Clark C40, 45, 50s, 55s D, C40, 45, 50s, 55s L Service Manual SM-810

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM-810

- Format: PDF

- Size: 101.4MB

- Number of Pages: 968

Category: Clark Service Manual PDF

-

Model List:

- C 40 D

- C 45 D

- C 50s D

- C 55s D

- C 40 L

- C 45 L

- C 50s L

- C 55s L

- 1. SERVICE MANUAL

- 2. CONTENTS

- 3. GROUP SASAFE MAINTENANCE

- 3.1. Safety

- 3.2. Lifting, Jacking, and Blocking the Truck

- 3.3. Towing

- 4. GROUP PSPeriodic Service

- 4.1. Maintenance Schedules

- 4.2. The Planned Maintenance Program

- 5. GROUP 00(DIVECO) DIESEL ENGINE

- 5.1. General Specifications

- 5.2. Industrial Application

- 5.3. Overhaul And Technical Specifications

- 5.4. Tools

- 5.5. Engine Replacement

- 6. GROUP 00(DKubota) DIESEL ENGINE

- 6.1. GENERAL

- 6.2. CHECK AND MAINTENANCE

- 6.3. Mechanism

- 6.4. Servicing

- 7. GROUP 00(L)LPG Engine,GM V6 4.3L

- 7.1. ENGINE REMOVAL AND REPLACEMENT

- 7.2. V6 ENGINE REPAIR PROCEDURES

- 7.3. COOLING SYSTEM

- 8. GROUP 01Engine Cooling System

- 8.1. Specifications and Description

- 8.2. Troubleshooting

- 8.3. Testing and Maintenance

- 8.4. Radiator Removal and Replacemant

- 9. GROUP 02(LPTIER3)MI07 LP SYSTEM (GM V6 4.3)

- 9.1. Regulatory Compliance

- 9.2. LPG System Overview

- 9.3. Specifications

- 9.4. Recommended Maintenance

- 9.5. Installation Procedures

- 9.6. Tests And Adjustments

- 9.7. Basic Troubleshooting

- 9.8. Advanced Diagnostics

- 9.9. Parts Description

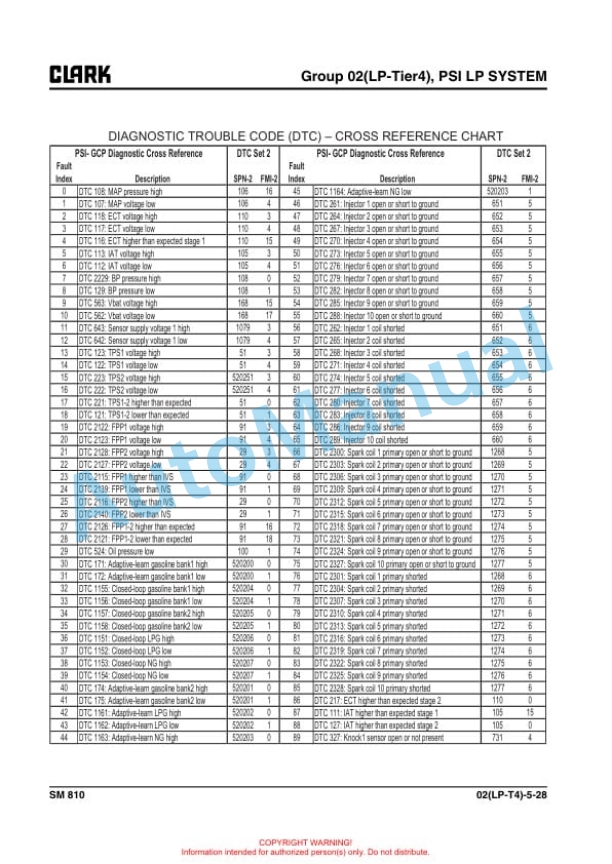

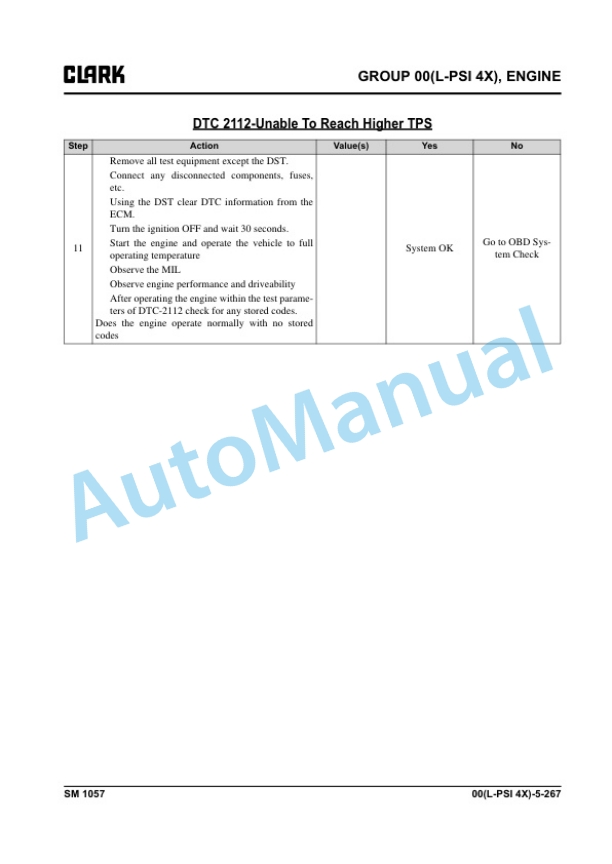

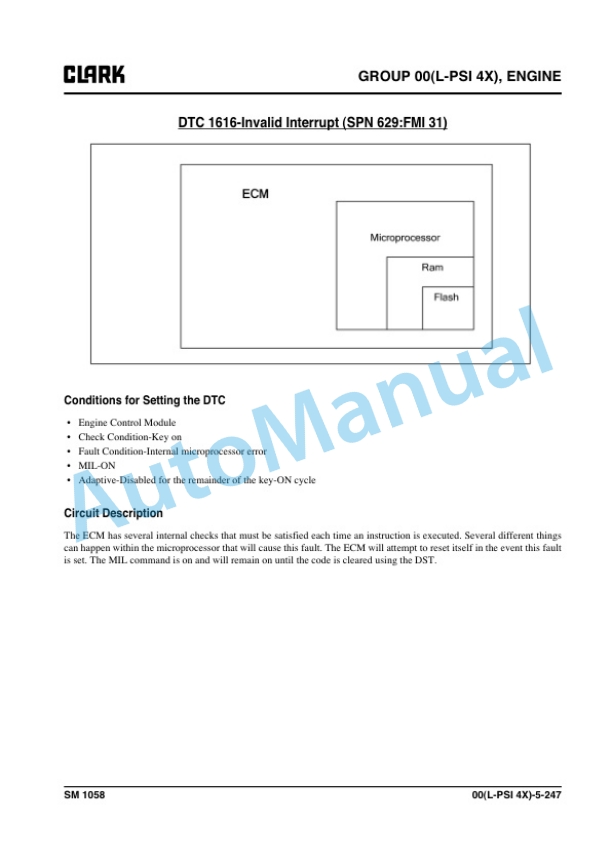

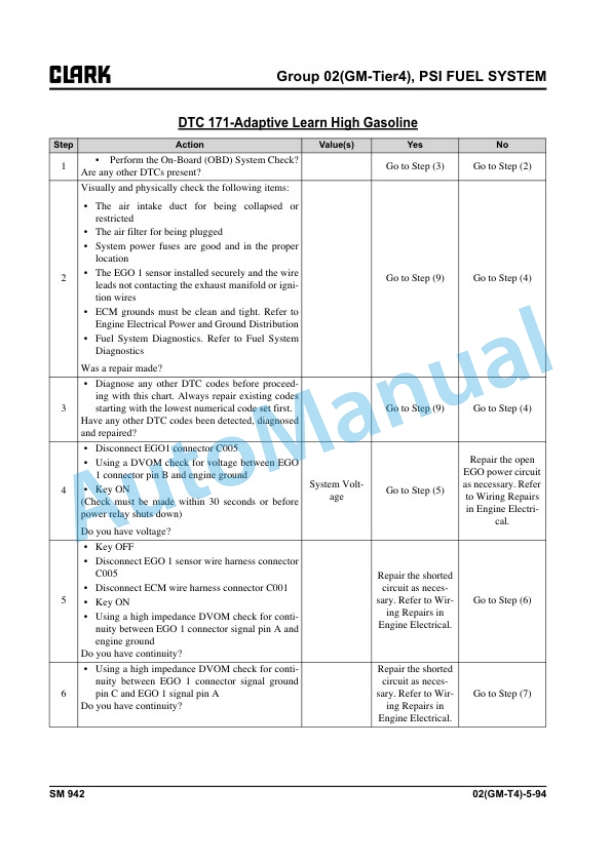

- 10. GROUP 02(LPTIER4)PSI LP SYSTEM (GM V6 4.3)

- 10.1. General Information

- 10.2. Maintenance

- 10.3. LPG Fuel System

- 10.4. Fuel System Diagnosis

- 10.5. Electrical Section

- 10.6. Definitions

- 11. GROUP 03Air Induction and Exaust System

- 11.1. Specifications and Description

- 11.2. Troubleshooting

- 11.3. Air Induction System Service

- 11.4. Exhaust Systems

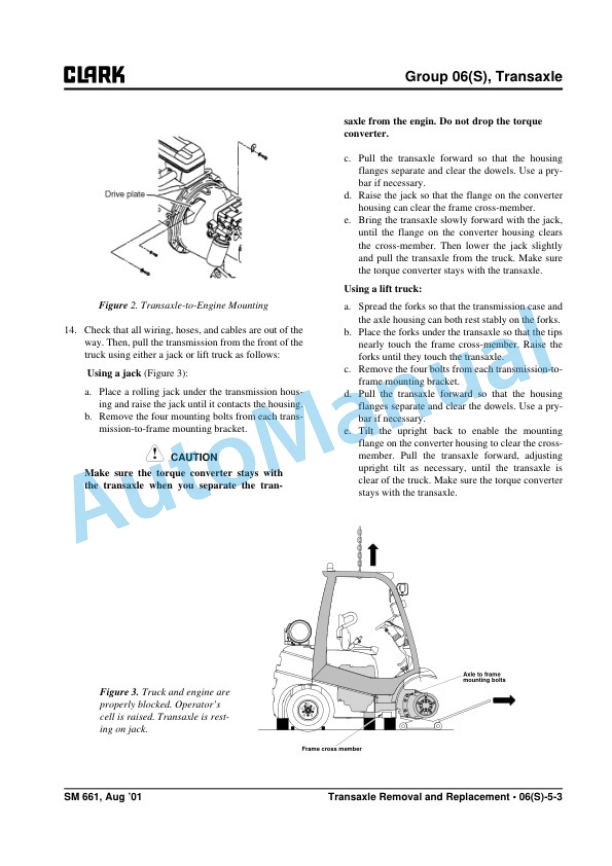

- 12. GROUP 06Tranmission

- 12.1. Torque Converter

- 12.2. Testing and Adjusting

- 12.3. Transmission Specifications

- 12.4. Transmission

- 12.5. Disassembly and Assemblyof the Control Valve

- 12.6. Transmission Disassembly andAssembly

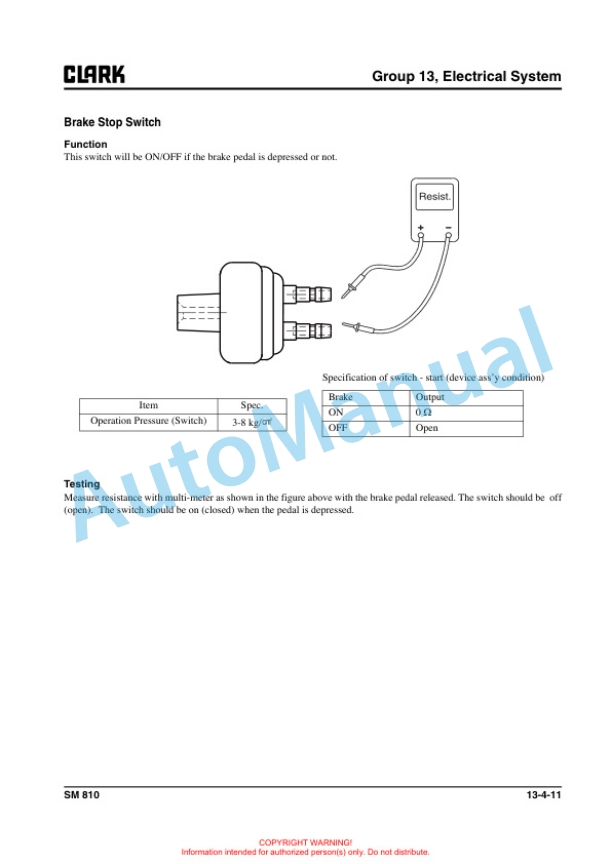

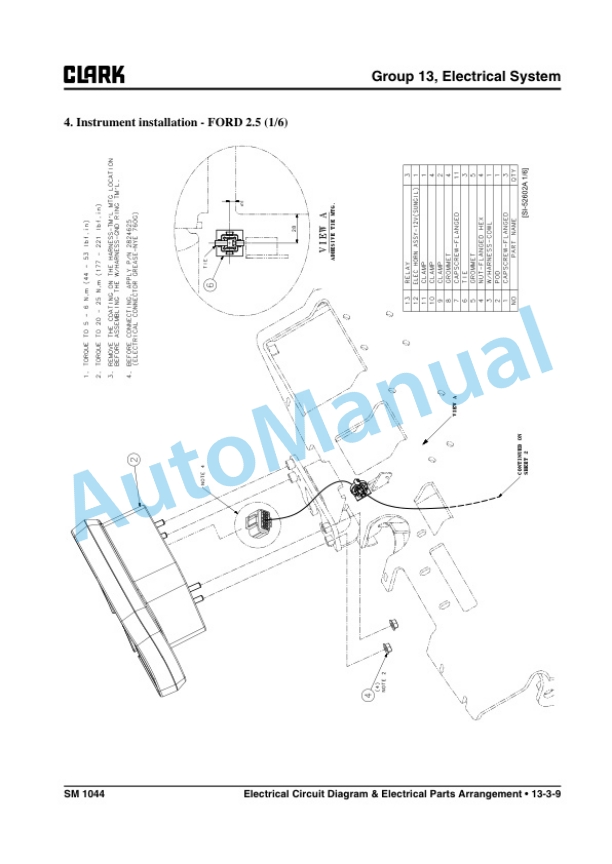

- 13. GROUP 13Electrical System

- 13.1. Cautions for working on the electrical system

- 13.2. Specifications and features of electrical system

- 13.3. Electrical Circuit Diagram Electrical Parts Arrangement

- 13.4. Electrical Components Specification and Operation

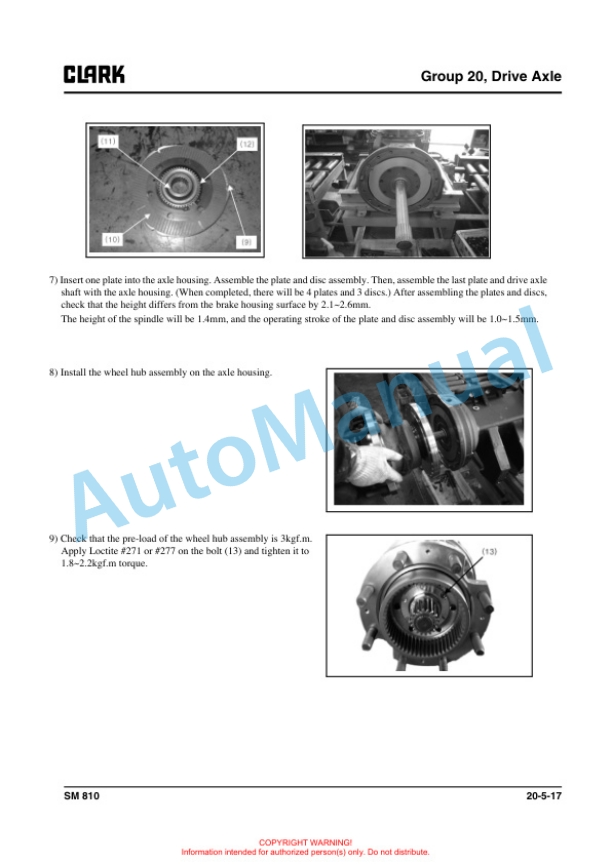

- 14. GROUP 20DRIVE AXLE

- 14.1. Introduction

- 14.2. Differential Carrier Assembly

- 14.3. Drive Axle

- 14.4. Troubleshooting

- 14.5. Disassembly and Assembly

- 15. GROUP 22Wheels and Tires

- 15.1. Specifications and Description

- 15.2. Wheels and Tires

- 16. GROUP 23Brake System

- 16.1. Specifications and Description

- 16.2. Troubleshooting

- 16.3. Brake/Inching Pedals and Linkages Adjustments

- 16.4. Brake System Bleeding

- 16.5. Brake Master Cylinder Service

- 16.6. Parking Brake Service

- 17. GROUP 25Steering Column and Gear

- 17.1. Specifications and Description

- 17.2. Troubleshooting

- 17.3. Steering Column and ComponentRemoval and Replacement

- 17.4. Steering System Relief Pressure Checkand Adjustment

- 17.5. Steering Gear Overhaul

- 18. GROUP 26Steer Axle

- 18.1. Steering Axle Specificationsand Description

- 18.2. Steer Axle WheelBearing Maintenance and Adjustment

- 18.3. Steer Axle Removal and Replacement

- 18.4. Steer Axle Overhaul

- 18.5. Steer Cylinder Removal and Replacement

- 18.6. Steer Cylinder Overhaul

- 19. GROUP 29Hydraulic Sump, Filters, and Pump

- 19.1. Specifications and Description

- 19.2. Main Hydraulic Pump Troubleshooting

- 19.3. Hydraulic Filters andFluid Maintenance and Change

- 20. GROUP 30Hydraulic Control Valve (Daesung Nachi)

- 20.1. Operation of Hydraulic Control Valve

- 20.2. Hydraulic Circuit

- 20.3. Disassembling Hydraulic Valve

- 20.4. Assembling Hydraulic Control Valve

- 20.5. Testing Hydraulic Valve

- 21. GROUP 32Tilt Cylinders

- 21.1. Tilt Cylinder Specifications and Description

- 21.2. Tilt Cylinder Checks and Adjustments

- 21.3. Tilt Cylinder Removal and Replacement

- 21.4. Tilt Cylinder Overhaul

- 22. GROUP 34Uprights

- 22.1. Specifications and Description

- 22.2. Troubleshooting

- 22.3. Upright Inspection

- 22.4. Carriage and Upright Roller Clearance Checks and Shim

- 22.5. Cylinder Removal, Shimming, Overhaul, and Replacement

- 22.6. Upright Chain Inspection, Adjustment, and Replacement

- 22.7. Fork and Carriage Removal and Replacement

- 22.8. Upright Removal and Replacement

- 23. GROUP 38Counterweight and Chassis

- 23.1. Specifications and Description

- 23.2. Counterweight Removal and Replacement

- 23.3. Overhead Guard/Operators Cell Removal and Replacement

- 23.4. Floorboard, Cowls, Radiator Cover, and Seat Deck Removal and Replacement

- 24. GROUP 40SPECIFICATIONS

- 24.1. Nameplates and Decals

- 24.2. General Specifications

- 24.3. Hydraulic Fitting TighteningProcedures

Rate this product

You may also like

Clark Service Manual PDF

Clark 21 D Series Planetary Drive Axle Maintenance and Service Manual SM-21D

$30.00

Clark Service Manual PDF

Clark C 40, 45, 50s, 55s D, C 40, 45, 50s, 55s L Service Manual SM-942

$30.00

Clark Service Manual PDF

Clark C 20, 25, 30, 35 L-G, C 20, 25, 30, 32C L Service Manual SM-1044

$30.00