Clark G127, GP127, G127E, GP127E Service Manual SM-619

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM-619

- Format: PDF

- Size: 21.9MB

- Number of Pages: 389

Category: Clark Service Manual PDF

-

Model List:

- G127

- GP127

- G127E

- GP127E

- 1. Arrangement and Use of This Manual

- 2. Foreword

- 3. CONTENTS

- 4. SA SAFE MAINTENANCE

- 4.1. Section 1 Safety

- 4.1.1. Safety Signs and Messages

- 4.1.2. Safe Maintenance Practices

- 4.2. Section 2 Lifting, Jacking, and Blocking

- 4.2.1. Raising Drive Wheels

- 4.2.2. Chaining the Upright in Raised Position

- 4.2.3. Raising Rear of Truck

- 4.2.4. Raising Entire Truck

- 4.2.5. Shipping TieDown Instructions

- 4.3. Section 3 Towing

- 5. PS PERIODIC SERVICE

- 5.1. Section 1 Maintenance Schedules

- 5.1.1. Maintenance Schedules

- 5.1.2. Lubrication Chart Key

- 5.1.3. Miscellaneous Lubricants

- 5.2. Section 2 Planned Maintenance

- 5.2.1. PM Report Form

- 5.2.2. Visual Inspection

- 5.2.3. Wheels and Tires

- 5.2.4. Pneumatic tires

- 5.2.5. Functional Tests

- 5.2.6. Steering system

- 5.2.7. Lift mechanism and controls

- 5.2.8. Auxiliary function control

- 5.2.9. Test Drive The Truck

- 5.2.10. Inspect Engine Accessories

- 5.2.11. Air Cleaning

- 5.2.12. Critical Fastener Torque Checks

- 5.2.13. LUBRICATION, FLUIDS AND FILTERS

- 5.2.14. PLANNED MAINTENANCE INTERVALS

- 5.3. Section 3. The PM Inspection Form

- 5.3.1. GAS LPG or DIESEL PLANNED MAINTENANCE REPORT

- 6. ENGINES

- 6.1. ENGINE 0011

- 6.1.1. GENERAL DESCRIPTION

- 6.1.2. ENGINE TUNEUP

- 6.2. ENGINE 0021

- 6.2.1. CONTENTS

- 6.2.2. GENERAL DESCRIPTION

- 6.2.3. ENGINE TUNEUP

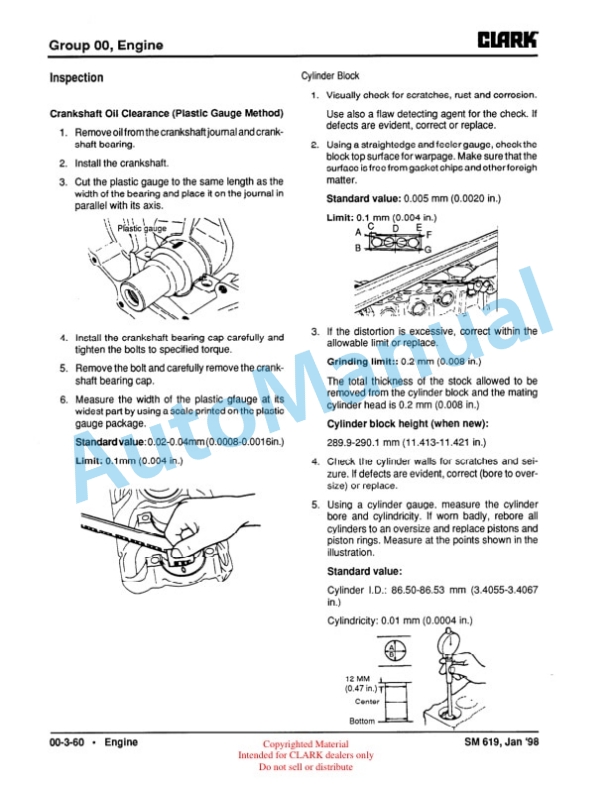

- 6.3. ENGINE 0031

- 6.3.1. Engine Specifications (4G63 Gas LPG Engine)

- 6.3.2. Engine Troubleshooting (4G63 Gas LPG Engine)

- 6.3.3. Engine Oil (4G63 Gas LPG Engine)

- 6.3.4. Engine TuneUp (4G63 Gas LPG Engine)

- 6.3.5. RPM, Vacuum, and Stall Tests (4G63 Gas LPG Engine)

- 6.3.6. Compression Checks (4G63 Gas LPG Engine)

- 6.3.7. ENGINE REMOVAL

- 6.3.8. Engine Overhaul (4G63 Gas LPG)

- 7. COOLING SYSTEM

- 7.1. SECTION 1 COOLING SYSTEM TROUBLESHOOTING

- 7.2. SECTION 2 COOLING SYSTEM

- 8. FUEL SYSTEMS

- 8.1. SECTION 01 FUEL SYSTEMGASOLINE

- 8.1.1. CARBURETOR

- 8.1.2. ENGINE IDLE SPEED ADJUSTMENT

- 8.1.3. GOVERNOR

- 8.1.4. GOVERNOR ADJUSTMENT PROCEDURE

- 8.1.5. CARBURETOR OVERHAUL

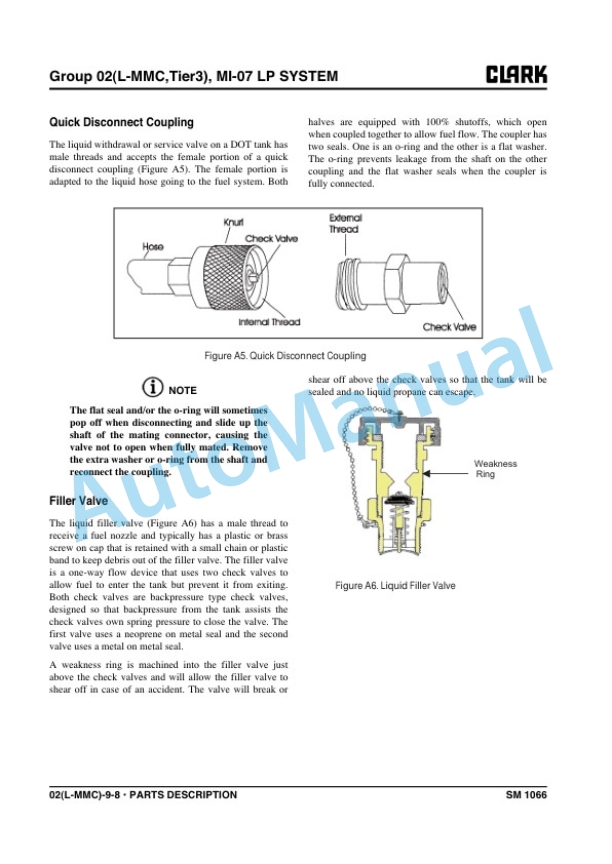

- 8.2. SECTION 02 FUEL SYSTEMLPG

- 8.2.1. GENERAL DESCRIPTION LPG FUEL SYSTEM

- 8.2.2. MAINTENANCE

- 8.2.3. CARBURETOR OVERHAUL

- 8.2.4. VAPOR REGULATOR OVERHAUL

- 8.2.5. LPG Air Intake System

- 9. TRANSAXLE

- 9.1. GENERAL DESCRIPTION

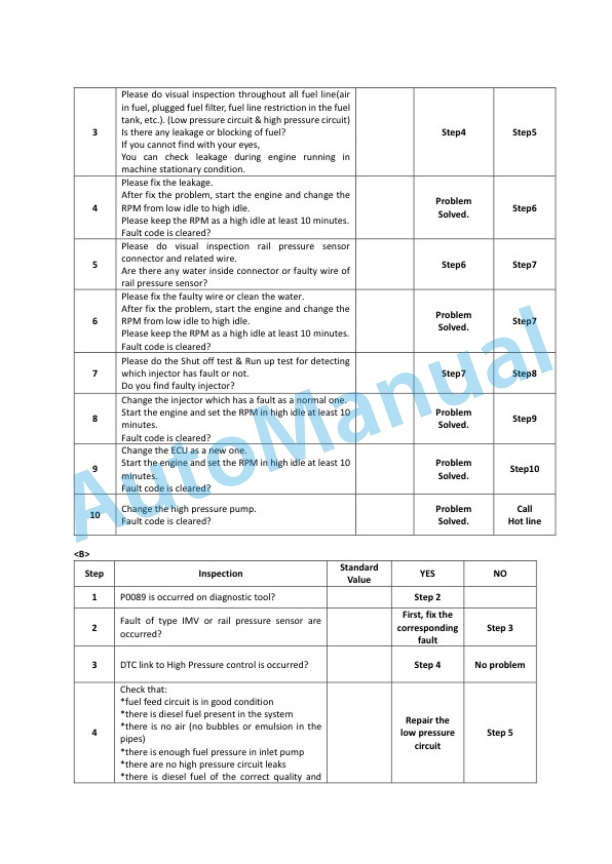

- 9.2. TRANSMISSION TROUBLESHOOTING

- 9.3. TRANSMISSION PRESSURE CHECKS

- 9.4. TRANSAXLE REMOVAL

- 9.5. TRANSAXLE OVERHAUL

- 9.5.1. TRANSAXLE DISASSEMBLY

- 9.5.2. CLUTCH DISASSEMBLY

- 9.5.3. CLUTCH ASSEMBLY

- 9.5.4. DIFFERENTIAL DISASSEMBLY

- 9.5.5. DIFFERENTIAL ASSEMBLY

- 9.5.6. TRANSAXLE ASSEMBLY

- 9.5.7. BRAKE ADJUSTMENT PROCEDURE

- 9.6. TRANSAXLE INSTALLATION

- 10. ELECTRICAL

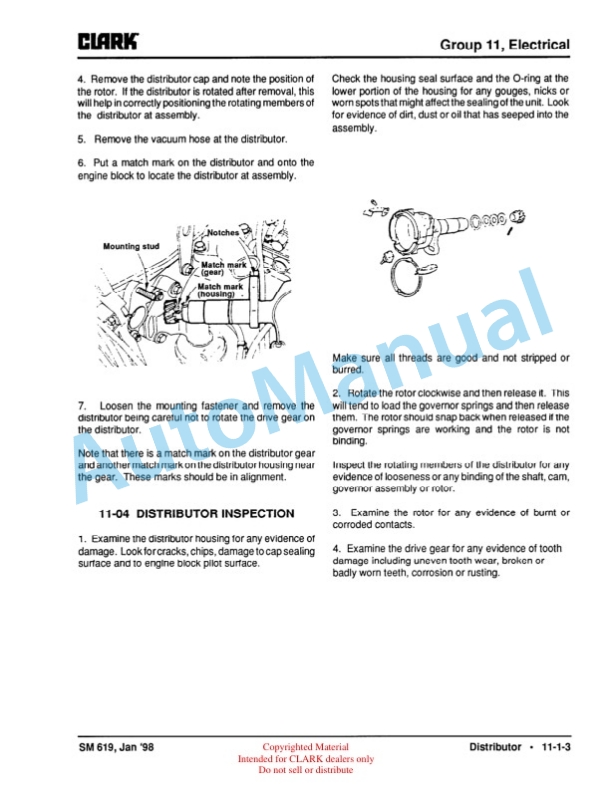

- 10.1. SECTION 1 DISTRIBUTOR 1.6L ENGINE

- 10.1.1. DISTRIBUTOR OVERVIEW

- 10.1.2. DISTRIBUTOR CHECKING

- 10.1.3. DISTRIBUTOR REMOVAL

- 10.1.4. DISTRIBUTOR INSPECTION

- 10.1.5. DISTRIBUTOR ASSEMBLY

- 10.2. SECTION 2 DISTRIBUTOR 2.0 ENGINE

- 10.2.1. DISTRIBUTOR OVERVIEW

- 10.2.2. DISTRIBUTOR TESTS

- 10.2.3. DISTRIBUTOR REMOVAL

- 10.2.4. DISTRIBUTOR INSPECTION

- 10.2.5. DISTRIBUTOR MAINTENANCE

- 10.2.6. DISTRIBUTOR INSTALLATION

- 11. ELECTRICAL

- 11.1. SECTION 1 ALTERNATOR

- 11.1.1. ALTERNATOR DESCRIPTION

- 11.1.2. ALTERNATOR INSPECTION

- 11.1.3. ALTERNATOR REMOVAL

- 11.1.4. ALTERNATOR OVERHAUL

- 11.1.5. ALTERNATOR INSTALLATION

- 11.2. SECTION 2 STARTER

- 11.2.1. STARTER OVERVIEW

- 11.2.2. STARTER INSPECTION (BEFORE REMOVAL)

- 11.2.3. STARTER REMOVAL

- 11.2.4. STARTER DISASSEMBLY

- 11.2.5. STARTER INSPECTION (AFTER REMOVAL)

- 11.2.6. STARTER ASSEMBLY

- 11.2.7. STARTER INSTALLATION

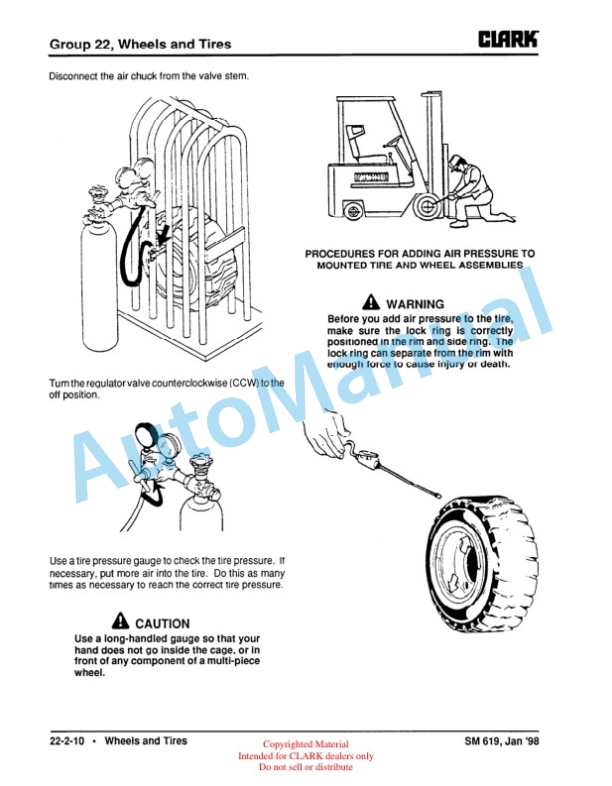

- 12. WHEELS AND TIRES

- 12.1. SECTION 1 CUSHION WHEELS AND TIRES

- 12.1.1. DRIVE TIRE SPECIFICATIONS

- 12.1.2. DRIVE TIRE REMOVAL

- 12.1.3. STEER TIRE SPECIFICATIONS

- 12.1.4. STEER TIRE REPLACEMENT

- 12.2. SECTION 2 PNEUMATIC TIRE AND WHEEL MAINTENANCE

- 12.2.1. PNEUMATIC TIRE MAINTENANCE

- 12.2.2. TIRE REMOVAL AND DISASSEMBLY

- 12.2.3. TIRE ASSEMBLY

- 12.2.4. FILLING TIRES WITH AIR

- 12.2.5. FILLING TIRES WITH NITROGEN

- 12.2.6. SPLIT WHEEL ASSEMBLIES

- 12.2.7. DIRECTIONALTREAD TIRES

- 12.2.8. SAFETY PROCEDURES

- 13. HYDRAULIC SERVICE BRAKE INCHING SYSTEM

- 13.1. GENERAL DESCRIPTION

- 13.2. BRAKE BLEEDING PROCEDURE

- 13.3. INCHING BRAKE

- 13.4. INCHING CYLINDER ADJUSTMENT

- 13.5. BRAKE MASTER CYLINDER PEDAL REMOVAL/DISASSEMBLY

- 13.6. BRAKE REASSEMBLY

- 13.7. HYDRAULIC BRAKE FLUID AND BLEEDING GENERAL INFORMATION

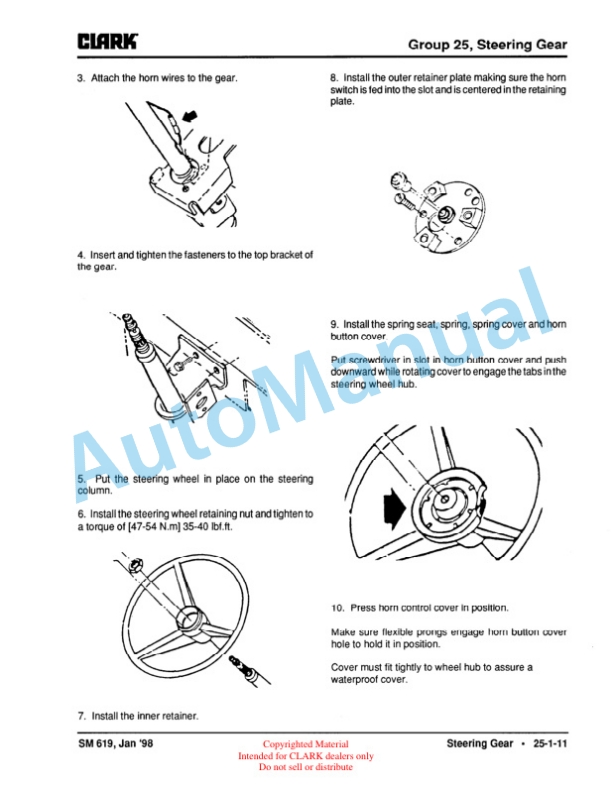

- 14. STEERING GEAR

- 14.1. STEERING GEAR SYSTEM

- 14.2. STEERING SYSTEM RELIEF PRESSURE CHECK

- 14.3. STEERING GEAR TROUBLESHOOTING

- 14.4. STEERING GEAR REMOVAL

- 14.5. STEERING GEAR OVERHAUL

- 14.5.1. STEERING GEAR DISSASSEMBLY

- 14.5.2. STEERING GEAR INSPECTION

- 14.5.3. STEERING GEAR ASSEMBLY

- 14.5.4. STEERING GEAR INSTALLATION

- 15. POWER STEERING SYSTEM, STEER AXLE

- 15.1. POWER STEERING SYSTEM

- 15.2. STEERING SYSTEM RELIEF PRESSURE CHECK

- 15.3. STEER AXLE DESCRIPTION

- 15.4. STEER AXLE REMOVAL

- 15.5. STEER AXLE OVERHAUL

- 15.6. STEER AXLE INSTALLATION

- 16. HYDRAULIC SYSTEM

- 16.1. MAIN HYDRAULIC SYSTEM

- 16.2. HYDRAULIC FLUID AND FILTER CHANGE

- 16.2.1. ALTERNATE DRAINAGE METHOD

- 16.2.2. REVISED FILTER SYSTEM

- 16.2.3. HYDRAULIC SUMP FILTER

- 16.3. MAIN HYDRAULIC PUMP

- 16.4. PUMP TROUBLESHOOTING

- 16.5. PUMP REMOVAL

- 16.6. PUMP OVERHAUL

- 16.6.1. PUMP DISASSEMBLY

- 16.6.2. INSPECTION OF PUMP PARTS

- 16.6.3. PUMP REASSEMBLY

- 16.6.4. PUMP TEST PROCEDURE

- 16.6.5. PUMP INSTALLATION

- 17. MAIN HYDRAULIC VALVE

- 17.1. GENERAL DESCRIPTION

- 17.2. MAIN VALVE RELIEF PRESSURE CHECK ADJUSTMENT

- 17.3. MAIN VALVE REMOVAL

- 17.4. MAIN VALVE OVERHAUL

- 17.4.1. VALVE DISASSEMBLY

- 17.4.2. INSPECTION OF COMPONENTS

- 17.4.3. VALVE REASSEMBLY

- 17.5. MAIN VALVE INSTALLATION

- 18. TILT CYLINDER

- 18.1. TILT CYLINDER ADJUSTMENT

- 18.2. TILT CYLINDER REMOVAL

- 18.3. TILT CYLINDER OVERHAUL

- 18.3.1. TILT CYLINDER DISASSEMBLY

- 18.3.2. TILT CYLINDER INSPECTION

- 18.3.3. TILT CYLINDER ASSEMBLY

- 18.3.4. TILT CYLINDER INSTALLATION

- 19. UPRIGHT

- 19.1. UPRIGHT MAINTENANCE

- 19.2. UPRIGHT SHIM INSPECTION, TRIPLE STAGE

- 19.3. CARRIAGE SHIM INSPECTION TRIPLE STAGE

- 19.4. CARRIAGE SHIM INSTALLATION TRIPLE STAGE

- 19.5. UPRIGHT AND CARRIAGE SHIM INSPECTION TRIPLE STAGE

- 19.6. TRIPLE STAGE SHIM DISASSEMBLY

- 19.7. UPRIGHT TRIPLE STAGE REASSEMBLY

- 19.8. TRIPLE STAGE CYLINDER TROUBLESHOOTING

- 19.9. HYDRAULIC CYLINDER REPAIR TRIPLE STAGE

- 19.10. SEAL INSTALLATION TOOL LIFT CYLINDER

- 19.11. T INSTALLATION TOOL UCUP TO PISTONLIFT CYLINDER

- 19.12. T INSTALLATION TOOL UCUP TO PISTONLIFT CYLINDER

- 19.13. UPRIGHT LIFT CHAIN MAINTENANCE

- 19.13.1. Periodic Inspections

- 19.13.2. Chain Length Adjustments

- 20. COUNTERWEIGHT JACKING BLOCKING

- 20.1. SECTION 1 COUNTERWEIGHT

- 20.1.1. COUNTERWEIGHT MAINTENANCE

- 20.1.2. COUNTERWEIGHT REMOVAL

- 20.1.3. COUNTERWEIGHT INSTALLATION

- 20.2. SECTION 2 MACHINE JACKING AND BLOCKING

- 20.2.1. RAISING DRIVE WHEELS

- 20.2.2. BLOCKING THE UPRIGHT IN RAISED POSITION

- 20.2.3. RAISING REAR OF TRUCK

- 20.2.4. RAISING ENTIRE TRUCK

- 20.2.5. RAISING TRUCK WITH A HOIST

- 21. SPECIFICATIONS

- 21.1. SECTION 1 TRUCK DATE PLATES DECALS

- 21.2. SECTION 2 SPECIFICATIONS

- 21.2.1. FILL CAPACITIES

- 21.2.2. FLUID RECOMMENDATIONS

- 21.2.3. TRUCK WEIGHTS

- 21.2.4. COUNTERWEIGHT

- 21.2.5. HYDRAULIC SYSTEM

- 21.2.6. LUBRICANT SPECIFICATIONS

- 21.2.7. CRITICAL FASTENER TORQUE SPECIFICATIONS

- 21.3. SECTION 3 HYDRAULIC AND ELECTRICAL DIAGRAMS

- 22. SM619 INDEX

Rate this product

You may also like

Clark Service Manual PDF

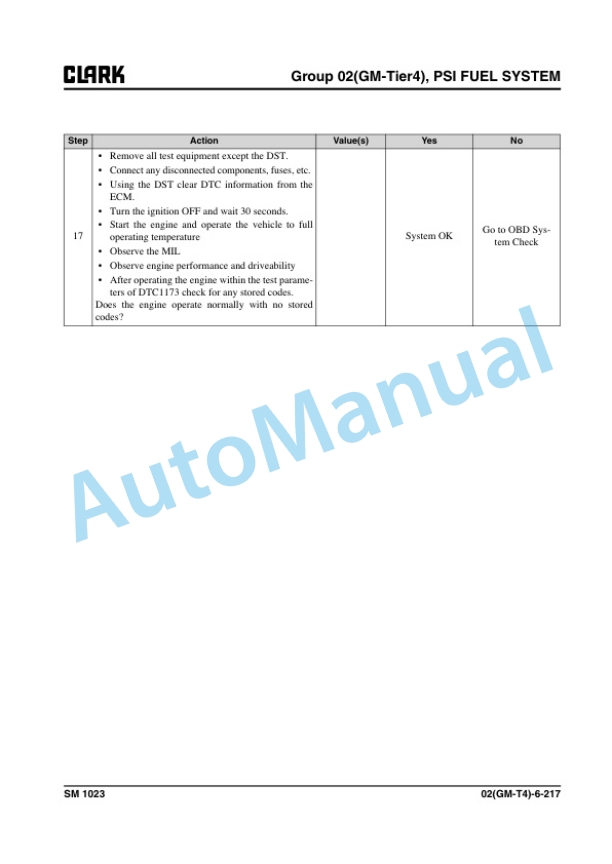

Clark C60 D, C70 D, C80 D, C80D900, C60 L, C70 L, C75 L Service Manual SM -1023

$30.00

Clark Service Manual PDF

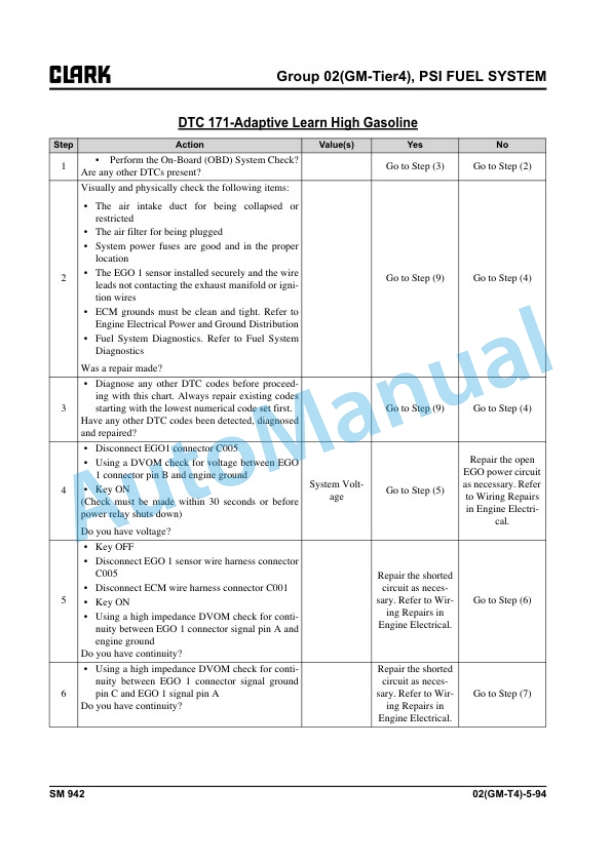

Clark C 40, 45, 50s, 55s D, C 40, 45, 50s, 55s L Service Manual SM-942

$30.00

Clark Service Manual PDF

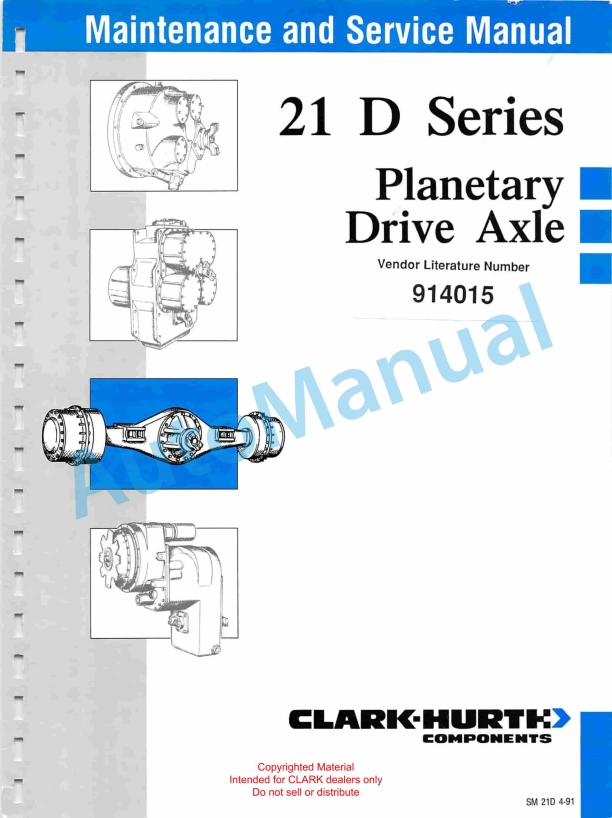

Clark 21 D Series Planetary Drive Axle Maintenance and Service Manual SM-21D

$30.00

Clark Service Manual PDF

Clark C500-355, C500-H355, C500-Y355, C500-HY355 Gasoline, LPG Service Manual SM-333

$30.00

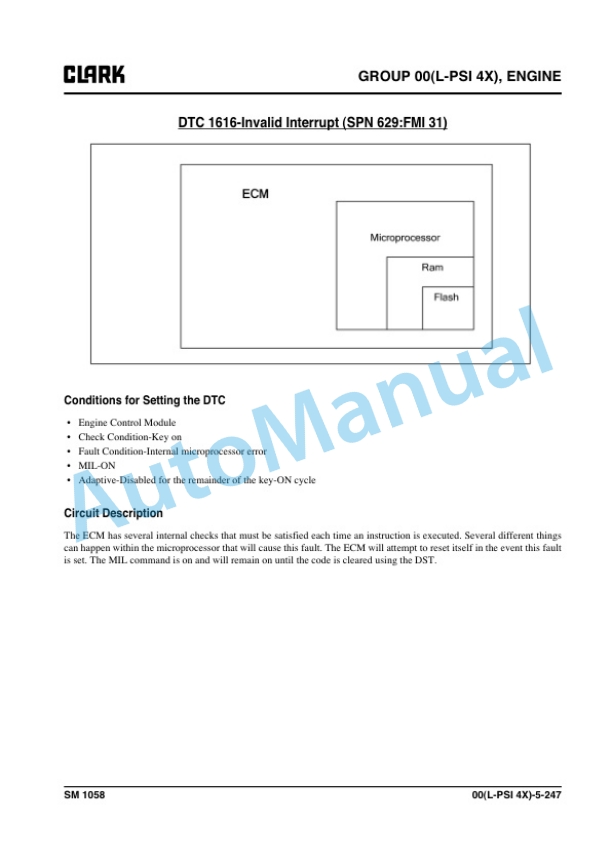

Clark Service Manual PDF

$30.00

Clark Service Manual PDF

Clark C15s D-L, C 18s D-L, C 20s D-L, C15s C-L, C 18s C-L, C 20s C-L Service Manual SM-1066

$30.00