- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

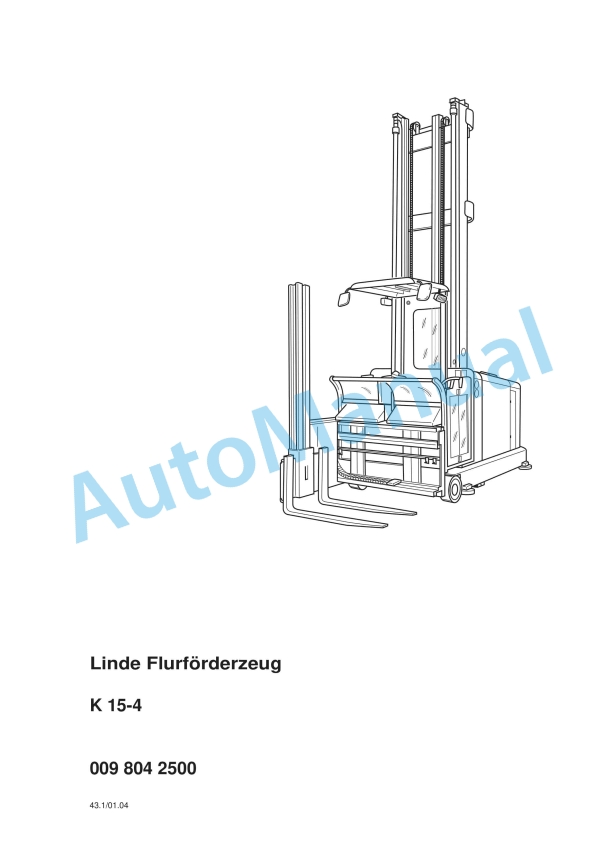

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 1151-02 – T16P, T20P Production site Xiamen Operating Instructions SN C11151F50001 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN C11151F50001 and up

- Format: PDF

- Size: 46.2MB

- Number of Pages: 375

- Serial Number:

SN C11151F50001 and up

-

Model List:

- T16P

- T20P

- 1. Electric Pallet TruckT16P02T20P02

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Introduction

- 1.2.2. General information

- 1.2.3. Conformity marking

- 1.2.4. Declaration that reflects the content of the declaration of conformity

- 1.2.5. Intended use of the trucks

- 1.2.6. Additional information

- 1.2.7. Hazard assessment

- 1.2.8. Disposing of components and batteries

- 1.2.9. Impermissible use

- 1.2.10. Description of use and climatic conditions

- 1.2.11. Symbols used

- 1.2.12. Electric Pallet Truck 115102

- 1.3. safety

- 1.3.1. Safety guidelines

- 1.3.2. Residual risks

- 1.3.3. Stability

- 1.3.4. Operating company

- 1.3.5. Drivers

- 1.3.6. Competent person

- 1.3.7. Regulations

- 1.3.8. Handling consumables

- 1.3.9. EMC Electromagnetic compatibility

- 1.4. General layout

- 1.4.1. Labels

- 1.4.2. Nameplate

- 1.4.3. Full view of 115102, models T16P02 and T20P02

- 1.4.4. control unit

- 1.4.5. Battery charge indicator

- 1.4.6. Digicode option (LFM Go)

- 1.4.7. LFM Connect option

- 1.5. Application

- 1.5.1. Settings

- 1.5.2. Checks before first commissioning

- 1.5.3. Preshift checks before starting work

- 1.5.4. Operating Instructions

- 1.5.5. Driving the truck

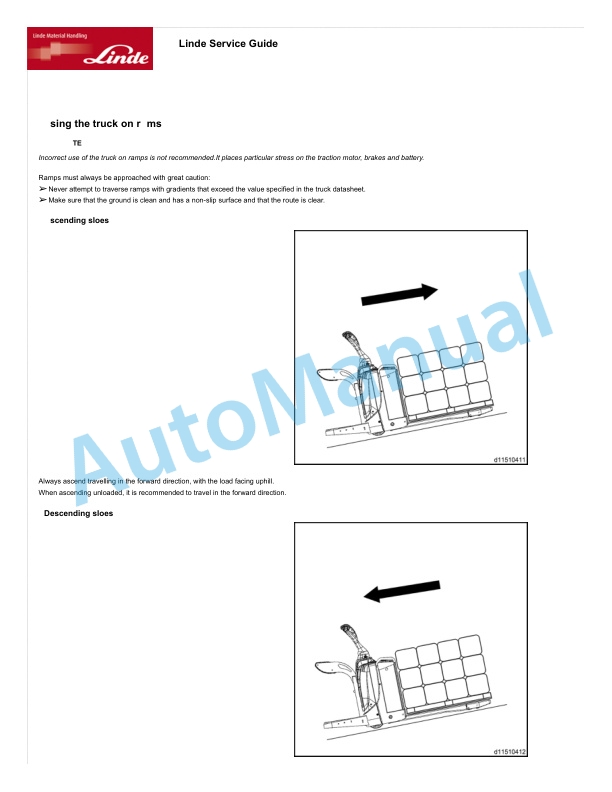

- 1.5.6. Using the truck on ramps

- 1.5.7. Creep Speed function

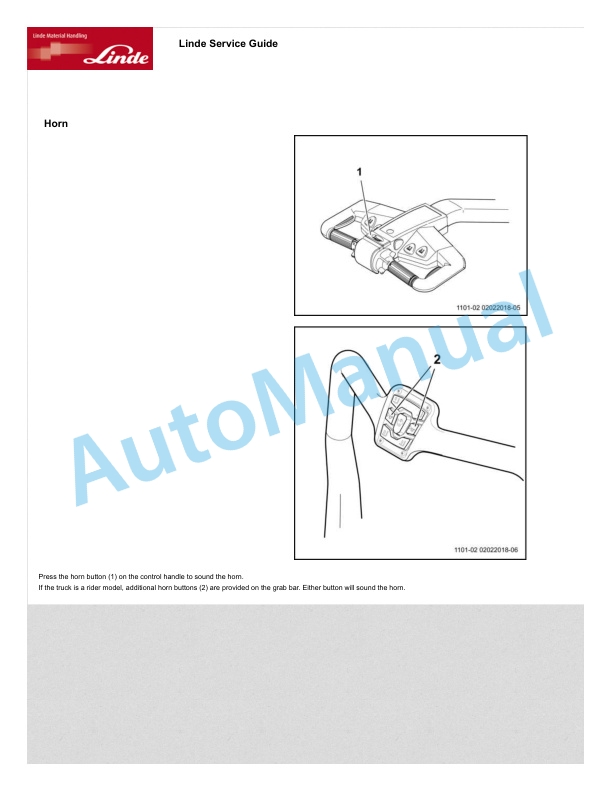

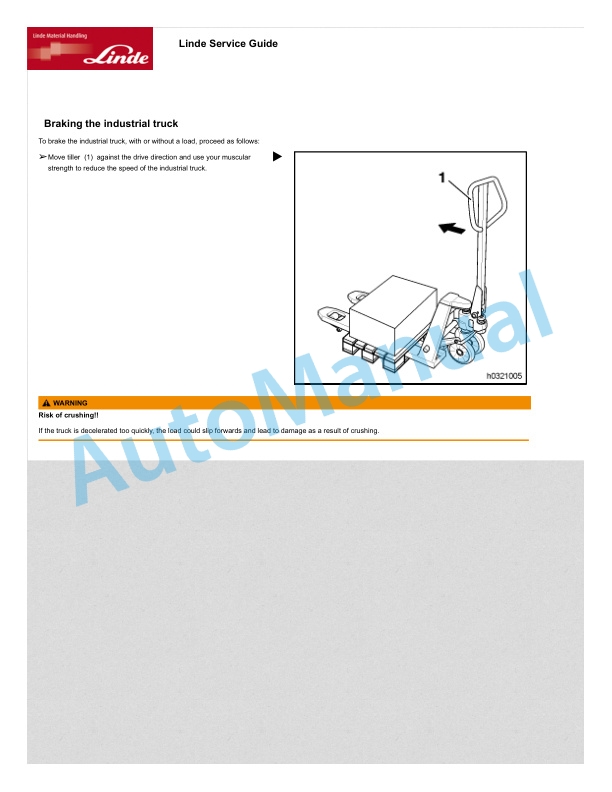

- 1.5.8. Braking, lifting, lowering, horn

- 1.5.9. Working with loads

- 1.5.10. Lifting and towing

- 1.5.11. Cold store usage (optional)

- 1.6. Maintenance

- 1.6.1. Inspection and maintenance work tables

- 1.6.2. hour maintenance plan

- 1.6.3. hour maintenance plan

- 1.6.4. hour maintenance plan

- 1.6.5. Technical inspection and maintenance characteristics

- 1.6.6. Recommended lubricants

- 1.6.7. Preshift checks

- 1.6.8. Check braking

- 1.6.9. Testing safety devices

- 1.6.10. Checking the battery charging status

- 1.6.11. Connecting.disconnecting the battery plug connector

- 1.6.12. Opening the battery cover

- 1.6.13. Battery charging with an external charger

- 1.6.14. Cleaning the battery and its compartment

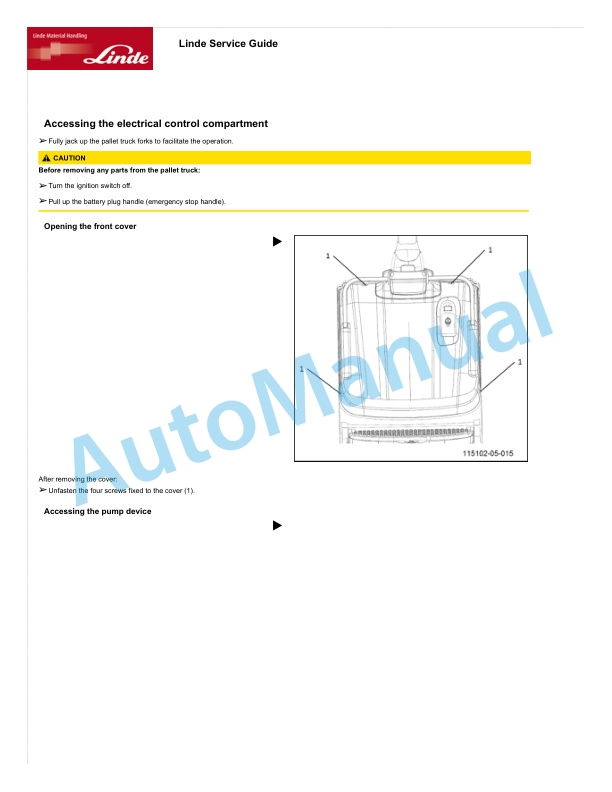

- 1.6.15. Accessing the electrical control compartment

- 1.6.16. Checking fuses

- 1.6.17. Checking the condition of cables, terminals and the battery connector

- 1.6.18. Vertical change batteriesremoval.replacement

- 1.6.19. Lateral change batterychanging the battery using a trolley

- 1.6.20. Lateral change batterychanging the battery using a mobile support

- 1.6.21. hour maintenance plan

- 1.6.22. hour maintenance plan

- 1.6.23. hour maintenance plan

- 1.7. Datasheet

- 1.7.1. Technical datasheet

- 1.7.2. Technical datasheet T16P02

- 1.7.3. Technical datasheet T2002

- 1.7.4. Ecodesign requirements for electric motors and variable speed drives

- 2. Electric pallet truckT16P02, T20P02Zapi controller

- 2.1. Table of content

- 2.2. Introduction

- 2.2.1. Legal requirements for marketing

- 2.2.2. Introduction

- 2.2.3. Intended use

- 2.2.4. Improper use

- 2.2.5. Additional information

- 2.2.6. Description of use and climatic conditions

- 2.2.7. Symbols used

- 2.2.8. Electric Pallet Truck 115102

- 2.3. Safety

- 2.3.1. Safety guidelines

- 2.3.2. Residual risks

- 2.3.3. Stability

- 2.3.4. EMC Electromagnetic compatibility

- 2.3.5. Handling consumables

- 2.3.6. Regulations

- 2.3.7. Competent person

- 2.4. General layout

- 2.4.1. Labels

- 2.4.2. Identification plates

- 2.4.3. Full view of 115102, models T16P02 and T20P02

- 2.4.4. control unit

- 2.4.5. Battery Charging Indicator

- 2.4.6. Digicode option (LFM Go)

- 2.4.7. LFM Connect option

- 2.5.1. Settings

- 2.5.2. Checks before first commissioning

- 2.5.3. Preshift checks before starting work

- 2.5.4. Operating Instructions

- 2.5.5. Driving the truck

- 2.5.6. Using the truck on ramps

- 2.5.7. Creep Speed Function

- 2.5.8. Braking, lifting, lowering, horn

- 2.5.9. Working with loads

- 2.5.10. Lifting and towing

- 2.5.11. Cold store usage (optional)

- 2.6. Maintenance

- 2.6.1. Inspection and maintenance work tables

- 2.6.2. hour maintenance plan

- 2.6.3. hour maintenance plan

- 2.6.4. hour maintenance plan

- 2.6.5. Technical inspection and maintenance characteristics

- 2.6.6. Recommended lubricants

- 2.6.7. Preshift checks

- 2.6.8. Check braking

- 2.6.9. Testing the safety devices

- 2.6.10. Checking the battery charging status

- 2.6.11. Connecting.disconnecting the battery plug connector

- 2.6.12. Opening the battery cover

- 2.6.13. Battery charging with an external charger

- 2.6.14. Cleaning the battery and its compartment

- 2.6.15. Accessing the electrical control compartment

- 2.6.16. Checking the fuses

- 2.6.17. Checking the condition of cables, terminals and the battery connector

- 2.6.18. Vertical change batteriesremoval.replacement

- 2.6.19. Lateral change batterychanging the battery using a trolley

- 2.6.20. Lateral change batterychanging the battery using a mobile support

- 2.6.21. hour maintenance plan

- 2.6.22. hour maintenance plan

- 2.6.23. hour maintenance plan

- 2.7. Datasheet

- 2.7.1. Technical datasheet

- 2.7.2. Technical datasheet T16P02

- 2.7.3. Technical datasheet T2002

- 3. Electric pallet truckT20PHP

- 3.1. Table of content

- 3.2. Introduction

- 3.2.1. Introduction

- 3.2.2. Specific uses of the truck

- 3.2.3. Description of use and climatic conditions

- 3.2.4. Symbols used

- 3.2.5. Legal requirements for marketing

- 3.2.6. Electric pallet truck

- 3.3. Safety

- 3.3.1. Safety guidelines

- 3.3.2. Residual risks

- 3.3.3. Stability

- 3.3.4. Safety rules

- 3.3.5. Handling consumables

- 3.3.6. Periodic general checks on the trucks

- 3.4. General layout

- 3.4.1. Labels

- 3.4.2. Identification label

- 3.4.3. General view

- 3.4.4. Control unit

- 3.4.5. Battery charge indicator

- 3.4.6. Digicode option (LFM Go)

- 3.4.7. LFM Connect option

- 3.5. Application

- 3.5.1. Settings

- 3.5.2. Checks before first commissioning

- 3.5.3. Routine preshift checks

- 3.5.4. Driving the truck

- 3.5.5. Using the truck on ramps

- 3.5.6. Braking, lifting, lowering, horn

- 3.5.7. Working with loads

- 3.5.8. Lifting and towing

- 3.5.9. Cold store usage (optional)

- 3.6. Maintenance

- 3.6.1. Inspection and maintenance work tables

- 3.6.2. hour maintenance plan

- 3.6.3. hour maintenance plan

- 3.6.4. hour maintenance plan

- 3.6.5. Technical inspection and maintenance characteristics

- 3.6.6. Recommended lubricants

- 3.6.7. Preshift checks

- 3.6.8. Checking the brakes

- 3.6.9. Testing safety devices

- 3.6.10. Checking the battery charging status

- 3.6.11. Connecting.disconnecting the battery plug connector

- 3.6.12. Opening the battery cover

- 3.6.13. Battery charging with an external charger

- 3.6.14. Cleaning the battery and its compartment

- 3.6.15. Accessing the electrical control compartment

- 3.6.16. Check fuses

- 3.6.17. Checking the condition of cables, terminals and the battery connector

- 3.6.18. Lateral change batterychanging the battery using a trolley

- 3.6.19. Lateral change batterychanging the battery using a mobile support

- 3.6.20. hour maintenance plan

- 3.6.21. hour maintenance plan

- 3.6.22. hour maintenance plan

- 3.7. Datasheet

- 3.7.1. Main technical data

- 3.7.2. Technical datasheet T20PHP

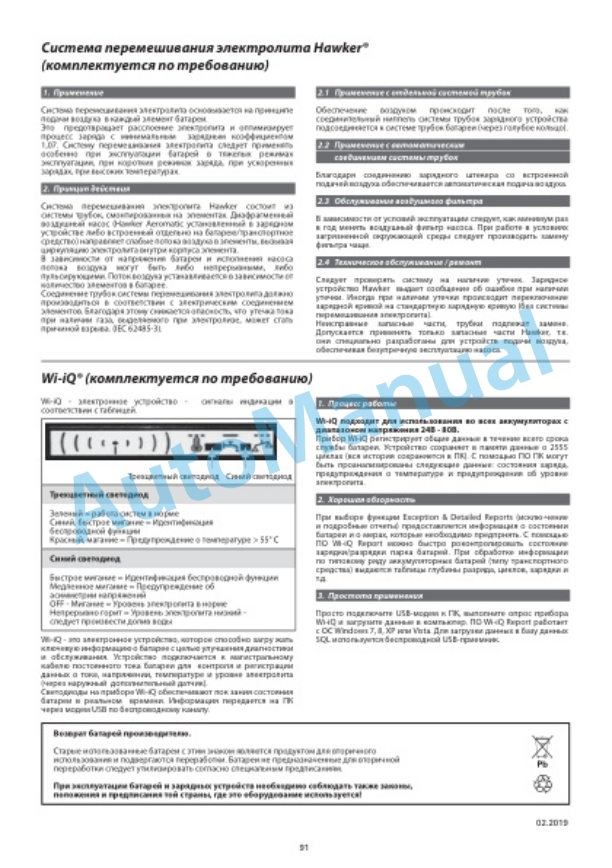

- 4. Leadacid battery charger 24V

- 5. Leadacid battery charger 24V . 48V

- 6. Leadacid battery charger 24V . 48V . 80V

Linde Operator Manual PDF

Linde 1111-01 – N20VI, N20VLI Operating Instructions SN 10.09 and up SN up to W41111V00299

Linde Operator Manual PDF

Linde 1120-01 – R-matic, R10, R12, R14, R16, R20, R25 Operating Instructions SN 10.12 and up

Linde Operator Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

Linde Operator Manual PDF

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions

Linde Operator Manual PDF

Linde 1123-01 – R14SP, R16SP, R18SP Operating Instructions SN 12.09 and up

Linde Operator Manual PDF

Linde 1115-01 – N16Li to N25SA Operating Instructions SN W41115V00001 and up

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF