- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

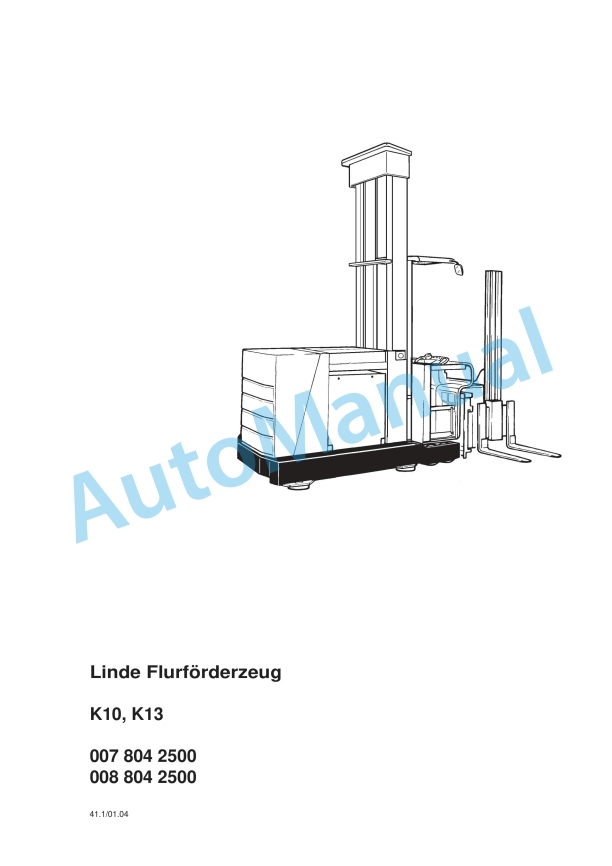

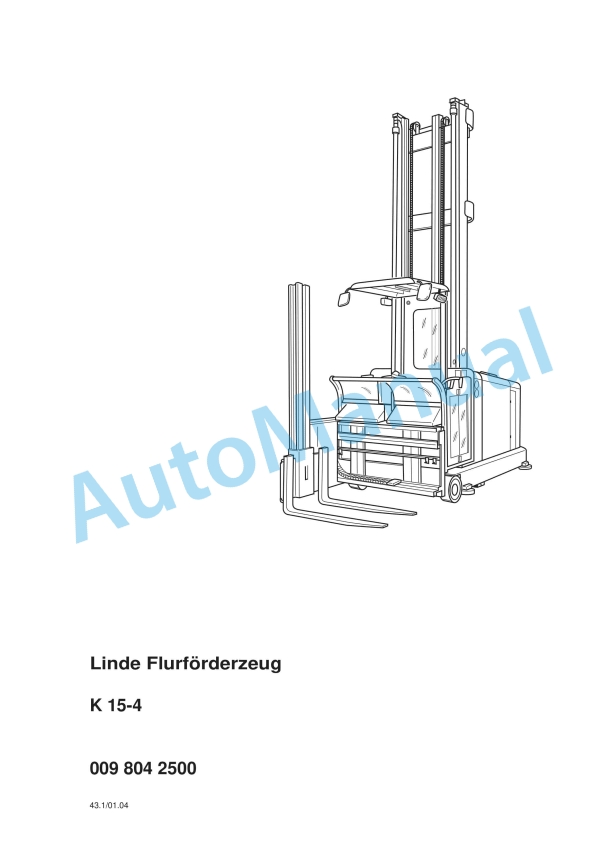

Linde 1158-06 – T20AP-06, T30-06, T30AP-06 Production site Xiamen Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 27.9MB

- Number of Pages: 167

Category: Linde Operator Manual PDF

-

Model List:

- T20AP-06

- T30-06

- T30AP-06 Production site Xiamen

- 1. Electric Pallet Forklift TruckT20AP06, T30AP06, T3006

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Introduction

- 1.2.2. General information

- 1.2.3. Conformity marking

- 1.2.4. Declaration that reflects the content of the declaration of conformity

- 1.2.5. Nameplate

- 1.2.6. Intended use

- 1.2.7. Additional information

- 1.2.8. Special use of equipment

- 1.2.9. Hazard assessment

- 1.2.10. Improper use

- 1.2.11. Improper use

- 1.2.12. Symbols used

- 1.2.13. Disposing of components and batteries

- 1.2.14. Description of use and climatic conditions

- 1.2.15. Technical description

- 1.3. Safety

- 1.3.1. Residual risks

- 1.3.2. Stability

- 1.3.3. Noise level

- 1.3.4. Vibration of arms

- 1.3.5. EMC Electromagnetic compatibility

- 1.3.6. Operating company

- 1.3.7. Drivers

- 1.3.8. Competent person

- 1.3.9. Regulations

- 1.3.10. Handling consumables

- 1.4. Overview

- 1.4.1. General view, T20AP.T30AP

- 1.4.2. General view T30

- 1.4.3. Collective drawing of labels T20AP.T30AP

- 1.4.4. Summary diagram of labels (T30)

- 1.4.5. Display unit T20AP.T30AP

- 1.4.6. Display T20SP.T30

- 1.4.6.1. Display unit

- 1.4.6.2. Display unit settings

- 1.4.7. Controls T20AP.T30AP

- 1.4.8. Controls T30

- 1.5. Operations

- 1.5.1. Checks before first commissioning

- 1.5.2. Daily inspection items

- 1.5.3. Operating instructions

- 1.5.4. Instructions for runningin

- 1.5.5. Daily checks before starting work

- 1.5.5.1. Checking the drive direction controls

- 1.5.5.2. Checking the lifting.lowering controls

- 1.5.5.3. Checking the electric steering

- 1.5.5.4. Checking the brakes for T20AP.T30AP trucks

- 1.5.5.5. Checking the brakes T30

- 1.5.5.6. Checking the emergency off switch and horn

- 1.5.5.7. Check the safety device T20AP.T30AP

- 1.5.5.8. Checking the safety devices T30

- 1.5.5.9. Checking the battery locking system (optional)

- 1.5.6. Driving T20AP.T30AP trucks

- 1.5.6.1. Setting the drive direction

- 1.5.6.2. Starting

- 1.5.6.3. Forward travel.reverse travel

- 1.5.6.4. Steering system

- 1.5.6.5. Changing the drive direction

- 1.5.6.6. Safety reverser

- 1.5.6.7. Emergency off switch

- 1.5.6.8. Driving in pedestrian mode

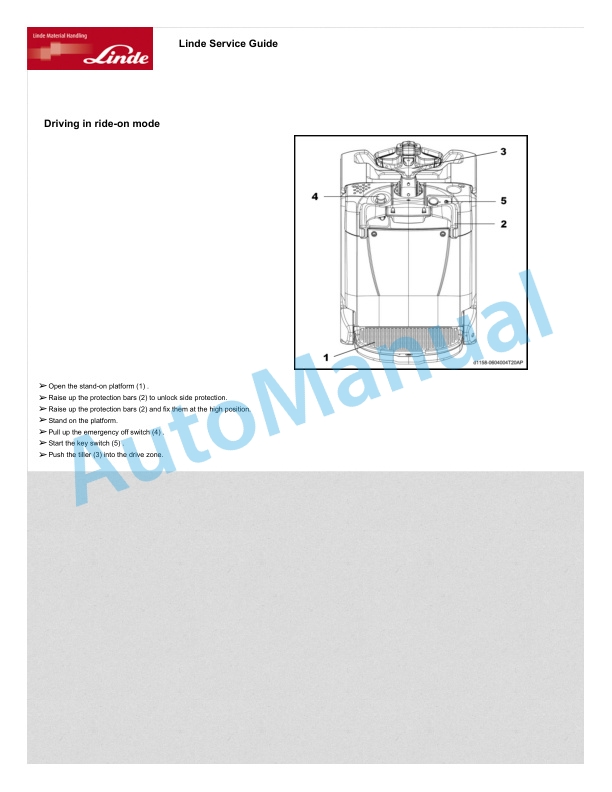

- 1.5.6.9. Driving in rideon mode

- 1.5.6.10. Horn

- 1.5.6.11. Using the truck on ramps

- 1.5.7. Driving T30 trucks

- 1.5.7.1. Setting the drive direction

- 1.5.7.2. Starting

- 1.5.7.3. Forward travel.reverse travel

- 1.5.7.4. Steering system

- 1.5.7.5. Changing the drive direction

- 1.5.7.6. Safety reverser

- 1.5.7.7. Emergency off switch

- 1.5.7.8. Horn

- 1.5.7.9. Using the truck on ramps

- 1.5.8. Creep Speed function

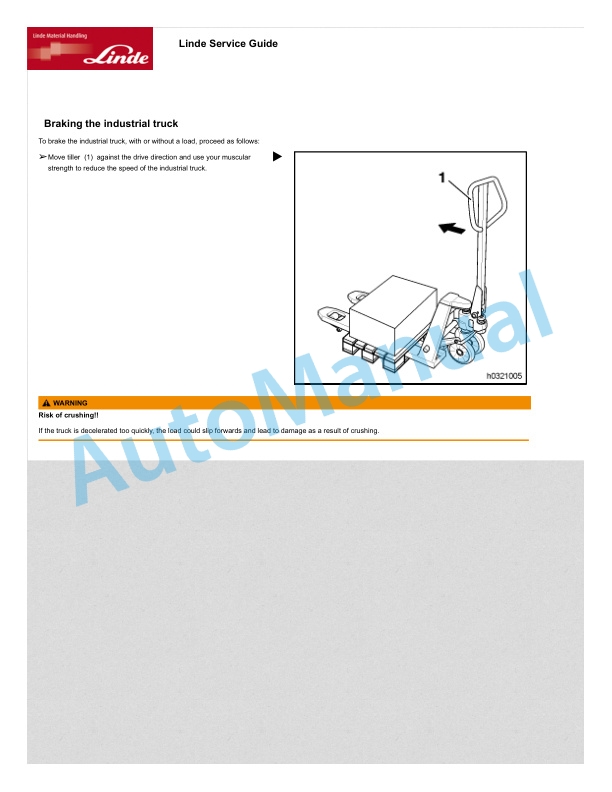

- 1.5.9. Braking

- 1.5.10. Lift and lower the forks

- 1.5.11. Working with loads

- 1.5.12. Cold store usage (option)

- 1.5.13. Towing and transporting the truck

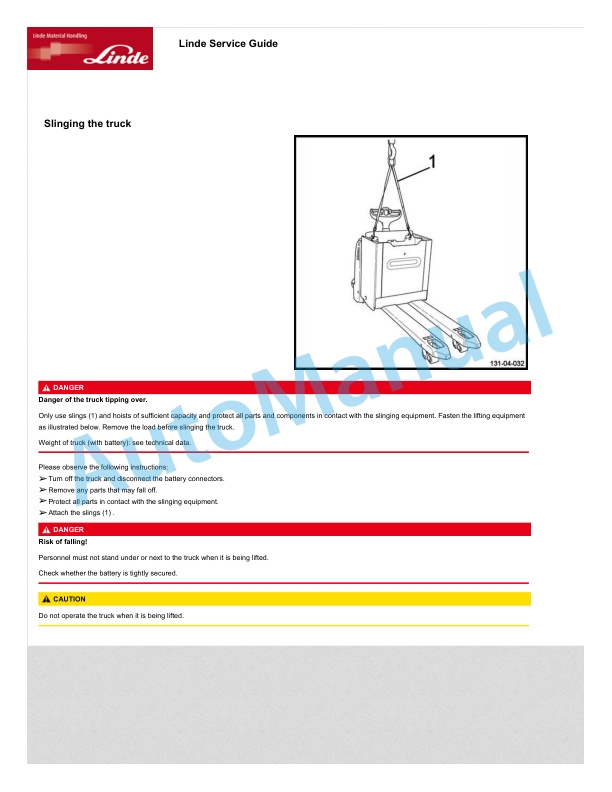

- 1.5.14. Slinging the truck

- 1.5.15. Jacking the forklift truck

- 1.5.16. Battery

- 1.5.16.1. Checking the battery charge status

- 1.5.16.2. Opening the battery cover

- 1.5.16.3. Plugging.unplugging the battery connector

- 1.5.16.4. Recharging the battery with an external battery charger

- 1.5.16.5. Vertical battery replacement

- 1.5.16.6. Side access battery unlocking.locking the battery

- 1.5.16.7. Changing the battery sidewaysusing a roller frame

- 1.5.16.8. Changing the battery sidewayschanging using a trolley

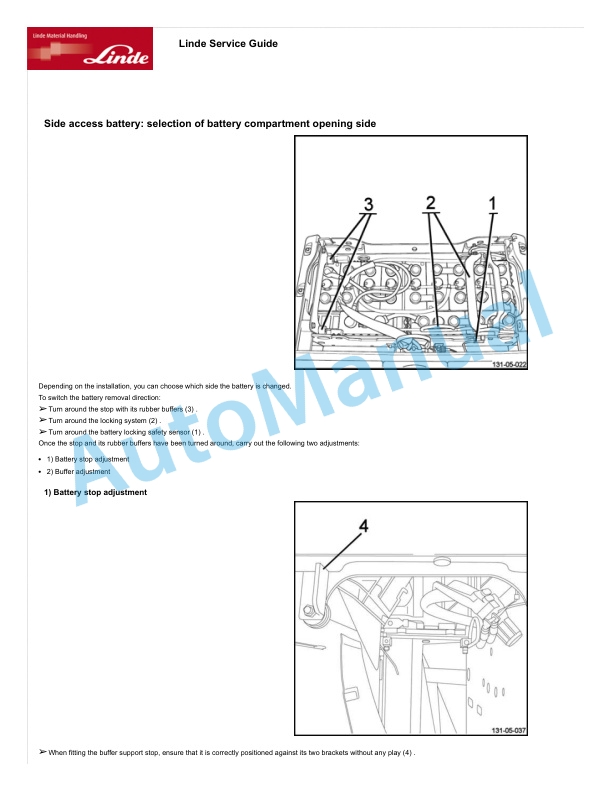

- 1.5.16.9. Side access battery selection of battery compartment opening side

- 1.5.17. Before exiting the truck

- 1.5.18. Storing the truck

- 1.5.18.1. Storing a truck equipped with a Gel or Lead battery

- 1.5.19. Disposal of old trucks

- 1.6. Maintenance

- 1.6.1. Safety information for inspection and maintenance work

- 1.6.2. Inspection and maintenance data

- 1.6.3. Recommended lubricants

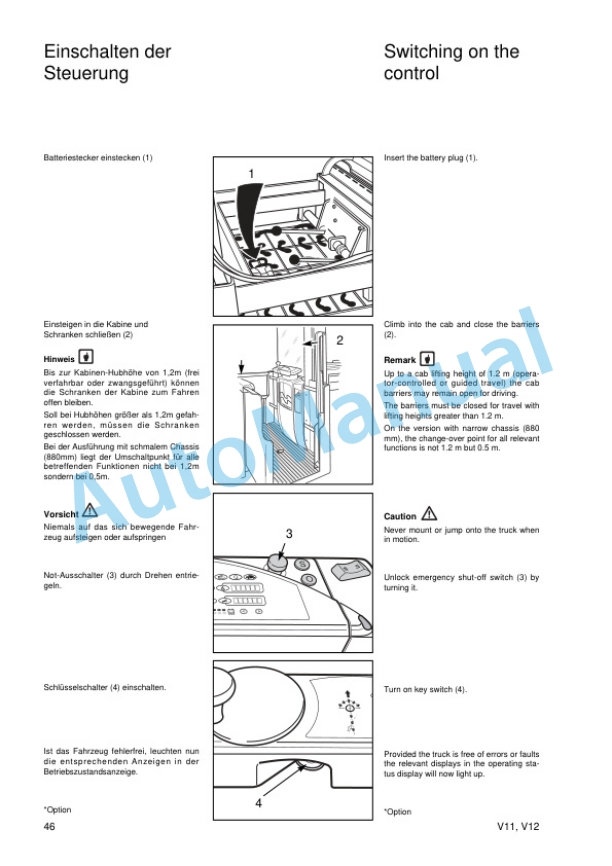

- 1.6.4. Regular maintenance

- 1.6.5. Service plan

- 1.6.6. Chassis and bodywork

- 1.6.6.1. Cleaning the truck

- 1.6.6.2. Cleaning the battery and its compartment

- 1.6.6.3. Opening the front hood (T20AP.T30AP)

- 1.6.6.4. Opening the front hood T30

- 1.6.7. Drive mechanism and transmission system

- 1.6.7.1. Cleaning the traction motor cooling fins

- 1.6.7.2. Checking the condition of the wheels

- 1.6.7.3. Check the wheel fastenings

- 1.6.8. Electrical system

- 1.6.8.1. Cleaning the electrical plate and checking the connections

- 1.6.8.2. Inspecting the control module and checking the wiring

- 1.6.8.3. Checking and cleaning the fans

- 1.6.8.4. Checking fuses

- 1.6.8.5. Checking the condition of cables, and the electrical wiring

- 1.6.8.6. Battery maintenance

- 1.6.8.7. Checking the condition of cables, terminals and battery connector

- 1.6.9. Hydraulic system

- 1.6.9.1. Checking the hydraulic oil level

- 1.6.9.2. Changing the hydraulic oil

- 1.6.9.3. Checking the hydraulic system for leakage

- 1.6.10. Lifting system

- 1.6.10.1. Checking the hinge pins and rings for wear

- 1.6.10.2. Checking the tightness of the axial nuts on the chassis.connecting rods

- 1.6.10.3. Slotted lubrication rings and fittings (grease version)

- 1.7. Technical data

- 1.7.1. Datasheet T20AP.T30AP

- 1.7.2. Datasheet T30

- 1.7.3. Ecodesign requirements for electric motors and variable speed drives

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 1120-01 – R-matic, R10, R12, R14, R16, R20, R25 Operating Instructions SN 10.12 and up

$20.00

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

$20.00

Linde Operator Manual PDF

Linde 1123-01 – R14SP, R16SP, R18SP Operating Instructions SN 12.09 and up

$20.00

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions

$20.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF