Bomag BW 226 DH-4i BVC Single Drum Roller Service Training 00892433

$30.00

- Type Of Manual: Service Training

- Manual ID: 00892433

- Format: PDF

- Size: 35.3MB

- Number of Pages: 752

- Serial Number:

10158501, 10158544

Category: Bomag Service Manual PDF

-

Model List:

- BW 226 DH-4i BVC Single Drum Roller

- 1. BW 226 DH4i

- 2. Single drum roller

- 3. Introduction

- 4. Safety regulations

- 5. General repair instructions

- 6. Tightening torques

- 7. BOMAG single drum rollers

- 8. Technical data

- 9. General notes on maintenance

- 10. Fuels and lubricants

- 11. Table of fuels and lubricants

- 12. Runningin instructions

- 13. Maintenance table

- 14. Overview

- 15. Acceleration transducer

- 16. Battery service

- 17. Starting the engine with jump leads

- 18. Main battery switch

- 19. Overview of electric components

- 20. Description of indicators and control elements

- 21. Fuse assignment

- 22. Electronic control units

- 23. Checking the voltage supply for the control unit

- 24. Diagnostics concept

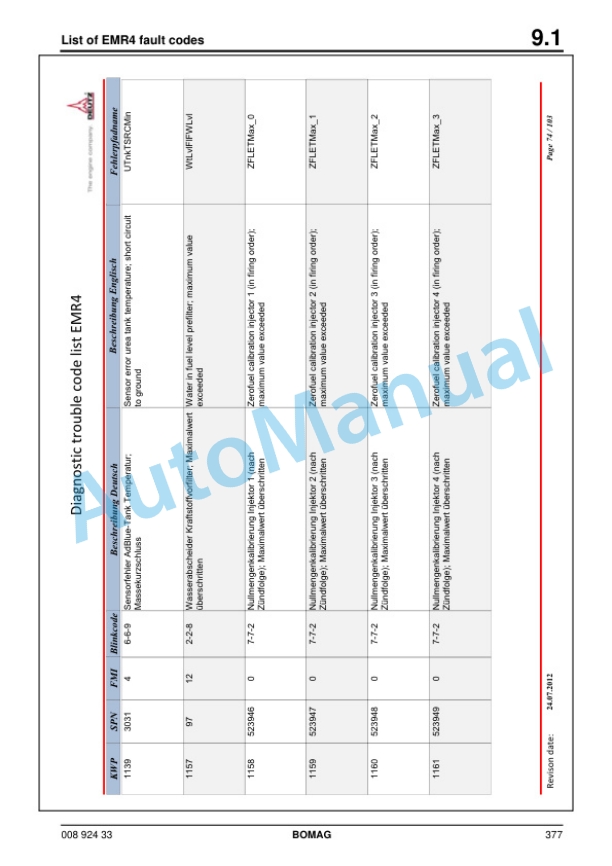

- 25. EMR4 system overview

- 26. EMR4 system components

- 27. Fuel control unit (FCU)

- 28. Injector

- 29. Crankshaft speed sensor

- 30. Camshaft speed sensor

- 31. Rail pressure sensor

- 32. EMR coolant temperature sensor

- 33. Fuel pressure sensor

- 34. Charge air temperature charge air pressure sensor

- 35. Oil pressure sensor

- 36. Sensor, water in fuel

- 37. Fuel preheating

- 38. Heating flange on engine

- 39. Rotary switch for engine speed

- 40. Data collector

- 41. Fault display

- 42. Variocontrol

- 43. Control circuit and MESX

- 44. Acceleration transducer

- 45. Potentiometer on the slewing motor, B62

- 46. Display and control elements Variocontrol

- 47. Description of indicating and control elements Variocontrol

- 48. BVC/BTM05 settings before startup

- 49. Variocontrol, selecting the operating mode

- 50. Variocontrol, selecting the operating mode

- 51. Variocontrol, selecting the operating mode

- 52. Measuring pass with Variocontrol

- 53. Teaching distance pulses

- 54. Amplitude limitation (BVC only)

- 55. Hydraulic circuit

- 56. Travel and vibration pump, H1

- 57. Troubleshooting axial piston pumps

- 58. Travel motor 51 C/D 110

- 59. Vibration motor A2FM80

- 60. Trouble shooting, variable displacement axial piston motor

- 61. External gear pumps

- 62. Slewing motor

- 63. Travel circuit

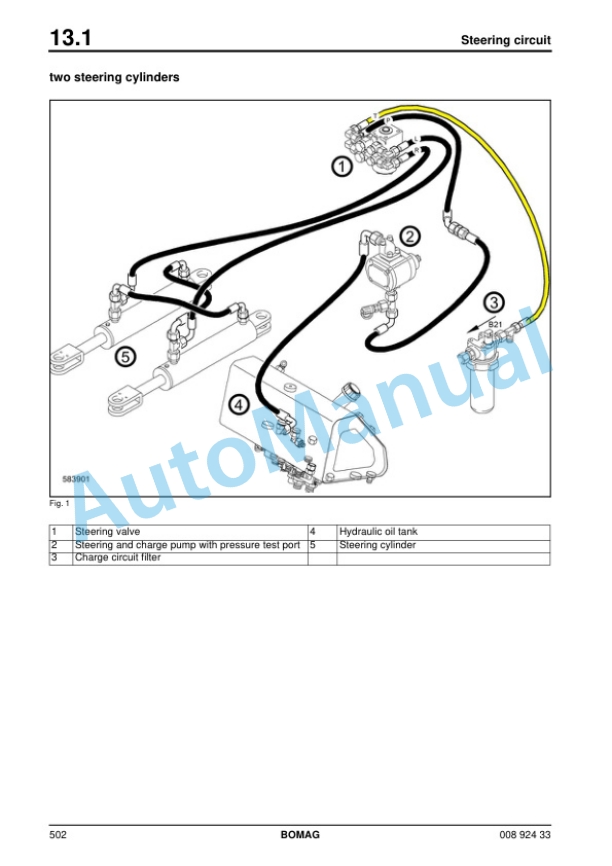

- 64. Towing in case of an engine failure

- 65. Adjust the parking brake

- 66. Change the oil in the drive axle

- 67. Changing the oil in the wheel hubs

- 68. Changing the oil in the axle reduction gear

- 69. Change the oil in the drum reduction gear

- 70. Vibration circuit

- 71. Vario exciter oil change

- 72. Check the hydraulic oil level

- 73. Changing hydraulic oil and breather filter

- 74. Replace hydraulic oil filter

- 75. Changing the bypass filter

- 76. Steering circuit

- 77. Electric steering wheel

- 78. Steering circuit

- 79. Special tools, tests and adjustments

- 80. Activate service mode

- 81. Driving against the closed brake

- 82. Turn the steering against an end stop.

- 83. Check the leakage rate of the vibration motor

- 84. Pressure test in steering circuit

- 85. Special tools for flushing

- 86. Flushing general

- 87. Flushing schematic travel circuit (distribution axle motor)

- 88. Flushing the travel circuit (axle motor distribution)

- 89. Flushing schematic for vibration drive

- 90. Flushing the vibration circuit

- 91. Bleeding the travel circuit

- 92. Bleeding the vibration circuit

- 93. Diesel engine

- 94. Engine description TCD 6.1 L6

- 95. Lubrication oil circuit TCD 4.1 / 6.1

- 96. Coolant circuit TCD 4.1 / 6.1

- 97. Common Rail System (CRS) TCD 4.1 / 6.1

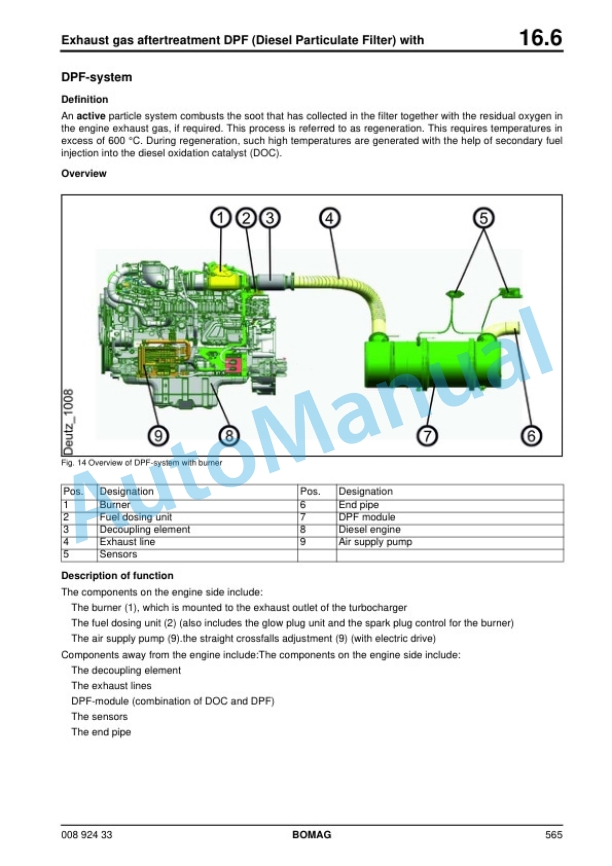

- 98. Exhaust gas aftertreatment DPF (Diesel Particulate Filter) with burner

- 99. DPFregeneration

- 100. Adjust the valve clearance

- 101. Check the engine oil level

- 102. Changing engine oil and oil filter cartridge

- 103. Check the coolant level

- 104. Check the antifreeze concentration and the condition of the coolant

- 105. Changing the coolant

- 106. Checking, cleaning the water separator

- 107. Replace the fuel filter cartridge

- 108. Change the fuel filter, bleed the fuel system

- 109. Replacing ribbed Vbelt and idler pulley

- 110. Air filter maintenance

- 111. Checking the DBFburner

- 112. Servicing the DBFburner

- 113. Checking the crankcase ventilation valve

- 114. Engine problems

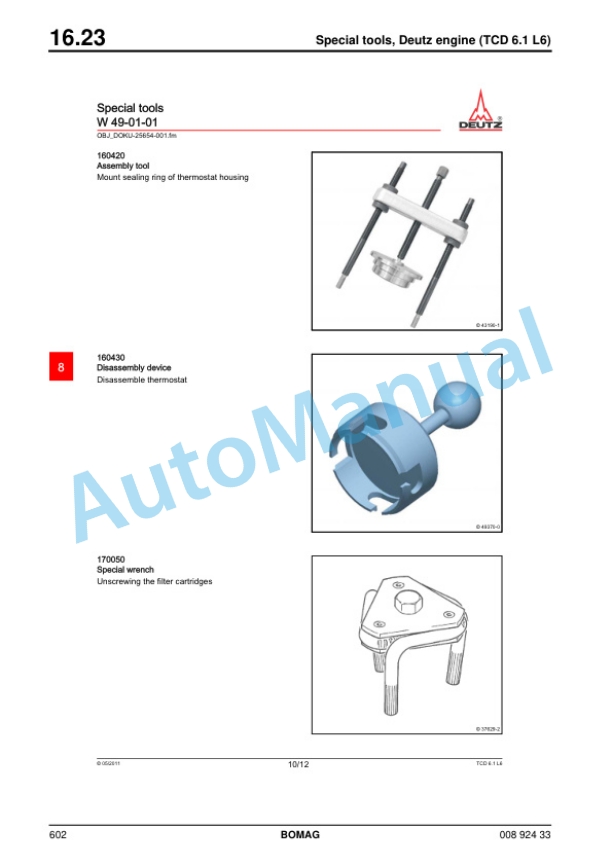

- 115. Special tools, Deutz engine (TCD 6.1 L6)

- 116. Overview

- 117. Physical basics

- 118. Refrigerant R134a

- 119. Compressor oil / refrigeration oil

- 120. Working principle of the air conditioning system

- 121. Monitoring devices

- 122. Description of components

- 123. Measuring the compressor oil level

- 124. Checking the magnetic clutch

- 125. Inspection and maintenance work

- 126. Servicing the Vbelt for the air con compressor

- 127. Service the air conditioning

- 128. Drying and evacuation

- 129. Emptying in case of repair

- 130. Leak test

- 131. Filling instructions

- 132. Trouble shooting in refrigerant circuit, basic principles

- 133. Trouble shooting, refrigerant circuit diagram

- 134. Trouble shooting procedure

- 135. Steam table for R134a

Rate this product

You may also like

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930051001 – 101930051010

$30.00

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930011002 – 101930011011

$30.00

Bomag Service Manual PDF

Bomag BC 463 RB-3 Refuse Compactor Electric Schematics Diagram 101930121001 – 101930129999

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930001002 – 101930001058

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00