Bomag BW 80 AD-5 to BW 100 SCC-5 Tandem Vibratory Roller Service Manual 00891737

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00891737

- Format: PDF

- Size: 31.7MB

- Number of Pages: 420

- Serial Number:

10146200 and up

10146201 and up

10146203 and up

10146205 and up

10146207 and up

10146204 and up

10146206 and up

Category: Bomag Service Manual PDF

-

Model List:

- BW 80 AD-5 Tandem Vibratory Roller

- BW 90 AD-5 Tandem Vibratory Roller

- BW 100 ADM-5 Tandem Vibratory Roller

- BW 90 SC-5 Tandem Vibratory Roller

- BW 100 SC-5 Tandem Vibratory Roller

- BW 100 ACM-5 Tandem Vibratory Roller

- BW 100 SCC-5 Tandem Vibratory Roller

- 1. BW 80 AD5/BW 90 AD5/BW 100 ADM5

- 1.1. BW 80 AD5/BW 90 AD5/BW 100 ADM5

- 2. General

- 2.1. General

- 2.2. Introduction

- 2.3. General

- 2.4. General

- 2.5. Transport work with cranes and lifting tackle

- 2.6. Precautions and codes of conduct for welding work

- 2.7. Operation of highvoltage systems

- 2.8. Old oils

- 2.9. Hydraulics

- 2.10. Hot fuels

- 2.11. Synthetic rubber

- 2.12. Poisonous substances

- 2.13. Battery

- 2.14. Special safety regulations

- 2.15. The values specified in the table apply for screws

- 2.16. The values specified in the table apply for screws

- 2.17. The values specified in the table apply for screws

- 2.18. The values specified in the table apply for screws

- 2.19. The values specified in the table apply for screws

- 2.20. The values specified in the table apply for screws

- 2.21. The values specified in the table apply for screws

- 2.22. The values specified in the table apply for screws

- 2.23. The values specified in the table apply for screws

- 2.24. The values specified in the table apply for screws

- 2.25. The values specified in the table apply for screws

- 2.26. The values specified in the table apply for screws

- 2.27. The values specified in the table apply for screws

- 3. The series 5

- 3.1. The series 5

- 4. Technical data

- 4.1. Technical data

- 4.2.

- 4.3.

- 5. Maintenance

- 5.1. Maintenance

- 5.2. General notes on maintenance

- 5.3. Fuels and lubricants

- 5.4. Coolant

- 5.5. Mineral oil based hydraulic oil

- 5.6. Biodegradable hydraulic oil

- 6. Overall view of machine

- 6.1. Overall view of machine

- 7. Electrics

- 7.1. Electrics

- 7.2. Battery service

- 7.3. Starting with jump wires

- 7.4.

- 7.5.

- 7.6.

- 7.7.

- 7.8.

- 7.9.

- 7.10.

- 7.11.

- 7.12.

- 7.13.

- 7.14.

- 7.15.

- 7.16.

- 7.17.

- 7.18.

- 7.19.

- 7.20.

- 7.21.

- 7.22.

- 7.23.

- 7.24. S53 Rotary switch for working lights

- 7.25.

- 8. Engine

- 8.1. Engine

- 8.2. Checking the engine oil level

- 8.3. Checking the engine oil level

- 8.4. Changing engine oil and oil filter

- 8.5. Checking the coolant level

- 8.6. Changing the coolant

- 8.7. Check radiator hoses and hose clamps

- 8.8. Cleaning radiator and hydraulic oil cooler

- 8.9. Checking, tensioning, replacing the Vbelt

- 8.10. Checking, cleaning the air filter, replacing if necessary

- 8.11. Check the air intake lines

- 8.12. Checking, cleaning the water separator

- 8.13. Change the fuel filter

- 8.14. Checking fuel lines and clamps

- 8.15. Changing fuel lines

- 8.16. Checking, adjusting the valve clearance

- 8.17. Checking, adjusting the valve clearance

- 8.18. Checking, adjusting the valve clearance

- 8.19. Checking, adjusting the valve clearance

- 8.20. Checking, adjusting the valve clearance

- 8.21. Checking, adjusting the valve clearance

- 8.22. Checking, adjusting the valve clearance

- 9. Hydraulics

- 9.1. Hydraulics

- 9.2. Variable displacement pumps, A10VG18 HW A10VG28 HW

- 9.3. Variable displacement pumps, A10VG18 HW A10VG28 HW

- 9.4. Variable displacement pumps, A10VG18 HW A10VG28 HW

- 9.5. Swash plate principle, pump

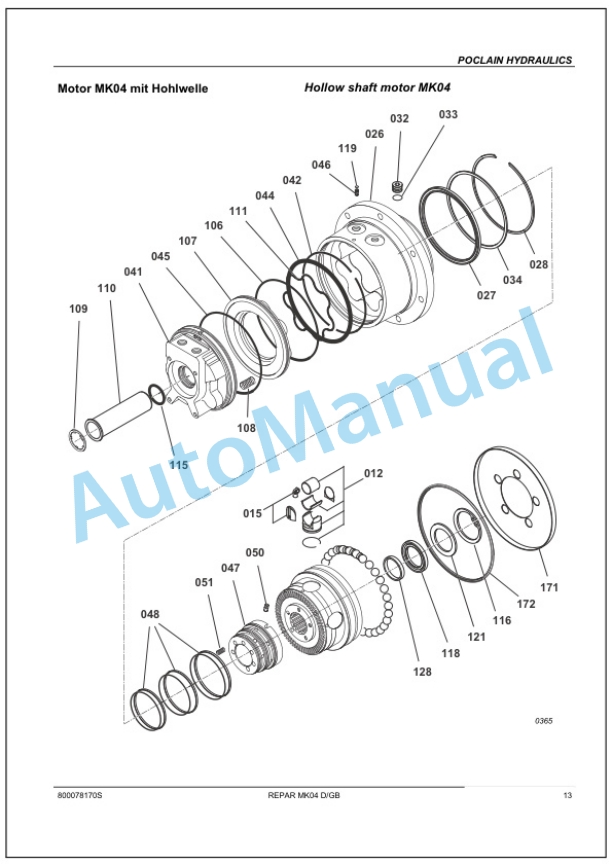

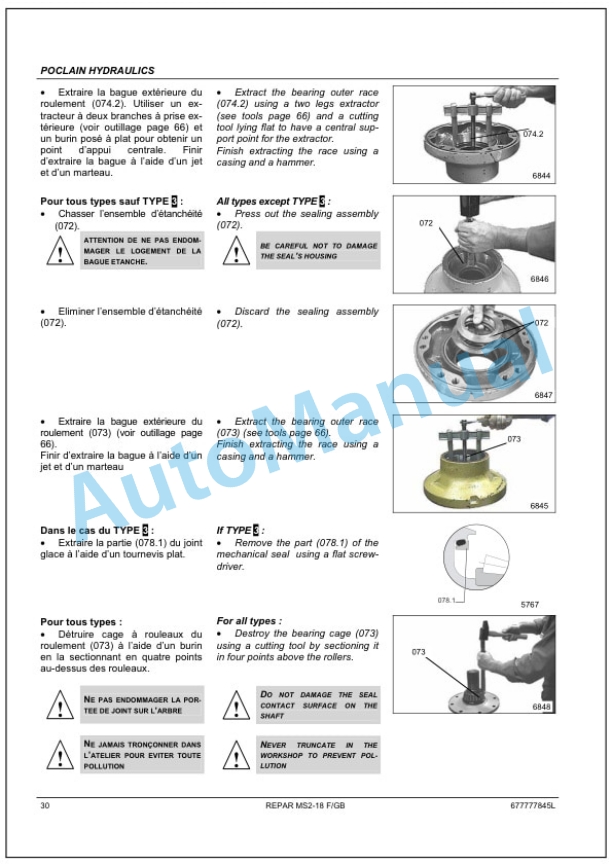

- 9.6. Operating principle of radial piston motor, MK

- 9.7. Operating principle of radial piston motor, MK

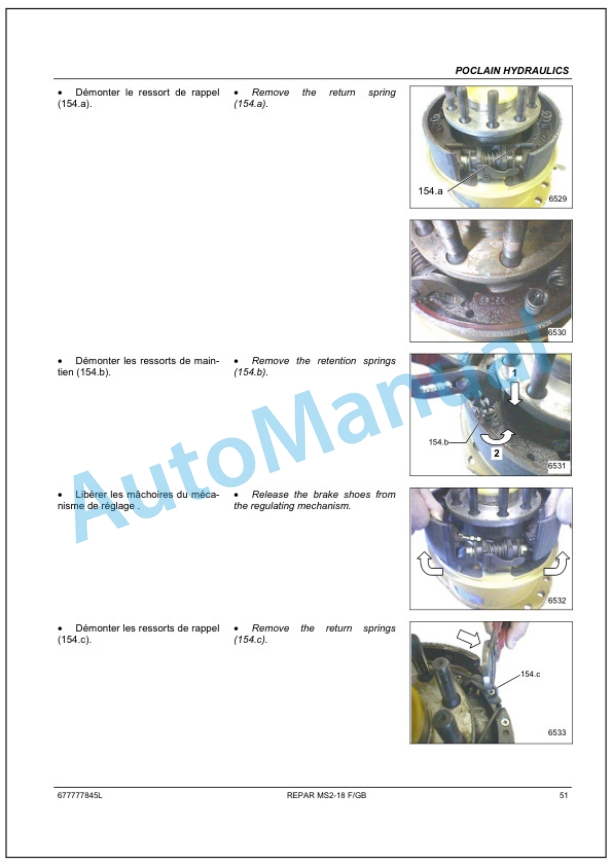

- 9.8. Functional principle radial piston motors, MS/MSE

- 9.9. Functional principle radial piston motors, MS/MSE

- 9.10. Outer gear motors nonreversible

- 9.11. Outer gear motors nonreversible

- 9.12. External gear pumps

- 9.13. External gear pumps

- 9.14. Towing

- 9.15. Towing

- 9.16. Towing

- 9.17. Checking the hydraulic oil level

- 9.18. Checking the hydraulic oil level

- 9.19. Changing the hydraulic oil

- 9.20. Checking the hydraulic oil filter element

- 9.21. Change the hydraulic oil filter

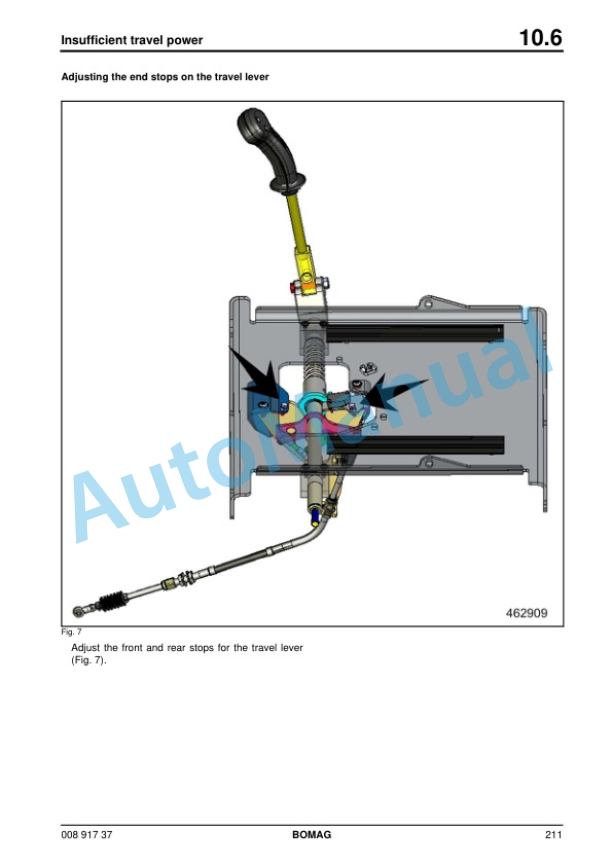

- 10. Tests and adjustments

- 10.1. Tests and adjustments

- 10.2. Checking the rotation speeds

- 10.3. Checking the rotation speeds

- 10.4. Pressure tests in the travel circuit

- 10.5. Checking / adjusting the neutral positions of the travel pump

- 10.6. Pressure test in the vibration circuit

- 10.7. Checking the leakage rate of the vibration motor

- 11. Trouble shooting

- 11.1. Trouble shooting

- 12. Flushing and bleeding

- 12.1. Flushing and bleeding

- 12.2. Special tools for flushing

- 12.3. Flushing schematic for travel system, AD/SCmachine

- 12.4. Flushing schematic for travel system, AD/SCmachine

- 13. Drum

- 13.1. Drum

- 13.2. Repair overview for drums

- 14. Oscillating articulated joint

- 14.1. Oscillating articulated joint

- 15. Suppliers documentation

- 15.1. Suppliers documentation

- 16. Circuit diagrams

- 16.1. Circuit diagrams

- 17.

- 17.1.

Rate this product

You may also like

Bomag Service Manual PDF

Bomag BC 473 RB-3 Refuse Compactor Electric Schematics Diagram 101930131001 – 101930139999

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930041001 – 101930041022

$30.00

Bomag Service Manual PDF

Bomag BC 473 EB-3 Refuse Compactor Electric Schematics Diagram 101930151001 – 101930159999

$30.00

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930051001 – 101930051010

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00