- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

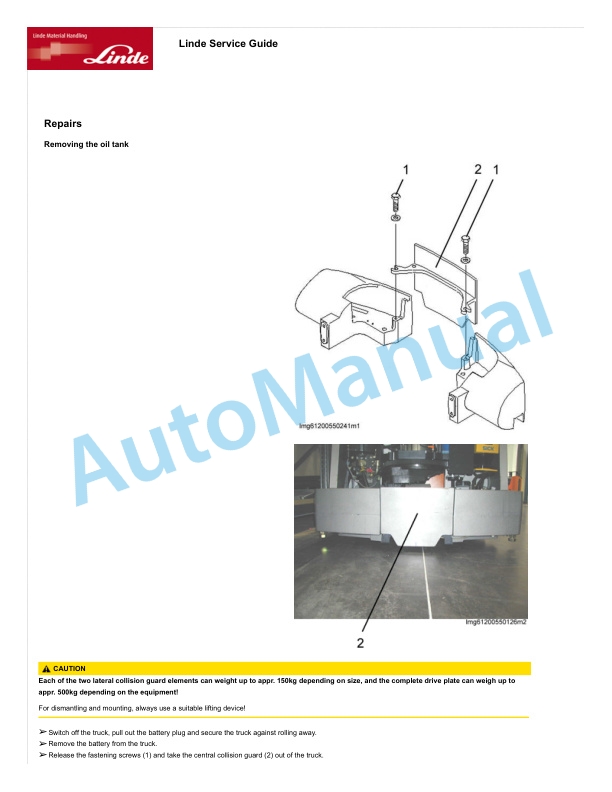

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Workshop Manuals SN A11102V00001 and up

$50.00

- Type Of Manual: Workshop Manuals

- Manual ID: SN A11102V00001 and up

- Format: PDF

- Size: 47.2MB

- Number of Pages: 332

- Serial Number:

SN A11102V00001 and up

Category: Linde Workshop Manual PDF

-

Model List:

- ECR30

- ECR40

- 1. Service case Release tools for contacts

- 1.1. Table of content

- 1.2. Safety information

- 1.2.1. Safety information for repair and maintenance work

- 1.3. Information

- 1.3.1. Information

- 1.4. Overview

- 1.4.1. Overview of service cases

- 1.5. Plug systems

- 1.5.1. ATS 2.8 plug connector

- 1.5.2. CMC plug connector

- 1.5.3. DCS 9.5 plug connector

- 1.5.4. DIN 1.5mm circular connector

- 1.5.5. DIN 2.5mm circular connector

- 1.5.6. Deutsch DTM plug connector

- 1.5.7. ECU appliance plug

- 1.5.8. MCON appliance plug

- 1.5.9. Appliance plug with JPT and MQS contacts

- 1.5.10. Appliance plug with MT2 and JPT contacts

- 1.5.11. SICMA appliance plug

- 1.5.12. Econoseal JMark 2 plug connector

- 1.5.13. Elobau 11pin receptacle housing

- 1.5.14. E5931 plug connector

- 1.5.15. FASTINFASTON 6.3mm plug connector

- 1.5.16. GT150 plug connector

- 1.5.17. HDSCS plug connector

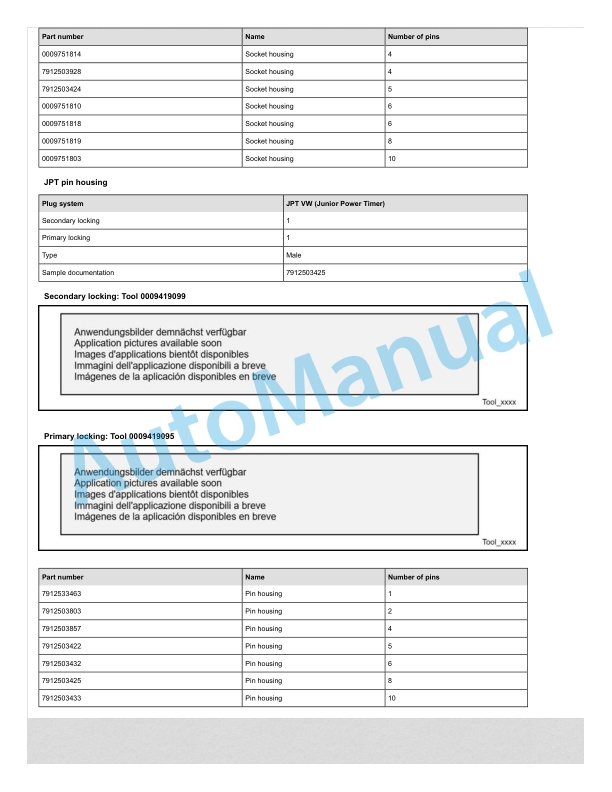

- 1.5.18. JPT plug connector

- 1.5.19. JPT SLD plug connector

- 1.5.20. JPT plug connector Saab

- 1.5.21. JPT plug connector VW

- 1.5.22. Kompakt 1.1 plug connector

- 1.5.23. Bosch Kompakt 4 plug connector

- 1.5.24. Leavyseal plug connector

- 1.5.25. MCON 1.2mm LL plug connector

- 1.5.26. MCON 1.2mm CB plug connector

- 1.5.27. MCP plug connector

- 1.5.28. MetriPack 150 plug connector

- 1.5.29. MiniFit plug connector

- 1.5.30. Mini Universal MATENLOK plug connector

- 1.5.31. Mini relay socket for DFK 1.3 and MDK 1.3

- 1.5.32. MKR Plus plug connector

- 1.5.33. MQS plug connector

- 1.5.34. MR plug connector

- 1.5.35. MTA plug housing and fuse housing

- 1.5.36. MT2 plug connector

- 1.5.37. MT2 1.5mm plug connector VW

- 1.5.38. Multilock plug connector

- 1.5.39. MX150 plug connector

- 1.5.40. NG1 plug connector

- 1.5.41. Phönix Contact HC plug connector

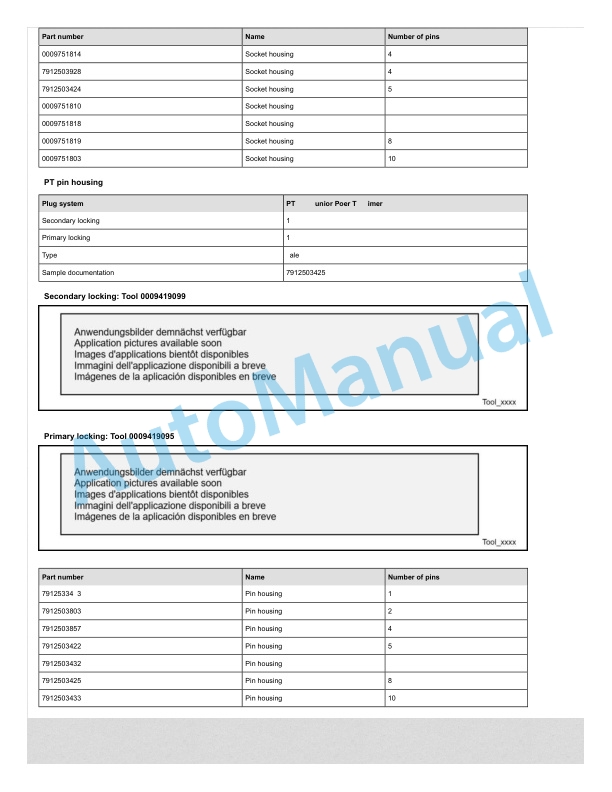

- 1.5.42. PT 3F plug connector

- 1.5.43. Relay socket with SPT contacts for DFK 1.3.4 and MDK 1.3.4

- 1.5.44. Relay socket with SPT and MPT contacts

- 1.5.45. Fuse holder with SPT contacts

- 1.5.46. Sicma plug connector

- 1.5.47. SLK 2.8 plug connector

- 1.5.48. Souriau UTL7 plug connector

- 1.5.49. Superseal 1.5mm plug connector

- 1.5.50. Trident Neptune plug connector

- 1.5.51. Universal MATENLOK plug connector

- 1.5.52. VW 9.5mm plug connector

- 2. Electric trucksECR30, ECR40

- 2.1. Table of content

- 2.2. Product information

- 2.2.1. Product Marking

- 2.2.1.1. Notes

- 2.2.1.2. Serial Number Location

- 2.2.1.3. Interpreting the Serial Number

- 2.2.1.4. Decal and Data Plate Location Manual Steer

- 2.2.1.5. Decal and Data Plate Location Electric Steer

- 2.2.2. Specifications

- 2.2.2.1. Specifications Manual Steer

- 2.2.2.2. Specifications Electric Steer

- 2.3. Maintenance

- 2.3.1. Routine Lubrication and Inspection

- 2.3.1.1. Routine Lubrication and Inspection Intervals

- 2.3.1.2. Minimum Lubrication and Inspection Intervals

- 2.3.1.3. Check Casters

- 2.3.1.4. Lubricate Load Wheel Axles

- 2.3.1.5. Check for Gear Oil Leakage

- 2.3.1.6. Check Lift Cylinder and Lines for Leaks

- 2.3.1.7. Check Hydraulic Oil Level

- 2.3.1.8. Check Drive Wheel and Fasteners

- 2.3.1.9. Lubricate Drive Axle Swivel Bearing

- 2.3.1.10. Lubricate Tie Bar Linkage

- 2.3.1.11. Lubricate Lift Cylinder and Fork Frame Pivots

- 2.3.1.12. Lubricate Caster Swivel Bearings

- 2.3.1.13. Lubricate Steering Gear (Electric steer only)

- 2.3.2. Scheduled Maintenance

- 2.3.2.1. General Maintenance Information

- 2.3.2.2. Maintenance Schedule

- 2.3.3. Fluids and Lubricants

- 2.3.3.1. Fluid and Lubricant Specifications

- 2.3.3.2. Capacities

- 2.4. Drive Motor and Brake

- 2.4.1. Drive Motor

- 2.4.1.1. Drive Motor Description

- 2.4.1.2. Testing

- 2.4.1.3. Drive Motor Replacement

- 2.4.1.4. Speed Sensor (B1)

- 2.4.1.5. Temperature Sensor (B4)

- 2.4.2. Brake

- 2.4.2.1. Brake Description

- 2.4.2.2. Manual Brake Release

- 2.4.2.3. Checking Brake Disc Clearance

- 2.4.2.4. Checking the Brake Coil

- 2.4.2.5. Brake Coil.Disc Replacement

- 2.5. Drive Unit

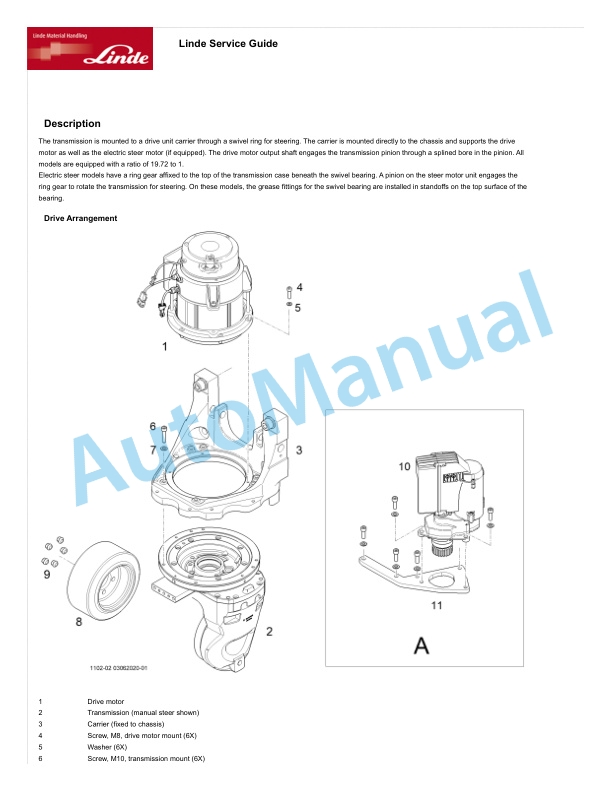

- 2.5.1. Transmission

- 2.5.1.1. Description

- 2.5.1.2. Transmission Removal and Installation

- 2.5.1.3. Components

- 2.5.2. Drive Wheel

- 2.5.2.1. Drive Wheel

- 2.6. Chassis

- 2.6.1. Fork Linkage

- 2.6.1.1. Chassis and Linkage

- 2.6.1.2. Fork Height Adjustment

- 2.6.2. Load Wheels and Shackles

- 2.6.2.1. Description

- 2.6.2.2. Shackle Replacement

- 2.6.2.3. Load Wheel Replacement

- 2.6.3. Floor Plate

- 2.6.3.1. Floor Plate

- 2.6.4. Casters

- 2.6.4.1. Caster Description

- 2.6.4.2. Caster Adjustment

- 2.7. Steering

- 2.7.1. Steering Variants

- 2.7.1.1. Steering Variants

- 2.7.2. Manual Steering

- 2.7.2.1. Manual Steer Connector Plate

- 2.7.2.2. Steering Bearing Replacement

- 2.7.3. Electric Steering (Optional Equipment)

- 2.7.3.1. Electric Steering System

- 2.7.3.2. Electric Steer Motor Unit (3A1)

- 2.7.3.3. Steer Motor Components

- 2.7.3.4. Steer Motor Contactor (3K1)

- 2.7.3.5. Steer Angle Control Unit (7A1)

- 2.7.3.6. Steer Angle Control Unit Replacement

- 2.7.3.7. Steer Brake Feature

- 2.7.3.8. Calibrating the Electric Steering System

- 2.7.3.9. Electric Steering System Fault Codes

- 2.8. Controls

- 2.8.1. Handle Manual Steer

- 2.8.1.1. Control Handle Removal and Installation

- 2.8.2. Control Head Manual Steer

- 2.8.2.1. Control Head Description

- 2.8.2.2. Throttle Mechanism

- 2.8.2.3. Horn Button

- 2.8.2.4. Brake Button

- 2.8.3. Control Head Electric Steer

- 2.8.3.1. Control Head Description

- 2.9. Electrical

- 2.9.1. Electrical System Overview

- 2.9.1.1. Electrical System Description

- 2.9.1.2. Fuses

- 2.9.1.3. Wiring and Connector Location

- 2.9.2. Switches

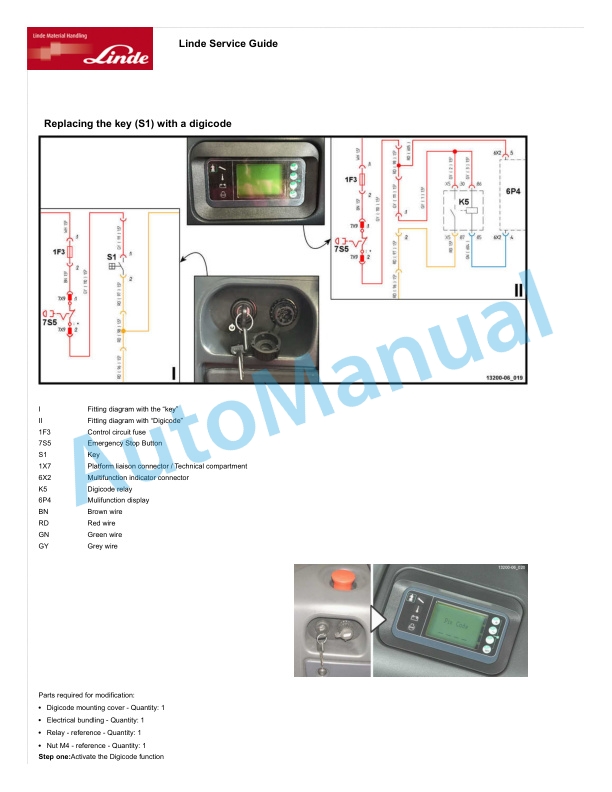

- 2.9.2.1. Key Switch (S1)

- 2.9.2.2. Floor Plate Switch (1S1)

- 2.9.2.3. Lift Limit Switch (2S1)

- 2.9.2.4. Auxiliary Lift and Lower Switches (option)

- 2.9.2.5. Order Pick Switches Electric steer variant (option)

- 2.9.3. Contactor

- 2.9.3.1. Contactor (K1)

- 2.9.4. Horn

- 2.9.4.1. Horn (H1)

- 2.9.6. Travel Alarm

- 2.9.6.1. Travel Alarm.Options Connector X9

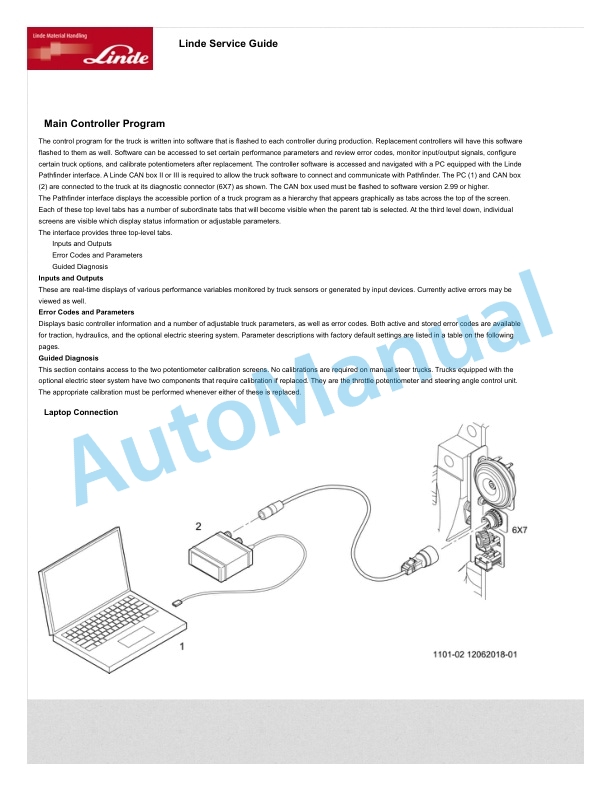

- 2.9.7. Main Controller

- 2.9.7.1. Main Controller

- 2.9.7.2. Main Controller Connector 1X1

- 2.9.7.3. Main Controller Program

- 2.9.7.4. Adjustable Parameters

- 2.9.7.5. Main Controller Troubleshooting

- 2.9.7.6. Main Controller Replacement

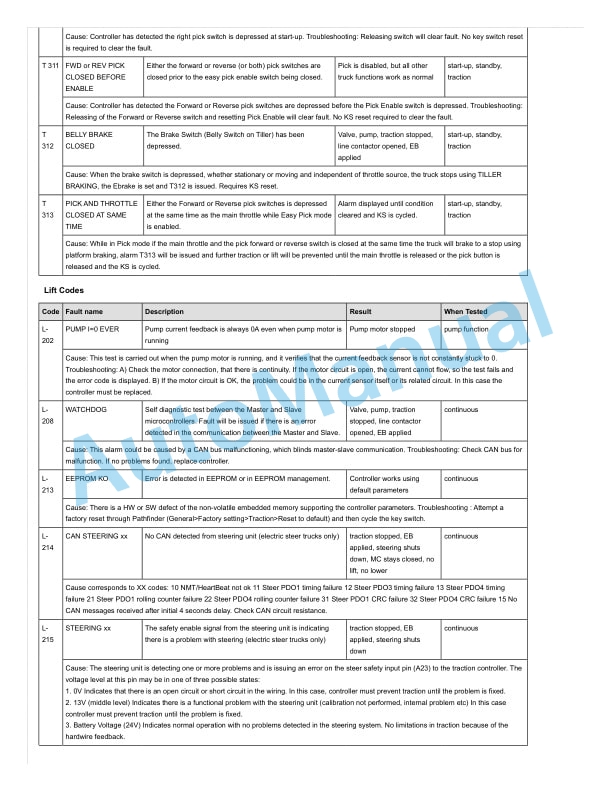

- 2.9.7.7. Fault Codes

- 2.9.8. Control Head Manual Steer

- 2.9.8.1. Control Head Overview

- 2.9.8.2. Control Head Disassembly

- 2.9.8.3. Control Head Switches

- 2.9.8.4. Control Head Circuit Board Components (Throttle Potentiometer and Brake Switch)

- 2.9.9. Control Head Electric Steer

- 2.9.9.1. Control Head Overview

- 2.9.9.2. Control Module and Throttle

- 2.9.9.3. Control Module Removal

- 2.9.9.4. Control Module Disassembly

- 2.9.9.5. Calibrating the Throttle Potentiometer Electric Steer

- 2.9.9.6. CAN Converter Module (A5)

- 2.9.10. Display Unit (6P3)

- 2.9.10.1. Description

- 2.9.10.2. Operation

- 2.9.10.3. Service Timer

- 2.9.10.4. Battery Discharge Indication

- 2.10. Hydraulic

- 2.10.1. Hydraulic System Description

- 2.10.1.1. Hydraulic System

- 2.10.2. Lift Cylinder

- 2.10.2.1. Lift Cylinder

- 2.10.2.2. Lift Cylinder Replacement

- 2.10.2.3. Lift Cylinder Overhaul

- 2.10.3. Hydraulic Pump Unit

- 2.10.3.1. Hydraulic Pump Unit Components

- 2.10.3.2. Hydraulic Pump Unit

- 2.10.4. Hydraulic Pump Motor

- 2.10.4.1. Pump Motor (2M1)

- 2.10.4.2. Hydraulic Pump Motor Components

- 2.10.5. Hydraulic Pump

- 2.10.5.1. Hydraulic Pump

- 3. Circuit DiagramsECR30, ECR40

- 3.1. Table of content

- 3.2. Circuit diagrams

- 3.2.1. Wiring diagram

- 3.2.1.1. Electrical Schematic page 1 Power Circuit (Both steering variants)

- 3.2.1.2. Electrical Schematic page 2 Control Circuit Manual Steer

- 3.2.1.3. Electrical Schematic page 3 Control Circuit Electric Steer

- 3.2.2. Hydraulic circuit diagram

- 3.2.2.1. Hydraulic Diagram

Rate this product

You may also like

Linde Workshop Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Workshop Manuals SN A11103V00001 and up

$50.00

Linde Workshop Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Workshop Manuals SN W41110V00529 and up

$50.00

Linde Workshop Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Workshop Manuals

$50.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF