- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

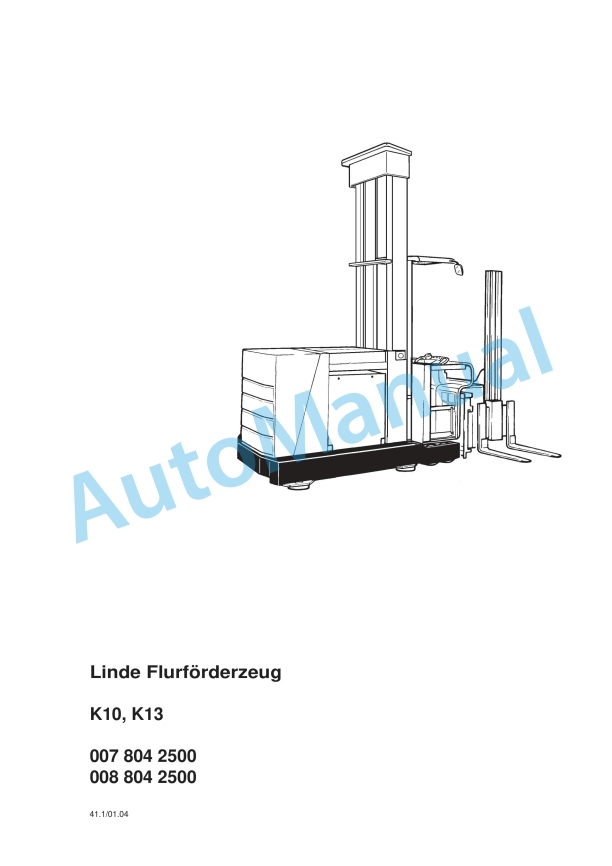

Linde 1164-01 – D12R Operating Instructions SN W41164H00006 and up SN up to W41164V00125

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN W41164H00006 and up SN up to W41164V00125

- Format: PDF

- Size: 83.3MB

- Number of Pages: 1075

- Serial Number:

SN W41164H00006 and up SN up to W41164V00125

Category: Linde Operator Manual PDF

-

Model List:

- D12R

- 1. Double pallet stackerD12R

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Your truck

- 1.2.2. Conformity marking

- 1.2.3. Declaration that reflects the content of the declaration of conformity

- 1.2.4. Identification label

- 1.2.5. Correct use

- 1.2.6. Description of use and climatic conditions

- 1.2.7. Impermissible use

- 1.2.8. Symbols used

- 1.2.9. Taking delivery of the industrial truck

- 1.2.10. Rules for the operating company of industrial trucks

- 1.2.11. Disposing of gel and lead batteries

- 1.3. Safety

- 1.3.1. Safety regulations

- 1.3.2. Handling consumables

- 1.3.3. Emissions

- 1.3.3.1. Noise emission values

- 1.3.3.2. Vibration values for upper limbs

- 1.3.4. Residual risks

- 1.3.5. Stability

- 1.3.6. Competent person

- 1.3.7. Periodic general checks on the trucks

- 1.4. General views

- 1.4.1. General view

- 1.4.2. General view of the technical compartment

- 1.4.3. Controls

- 1.4.4. Display

- 1.4.5. Electronic key (option)

- 1.4.6. Labels

- 1.5.1. Technical description

- 1.5.2. Checks before first commissioning

- 1.5.3. Preshift checks

- 1.5.4. Daily checks before starting work

- 1.5.4.1. Checking the function of the controls

- 1.5.4.2. Checking the safety devices

- 1.5.5. Truck operating instructions

- 1.5.6. Stepping on.off the truck

- 1.5.7. Operation of operator presence detection

- 1.5.8. Drivers compartment settings

- 1.5.8.1. Adjusting the seat

- 1.5.8.2. Adjusting the floor

- 1.5.8.3. Seat heater option

- 1.5.9. Display

- 1.5.9.1. Selection buttons

- 1.5.9.2. Display of the drive wheel position

- 1.5.9.3. Using the display unit

- 1.5.10. Driving regulations

- 1.5.11. Driving

- 1.5.11.1. Determining the drive direction

- 1.5.11.2. Starting up

- 1.5.11.3. Forward travel.reverse travel

- 1.5.11.4. Steering

- 1.5.11.5. Reversing the direction of travel

- 1.5.11.6. Emergency off switch

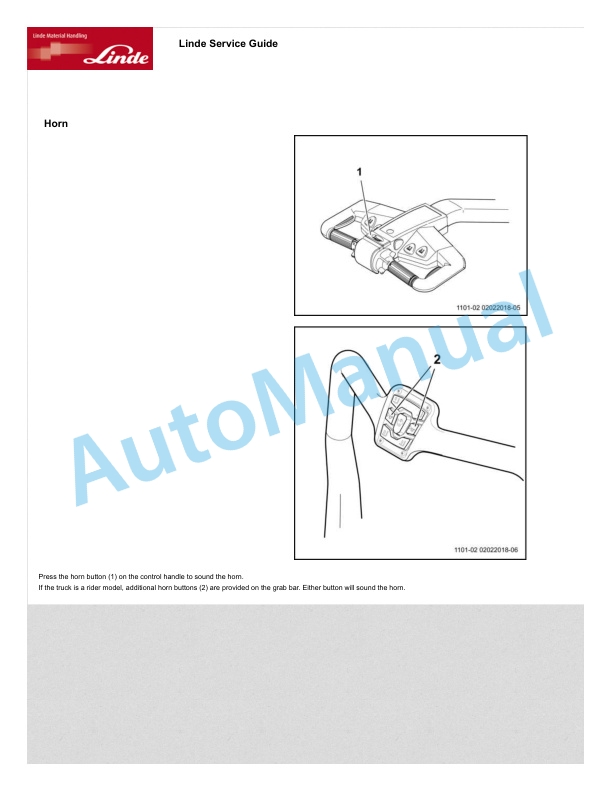

- 1.5.11.7. Horn

- 1.5.11.8. Adjusting the control unit

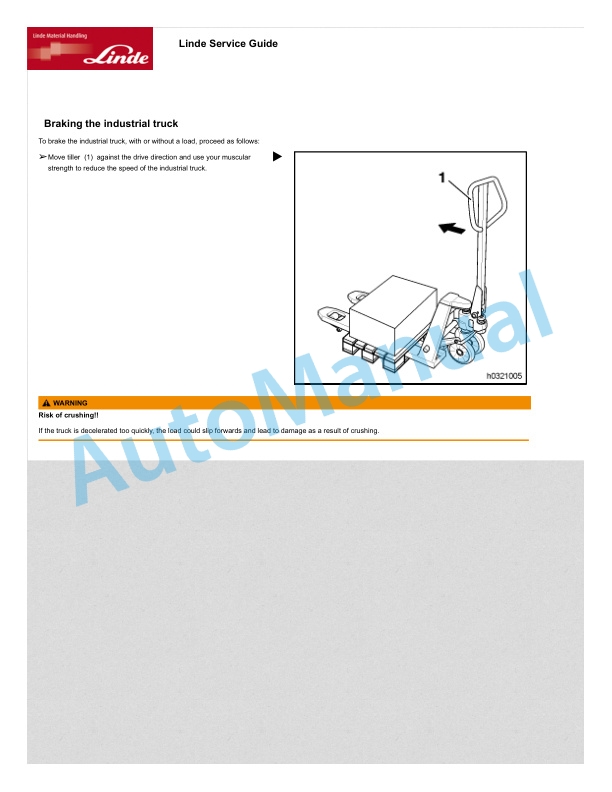

- 1.5.11.9. Braking

- 1.5.11.10. Drivers overhead guard

- 1.5.11.11. ECO mode

- 1.5.11.12. Using the truck on a slope

- 1.5.12. connect access system (LFM)

- 1.5.13. Transporting loads

- 1.5.13.1. Reading the capacity plate

- 1.5.13.2. Progressive stopping of the carriage in the lower position

- 1.5.13.3. Using the mast

- 1.5.13.4. Handling a single load

- 1.5.13.5. Handling two stacked pallets

- 1.5.14. Driving assistance system Speed Management

- 1.5.14.1. Description of Speed Management

- 1.5.15. Cold store usage (optional)

- 1.5.16. Before leaving the truck

- 1.5.17. Gel and lead battery

- 1.5.17.1. General information on batteries

- 1.5.17.2. Charging the battery

- 1.5.17.3. Opening and closing the battery hood

- 1.5.17.4. Disconnecting.connecting the battery connector

- 1.5.17.5. Charging the battery using an external charger

- 1.5.17.6. General information on changing batteries

- 1.5.17.7. Changing the side access battery

- 1.5.18. Handling the truck in an emergency

- 1.5.18.1. Emergency lowering of the mast

- 1.5.18.2. Towing the truck

- 1.5.19. Handling the truck in specific situations

- 1.5.19.1. Slinging the truck

- 1.5.19.2. Lifting the truck

- 1.6. Maintenance

- 1.6.1. General information

- 1.6.2. Technical data for inspection and maintenance

- 1.6.3. Recommended lubricants

- 1.6.4. Accessing the technical compartment

- 1.6.5. Regular maintenance

- 1.6.6. Maintenance plan

- 1.6.7. Chassis, bodywork and fittings

- 1.6.7.1. Cleaning the truck

- 1.6.7.2. Cleaning the battery and the battery compartment

- 1.6.8. Steering and wheels

- 1.6.8.1. Checking the condition of the wheels

- 1.6.9. Electrical equipment

- 1.6.9.1. Cleaning and blowing out the electrical components

- 1.6.9.2. Checking the electrolyte level and topping up with water

- 1.6.9.3. Checking the condition of cables, terminals and the battery connector

- 1.6.10. Hydraulic systems

- 1.6.10.1. Checking the hydraulic system for leaks

- 1.6.10.2. Checking the hydraulic oil level

- 1.6.11. Lift mast

- 1.6.11.1. Cleaning and lubricating the chains

- 1.6.11.2. Adjusting the length of the mast chains

- 1.6.11.3. Checking the protective screen

- 1.6.12. Storage and disposal

- 1.6.12.1. Storage of truck

- 1.6.12.2. Disposal of old trucks

- 1.7. Datasheet

- 1.7.1. D12R datasheet

- 1.7.2. D12R mast types

- 1.7.3. Ecodesign requirements for electric motors and variable speed drives

- 2. EnerSys.Hawker Batteries

- 3. KF Charger

- 4. Leadacid battery charger 24V

- 5. Leadacid battery charger 24V . 48V

- 6. Leadacid battery charger 24V . 48V . 80V

- 7. LiIonCharger 18 kW

- 8. LiIonCharger 24V . 120A

- 9. Lithiumion batteriesT20R.R.S.SF.SR, T25R.R.S.SF.SRD12R.R.S.SFL14.16R.R

- 9.1. Table of content

- 9.2. Introduction

- 9.2.1. Introduction

- 9.2.2. Information on the conformity of lithiumion batteries

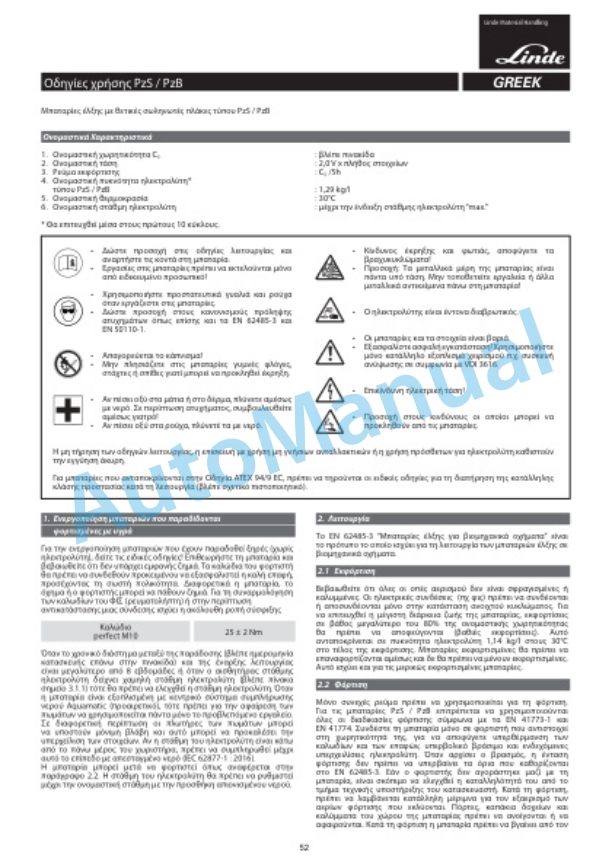

- 9.3. Safety

- 9.3.1. Special lithiumion safety rules

- 9.3.2. What to do in the event of incorrect use

- 9.3.3. Personal protective measures following an incident

- 9.3.4. What to do in the event of an accidental spillage

- 9.3.5. Transporting a lithiumion battery

- 9.3.6. Scrapping lithiumion batteries

- 9.4. General views

- 9.4.1. Lithiumion battery types

- 9.4.2. Labels on the top of lithiumion batteries

- 9.4.3. Labels on the sides of lithiumion batteries

- 9.5.1. Checking the charge status

- 9.5.2. Connecting.disconnecting the battery connector

- 9.5.3. Commissioning a truck equipped with a side access lithiumion battery

- 9.5.4. Automatic battery shutoff

- 9.5.5. Battery fitted with a compartment

- 9.5.6. Specific features of the display

- 9.5.7. Installing the external charger

- 9.5.8. Charging lithiumion batteries using an external charger

- 9.5.9. Using the side socket to charge the battery

- 9.5.10. Battery charging times

- 9.5.11. Side access lithiumion battery Changing the battery

- 9.5.12. Battery error codes

- 9.5.13. Lithiumion batteries Longterm storage

- 9.6. Maintenance

- 9.6.1. Maintenance plan for lithiumion batteries

- 9.6.2. Chassis, bodywork and fittings

- 9.6.2.1. Cleaning the lithiumion battery

- 9.6.3. Electrical equipment

- 9.6.3.1. Harnesses and cables

- 9.7. Technical specifications

- 9.7.1. Lithiumion battery weight precision

- 10. MIDAC Batteries

- 11. TAB Batteries

Rate this product

You may also like

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20VI, N20VLI Operating Instructions SN 10.09 and up SN up to W41111V00299

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

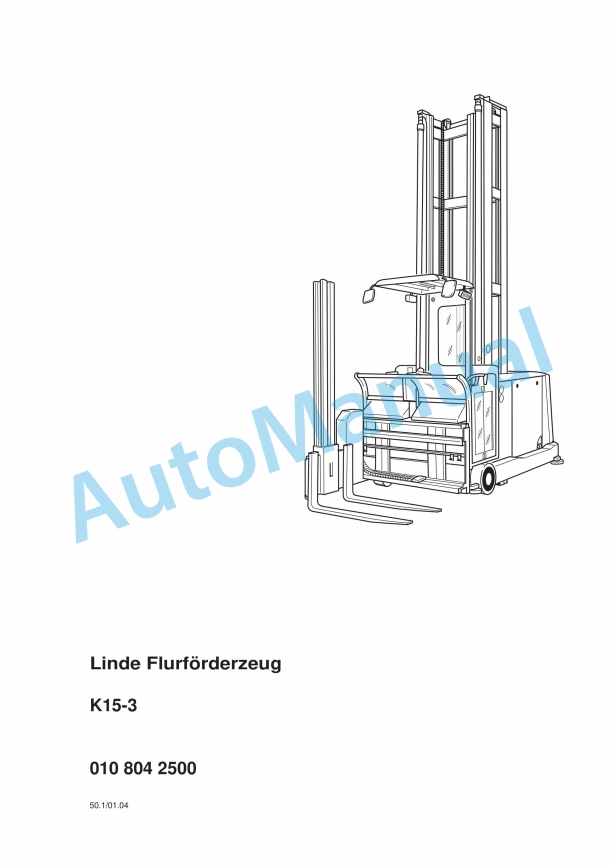

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

Linde Operator Manual PDF

$20.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF