- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 1152-01 – T16 EX, T20 EX Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 31.6MB

- Number of Pages: 290

Category: Linde Operator Manual PDF

-

Model List:

- T16 EX

- T20 EX

- 1. Leadacid battery charger 24V

- 2. Leadacid battery charger 24V . 48V

- 3. Leadacid battery charger 24V . 48V . 80V

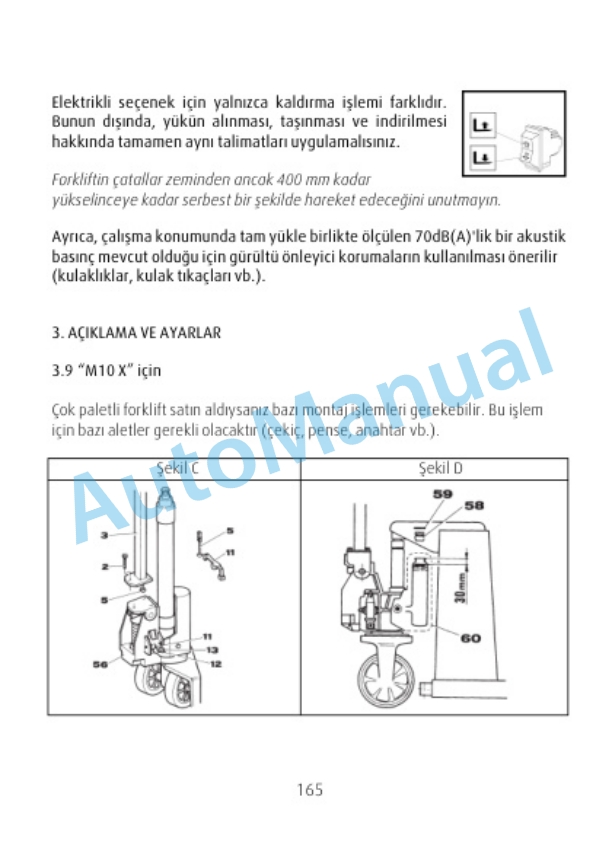

- 4. Pallet truckT16 , T20 EX2G

- 4.1. Table of content

- 4.2. Introduction

- 4.2.1. Your industrial truck

- 4.2.2. CE labelling

- 4.2.3. Legal requirements for marketing

- 4.2.4. Nameplate

- 4.2.5. Intended use

- 4.2.6. Description of use and climatic conditions

- 4.2.7. Impermissible use

- 4.2.8. Symbols used

- 4.2.9. Basic information on explosion protection

- 4.2.10. Receiving the industrial truck

- 4.2.11. Disposing of components and batteries

- 4.3. Safety

- 4.3.1. Safety regulations

- 4.3.2. Protection suit for explosion protection

- 4.3.3. Handling consumables

- 4.3.4. Noise emission values

- 4.3.5. Residual risks

- 4.3.6. Stability

- 4.3.7. Qualified person

- 4.3.8. Periodic safety inspection

- 4.4. Overview

- 4.4.1. Truck overview

- 4.4.2. Operating devices

- 4.4.3. Battery charge indicator

- 4.4.4. Explosion protection adhesive label

- 4.5. Operation

- 4.5.1. Technical description

- 4.5.1.1. Technical description

- 4.5.1.2. Drive

- 4.5.1.3. Steering

- 4.5.1.4. Hydraulic system

- 4.5.1.5. Operation

- 4.5.1.6. Brake system

- 4.5.1.7. Load lift system

- 4.5.1.8. Chassis frame

- 4.5.1.9. Electrical system

- 4.5.1.10. Insulation monitoring

- 4.5.1.11. Insulation monitoring warning

- 4.5.1.12. Insulation monitoring fault

- 4.5.1.13. Temperature monitoring warning

- 4.5.2. Service plan before initial commissioning

- 4.5.3. Instructions for runningin

- 4.5.4. Preshift checks

- 4.5.4.1. Overview

- 4.5.4.2. Check braking

- 4.5.4.3. Checking safety devices

- 4.5.5. Switching the warehouse truck on and off

- 4.5.6. Driving

- 4.5.7. Forwards travel

- 4.5.8. Reverse travel

- 4.5.9. Changing the drive direction

- 4.5.10. Creep Speed function

- 4.5.11. Proportional Speed function

- 4.5.12. Steering

- 4.5.13. Decelerating when cornering

- 4.5.14. Belly switch

- 4.5.15. Brake system

- 4.5.16. Horn

- 4.5.17. Emergency off switch

- 4.5.18. Working with a load

- 4.5.18.1. Taking up load

- 4.5.18.2. Driving with a load

- 4.5.18.3. Setting down a load

- 4.5.19. Before leaving the truck

- 4.5.20. Loading.transporting

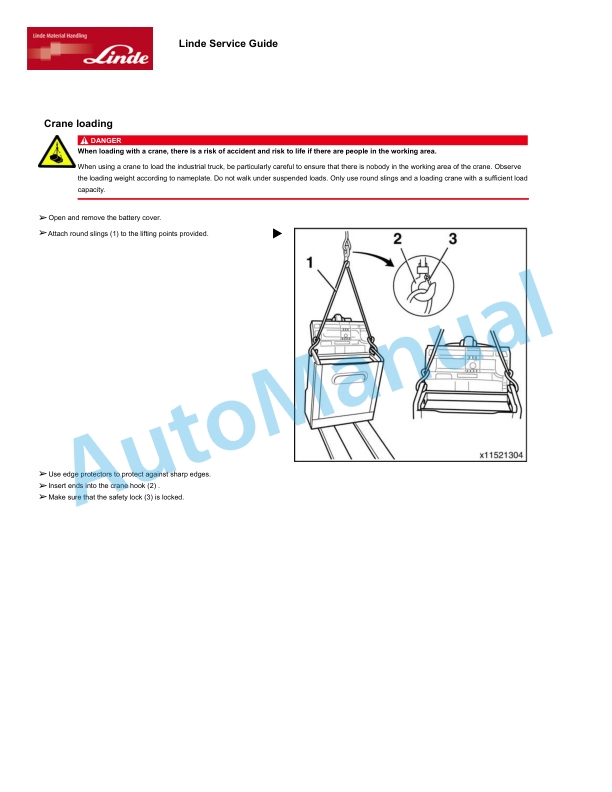

- 4.5.20.1. Crane loading

- 4.5.20.2. Transport

- 4.6. Maintenance

- 4.6.1. Safety information regarding servicing work

- 4.6.2. Inspection and maintenance data

- 4.6.3. Recommendations for consumables

- 4.6.4. Access to the technical compartment

- 4.6.5. Inspection and maintenance overview

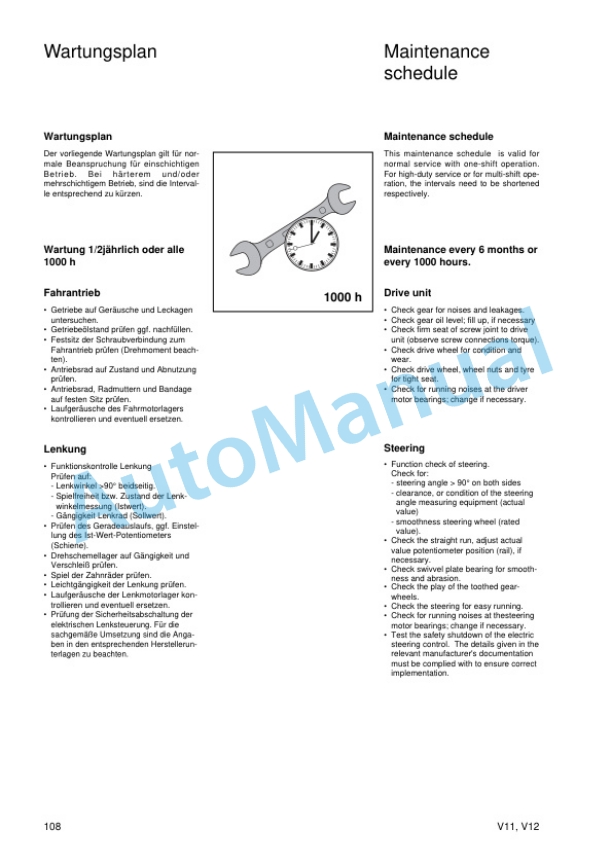

- 4.6.5.1. Maintenance plan

- 4.6.5.2. Additional service plan for explosion protection

- 4.6.6. Preparations

- 4.6.6.1. Cleaning the industrial truck

- 4.6.6.2. Reading out the error memory

- 4.6.7. Gearbox

- 4.6.7.1. Wheel gear

- 4.6.8. Chassis, bodywork and fittings

- 4.6.8.1. Cleaning the industrial truck

- 4.6.8.2. Cleaning the battery and the battery compartment

- 4.6.8.3. Regular maintenance of the transmission gear

- 4.6.8.4. Checking the flame proof enclosure

- 4.6.8.5. Checking and lubricating the bearing points and joints

- 4.6.9. Chassis frame

- 4.6.9.1. Tightening the wheel fastenings

- 4.6.9.2. Checking the wheels for wear and damage

- 4.6.9.3. Checking the stabilisers (reinforced stabilisers option)

- 4.6.9.4. Checking the brake system

- 4.6.10. Controls

- 4.6.10.1. Checking the horn for correct function

- 4.6.11. Electrics.electronics

- 4.6.11.1. Checking the battery charge status

- 4.6.11.2. Checking the electrolyte level and topping up with water

- 4.6.11.3. Connecting the battery to an external battery charger

- 4.6.11.4. Battery replacement

- 4.6.11.5. Checking the electric cables, cable connectors, cable connections and screw joints

- 4.6.12. Hydraulics

- 4.6.12.1. Servicing the hydraulic system

- 4.6.13. Load lift system

- 4.6.13.1. Checking the antispark protection on the fork arms for wear

- 4.6.14. Troubleshooting

- 4.6.14.1. Malfunctions during operation

- 4.6.14.2. Diagnostic connector

- 4.6.14.3. Fuses

- 4.7. Storage and disposal

- 4.7.1. Decommissioning the industrial truck

- 4.7.2. Disposal of old trucks

- 4.8. Technical data

- 4.8.1. Type sheet T16 EX

- 4.8.2. Type sheet T20 EX

- 5. Pallet truckT16 T20 EX 3G

- 5.1. Table of content

- 5.2. Introduction

- 5.2.1. Your industrial truck

- 5.2.2. Intended use

- 5.2.3. Impermissible use

- 5.2.4. Basic information on explosion protection

- 5.2.5. Description of use and climatic conditions

- 5.2.6. Symbols used

- 5.2.7. Technical description

- 5.2.8. Drive

- 5.2.9. Steering

- 5.2.10. Hydraulic system

- 5.2.11. Operation

- 5.2.12. Brake system

- 5.2.13. Load lift system

- 5.2.14. Chassis frame

- 5.2.15. Electrical system

- 5.2.16. Receiving the industrial truck

- 5.2.17. Legal requirements for placing on the market

- 5.3. Safety

- 5.3.1. Safety regulations

- 5.3.2. Residual risks

- 5.3.3. Stability

- 5.3.4. Handling consumables

- 5.3.5. Competent person

- 5.3.6. Periodic safety inspection

- 5.4. Overview

- 5.4.1. Adhesive labels

- 5.4.2. Nameplate

- 5.4.3. Truck overview

- 5.4.4. Operating devices

- 5.4.5. Tiller head

- 5.4.6. Battery charge indicator

- 5.4.7. Digicode option (LFM Go)

- 5.4.8. LFM AccessLFM Basic option

- 5.5. Operation

- 5.5.1. Service plan before initial commissioning

- 5.5.2. Instructions for runningin

- 5.5.3. Preshift checks

- 5.5.4. Switching the industrial truck on and off

- 5.5.5. Driving

- 5.5.6. Forwards travel

- 5.5.7. Reverse travel

- 5.5.8. Changing the drive direction

- 5.5.9. Creep speed

- 5.5.10. Proportional Speed function

- 5.5.11. Steering

- 5.5.12. Belly switch

- 5.5.13. Brake system

- 5.5.14. Horn

- 5.5.15. Emergency off switch

- 5.5.16. Working with a load

- 5.5.16.1. Taking up load

- 5.5.16.2. Driving with load

- 5.5.16.3. Using the industrial truck on a gradient

- 5.5.17. Loading.transporting

- 5.5.17.1. Crane loading

- 5.5.17.2. Transport

- 5.6. Servicing

- 5.6.1. General information

- 5.6.2. Inspection and maintenance data

- 5.6.3. Recommendations for consumables

- 5.6.4. Inspection and maintenance overview

- 5.6.4.1. Maintenance plan

- 5.6.4.2. Additional service plan for explosion protection

- 5.6.5. Preparatory tasks

- 5.6.5.1. Cleaning the industrial truck

- 5.6.5.2. Reading out the error memory

- 5.6.6. Gearbox

- 5.6.6.1. Wheel gear

- 5.6.7. Chassis, bodywork and fittings

- 5.6.7.1. Checking and lubricating the bearing points and joints

- 5.6.7.2. Other cleaning and greasing

- 5.6.8. Chassis frame

- 5.6.8.1. Tightening the wheel fastenings

- 5.6.8.2. Checking wheels for wear and damage

- 5.6.8.3. Adjusting the support rollers

- 5.6.8.4. Checking the brake system

- 5.6.9. Operating devices

- 5.6.9.1. Checking the horn for correct function

- 5.6.10. Electrical enclosure

- 5.6.10.1. Checking the battery charge status

- 5.6.10.2. Charging the battery

- 5.6.10.3. Replacing the battery

- 5.6.10.4. Checking the condition and secure attachment of the electric cables, cable connectors, cable connections andexplosionproof screw joints

- 5.6.11. Hydraulics

- 5.6.11.1. Servicing the hydraulic system

- 5.6.12. Load lift system

- 5.6.12.1. Checking the antispark protection on the fork arms and push rods for wear

- 5.6.13. Troubleshooting

- 5.6.13.1. Checking the Proplan safety unit (PSU)

- 5.6.13.2. Fuses

- 5.6.13.3. Diagnostic connector

- 5.6.13.4. Shutting down

- 5.6.13.5. Disposal of old trucks

- 5.7. Technical data

- 5.7.1. Type sheet T16 EX

- 5.7.2. Type sheet T20 EX

- 5.7.3. Noise emission values

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1123-01 – R14SP, R16SP, R18SP Operating Instructions SN 12.09 and up

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

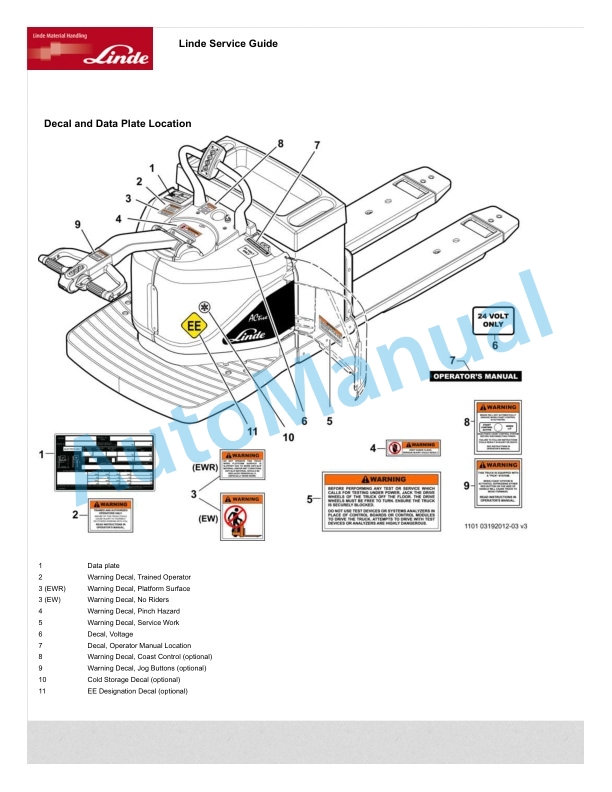

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20VI, N20VLI Operating Instructions SN 10.09 and up SN up to W41111V00299

$20.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF