Clark C 60 D, C 70 D, C 75 D, C 80 D Service Manual SM-1157

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM-1157

- Format: PDF

- Size: 113.5MB

- Number of Pages: 1600

- Serial Number:

Doosan (T4)

Category: Clark Service Manual PDF

-

Model List:

- C 60 D

- C 70 D

- C 75 D

- C 80 D

- 1. SM1157

- 2. CONTENTS

- 3. GROUP SA SAFE MAINTENANCE

- 3.1. Section 1 Safety

- 3.2. Section 2 Lifting, Jacking, and Blocking the Truck

- 3.3. Section 3 Towing

- 4. GROUP PS PERIODIC SERVICE

- 4.1. Section 1 Maintenance Schedules

- 4.2. Section 2 The Planned Maintenance Program

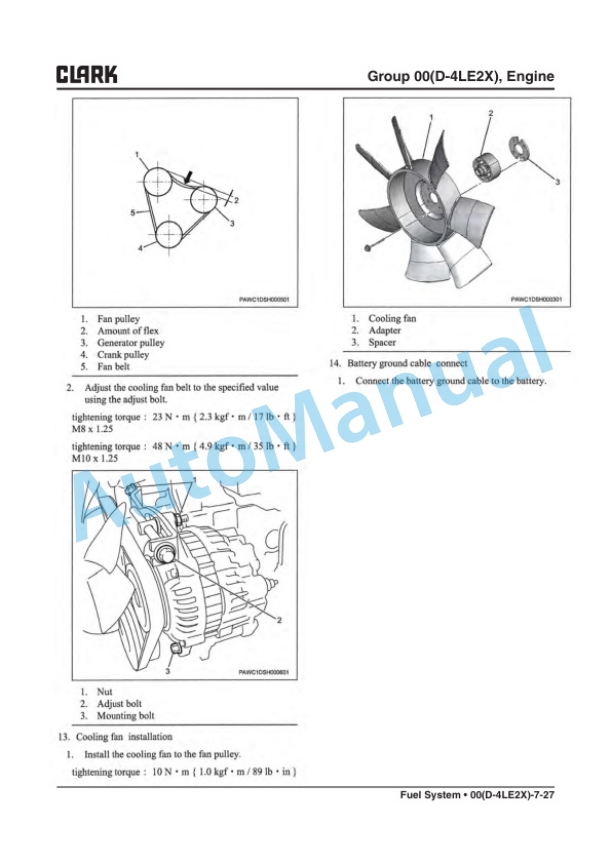

- 5. GROUP 00 ENGINE (Diesel Engine Model D34P (DooSan)

- 5.1. Section 1 General and Performance

- 5.2. Section 2 Regular Inspections

- 5.3. Section 3 General Engine Information

- 5.4. Section 4 Cooling System

- 5.5. Section 5 Lubrication System

- 5.6. Section 6 Fuel System

- 5.7. Section 7 Intake / Exhaust System

- 5.8. Section 8 Cylinder Block / Head

- 5.9. Section 9 Electrical System

- 5.10. Section 10 Other / Driving System

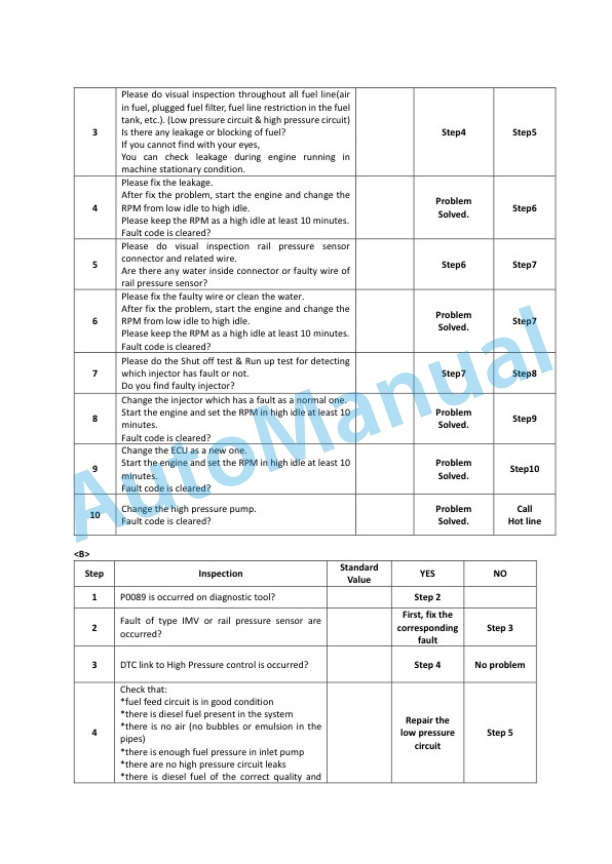

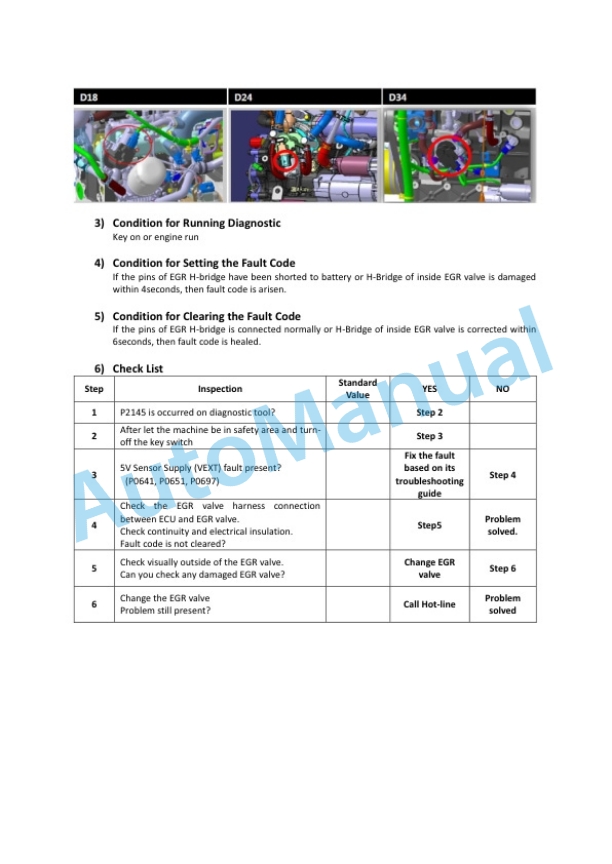

- 5.11. Section 11 DCU Error Code List

- 5.12. Section 12 ECU Error Code List

- 6. GROUP 01 ENGINE COOLING SYSTEM

- 6.1. Section 1 Specifications and Description

- 6.2. Section 2 Troubleshooting

- 6.3. Section 3 Testing and Maintenance

- 6.4. Section 4 Radiator Removal and Replacement

- 7. GROUP 03 INTAKE AND EXHAUST SYSTEM

- 7.1. Section 1 Specifications and Description

- 7.2. Section 2 Troubleshooting

- 7.3. Section 3 Intake System Service

- 7.4. Section 4 Exhaust Systems

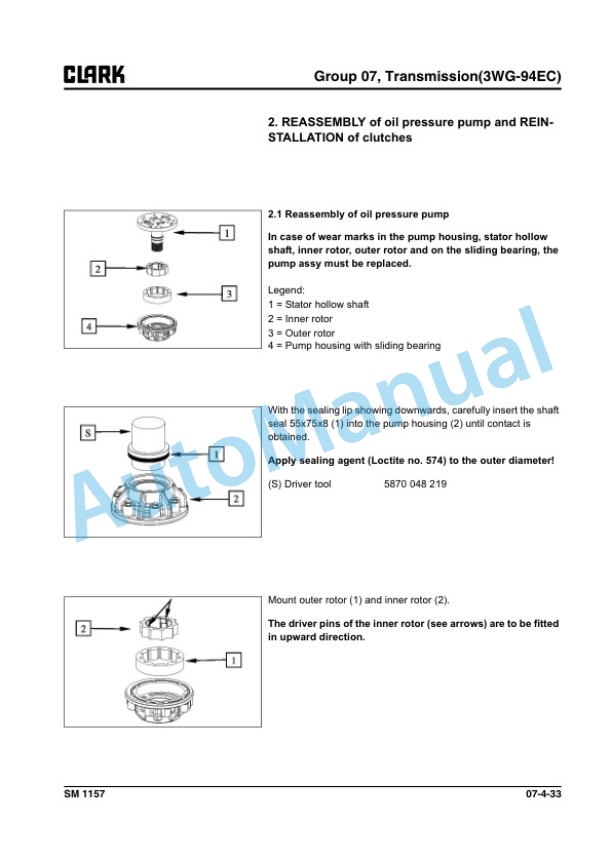

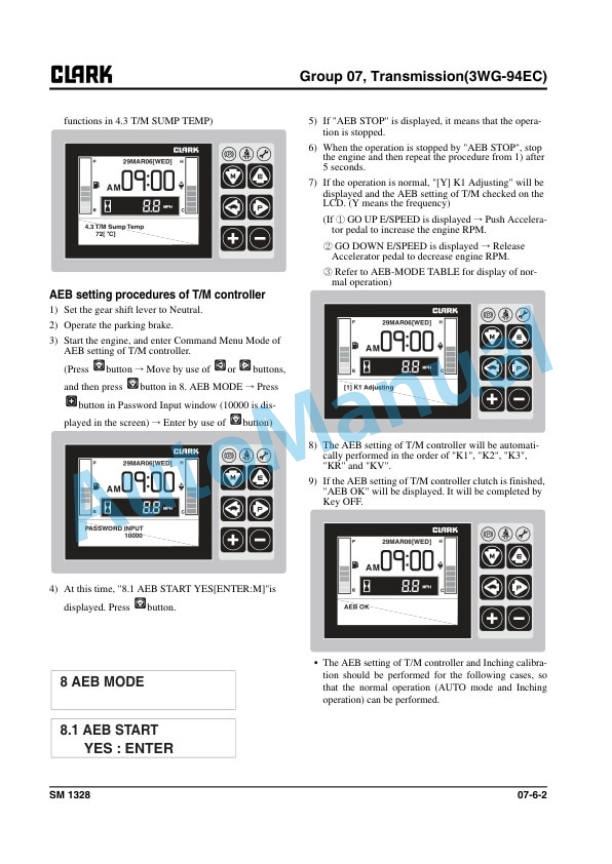

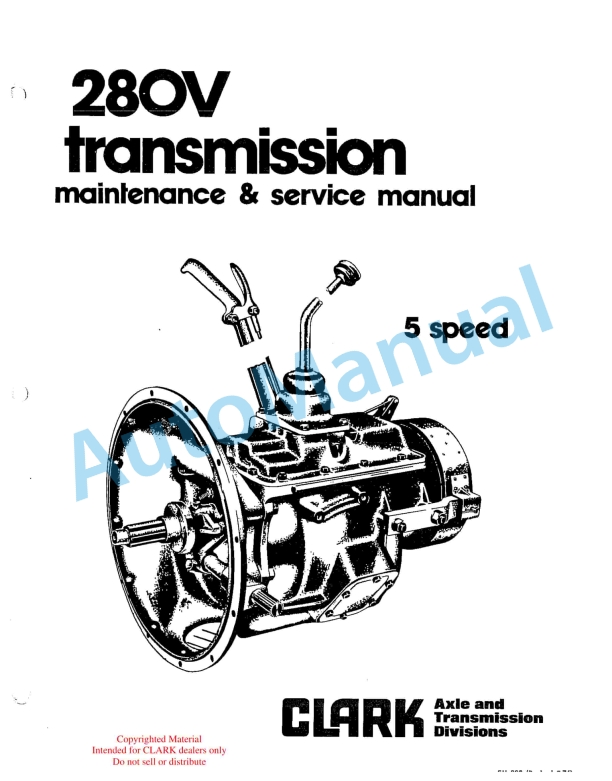

- 8. GROUP 07 TRANSMISSION Model 3WG94EC (for Diesel Truck)

- 8.1. Section 1 Layout (3WG94C)

- 8.2. Section 2 Measuring Points and Connections

- 8.3. Section 3 Disassembly

- 8.4. Section 4 Reassembly

- 8.5. Section 5 Removal and Installation

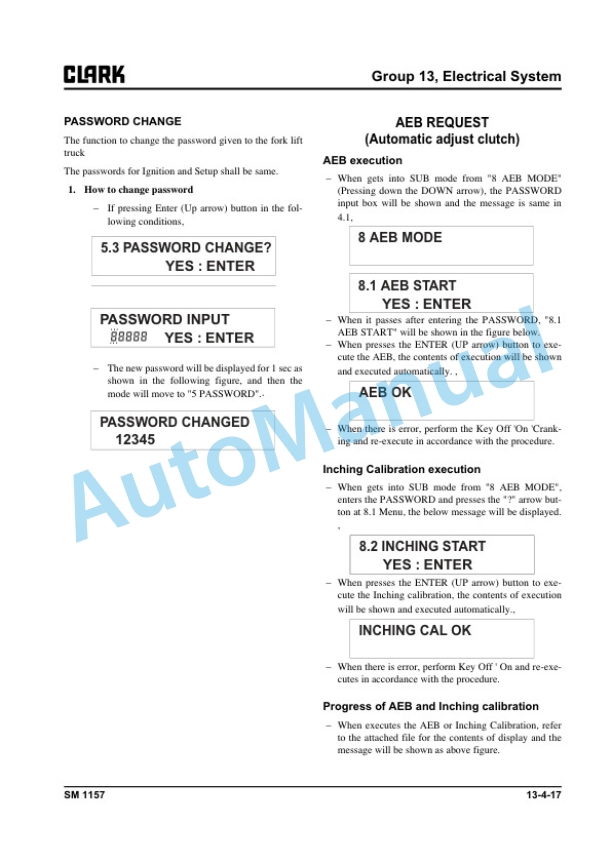

- 8.6. Section 6 AEB Setting of T/M Controller Clutch Inching Calibration

- 8.7. Section 7 Troubleshooting

- 9. GROUP 13 ELECTRICAL SYSTEM

- 9.1. Section 1 Electrical System Cautions

- 9.2. Section 2 Specifications and Features

- 9.3. Section 3 Electrical Circuit Diagram Electrical Parts Arrangement

- 9.4. Section 4 Instrument Pod

- 9.5. Section 5 Electrical Components Specification and Operation

- 9.6. Section 6 Air Conditioning System (Option)

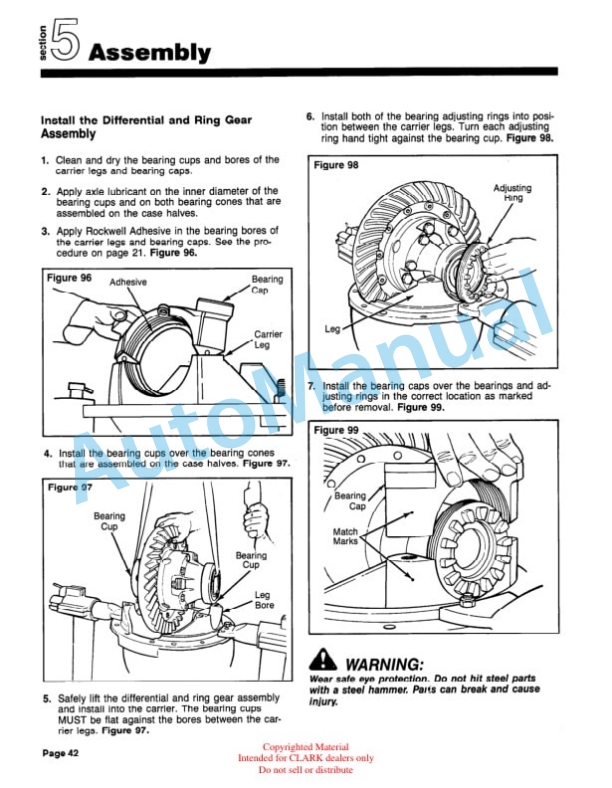

- 10. GROUP 20 (D) DRIVE AXLE

- 10.1. Section 1 System Operation

- 10.2. Section 2 Differential Carrier Assembly

- 10.3. Section 3 Drive Axle

- 10.4. Section 4 Problem and Cause

- 10.5. Section 5 Disassembly and Reassembly

- 10.6. Section 6 Removal and Installation

- 11. GROUP 22 WHEELS AND TIRES

- 11.1. Section 1 Specifications and Description

- 11.2. Section 2 Pneumatic Wheels and Tires

- 12. GROUP 23 BRAKE SYSTEM

- 12.1. Section 1 Braking / Inching System Specifications and Description

- 12.2. Section 2 Service Brake Troubleshooting

- 12.3. Section 3 Brake / Inching Pedals and Linkages Adjustments

- 12.4. Section 4 Brake System Bleeding

- 12.5. Section 5 Brake Valve Service

- 12.6. Section 6 Parking Brake Service

- 13. GROUP 25 STEERING COLUMN AND GEAR

- 13.1. Section 1 Specifications and Description

- 13.2. Section 2 Troubleshooting

- 13.3. Section 3 Steering Column and Component Removal and Replacement

- 13.4. Section 4 Steering System Relief Pressure Check and Adjustment

- 13.5. Section 5 Steering Gear Overhaul

- 14. GROUP 26 STEER AXLE

- 14.1. Section 1 Specifications and Description

- 14.2. Section 2 Steer Axle Bearing Maintenance and Adjustment

- 14.3. Section 3 Removal and Replacement

- 14.4. Section 4 Overhaul

- 14.5. Section 5 Steer Cylinder Removal and Replacement

- 14.6. Section 6 Steer Cylinder Overhaul

- 15. GROUP 29 HYDRAULIC SUMP, FILTERS, AND PUMP

- 15.1. Section 1 Specifications and Description

- 15.2. Section 2 Main Hydraulic Pump Troubleshooting

- 15.3. Section 3 Main Hydraulic Pump Removal and Installation

- 16. GROUP 31 HYDRAULIC CONTROL VALVE (DAESUNG NACHI)

- 16.1. Section 1 Operation of Hydraulic Control Valve

- 16.2. Section 2 Hydraulic Circuit

- 16.3. Section 3 Disassemblying Hydraulic Valve

- 16.4. Section 4 Assemblying Hydraulic Control Valve

- 16.5. Section 5 Hydraulic System Pressure Checks and Adjustments

- 16.6. Section 6 Hydraulic Control Valve Removal and Replacement

- 16.7. Section 7 Testing Hydraulic Valve

- 16.8. Section 8 EHL Valve Disassembly and Assembly

- 17. GROUP 32 TILT CYLINDERS

- 17.1. Section 1 Specifications and Description

- 17.2. Section 2 Checks and Adjustments

- 17.3. Section 3 Removal and Replacement

- 17.4. Section 4 Overhaul

- 18. GROUP 34 UPRIGHTS

- 18.1. Section 1 Specifications and Description

- 18.2. Section 2 Troubleshooting

- 18.3. Section 3 Inspection

- 18.4. Section 4 Carriage and Upright Roller Clearance Checks and Shim Adjustments

- 18.5. Section 5 Cylinder Removal, Shimming, Overhaul, and Replacement

- 18.6. Section 6 Chain Inspection, Adjustment, and Replacement

- 18.7. Section 7 Fork and Carriage Removal and Replacement

- 18.8. Section 8 Removal and Replacement

- 19. GROUP 38 COUNTERWEIGHT AND CHASSIS

- 19.1. Section 1 Specifications and Description

- 19.2. Section 2 Removal and Replacement

- 19.3. Section 3 Overhead Guard / Operators Cell Removal and Replacement

- 19.4. Section 4 Floorboard, Cowls, and Seat Deck Removal and Replacement

- 19.5. Section 5 Operators Seat Removal and Replacement

- 20. GROUP 40 SPECIFICATIONS

- 20.1. Section 1 Nameplates and Decals

- 20.2. Section 2 General Specifications

- 20.3. Section 3 Hydraulic Fitting Tightening Procedure

Rate this product

You may also like

Clark Service Manual PDF

$30.00

Clark Service Manual PDF

$30.00

Clark Service Manual PDF

$30.00

Clark Service Manual PDF

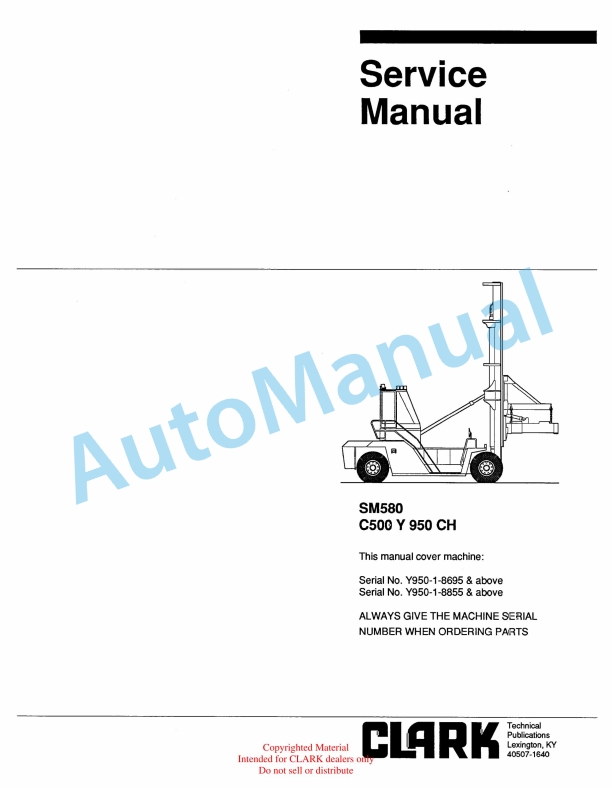

Clark C500 Y 180-200-225S-225L-250S-250L-300S-300L-350 Service Manual SM-575

$30.00