- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

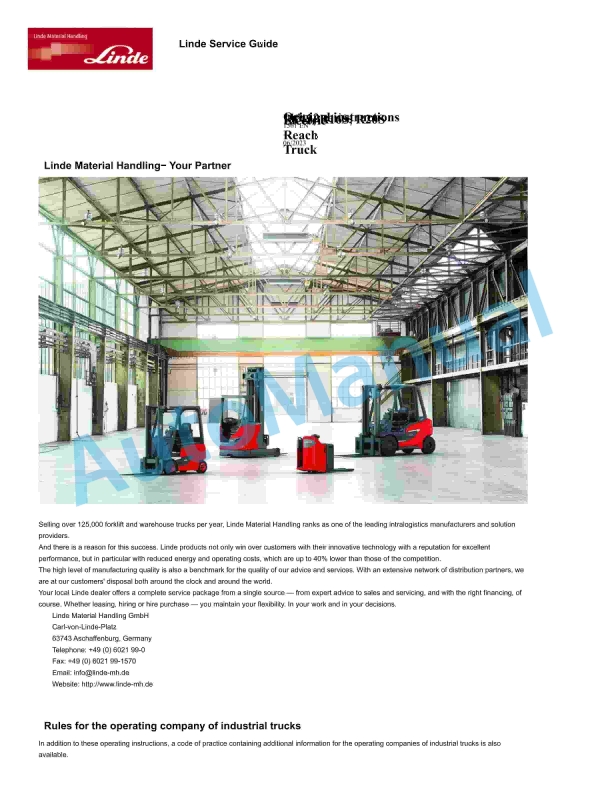

Linde 115-12 – R14, R16, R20 Production site Xiamen Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 27.6MB

- Number of Pages: 307

Category: Linde Operator Manual PDF

-

Model List:

- R14

- R16

- R20

- 1. Electric Reach TruckR14S, R16S, R20S

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Introduction

- 1.2.2. General information

- 1.2.3. Conformity marking

- 1.2.4. Declaration that reflects the content of the declaration of conformity

- 1.2.5. Factory nameplate

- 1.2.6. Intended use of the trucks

- 1.2.7. Additional information

- 1.2.8. Hazard assessment

- 1.2.9. Improper use

- 1.2.10. Disposing of components and batteries

- 1.2.11. Symbols used

- 1.3. Safety

- 1.3.1. Residual risks

- 1.3.2. Stability

- 1.3.3. In the case of tipover

- 1.3.4. EMC Electromagnetic compatibility

- 1.3.5. Operating company

- 1.3.6. Drivers

- 1.3.7. Competent person

- 1.3.8. Regulations

- 1.3.9. Handling consumables

- 1.3.10. Fitting attachments

- 1.4. Overview

- 1.4.1. Display unit from C1X115V00808 to C2Y115M00647

- 1.4.1.1. Multifunction indicator

- 1.4.1.2. Speed menu

- 1.4.1.3. Status menu

- 1.4.1.4. Settings menu

- 1.4.1.5. Fault menu

- 1.4.1.6. Status bar

- 1.5. Operation

- 1.5.1. Using the RFID Keypad (optional)

- 1.5.1.1. RFID Keypad installation position

- 1.5.2. Picking up a load

- 1.5.3. Handling loads

- 1.5.4. Taking the truck out of operation

- 1.5.5. Disposal of old trucks

- 1.6. Maintenance

- 1.6.1. Maintenance safety guidelines

- 1.6.2. Covers and cowlings

- 1.6.3. Fuses C2Y115M00648 and up

- 1.6.3.1. Fuses

- 1.6.4. Required checks and maintenance

- 1.6.4.1. Check the battery electrolyte level and specific gravity

- 1.6.4.2. Adjusting the length of the lifting chains and lubricating using chain spray

- 1.6.5. Taking the truck out of operation

- 1.6.6. Disposal of old trucks

- 1.7. Technical datasheet

- 1.7.1. Ecodesign requirements for electric motors and variable speed drives

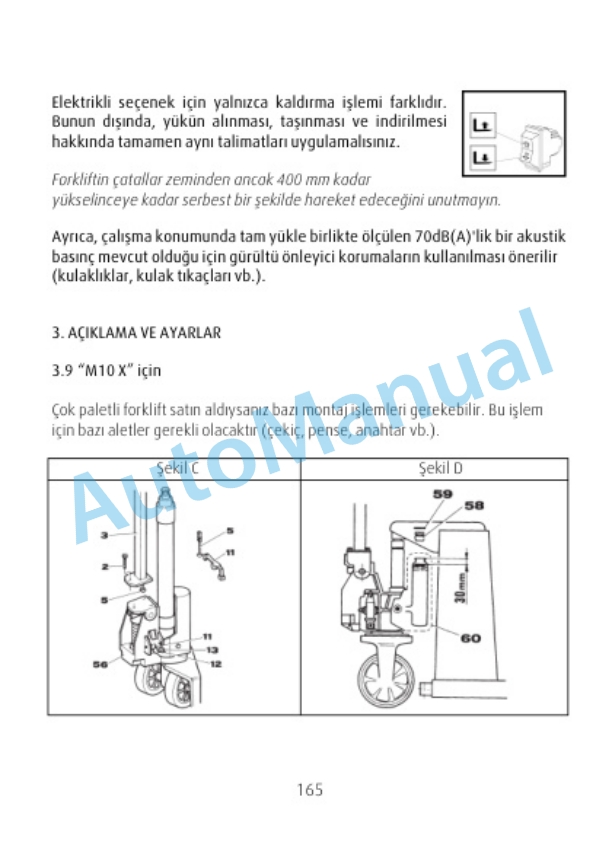

- 2. Electric reach truckR10CS.12CS.14CS11

- 2.1. Table of content

- 2.2. Introduction and general description

- 2.2.1. Introduction

- 2.2.2. Legal requirements for marketing

- 2.2.3. General description

- 2.3. Safety

- 2.3.1. Operator safety guidelines

- 2.3.2. Residual risks

- 2.3.3. Stability

- 2.3.4. In the event of tipover

- 2.3.5. Noise emission levels

- 2.3.6. Frequency characteristic for human body vibrations

- 2.4. Getting to know the truck

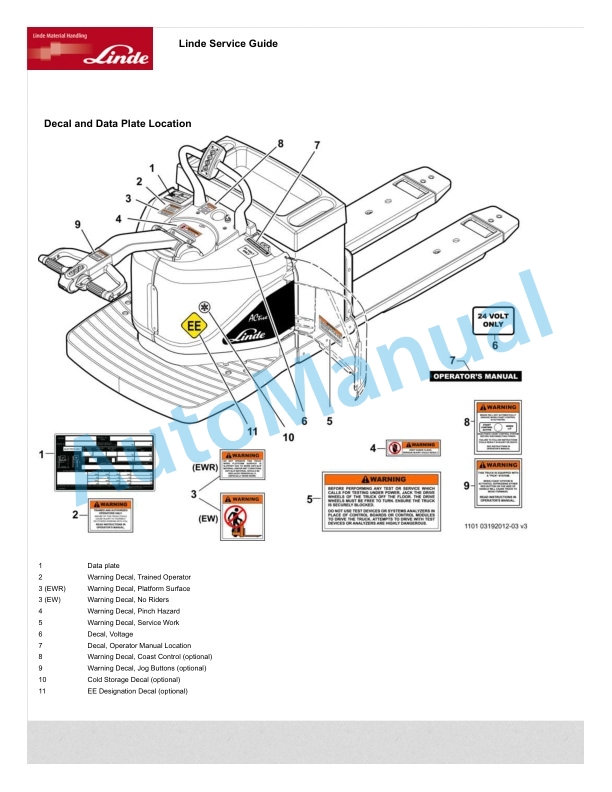

- 2.4.1. Location of identification plates and labels

- 2.4.2. Truck type.capacity plate

- 2.4.3. General view of truck

- 2.4.4. Operating controls and indicators

- 2.4.5. Operators display

- 2.4.6. Definition of direction of travel

- 2.5. Operation

- 2.5.1. Runningin instructions

- 2.5.2. Preshift checks

- 2.5.3. The battery

- 2.5.4. Operator adjustments

- 2.5.5. Braking twin pedal

- 2.5.6. Driving twin pedal

- 2.5.7. Travelling on an incline

- 2.5.8. Operating the mast and attachments (with two joystick control)

- 2.5.9. Handling loads

- 2.5.10. Before leaving the truck

- 2.5.11. Operator code entry (Option)

- 2.6. Maintenance

- 2.6.1. Maintenance safety guidelines

- 2.6.2. Report of Thorough Examination

- 2.6.3. Covers and cowlings

- 2.6.4. Fuses

- 2.6.5. Emergency lower

- 2.6.6. Emergency steering and parking brake release

- 2.6.7. Slinging the truck

- 2.6.8. Securing for transportation

- 2.6.9. Jacking the truck

- 2.6.10. Towing procedure

- 2.6.11. Mast unit

- 2.6.12. Recommended lubricants

- 2.6.13. Inspection and maintenance data

- 2.6.14. Inspection and maintenance schedule

- 2.6.14.1. Routine inspection and maintenance

- 2.6.14.2. Preshift checks

- 2.6.14.3. Inspection and maintenance as required

- 2.6.14.4. Inspection and maintenance every 1000 hours

- 2.6.14.5. Inspection and maintenance every 2000 hours

- 2.6.14.6. Inspection and maintenance every 5000 hours

- 2.6.14.7. Inspection and maintenance every 10000 hours or 5 years, whichever is earlier

- 2.6.15. Inspection and maintenance as required

- 2.6.15.1. Clean the truck

- 2.6.15.2. Check the battery electrolyte level and specific gravity

- 2.6.15.3. Adjusting the length of the lift chains, and lubricating using chain spray

- 2.6.15.4. Replace the hydraulic hoses and pipes

- 2.6.15.5. Check the drive wheel nuts

- 2.6.15.6. Replace the battery trolley slides

- 2.6.16. hr Inspection and maintenance

- 2.6.16.1. Check the condition and security of the wheels and tyres

- 2.6.16.2. Check the condition of the battery and battery cables

- 2.6.16.3. Check the condition and security of electrical connections and cables

- 2.6.16.4. Check the parking brake gap

- 2.6.16.5. Check the hydraulic hoses and pipes for damage

- 2.6.16.6. Check the lift chains for condition and security

- 2.6.16.7. Lubricate the mast, mast rollers, lift chains and chain pulleys

- 2.6.16.8. Lubricate the reach channels and rollers

- 2.6.16.9. Check and lubricate the battery trolley slides and associated mechanism

- 2.6.16.10. Check the hydraulic oil level

- 2.6.16.11. Lubricate the fork carriage and sideshift slider pad

- 2.6.16.12. Check and lubricate the sideshift mechanism

- 2.6.16.13. Check the pretension of the double hoses

- 2.6.17. hr Inspection and maintenance

- 2.6.17.1. Check the brake fluid level

- 2.6.17.2. Check the load wheel brake shoes for wear

- 2.6.17.3. Replace the hydraulic tank breather filter

- 2.6.17.4. Check the reach carriage rollers, adjust if required

- 2.6.18. hr Inspection and maintenance

- 2.6.18.1. Grease the load wheel bearings

- 2.6.18.2. Check condition of brake pipes

- 2.6.18.3. Change the hydraulic oil and suction filter

- 2.6.19. hr Inspection and maintenance

- 2.6.19.1. Change the brake fluid

- 2.6.20. Taking the truck out of operation

- 2.6.21. Decommissioning the truck

- 2.7. Technical data

- 2.7.1. Battery data

- 2.7.2. Dimensions (compact version)

- 2.7.3. Technical data 1.0 tonne capacity

- 2.7.4. Technical data 1.2 tonne capacity

- 2.7.5. Technical data 1.4 tonne capacity

- 2.7.6. Mast variations

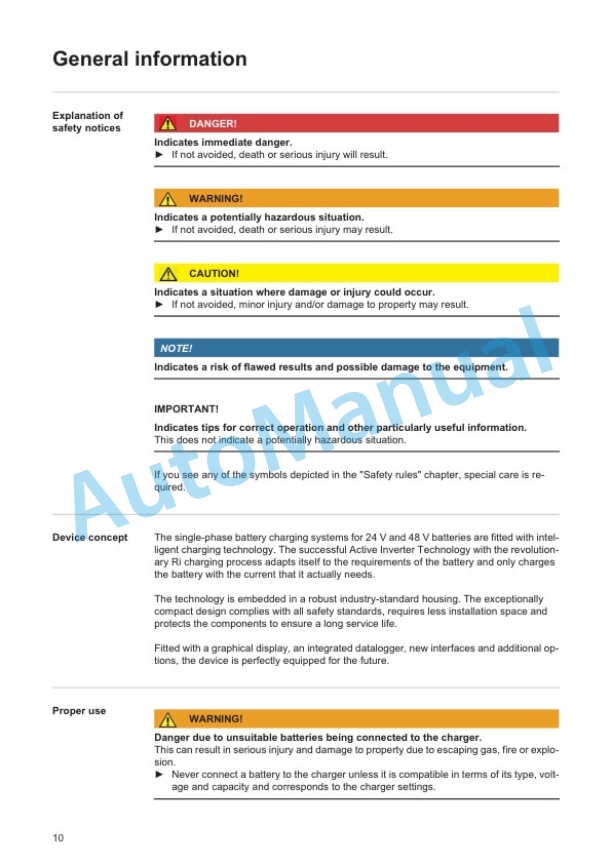

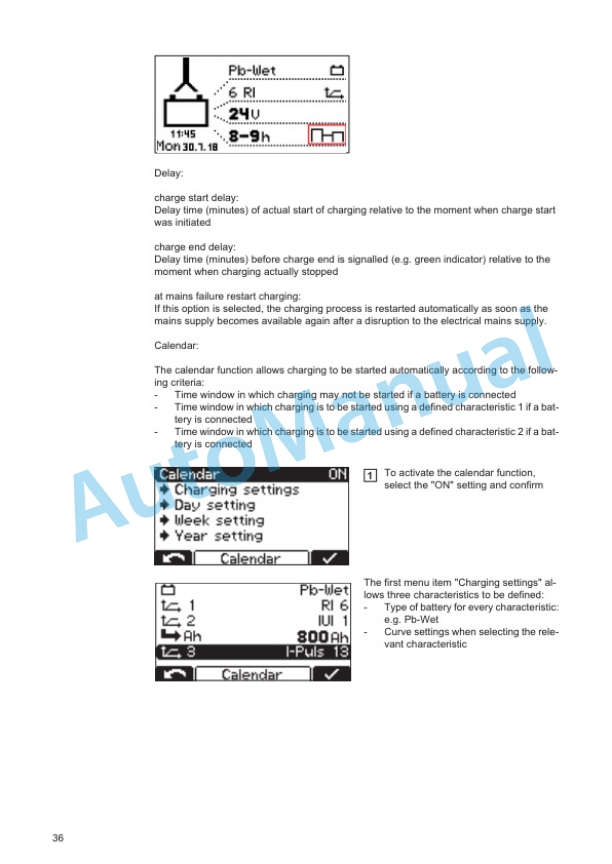

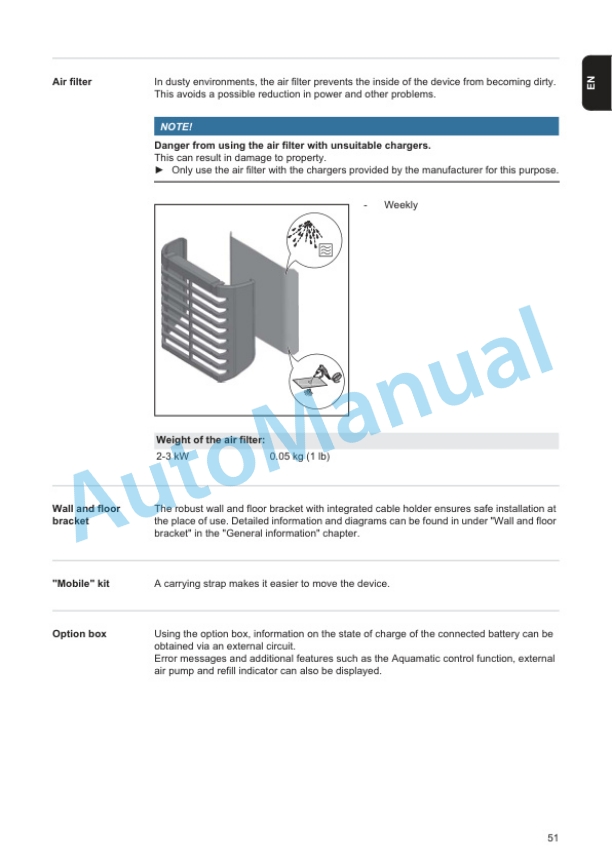

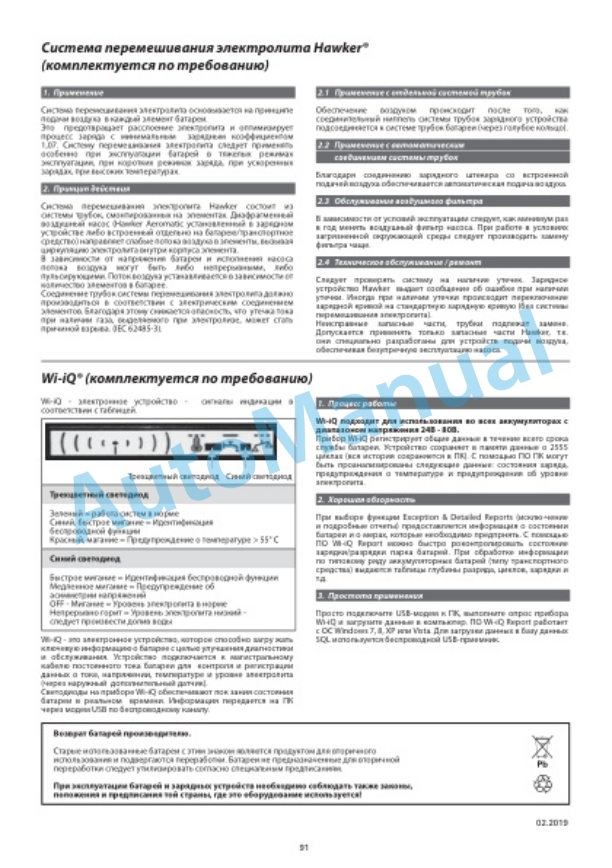

- 3. Leadacid battery charger 24V . 48V

- 4. Leadacid battery charger 24V . 48V . 80V

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 1120-01 – R-matic, R10, R12, R14, R16, R20, R25 Operating Instructions SN 10.12 and up

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions

$20.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF