Bomag BW 226 DH-4i BVC Single Drum Roller Operating and Maintenance Instructions 00807641

$20.00

- Type Of Manual: Operating and Maintenance Instructions

- Manual ID: 00807641

- Format: PDF

- Size: 9.8MB

- Number of Pages: 210

- Serial Number:

101585011001 and up

101585441001 and up

Category: Bomag Operator Manual PDF

-

Model List:

- BW 226 DH-4i BVC Single Drum Roller

- 1. Table of contents

- 2. Introduction

- 2.1. Foreword

- 2.2. Machine type plate and engine type plate

- 3. Technical data

- 3.1. Noise and vibration data

- 3.1.1. Noise data

- 3.1.2. Vibration data

- 4. Safety regulations

- 4.1. Information and safety stickers/decals on the machine

- 5. Display and control elements

- 5.1. General notes

- 5.2. Description of indicators and control elements

- 5.2.1. Monitor for reversing camera

- 5.3. Display and control elements Variocontrol

- 5.4. Description of indicating and control elements Variocontrol

- 5.5. Line graph Automatic (EVIB)

- 5.6. Description of line diagram Automatic (EVIB)

- 5.7. Line graph Manual (EVIB)

- 5.8. Description of line diagram Manual (EVIB)

- 5.9. Bar diagram (EVIB)

- 6. Operation

- 6.1. General

- 6.2. Tests before taking into operation

- 6.3. Adjusting the drivers seat

- 6.4. Electronic immobilizerOptional equipment

- 6.5. Starting the engine

- 6.6. Driving the machine

- 6.7. Stopping the machine, operating the parking brake

- 6.8. Using the machine for rock crushing

- 6.9. Shutting down the engine

- 6.10. DPFregeneration

- 6.11. Switching the vibration on and off

- 6.12. What to do in events of emergency

- 6.13. Operating the heating/air conditioning systemOptional equipment

- 6.14. Operating the hood

- 6.15. LCDisplay changing display fields

- 6.16. LCDisplay changing settings

- 6.17. BVC/BTM05 settings before startup

- 6.18. Variocontrol, selecting the operating mode

- 6.19. Measuring pass with Variocontrol

- 6.20. Finishing compaction of a track

- 6.21. Printing measuring data after completing compaction

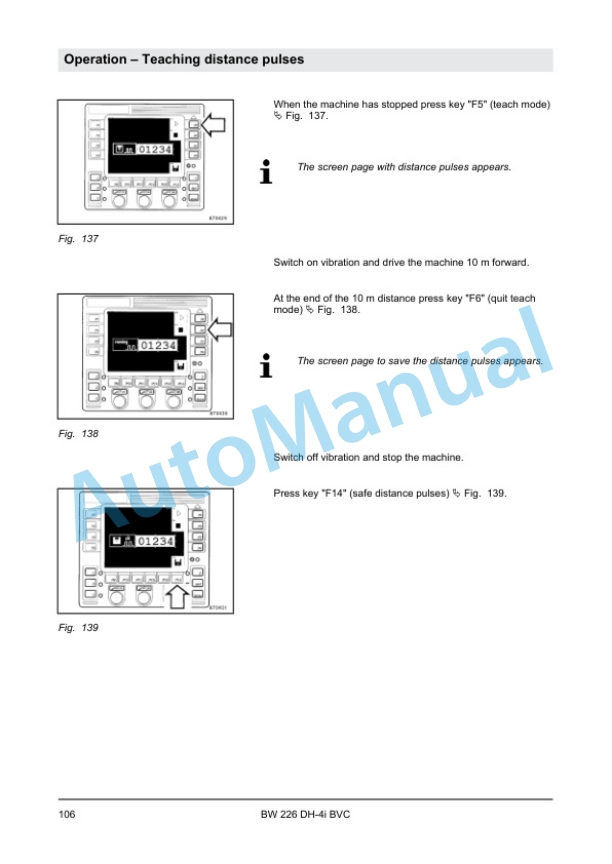

- 6.22. Teaching distance pulses

- 6.23. Amplitude limitation (BVC only)

- 6.24. Changing the paper roll in the measuring value printeronly BTM prof

- 6.25. Changing the printer ribbon in the measuring value printeronly BTM prof

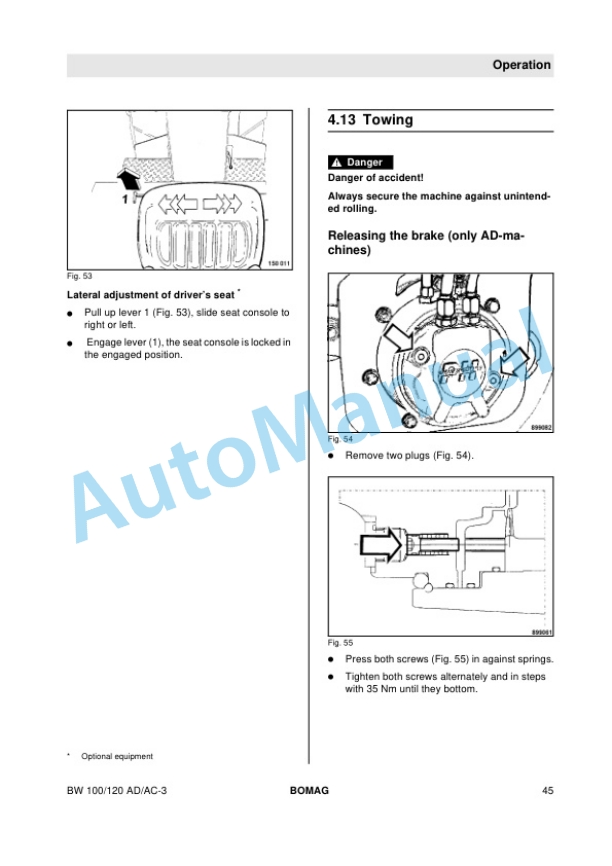

- 6.26. Towing in case of an engine failure

- 6.27. Loading/transport

- 7. Maintenance

- 7.1. General notes on maintenance

- 7.2. Fuels and lubricants

- 7.2.1. Engine oil

- 7.2.1.1. Oil quality

- 7.2.1.2. Oil viscosity

- 7.2.1.3. Oil change intervals

- 7.2.2. Fuel

- 7.2.2.1. Fuel quality

- 7.2.2.2. Winter fuel

- 7.2.2.3. Storage

- 7.2.3. Coolant

- 7.2.3.1. General

- 7.2.3.2. Water quality

- 7.2.3.3. Cooling system protection agent

- 7.2.4. Hydraulic oil

- 7.2.4.1. Mineral oil based hydraulic oil

- 7.2.4.2. Biodegradable hydraulic oil

- 7.2.5. Gear oil

- 7.2.6. Exciter system

- 7.3. Table of fuels and lubricants

- 7.4. Runningin instructions

- 7.4.1. General

- 7.4.2. After 250 operating hours

- 7.4.3. After 500 operating hours

- 7.4.4. After 1000 operating hours

- 7.5. Maintenance table

- 7.6. Every 10 operating hours

- 7.6.1. Check the engine oil level

- 7.6.2. Checking the fuel level

- 7.6.3. Check the coolant level

- 7.6.4. Check the hydraulic oil level

- 7.7. Every 250 operating hours

- 7.7.1. Check the tire pressure

- 7.7.2. Clean the cooling fins on engine and hydraulic oil cooler

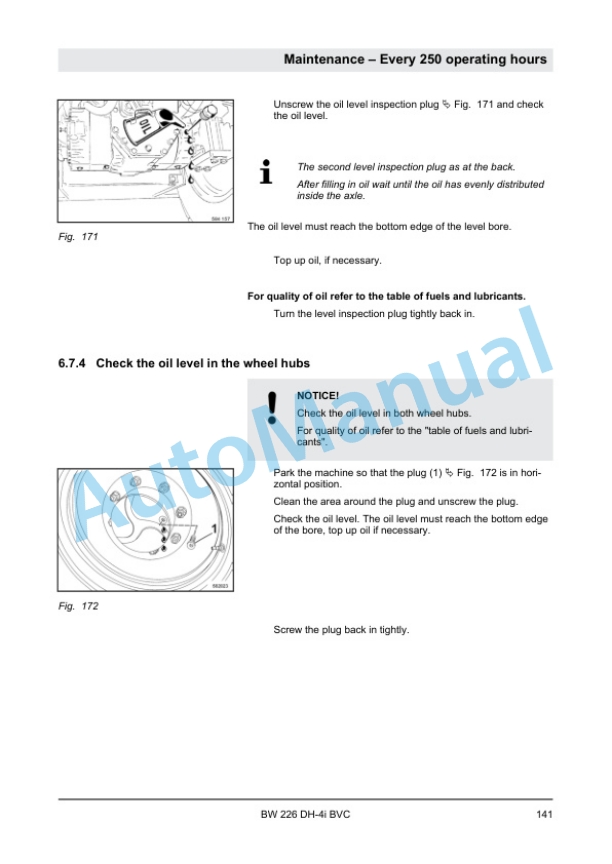

- 7.7.3. Check the oil level in the drive axle

- 7.7.4. Check the oil level in the wheel hubs

- 7.7.5. Check the oil level in the axle reduction gear

- 7.7.6. Check the oil level in the drum reduction gear

- 7.7.7. Check the parking brake

- 7.7.8. Servicing the Vbelt for the aircon compressorOptional equipment

- 7.8. Every 500 operating hours

- 7.8.1. Change engine oil and oil filter cartridge

- 7.8.2. Check the antifreeze concentration and the condition of the coolant

- 7.8.3. Checking, cleaning the water separator

- 7.8.4. Draining the sludge from the fuel tank

- 7.8.5. Battery service

- 7.8.6. Servicing the air conditioning systemoptional equipment

- 7.8.7. Cleaning the circulation air filter for the heatingOptional equipment

- 7.8.8. Changing the bypass filterOptional equipment

- 7.9. Every 1000 operating hours

- 7.9.1. Checking / replacing the ribbed Vbelt

- 7.9.2. Replace the fuel filter cartridge

- 7.9.3. Change the fuel prefilter cartridge

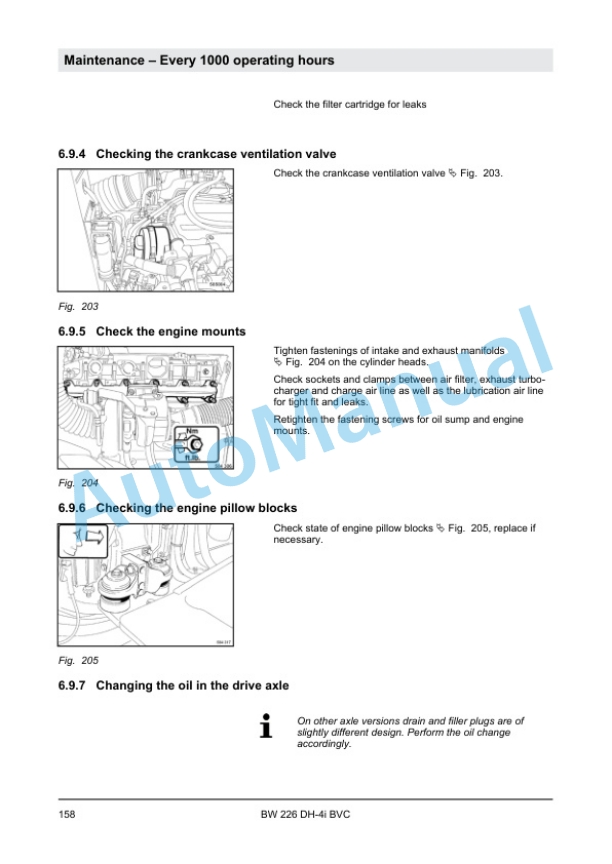

- 7.9.4. Checking the crankcase ventilation valve

- 7.9.5. Check the engine mounts

- 7.9.6. Checking the engine pillow blocks

- 7.9.7. Changing the oil in the drive axle

- 7.9.8. Changing the oil in the wheel hubs

- 7.9.9. Changing the oil in the axle reduction gear

- 7.9.10. Changing the oil in the drum reduction gear

- 7.9.11. Vario exciter oil change

- 7.9.12. Retighten the fastening of the axle on the frame

- 7.9.13. Tighten the wheel nuts

- 7.9.14. Check the ROPS

- 7.9.15. Check the travel control

- 7.10. Every 2000 operating hours

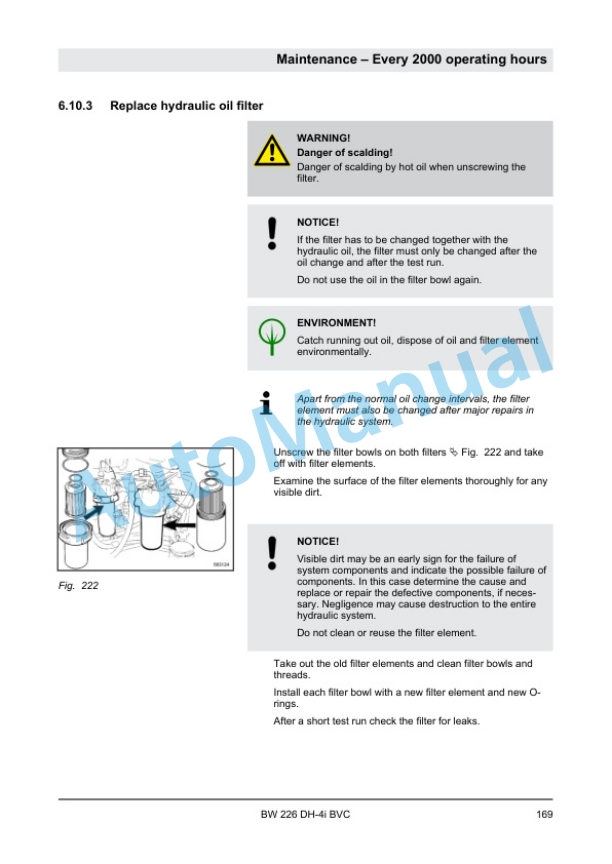

- 7.10.1. Adjust the valve clearance

- 7.10.2. Changing hydraulic oil and breather filter

- 7.10.3. Replace hydraulic oil filter

- 7.10.4. Changing the coolant

- 7.10.5. Replacing ribbed Vbelt and idler pulley

- 7.10.6. Checking the DBFburner

- 7.10.7. Checking, cleaning the components of the exhaust gas aftertreatment system

- 7.11. Every 4000 operating hours

- 7.11.1. Servicing the DBFburner

- 7.12. Every 6000 operating hours

- 7.12.1. Replace the injection valves

- 7.12.2. Replace the crank case ventilation valve

- 7.13. As required

- 7.13.1. Air filter maintenance

- 7.13.2. Retightening the padfoot shell

- 7.13.3. Adjust the scrapers

- 7.13.4. Clean the machine

- 7.13.5. Change the tires

- 7.13.6. Change the fresh air filter in the cabin

- 7.13.7. Fill the provision tank for the windscreen washer systemOptional equipment

- 7.13.8. Tightening torques

- 7.13.9. Engine conservation

- 8. Trouble shooting

- 8.1. Preliminary remarks

- 8.2. Starting the engine with jump leads

- 8.3. Fault code display

- 8.4. Reading out faults BVC/BTM05

- 8.5. Fuse assignment

- 8.6. Engine faults

- 9. Cabin assembly before initial commissioning

- 9.1. Preparations

- 9.2. Cabin assembly

- 9.3. Final function tests and checks

- 10. Disposal

- 10.1. Final shutdown of machine

Rate this product

You may also like

Bomag Operator Manual PDF

Bomag BM 2000-60 Cold Milling Machine Operating and Maintenance Instructions 00806061

$20.00

Bomag Operator Manual PDF

Bomag BC 473 EB-3 Soil Compactor Operating and Maintenance Instructions 00820281

$20.00

Bomag Operator Manual PDF

$20.00

Bomag Operator Manual PDF

Bomag BM 2200-75 Cold Planer Operating and Maintenance Instructions 00820166

$20.00

Bomag Operator Manual PDF

$20.00

Bomag Operator Manual PDF

$20.00

Bomag Operator Manual PDF

$20.00

Bomag Operator Manual PDF

$20.00

Bomag Operator Manual PDF

Bomag BPR 70-70 D Reversible Vibrating Plate Operating and Maintenance Instructions 00806761

$20.00