.7.3. Diagnostics with the module clock

- 8.7.4. Check the fuel supply

- 8.7.5. Circuit diagram, AIRTRONIC D2/D4

- 8.7.6. Fault code, AIRTRONIC D2/D4

- 9. Special tools

- 9.1. Special tools, electrics

- 9.2. Special tools, hydraulic system

- 9.2.1. Special tools, tests and adjustments

- 9.2.2. Special tools for flushing

- 9.3. Special tools for drum

- 9.4. List of special tools

- 10. Index

- 11. Appendix

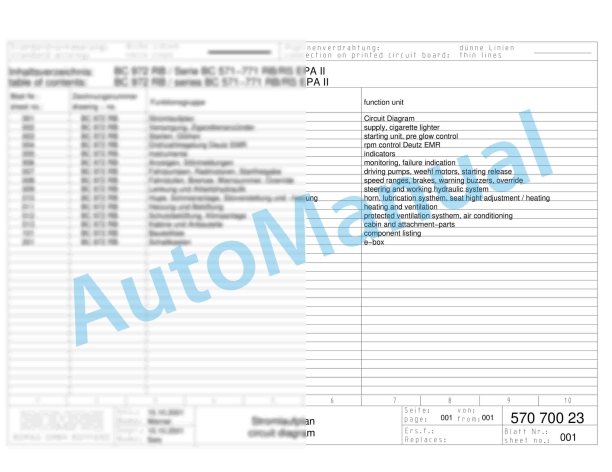

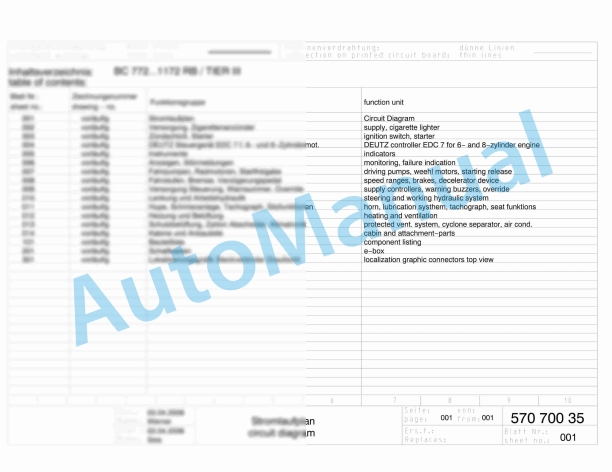

- 11.1. A Circuit diagrams

- 11.1.1. Circuit diagram 354

- 11.1.2. Circuit diagram 520

- 11.1.3. Hydraulic diagram 480

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930041001 – 101930041022

Bomag Service Manual PDF

Bomag BC 572 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570631001 – 101570631163

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930011002 – 101930011011

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 473 EB-3 Refuse Compactor Electric Schematics Diagram 101930151001 – 101930159999

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930021001 – 101930021018

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930001002 – 101930001058